Teaching the basics of model making, prototyping and Fabrication processes needs to start with a material that allows for free form sculpting, but at the same time be tougher than clay. That material for prototyping is Extruded Polystyrene AKA Blue Foam.

This material is very forgiving when it come to any type of modelling. Blue foam is easy to manipulate and so the students find it easy to shape and form this material to learn quick prototyping.

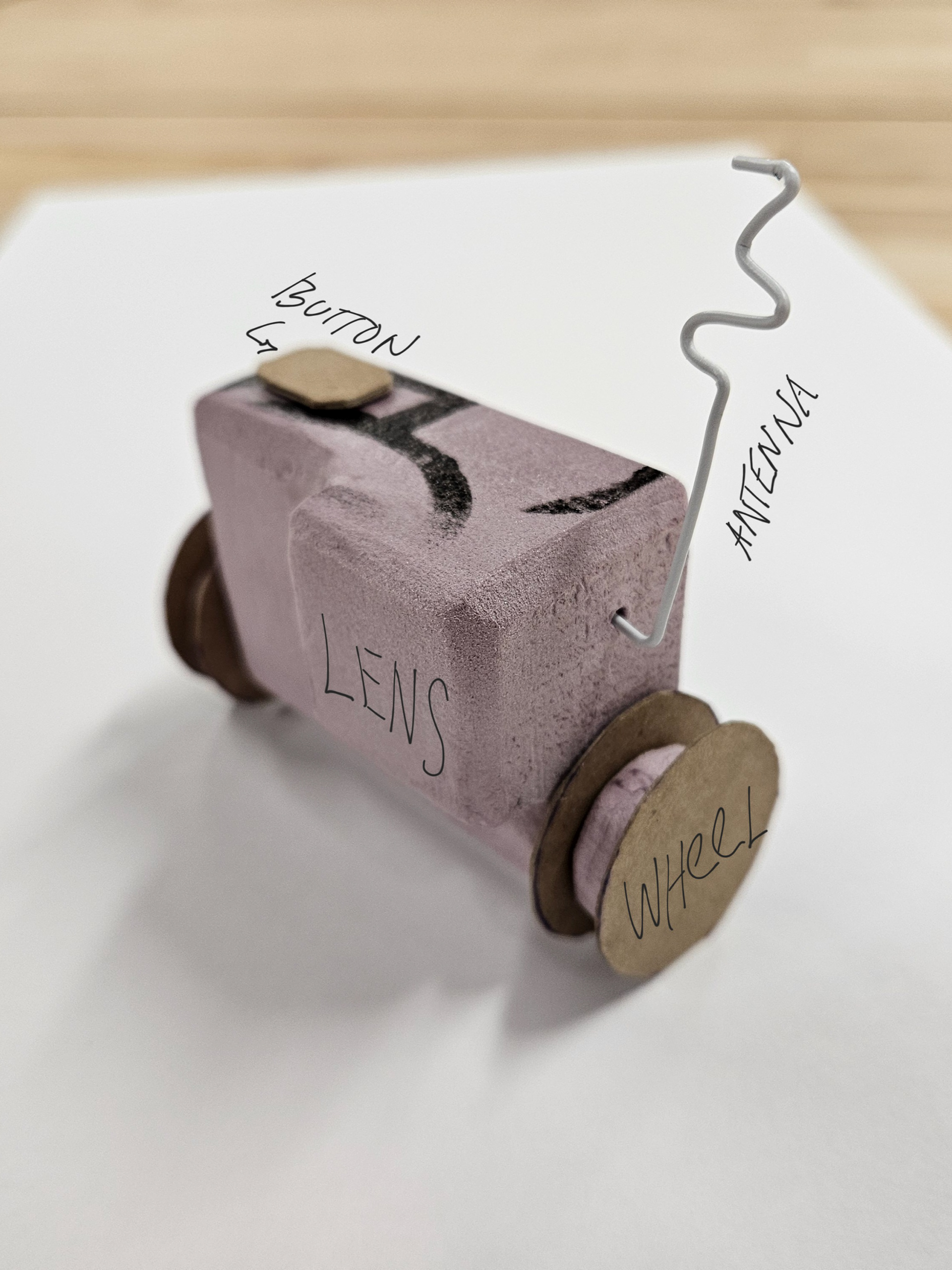

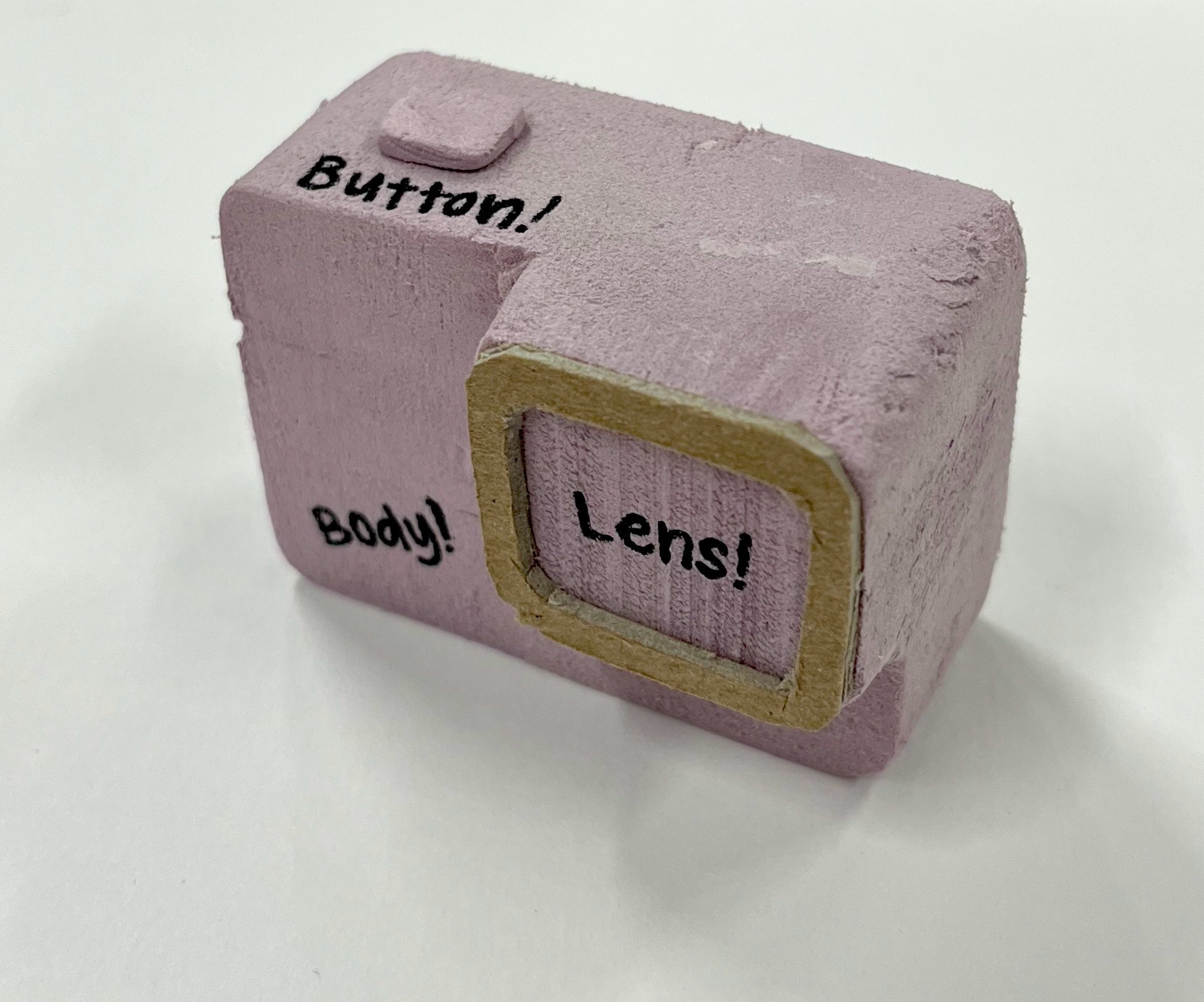

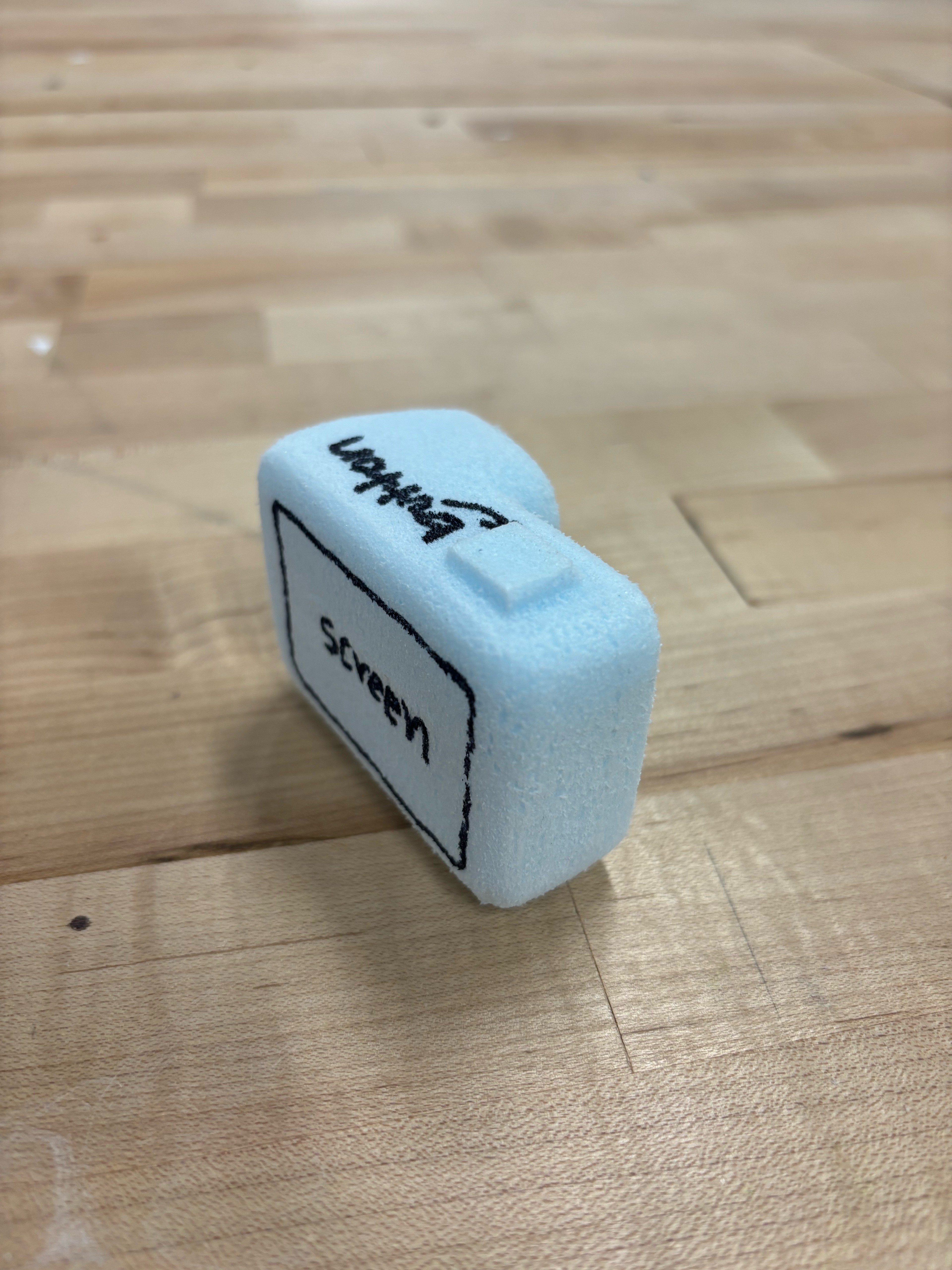

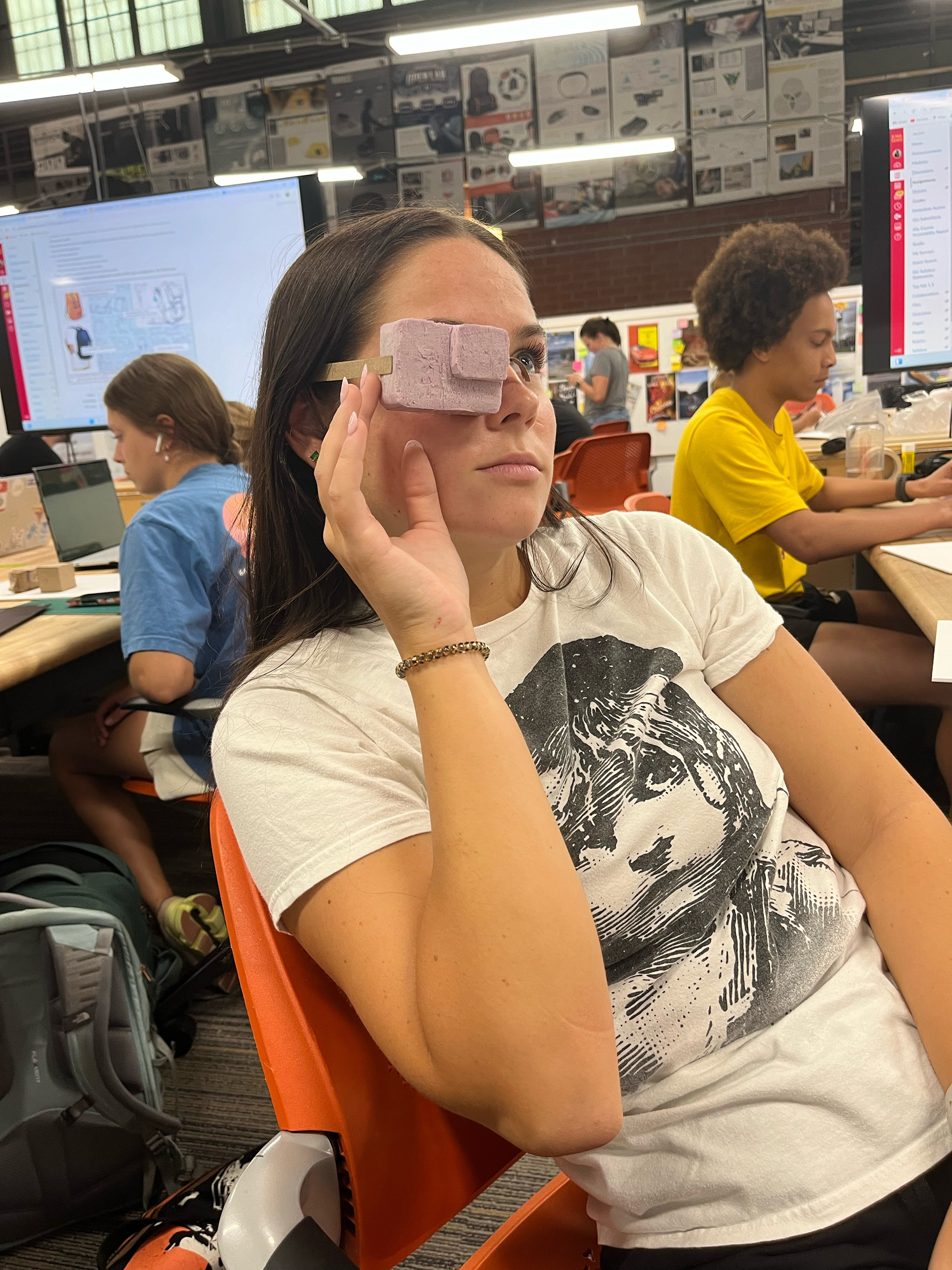

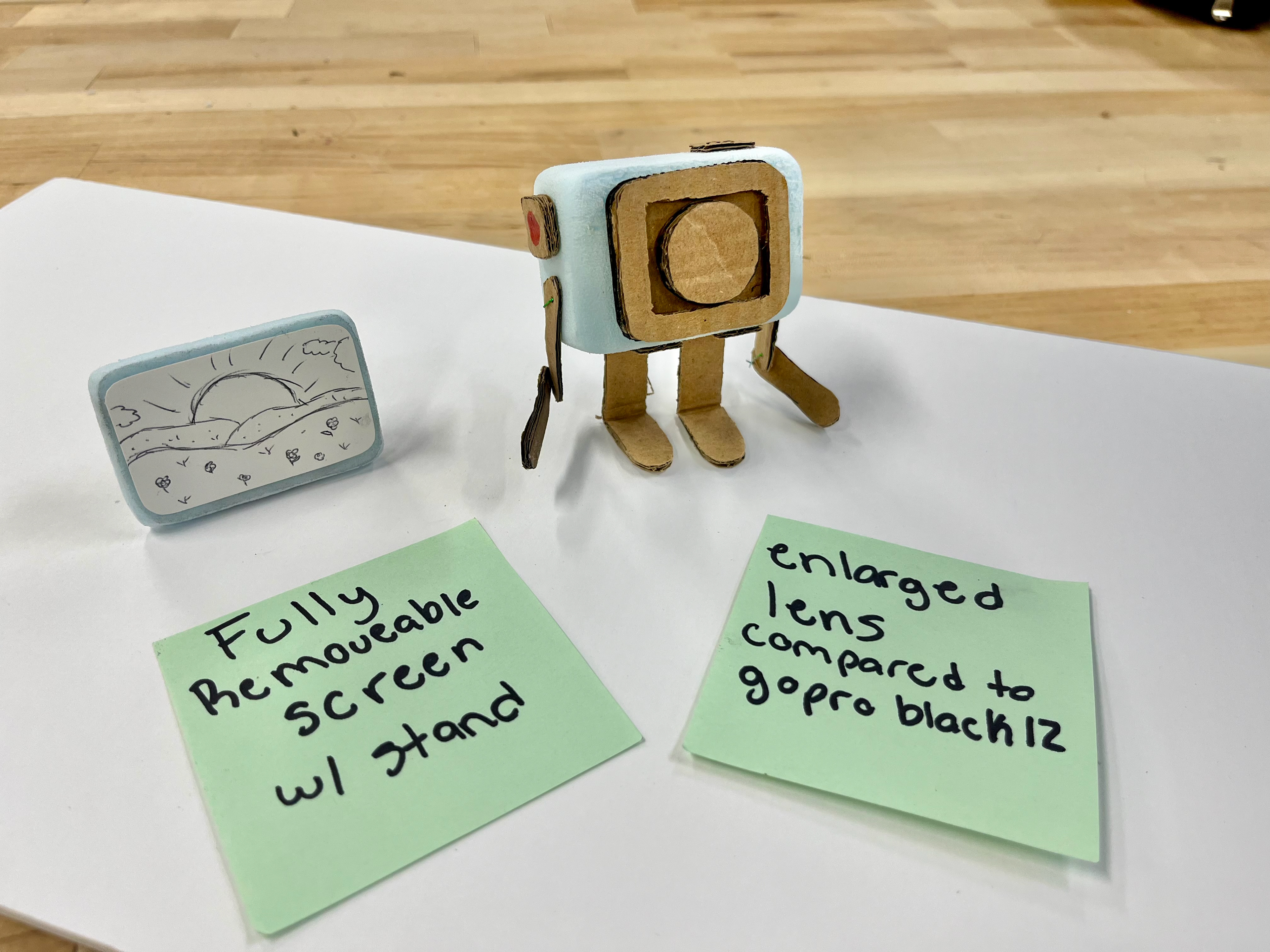

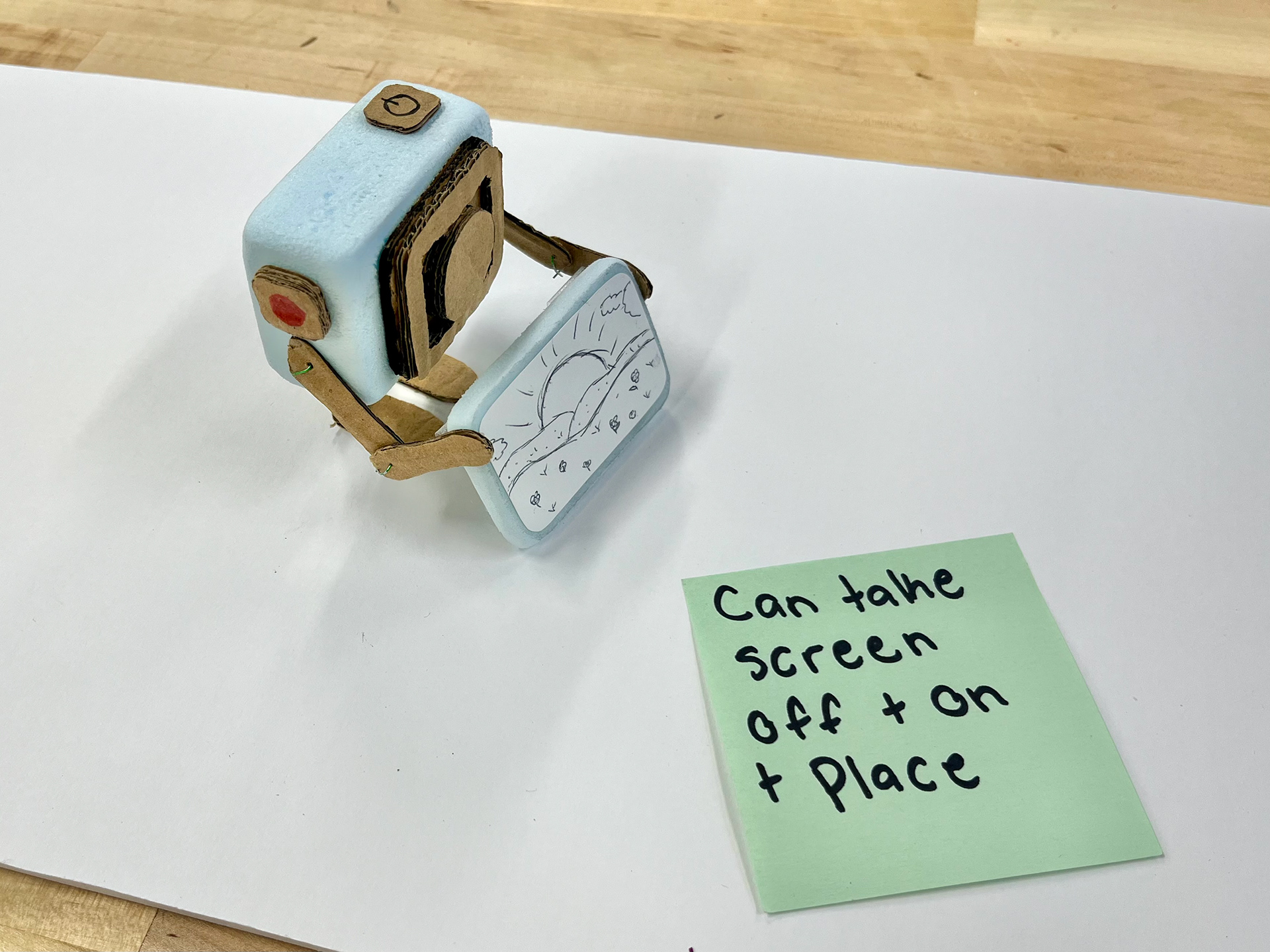

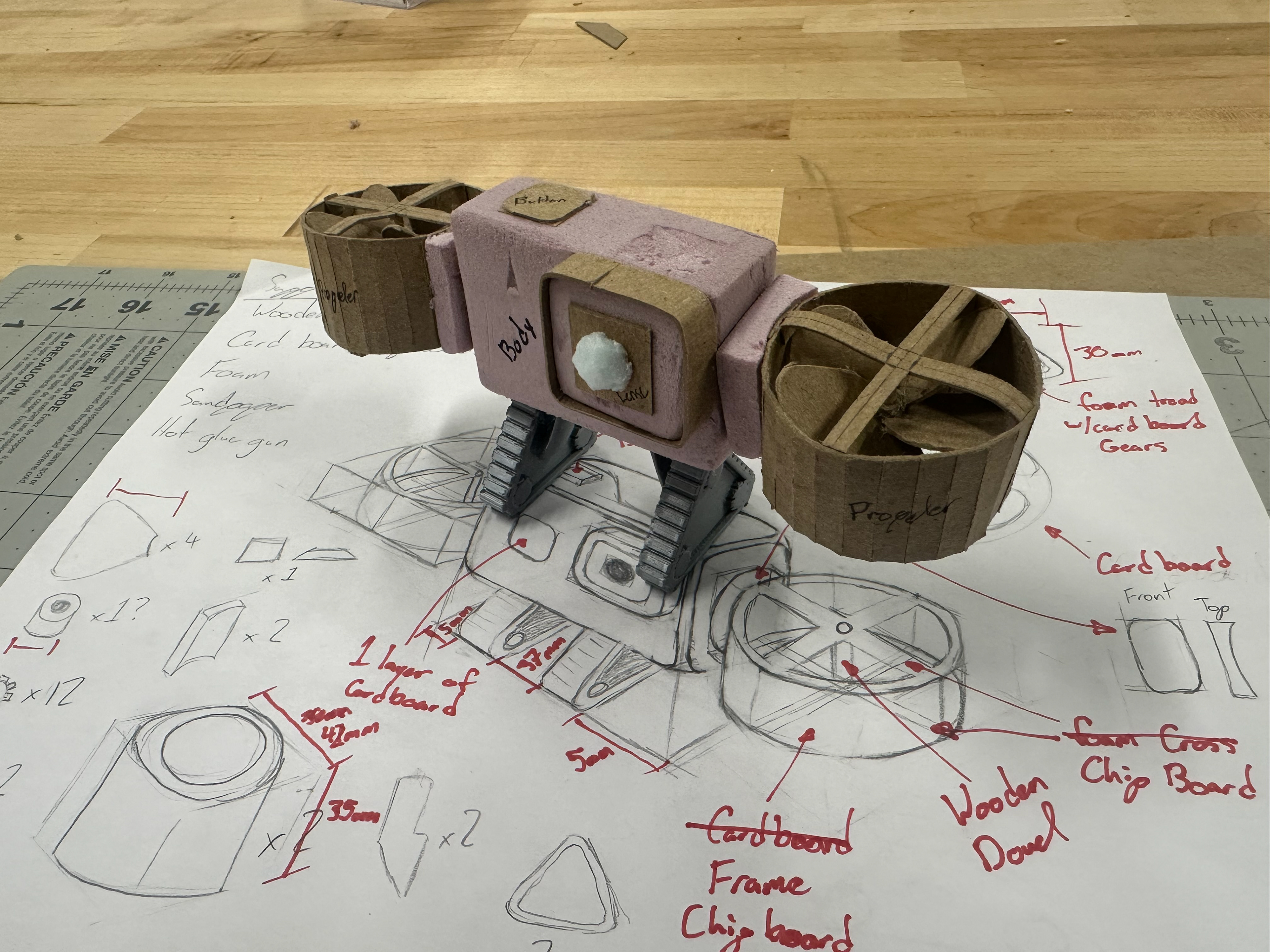

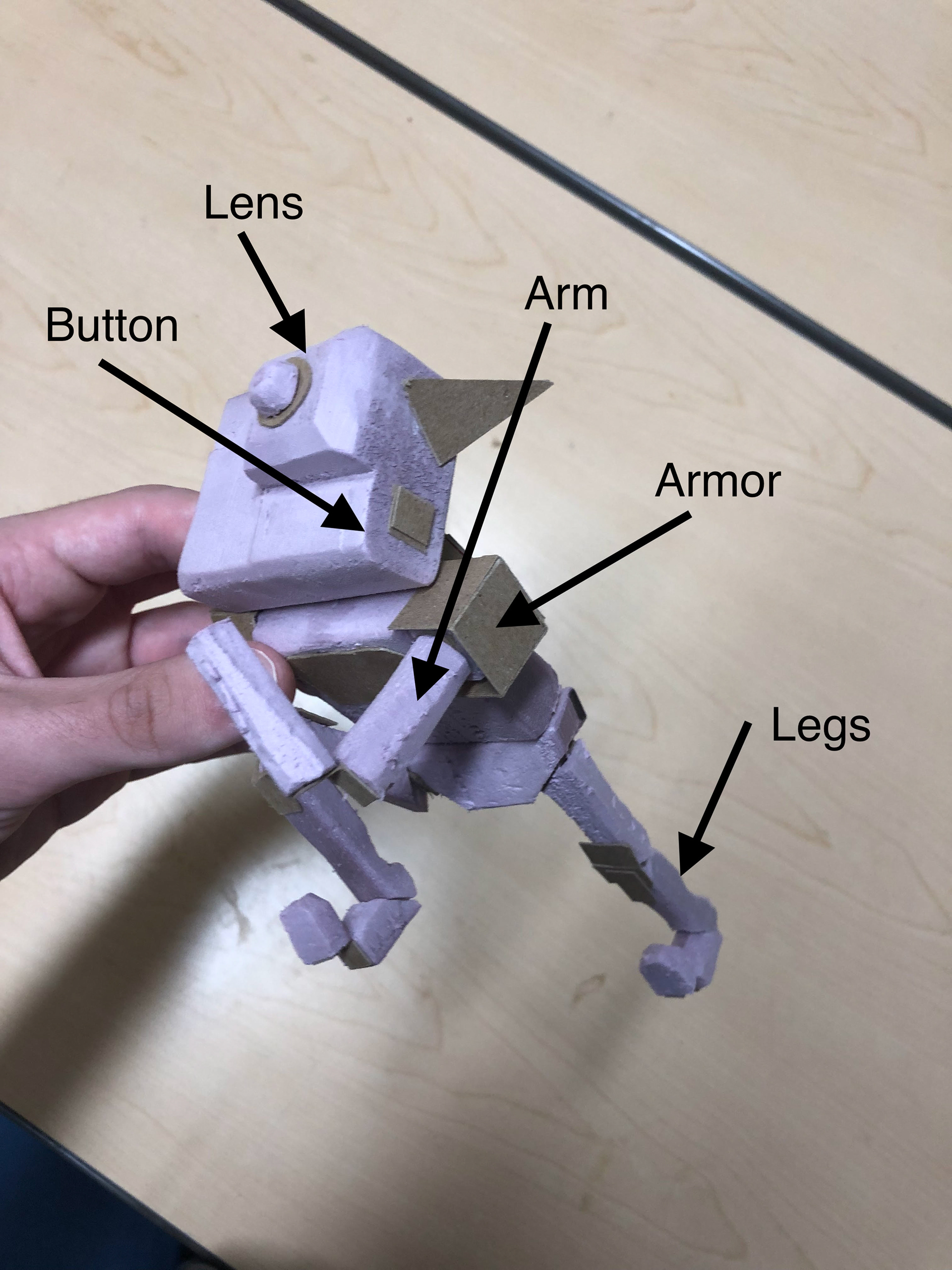

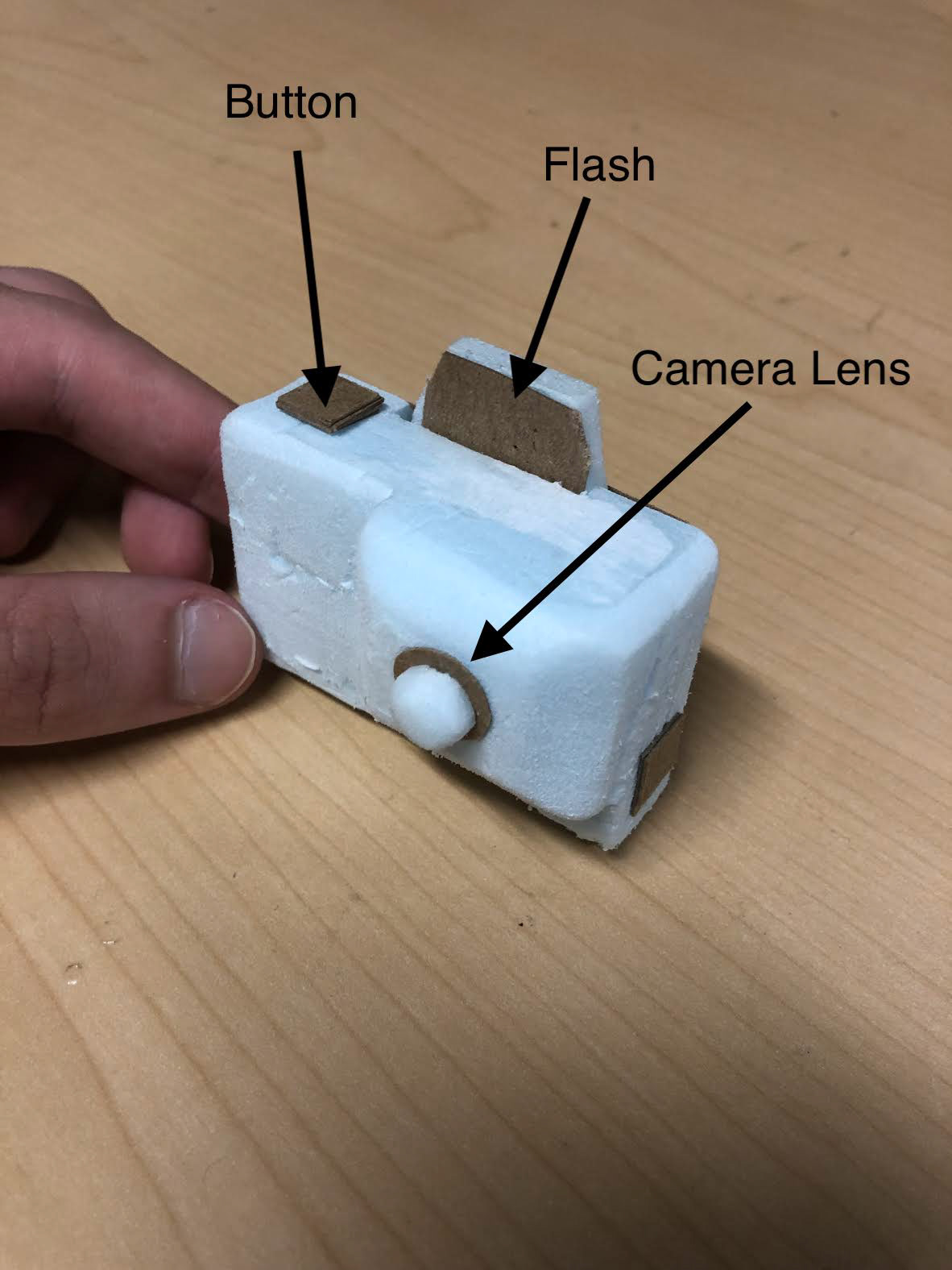

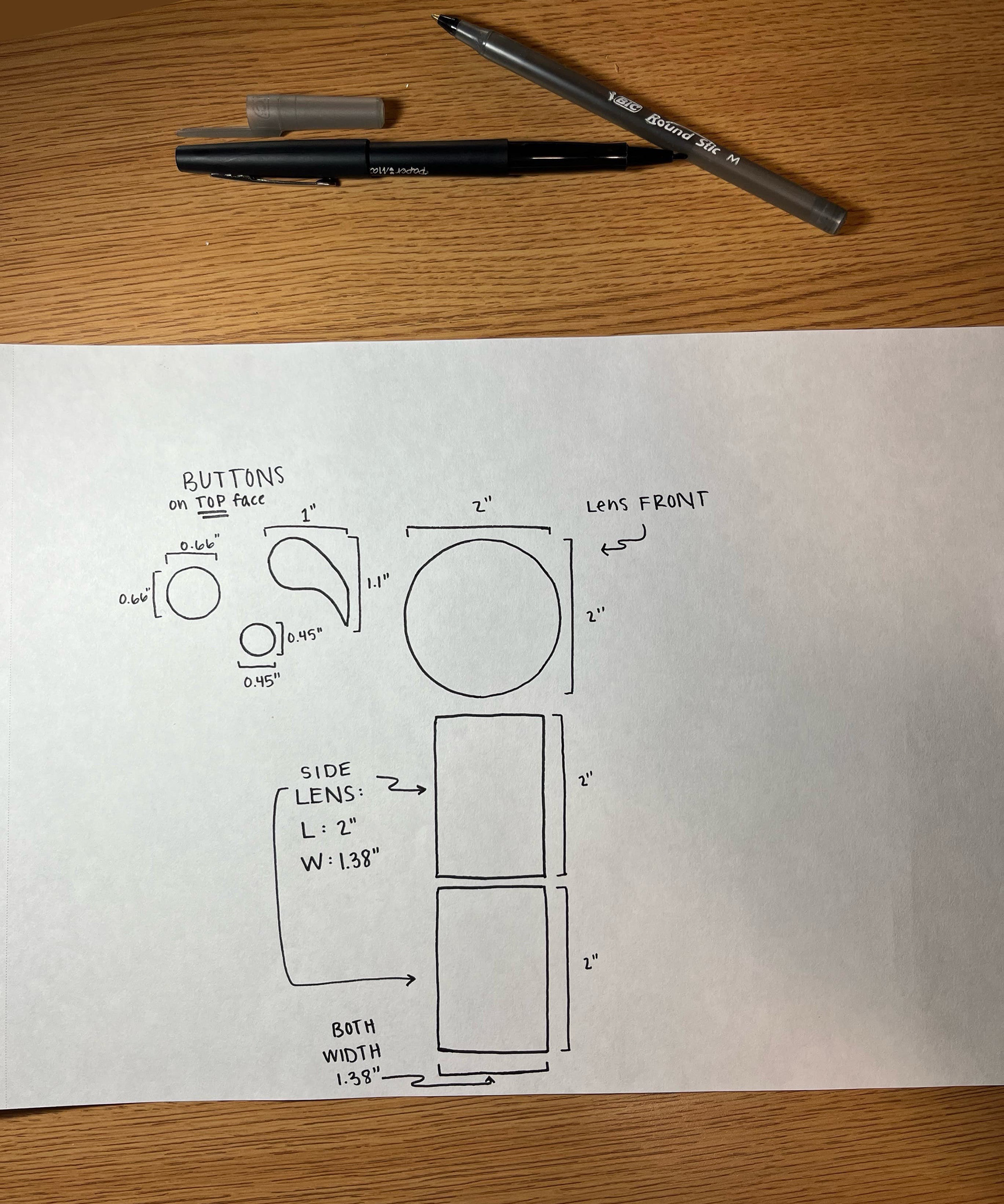

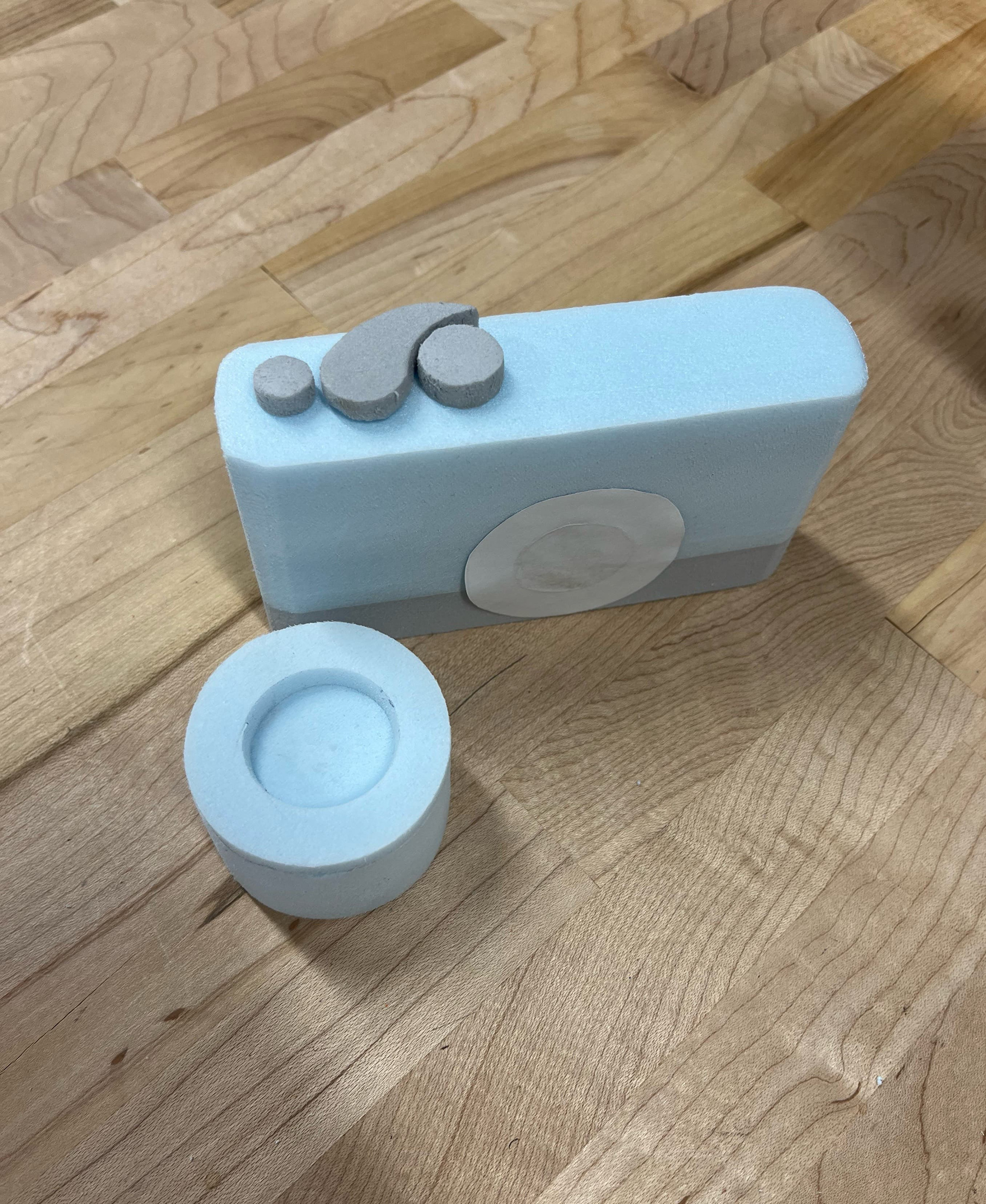

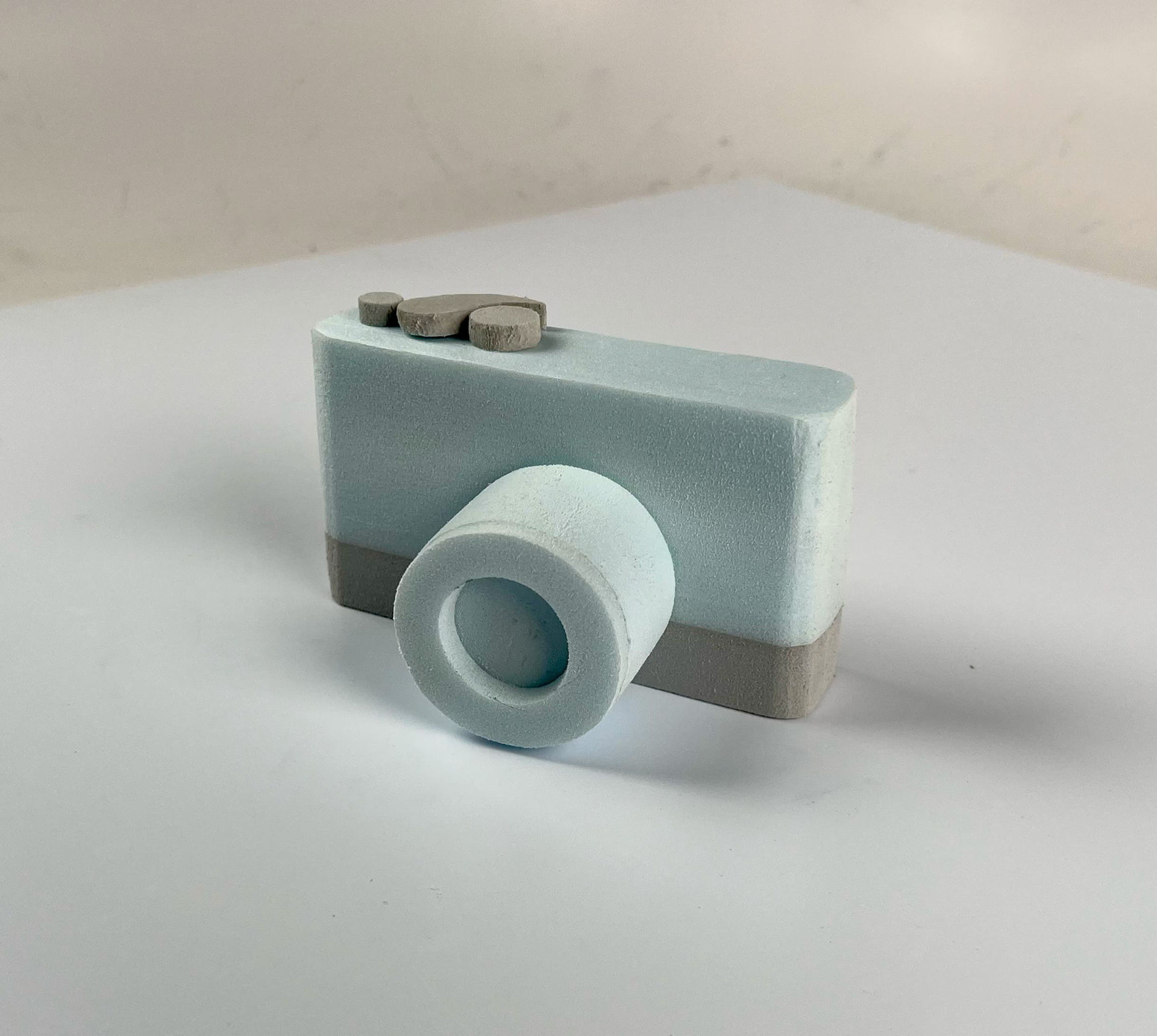

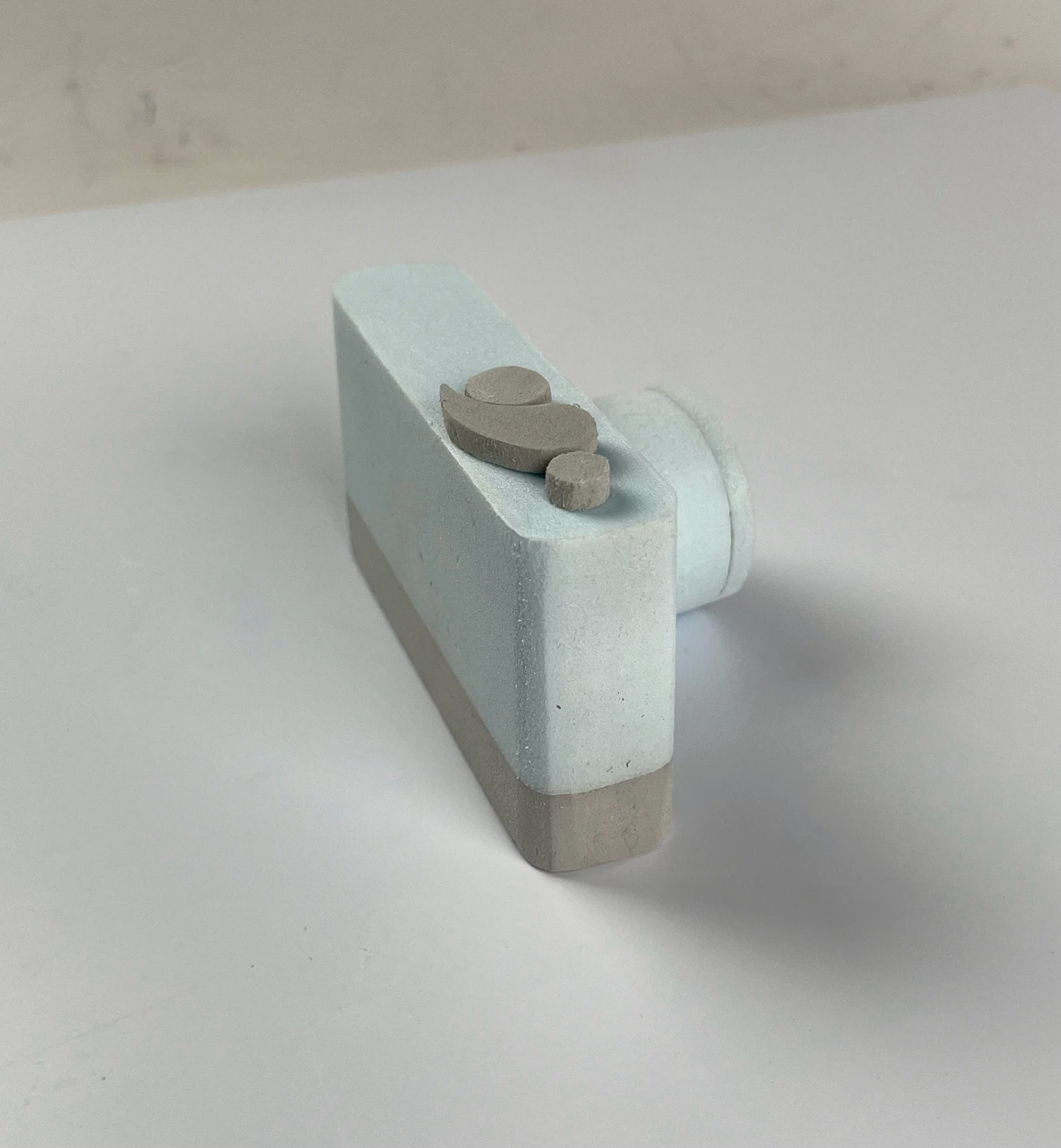

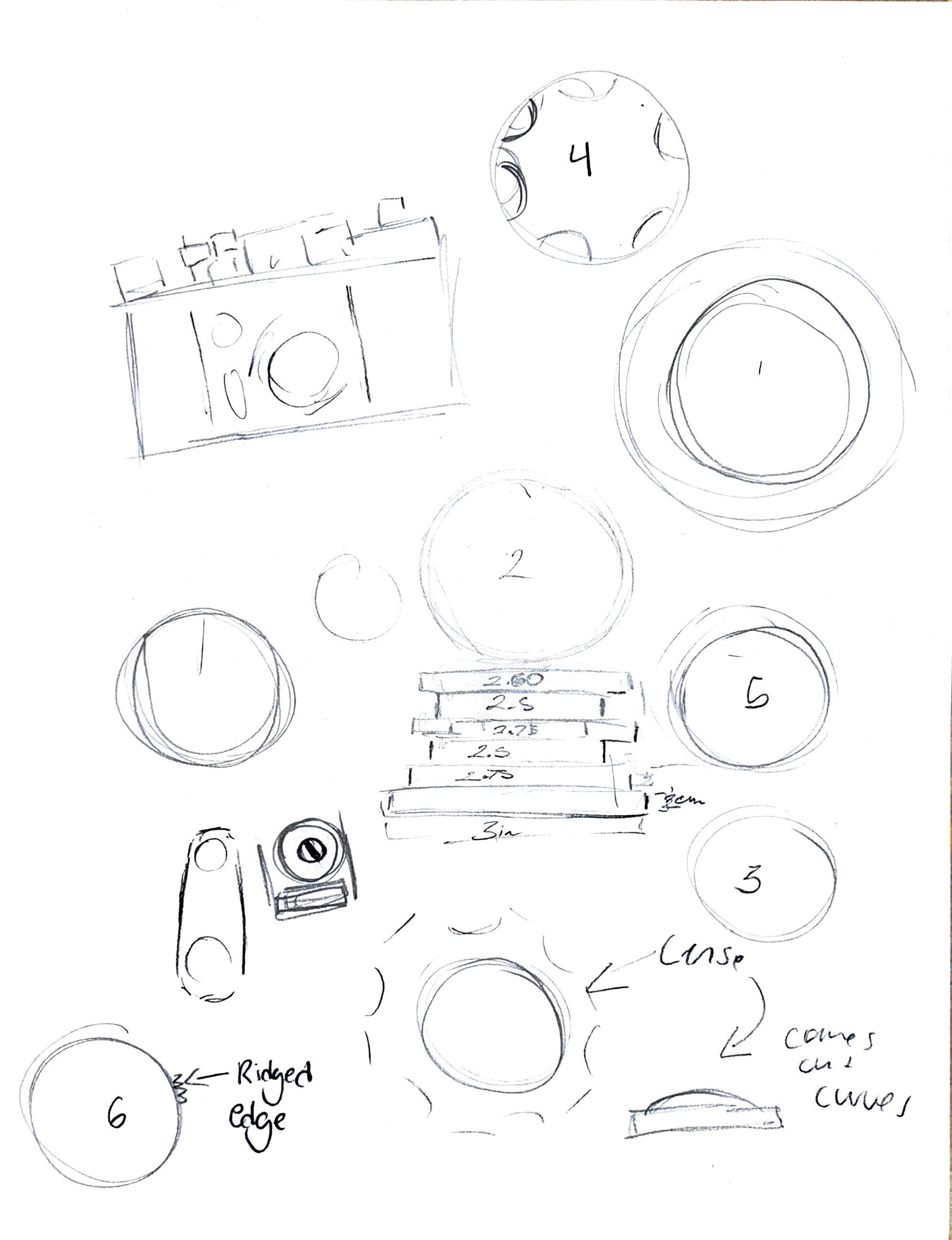

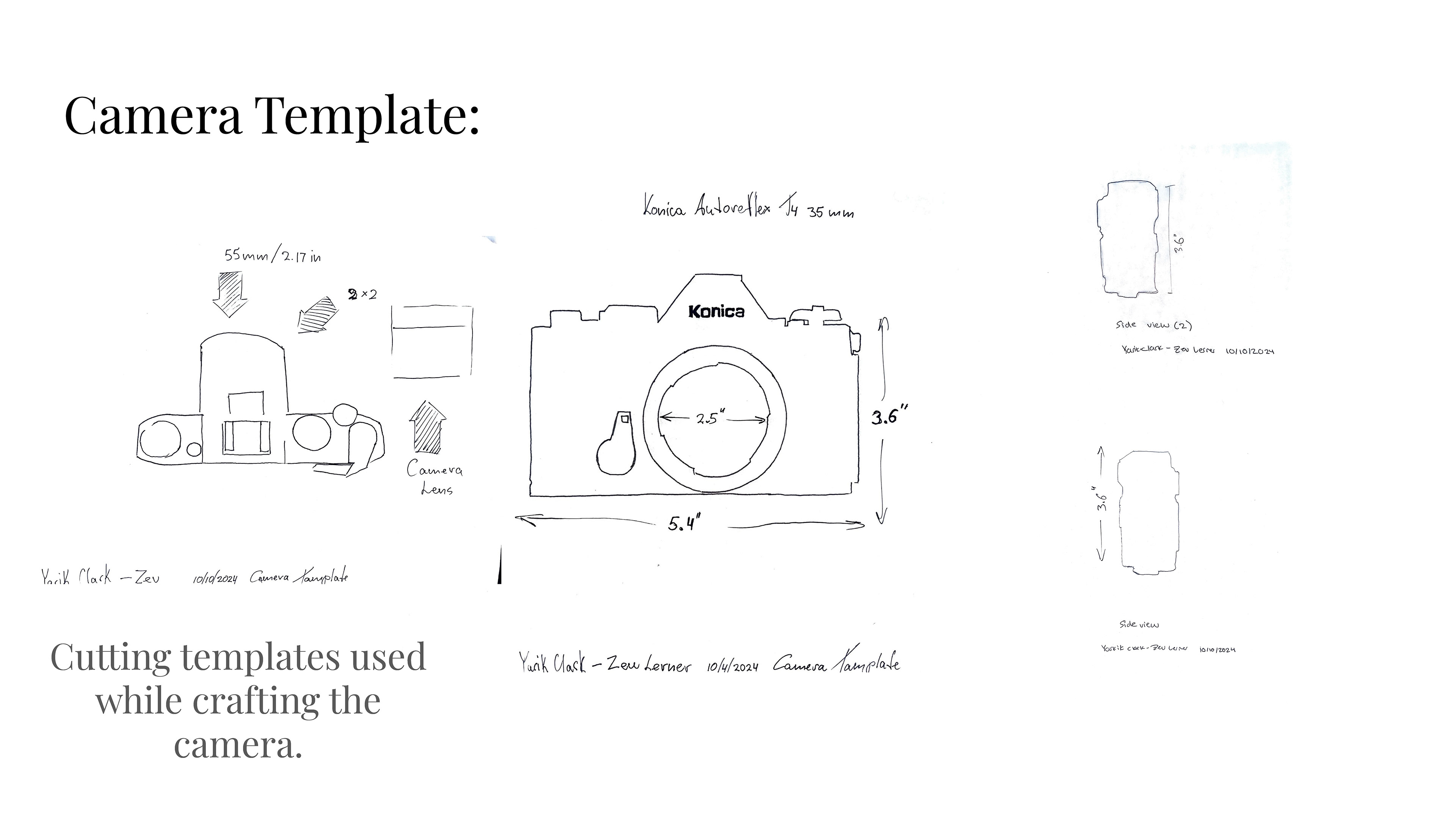

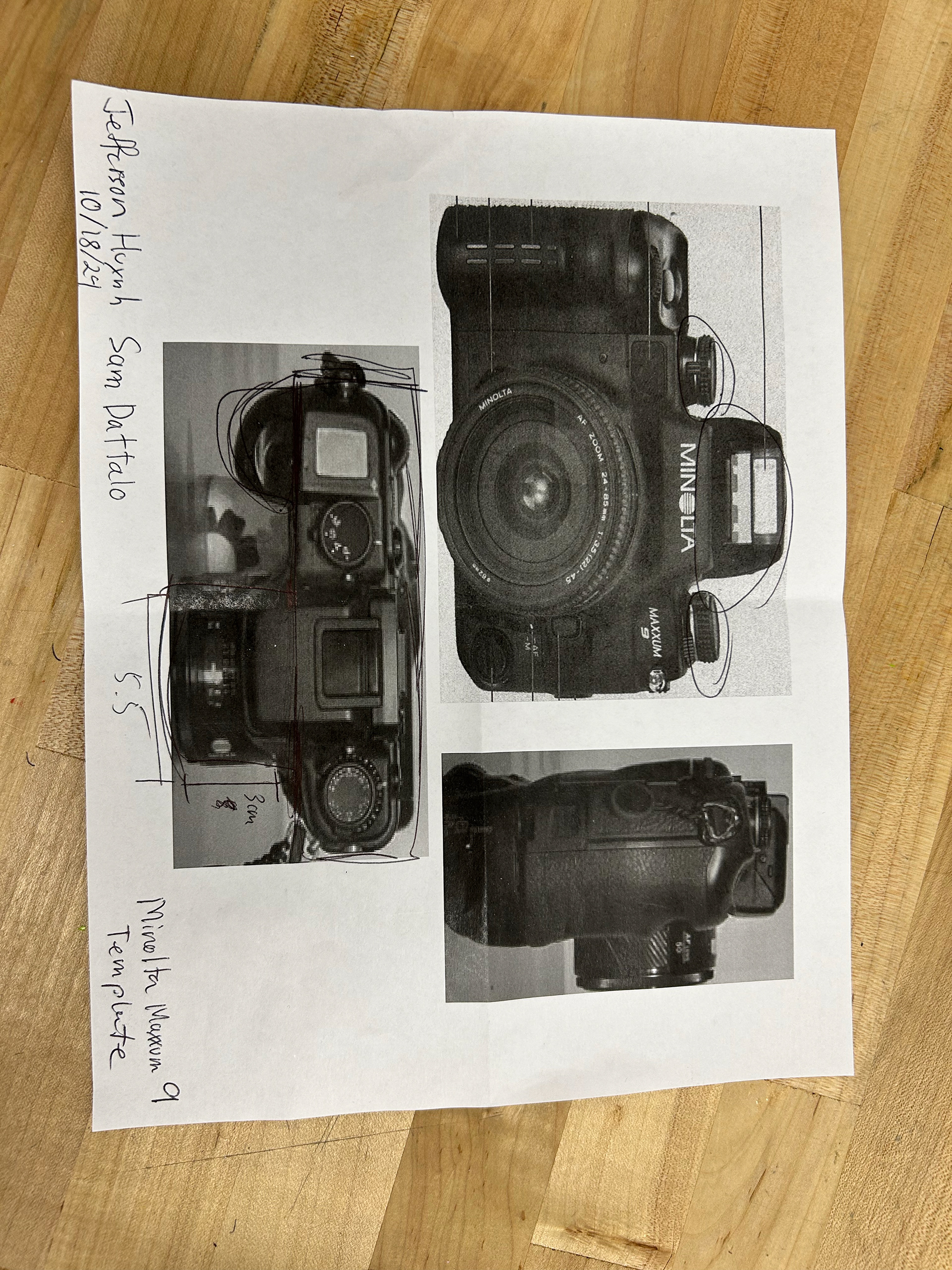

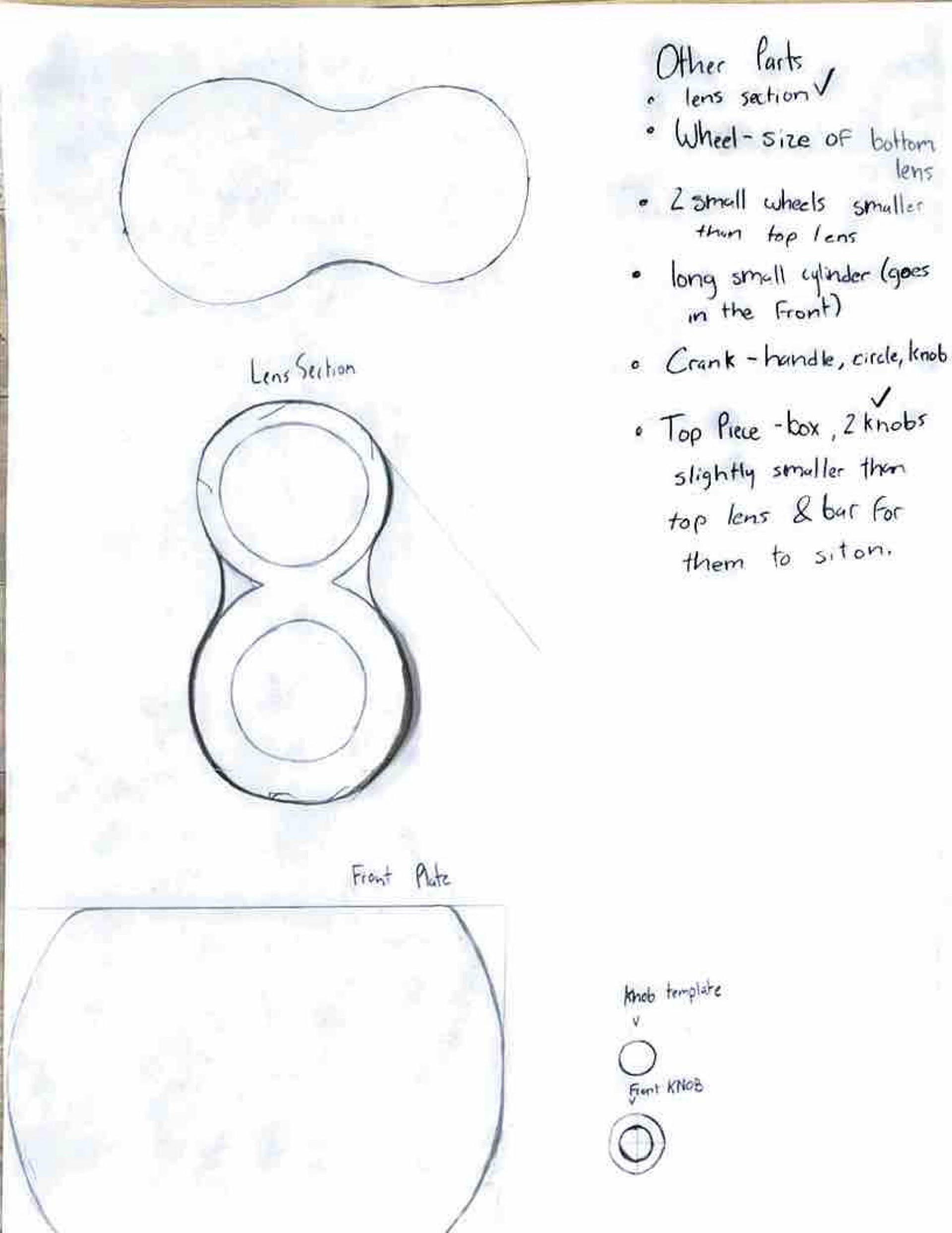

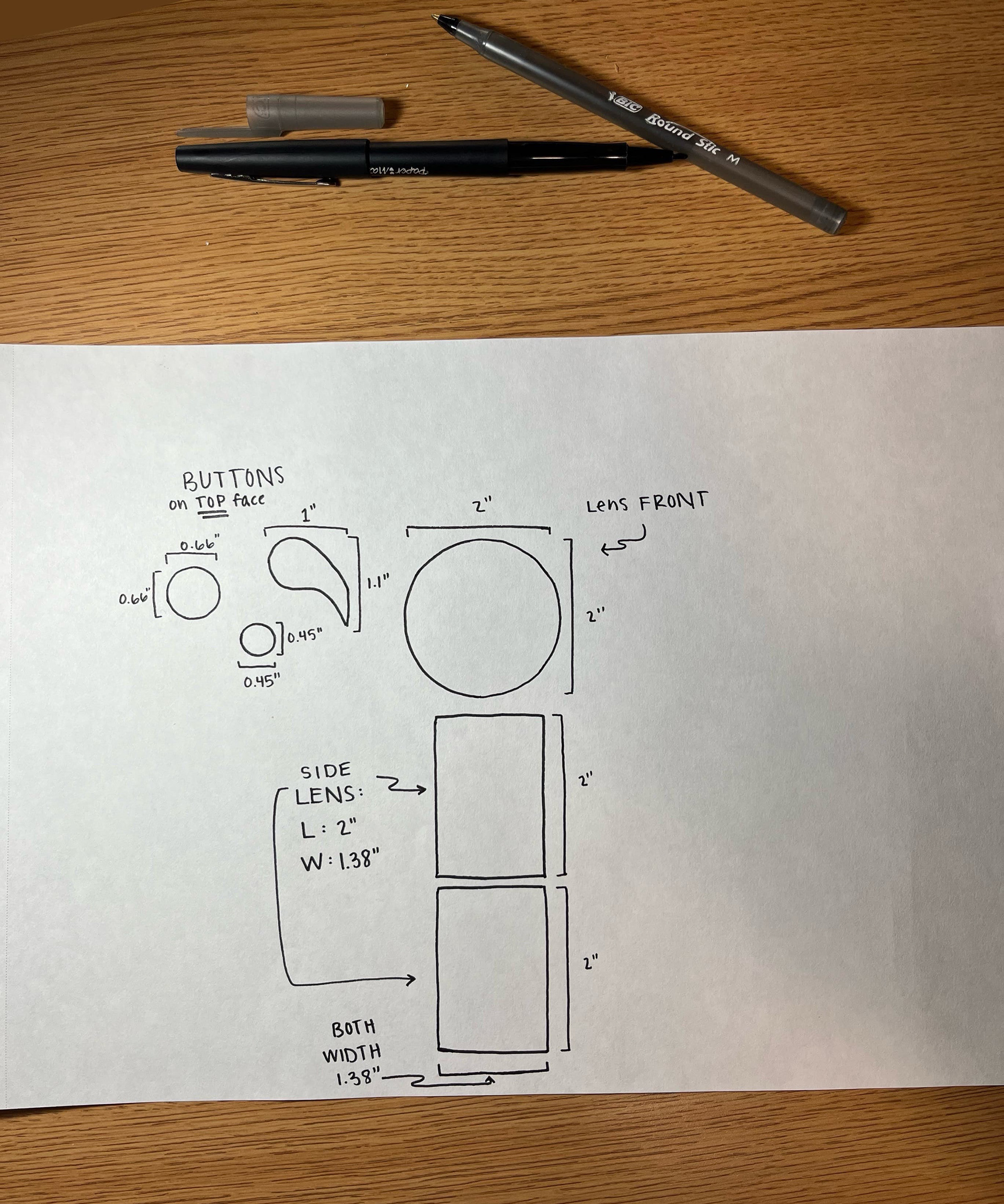

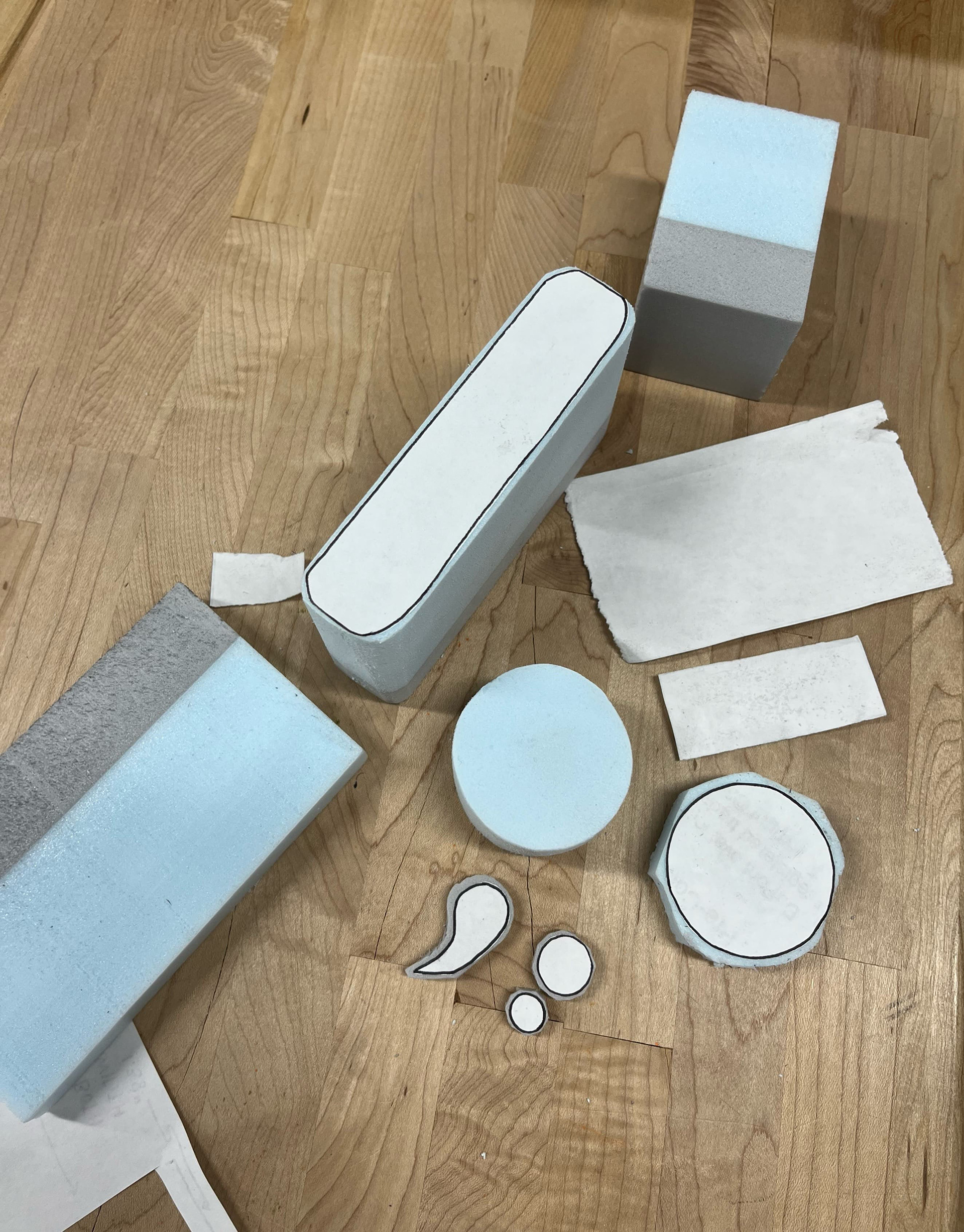

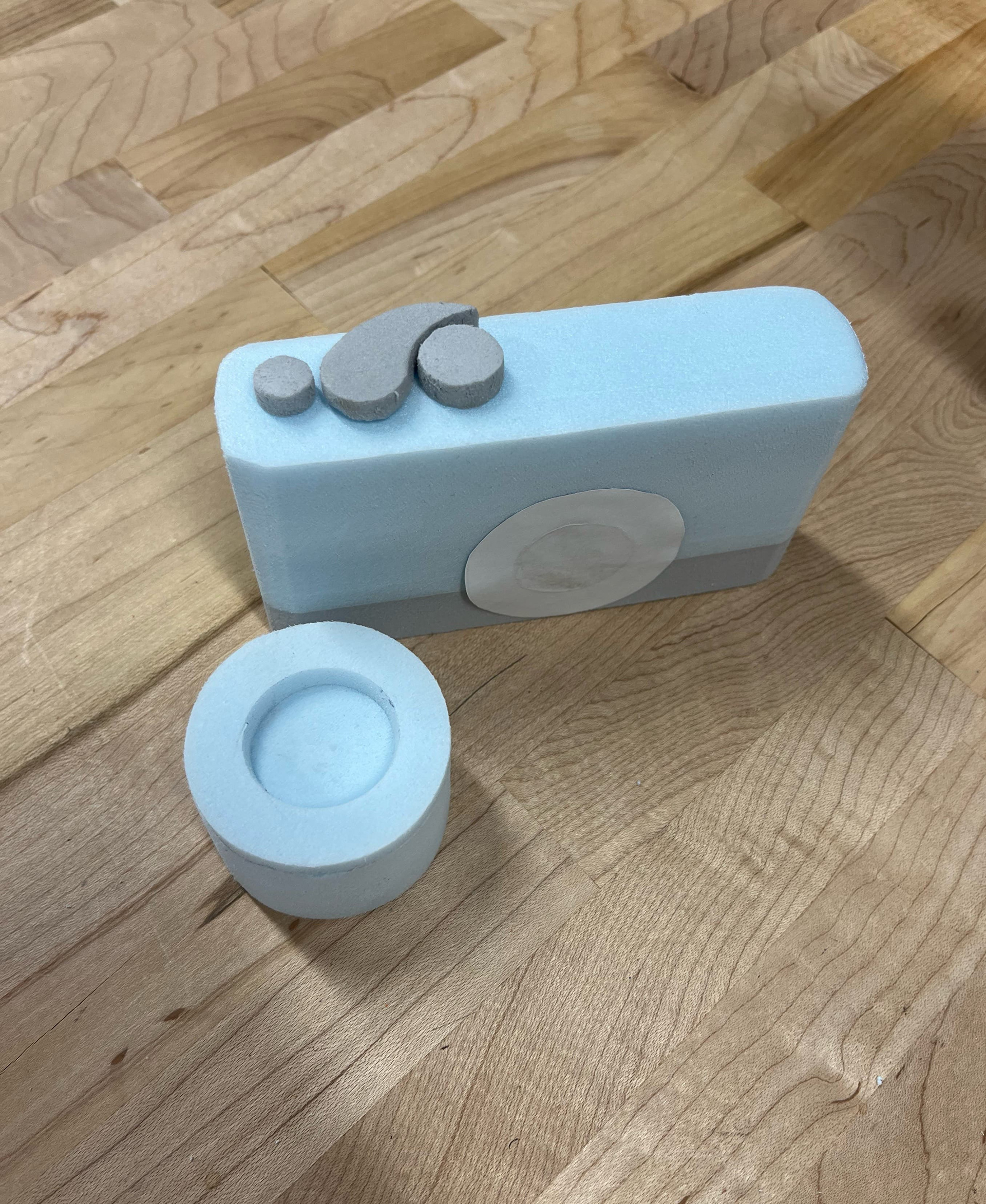

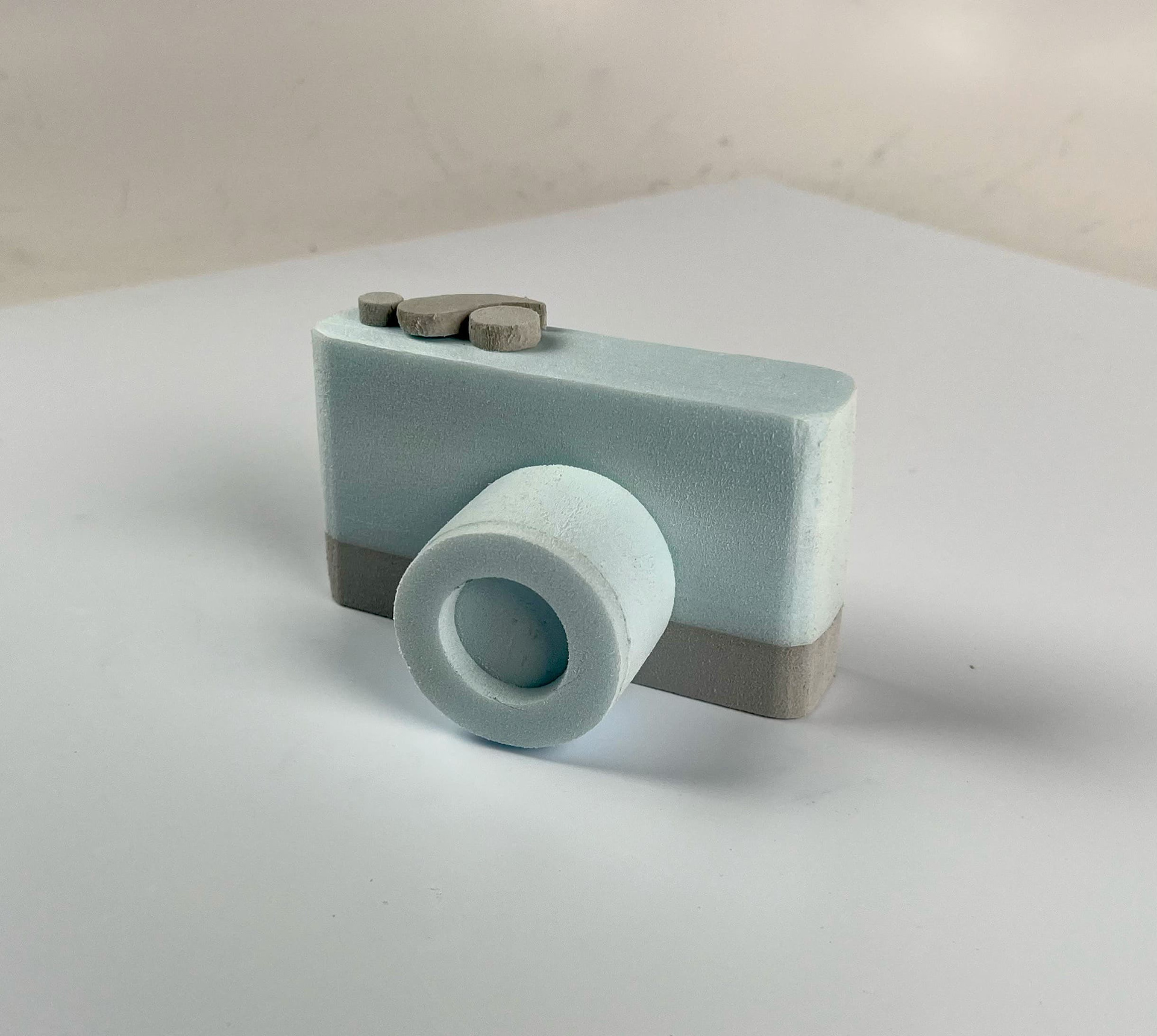

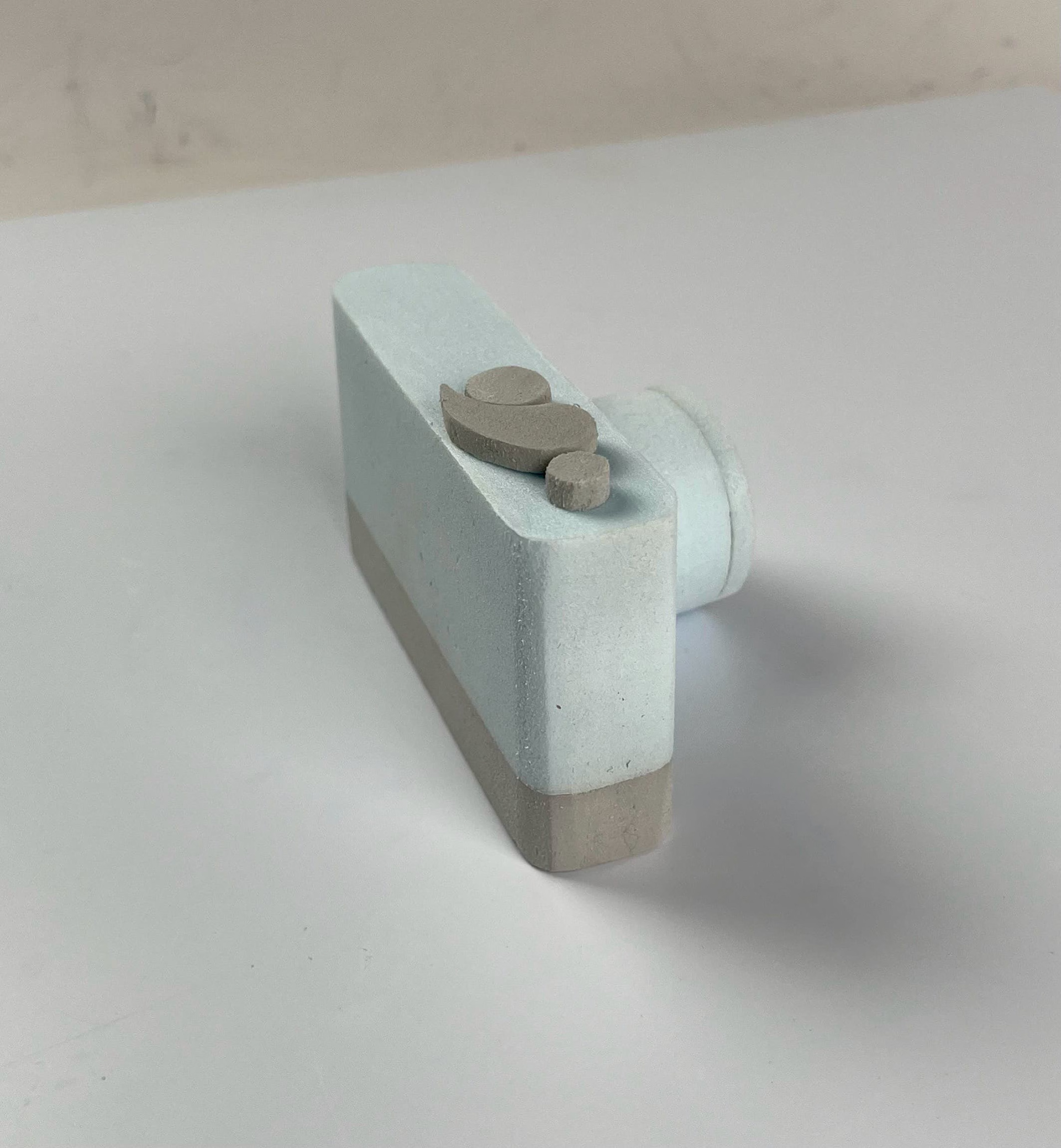

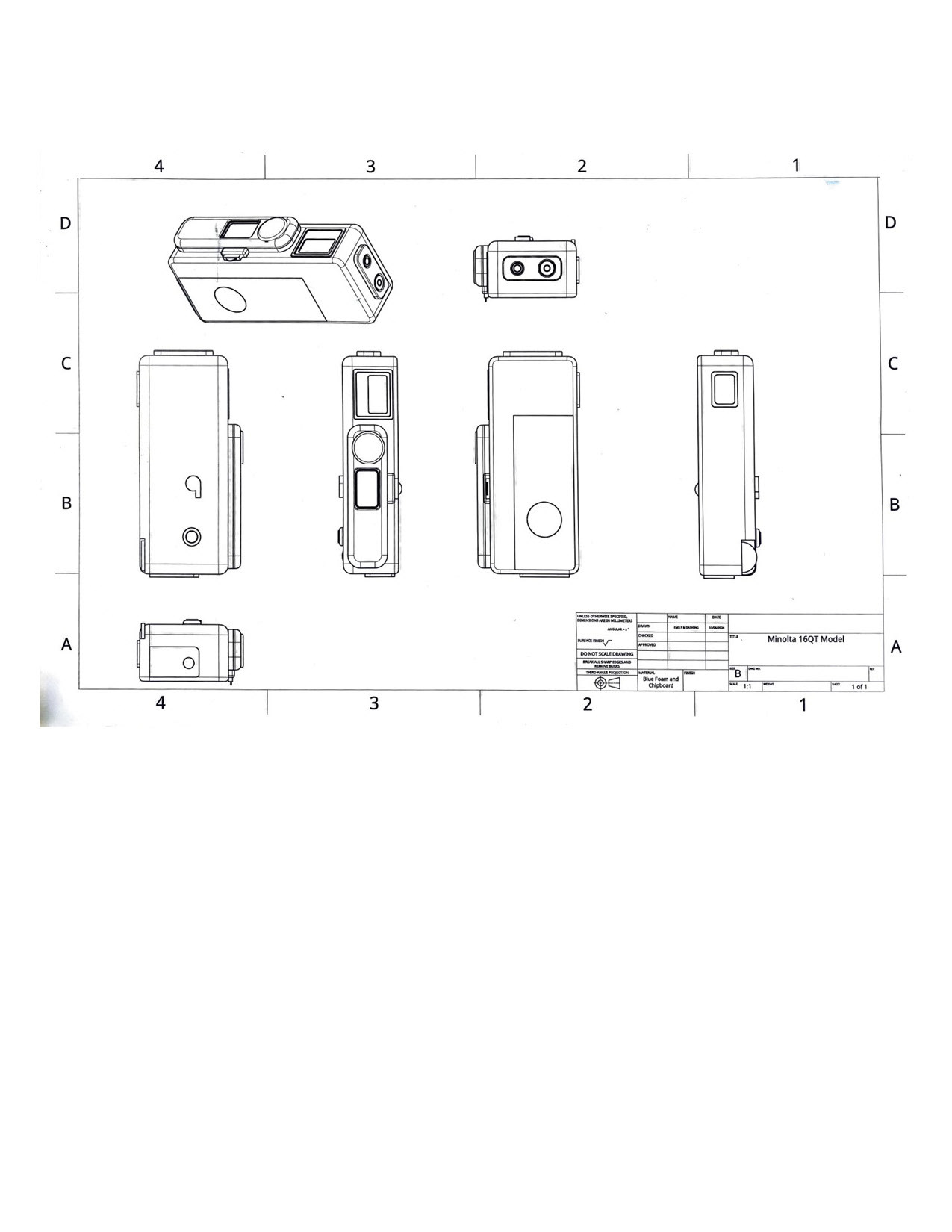

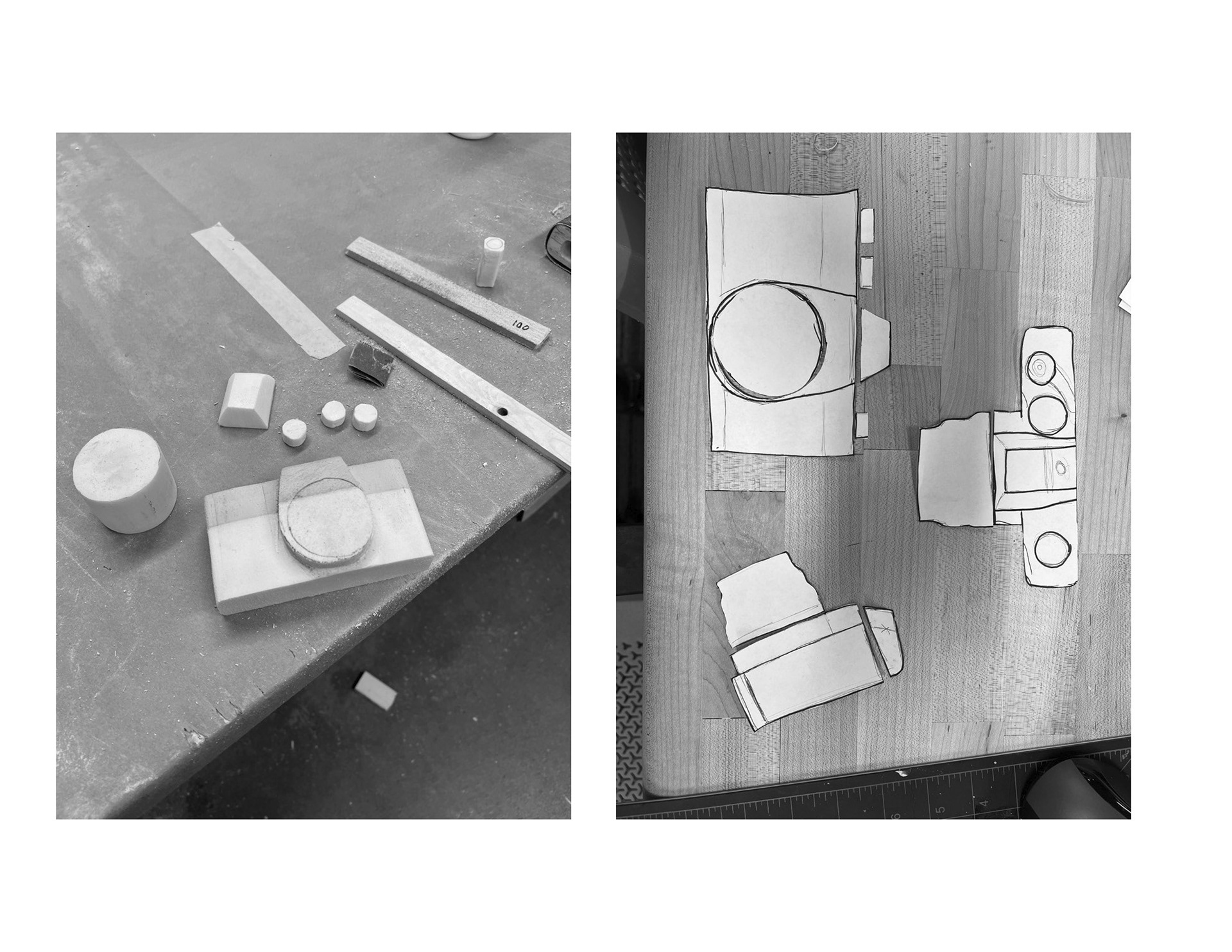

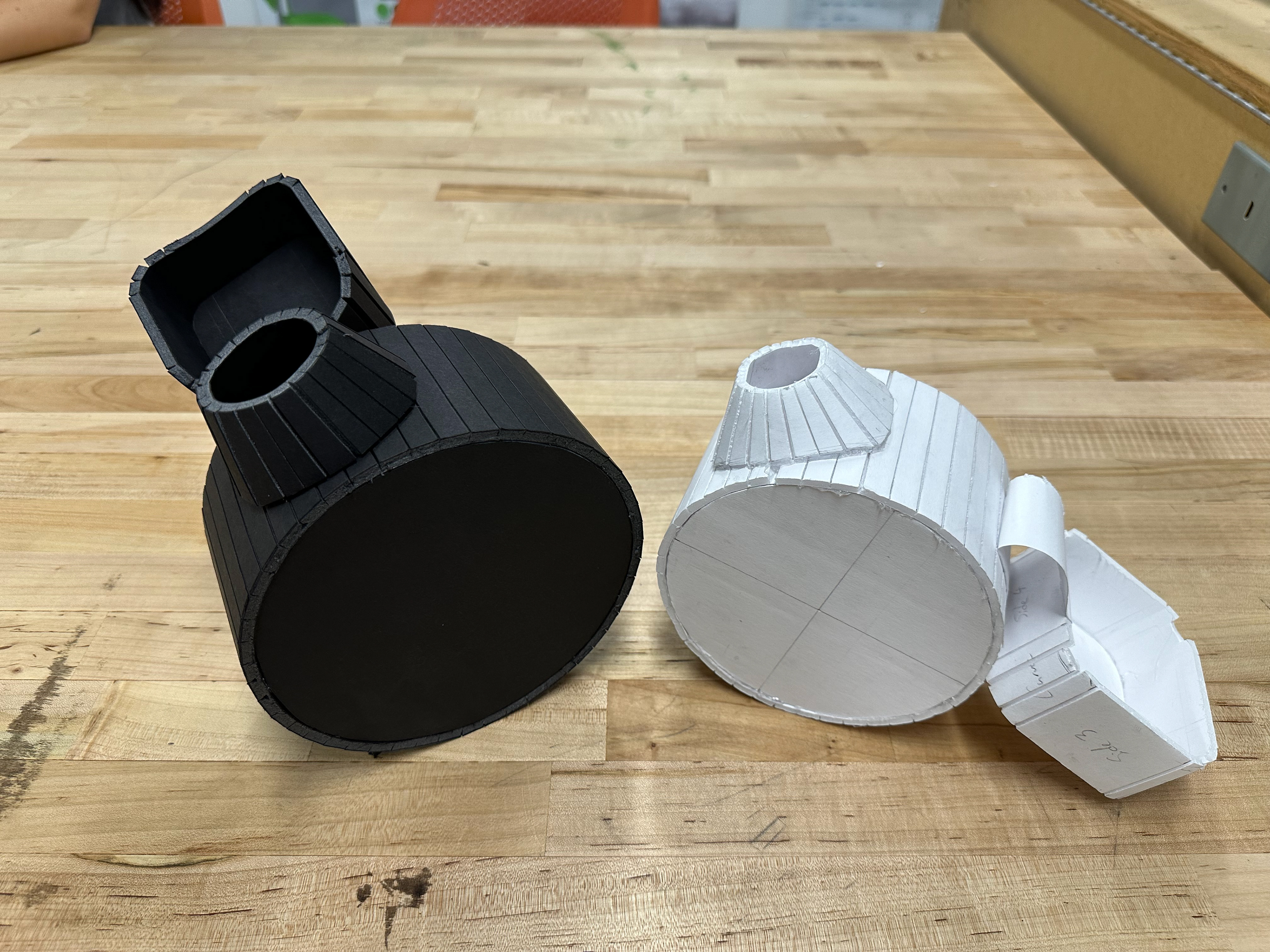

Here, the students have been assigned to create a Go Pro prototype that has a sci-fi addition that can be feasible in the very near future. This allows them to create an existing object with templates and measurements and be able to add their innovative designs to an existing product.

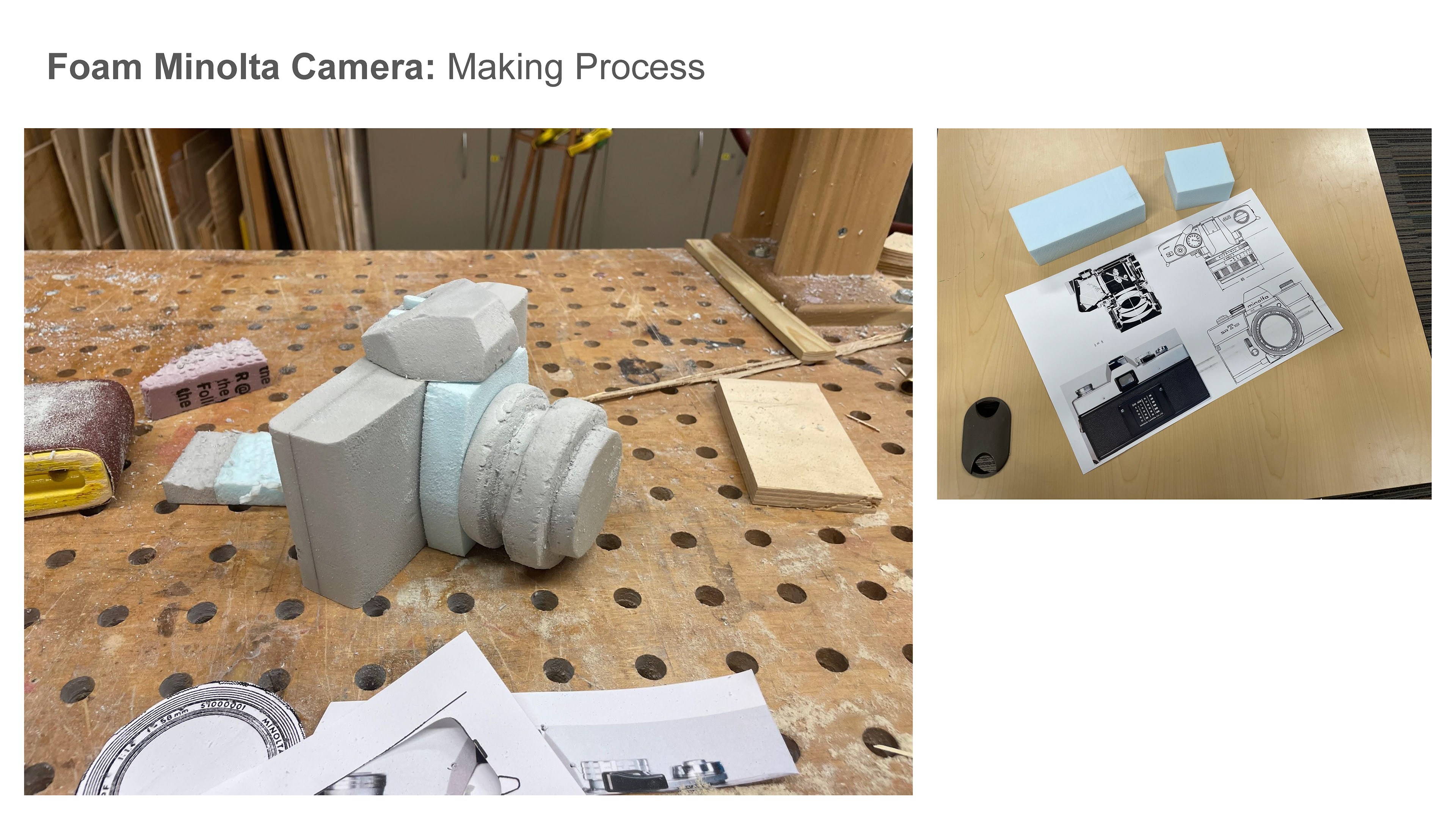

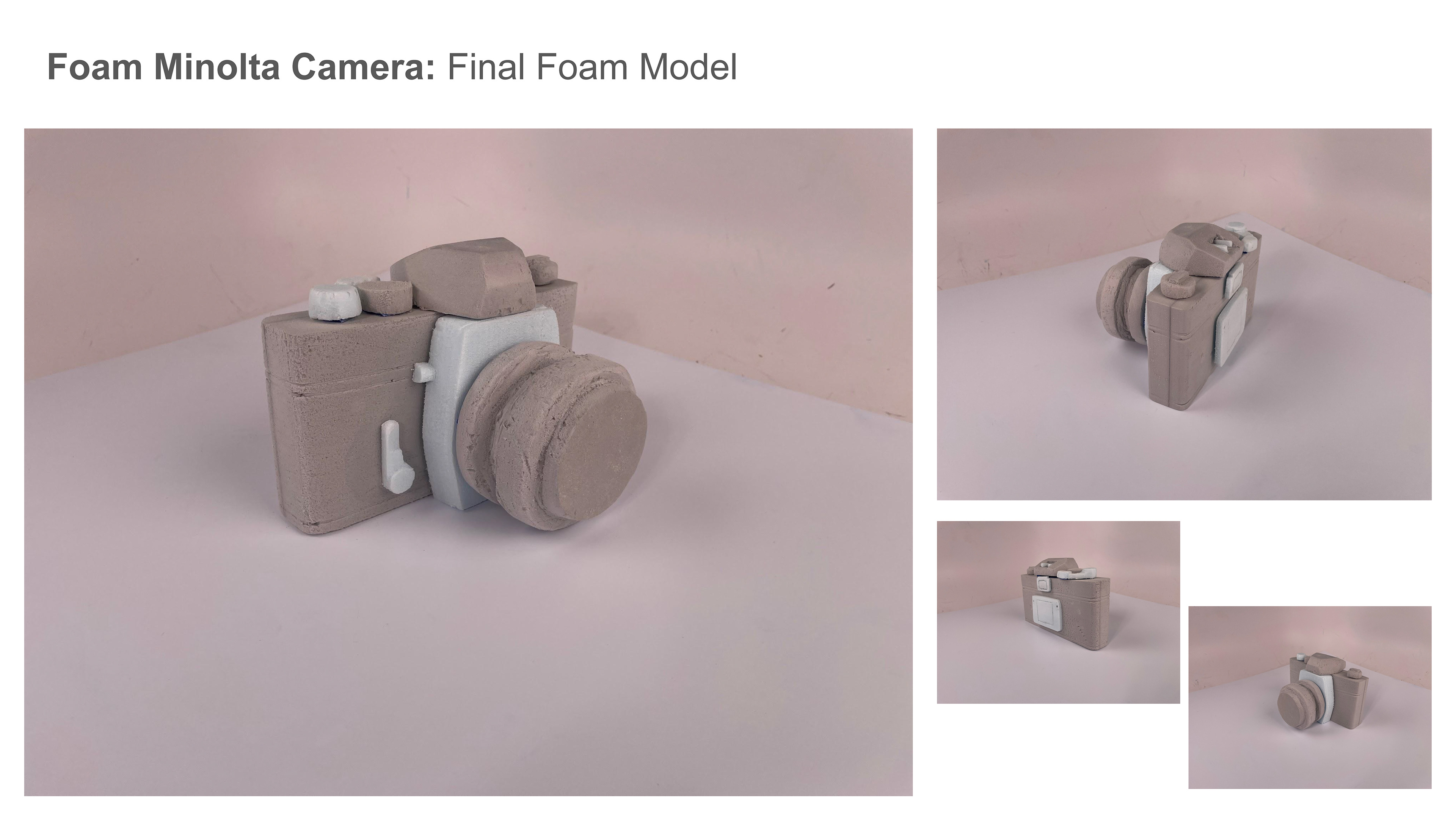

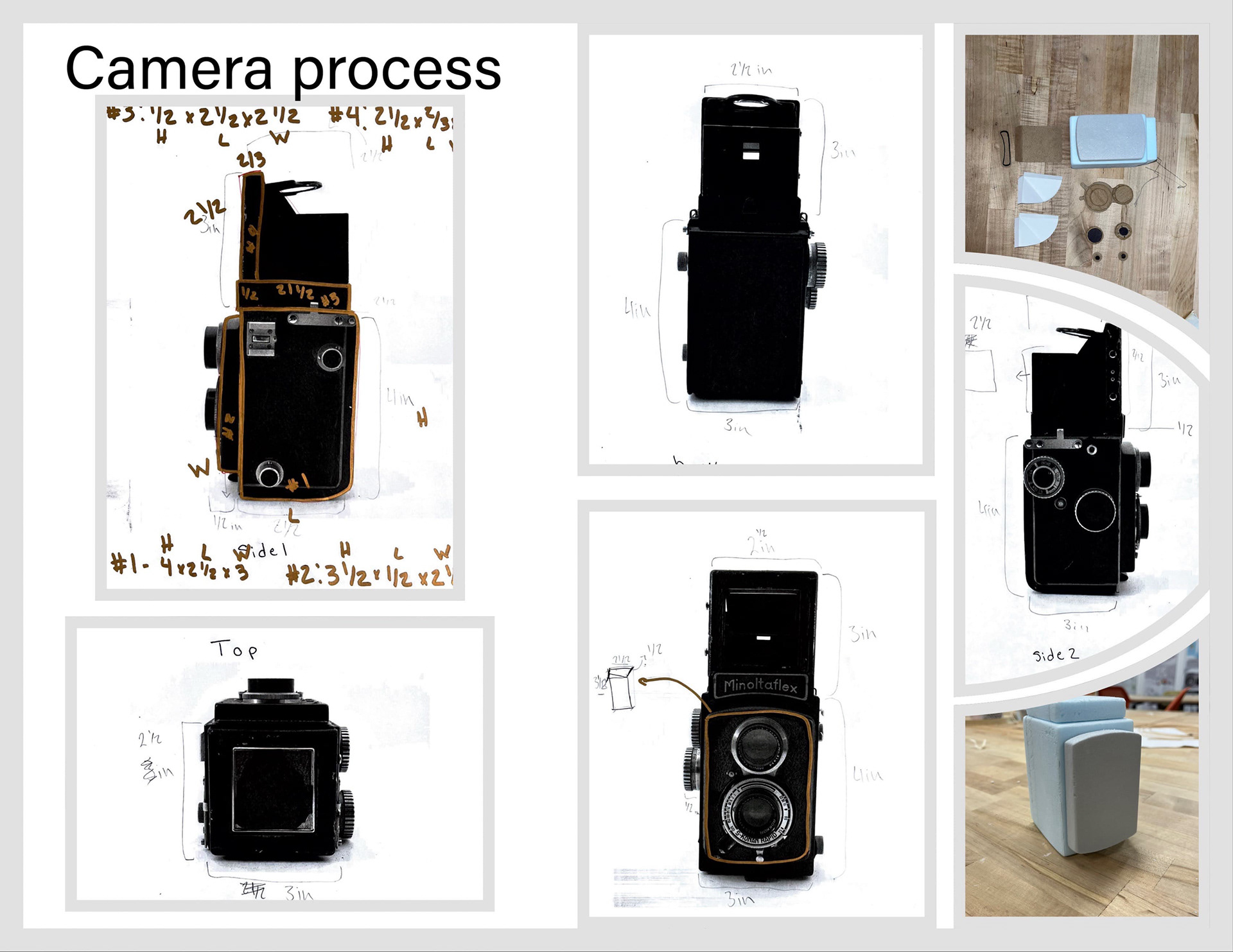

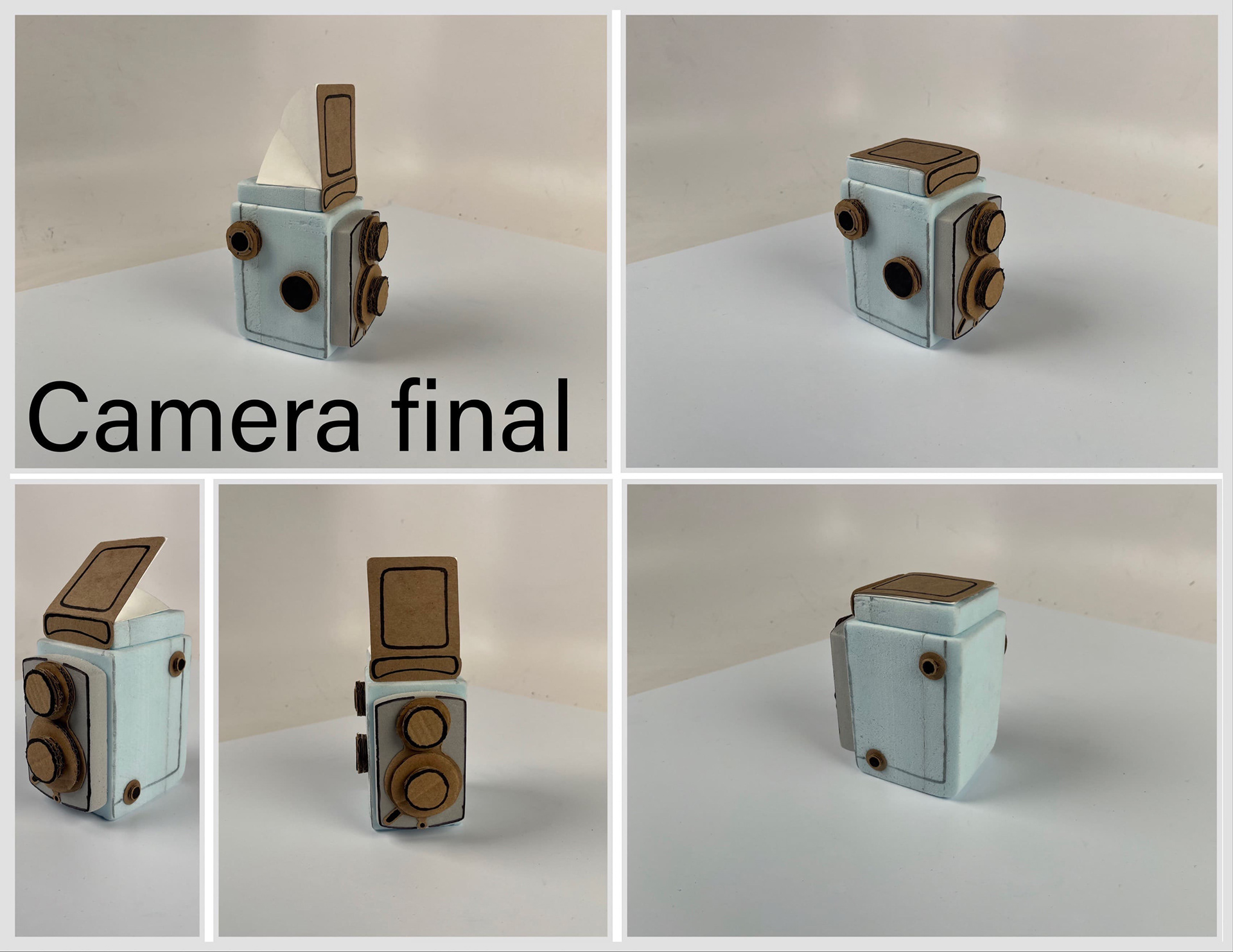

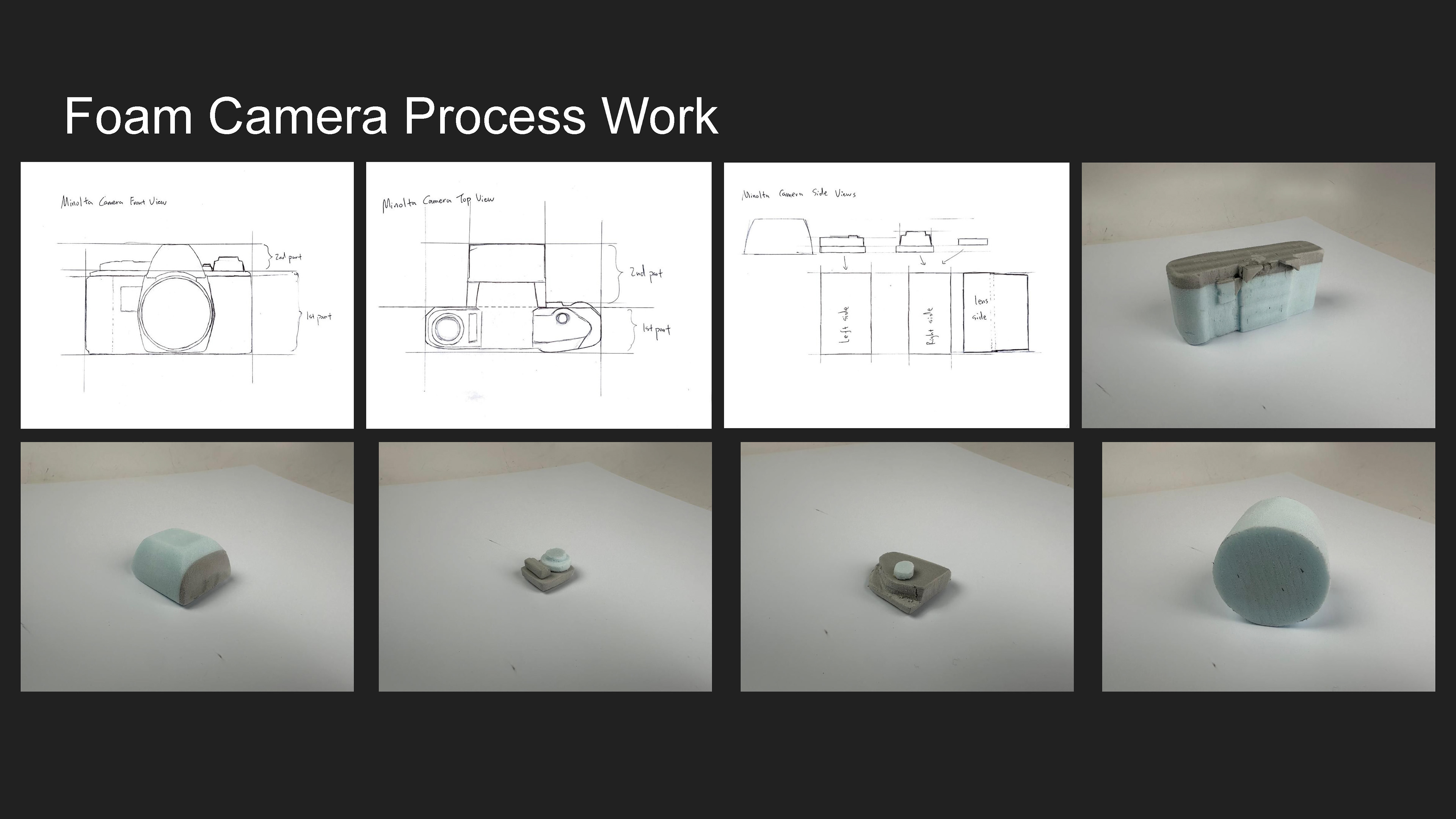

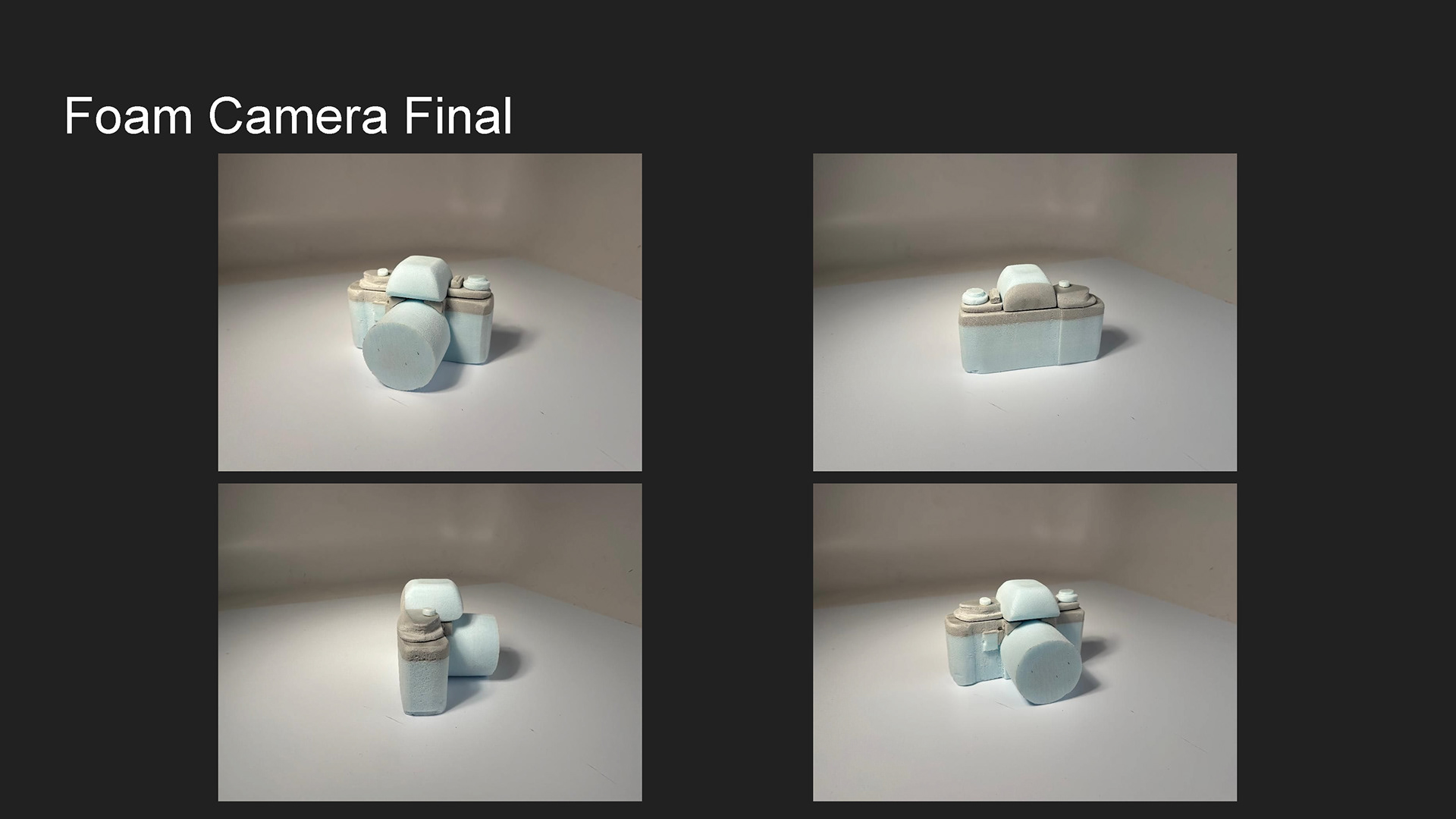

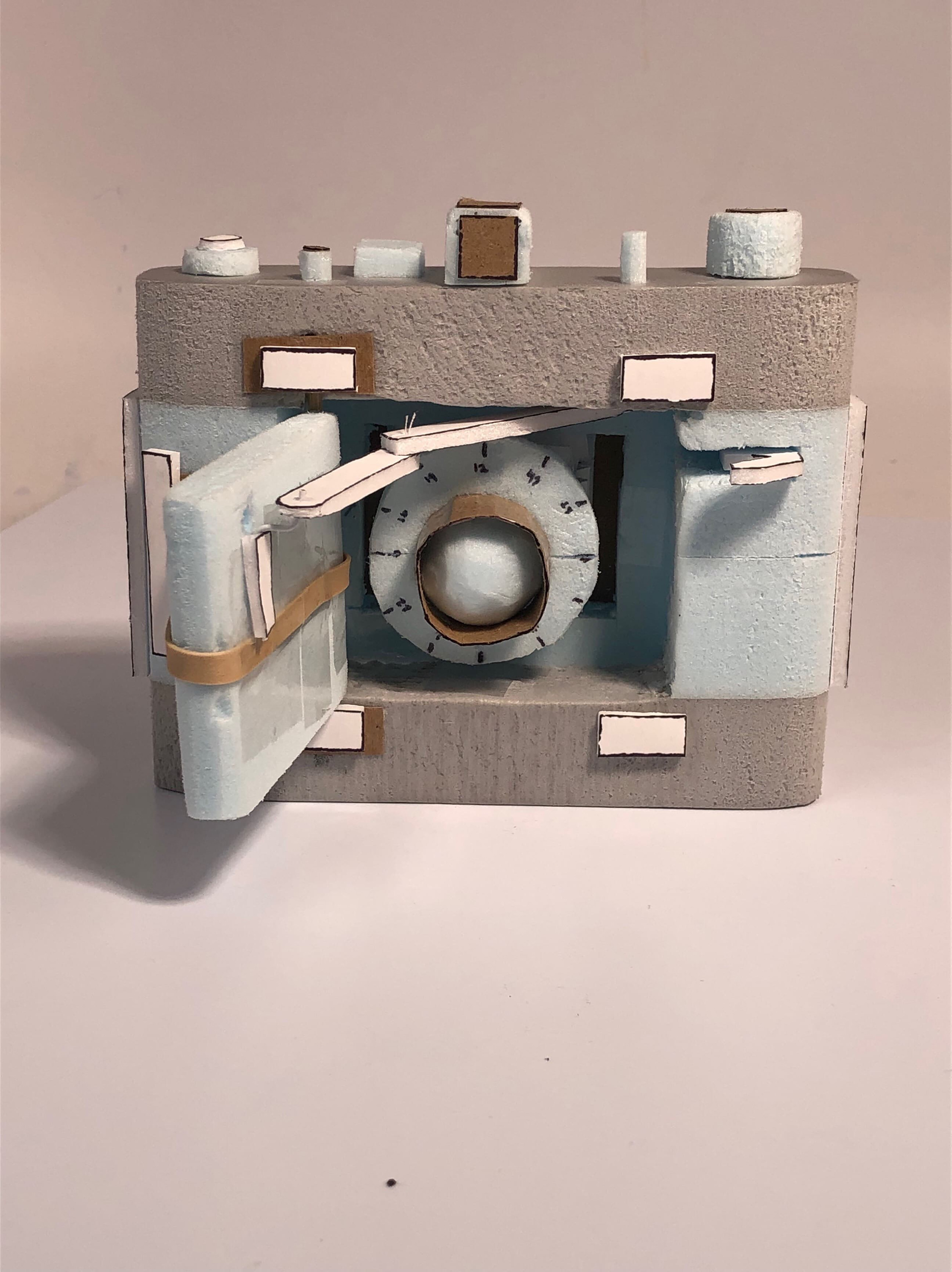

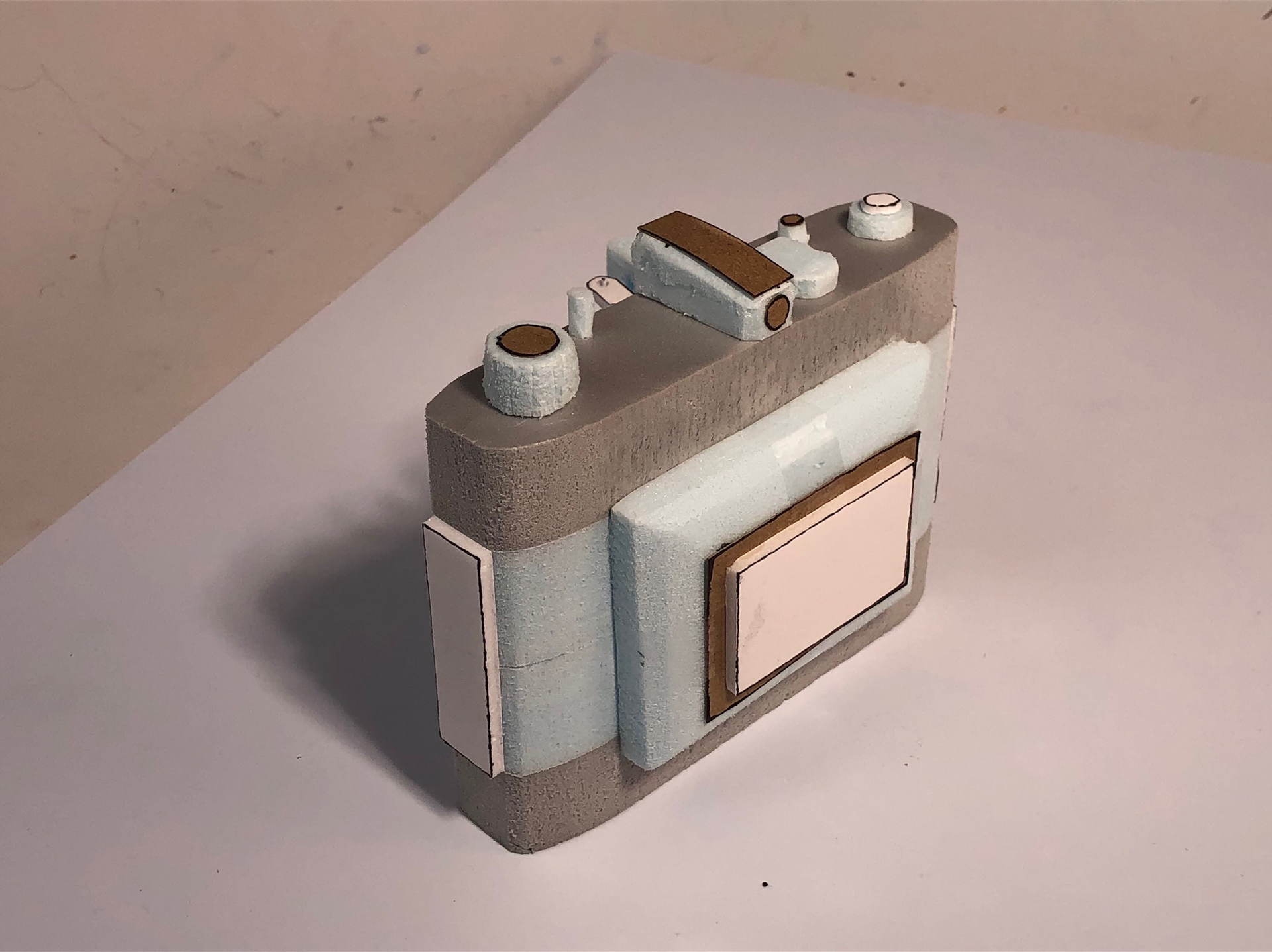

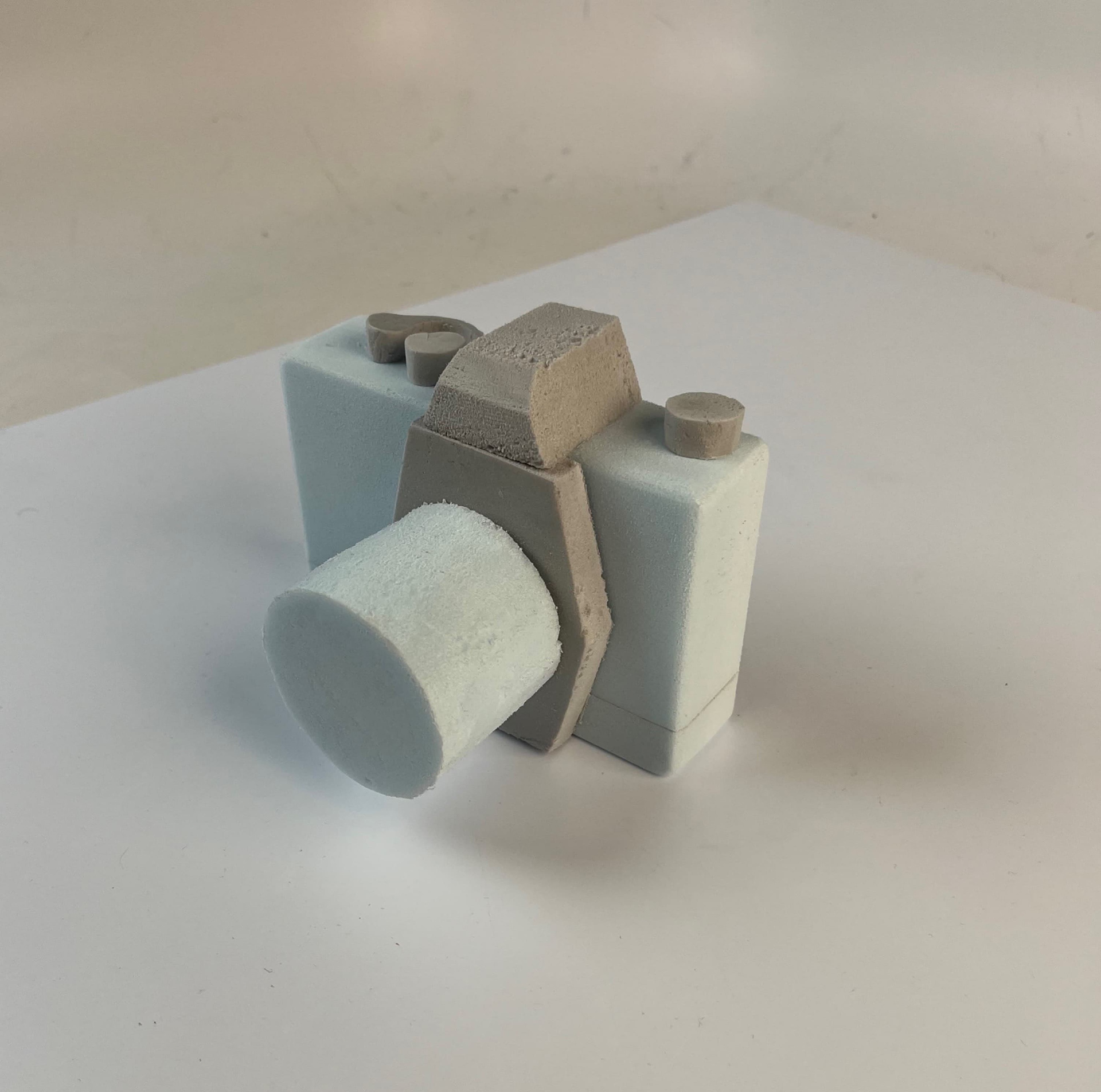

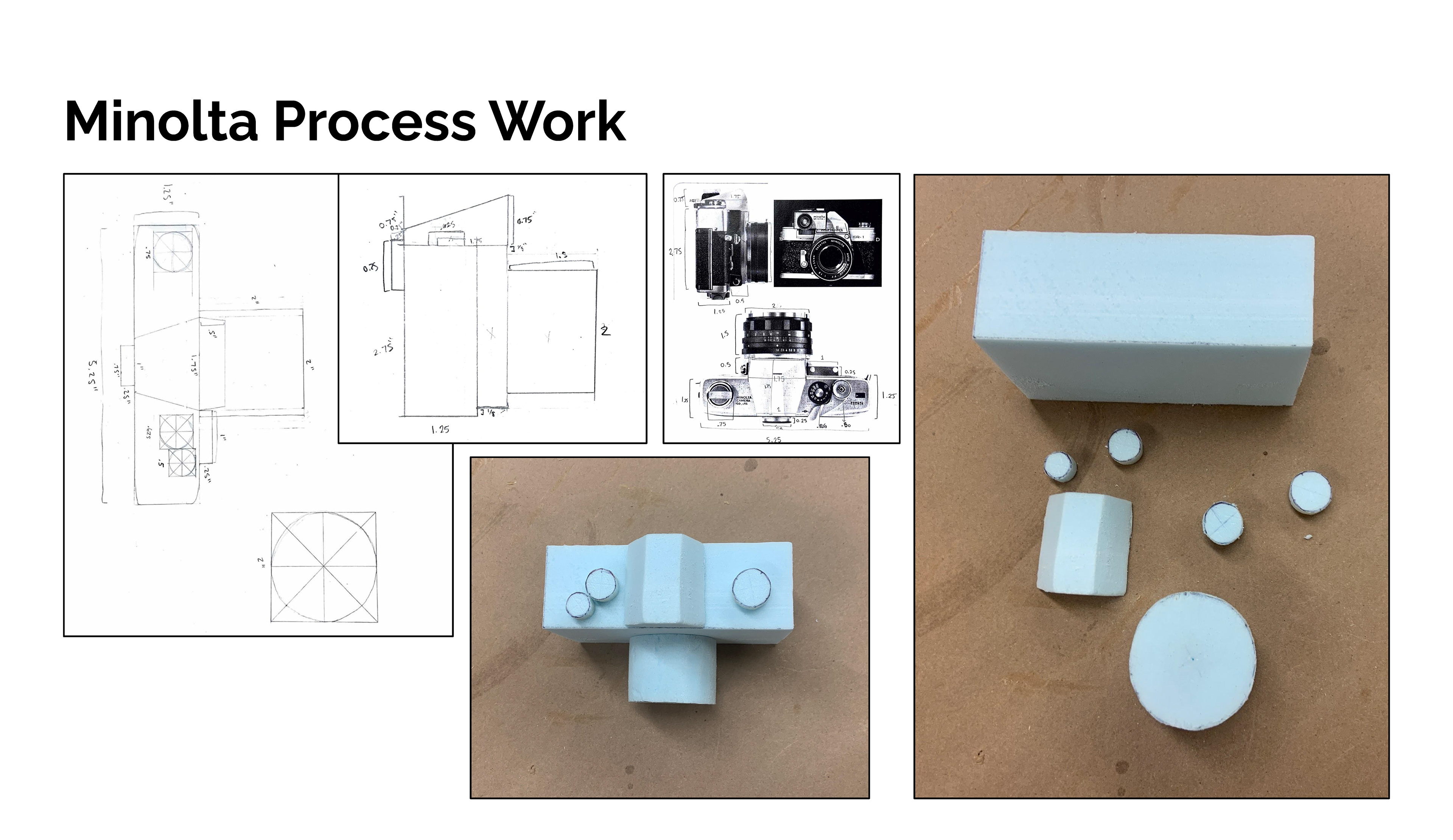

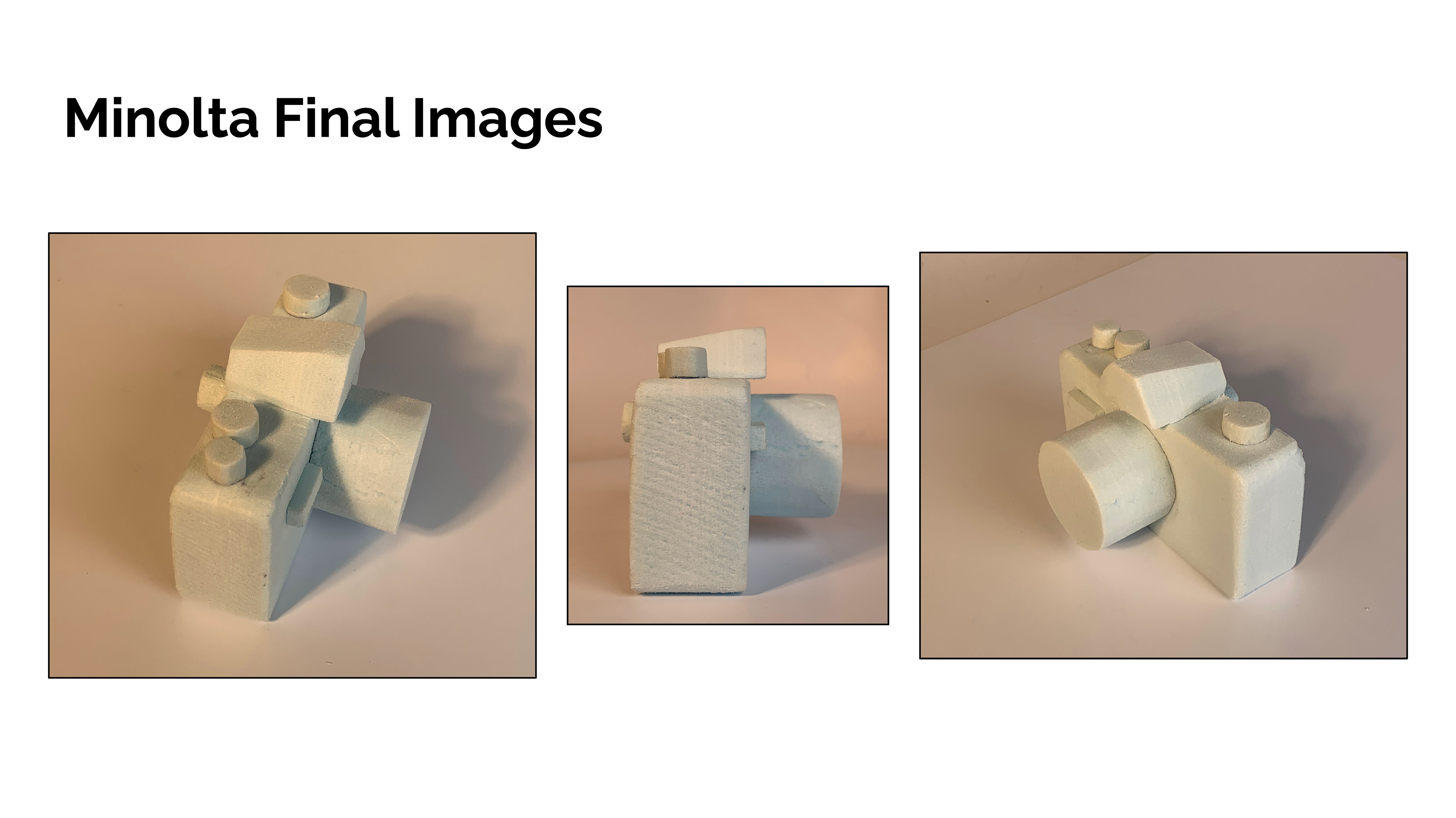

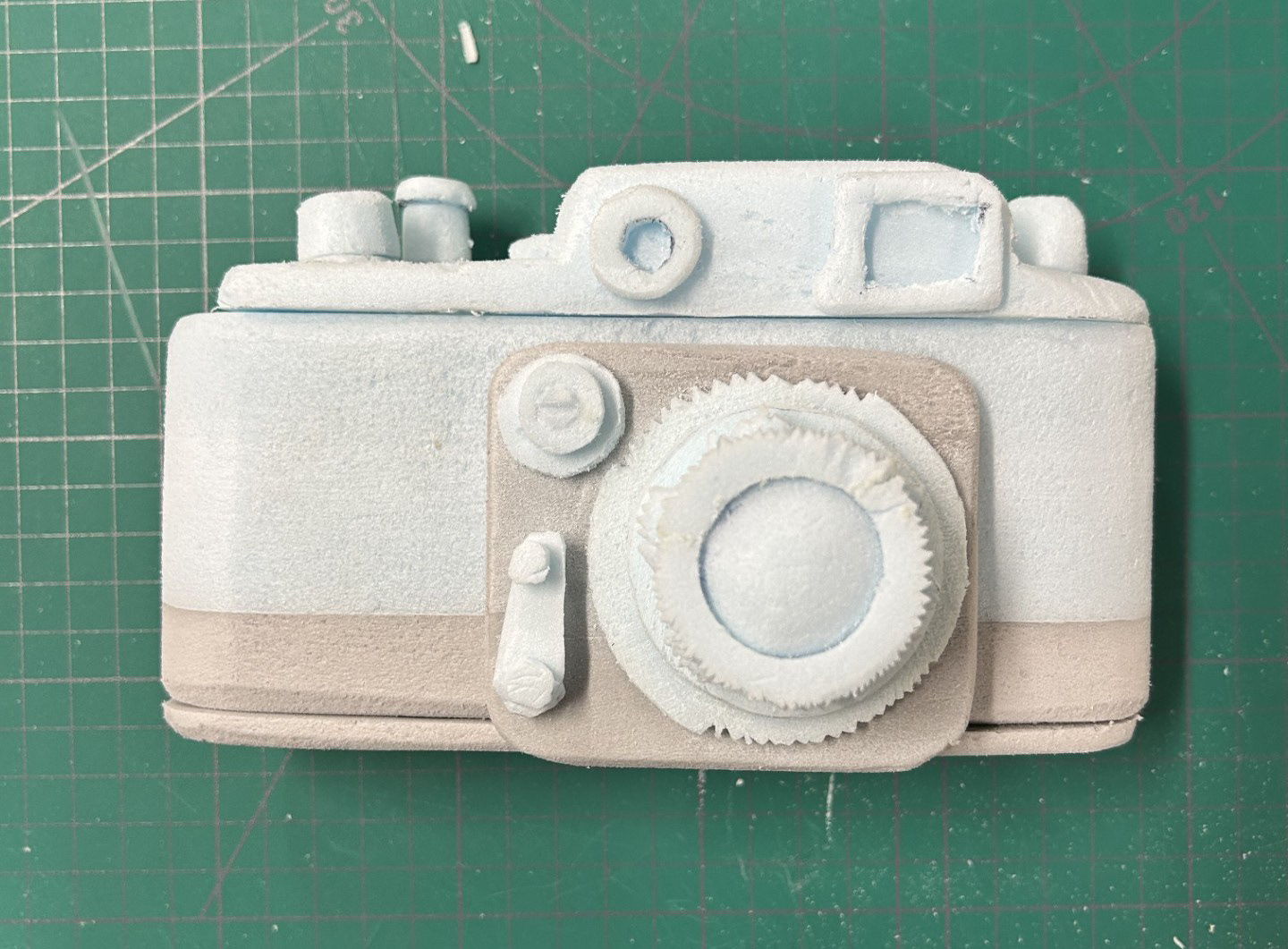

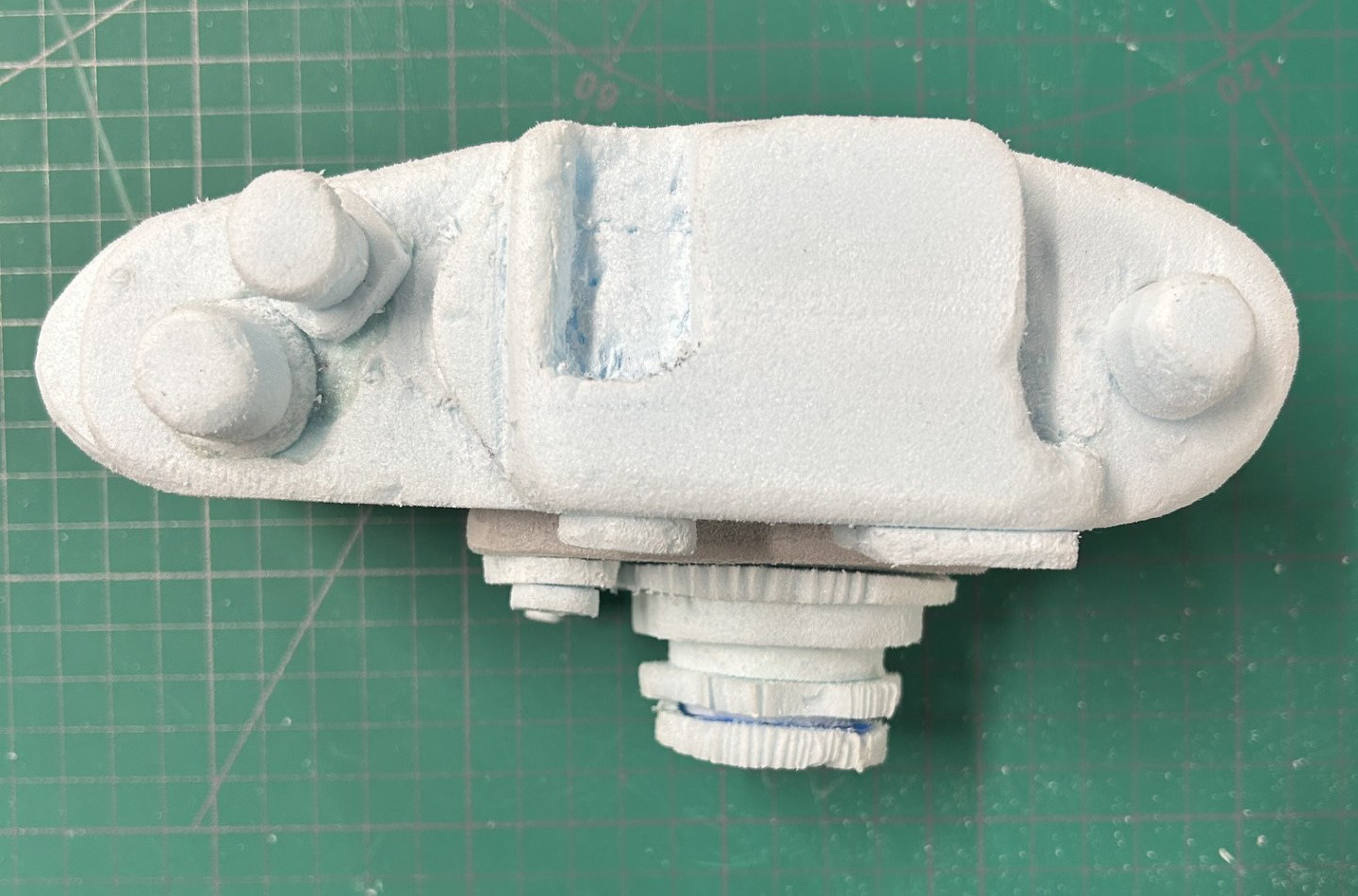

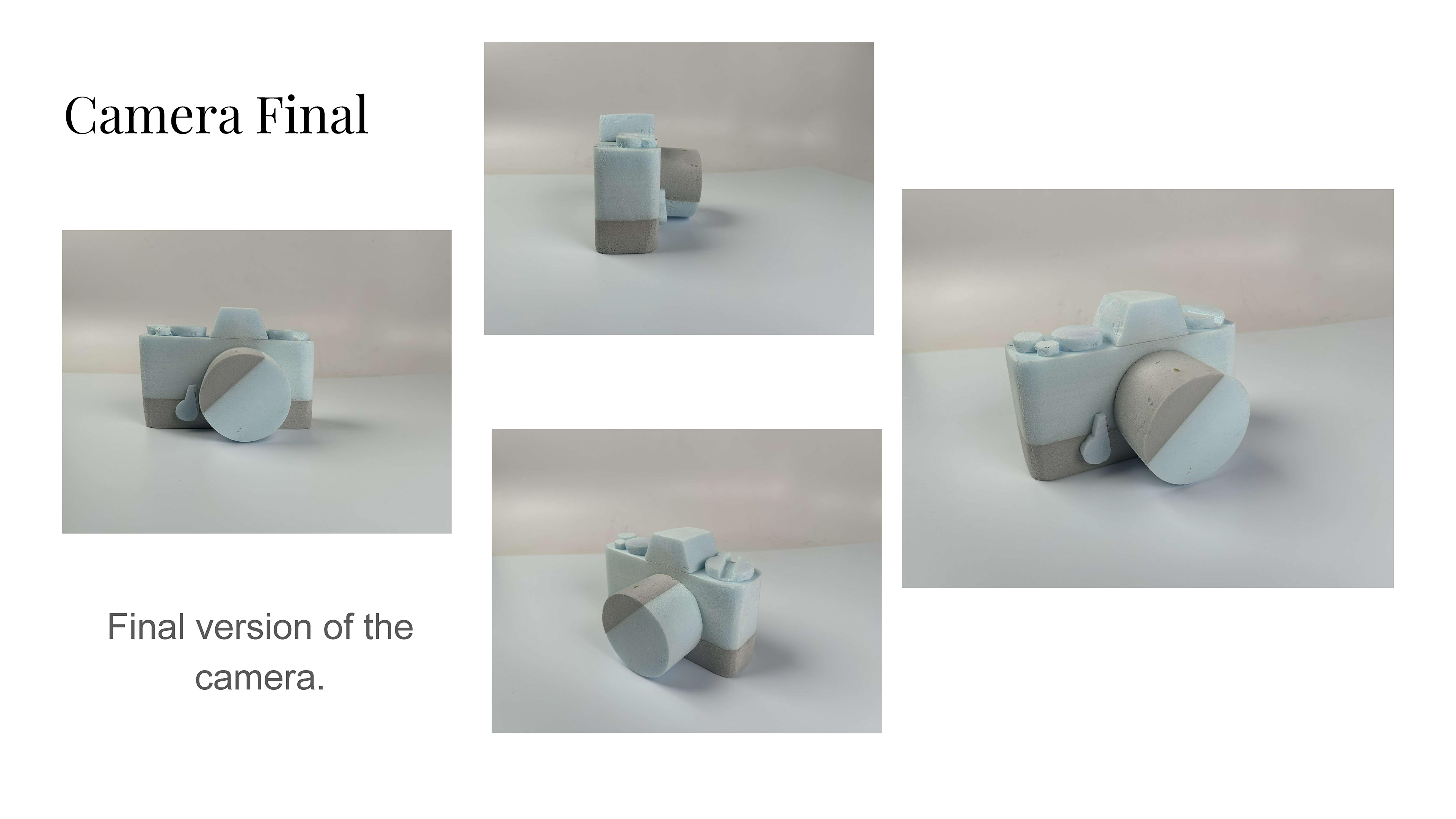

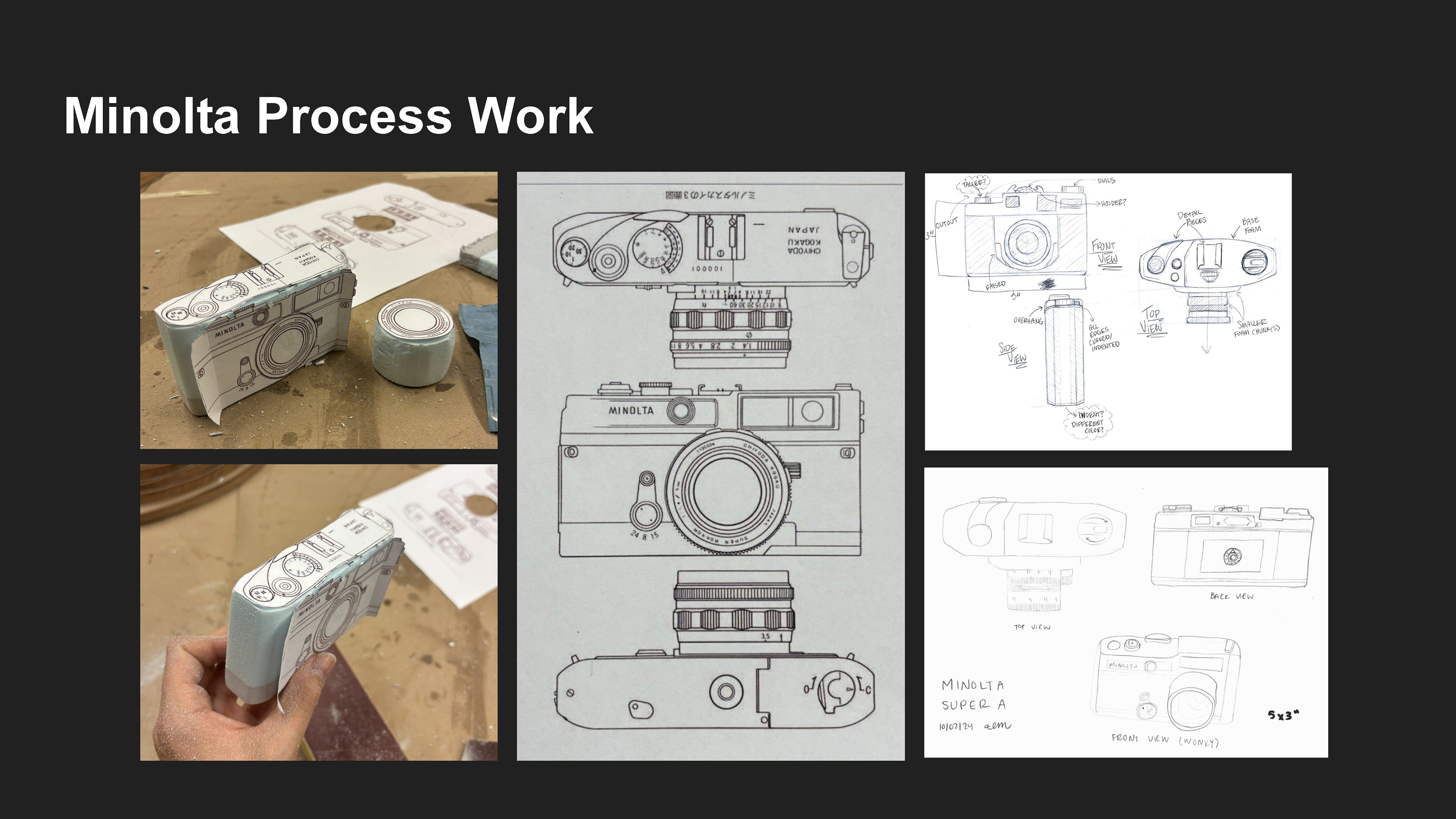

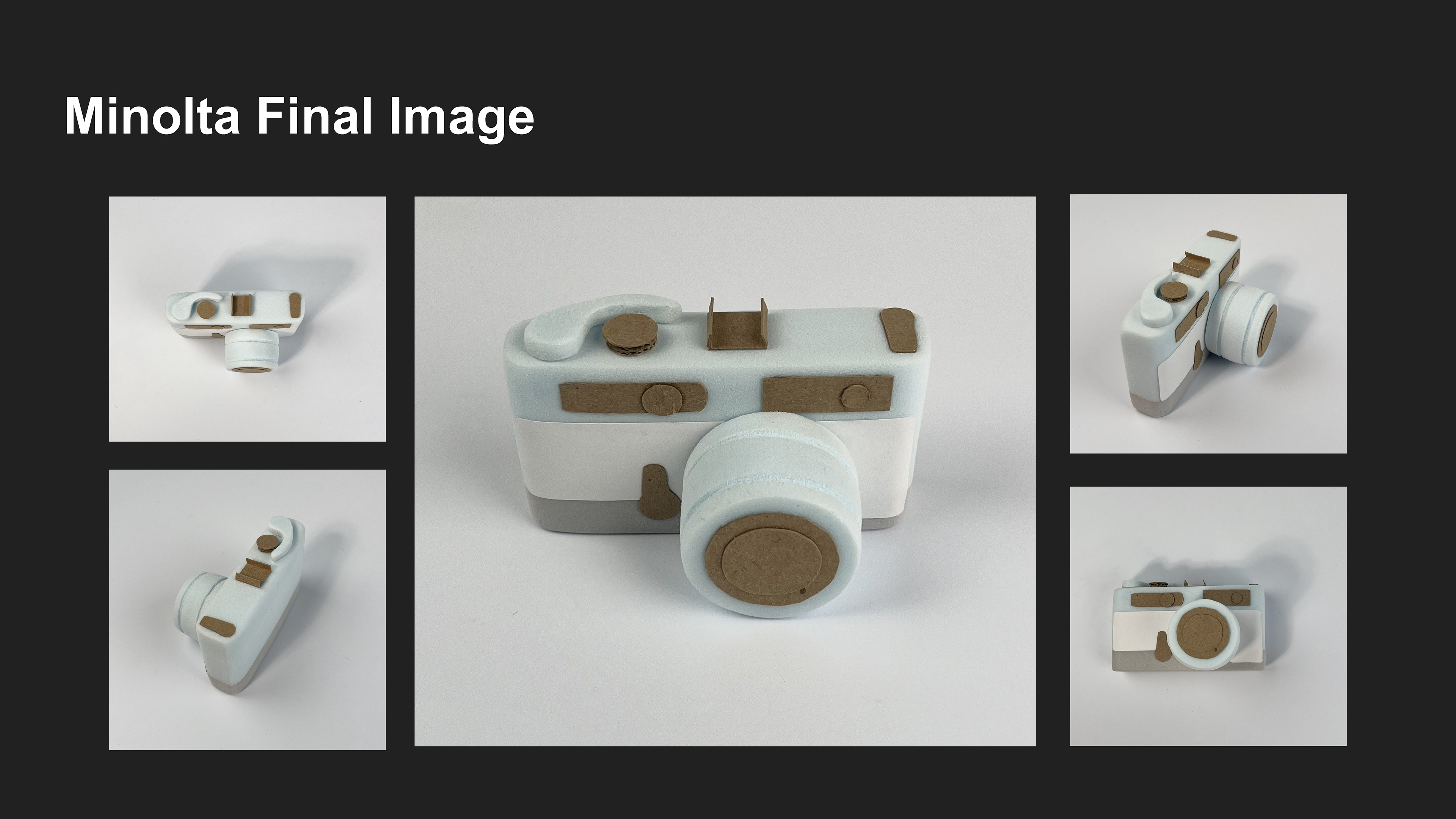

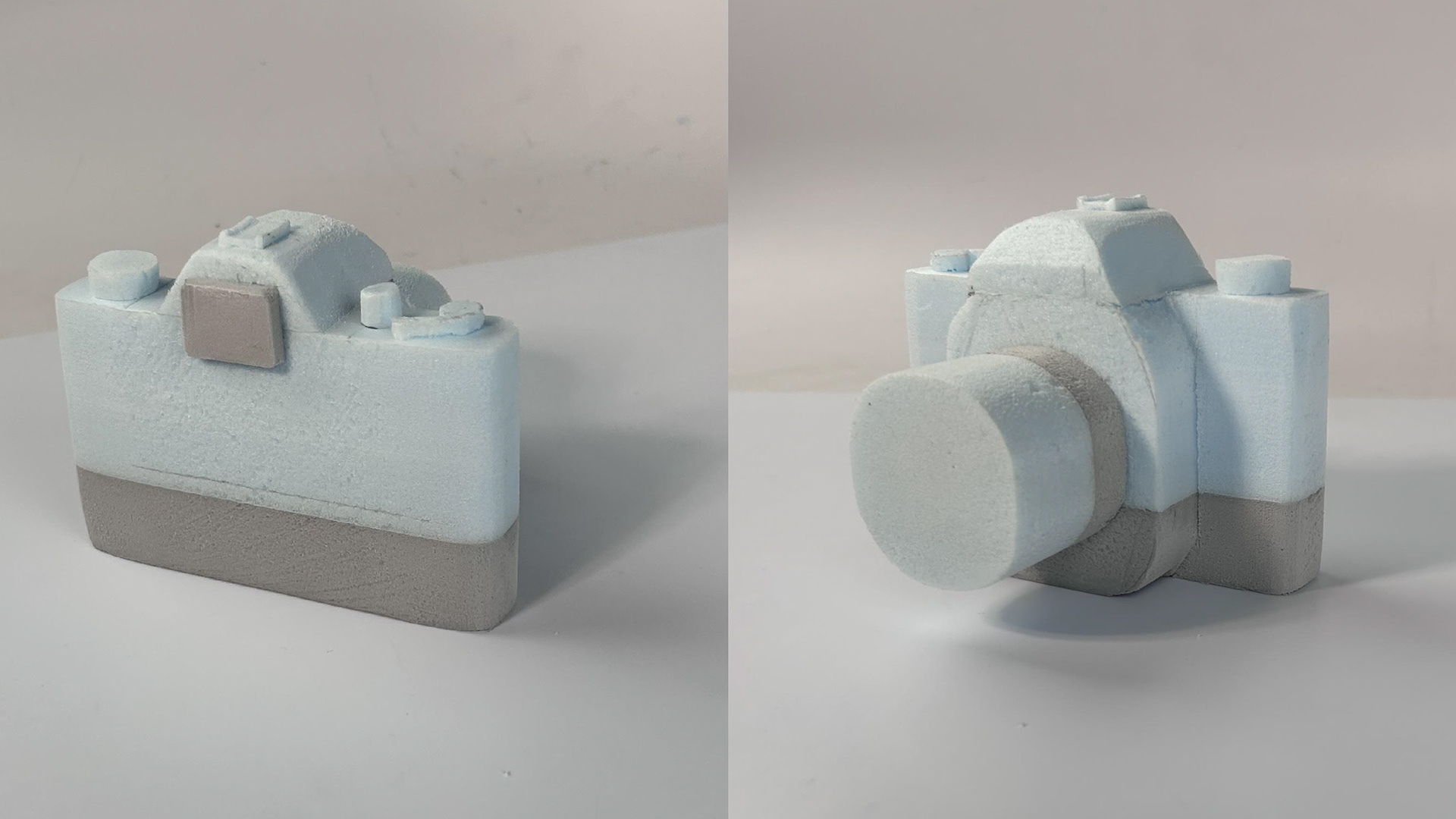

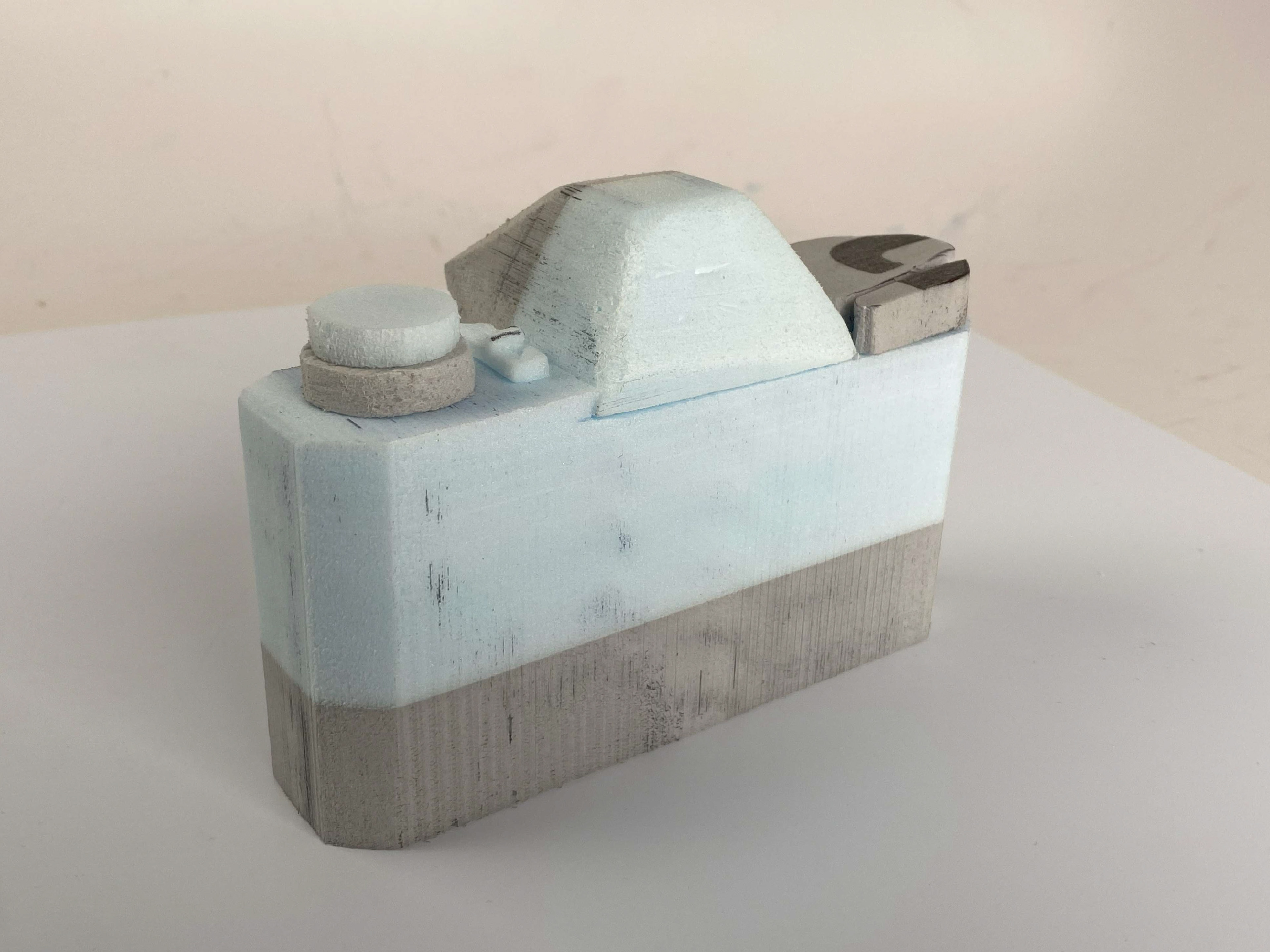

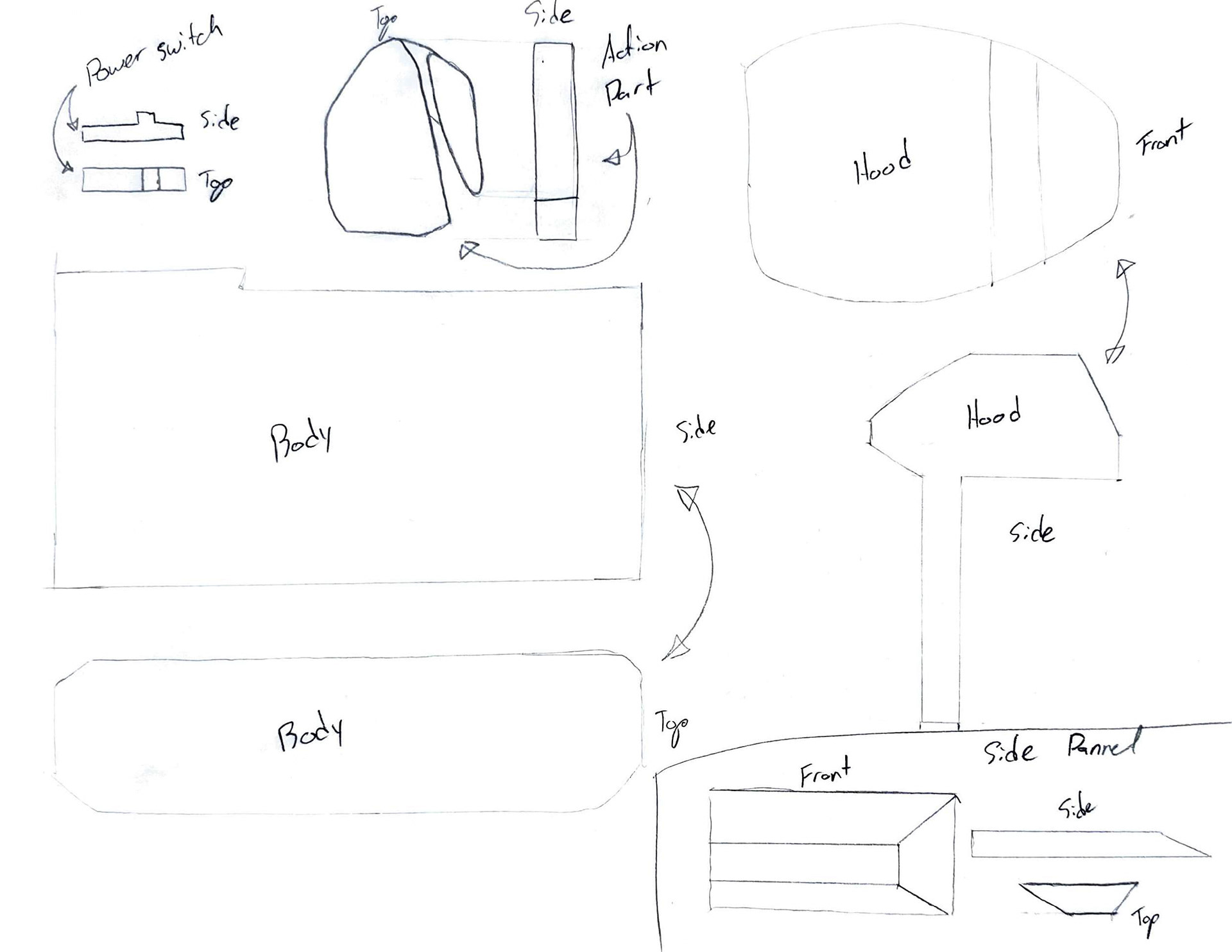

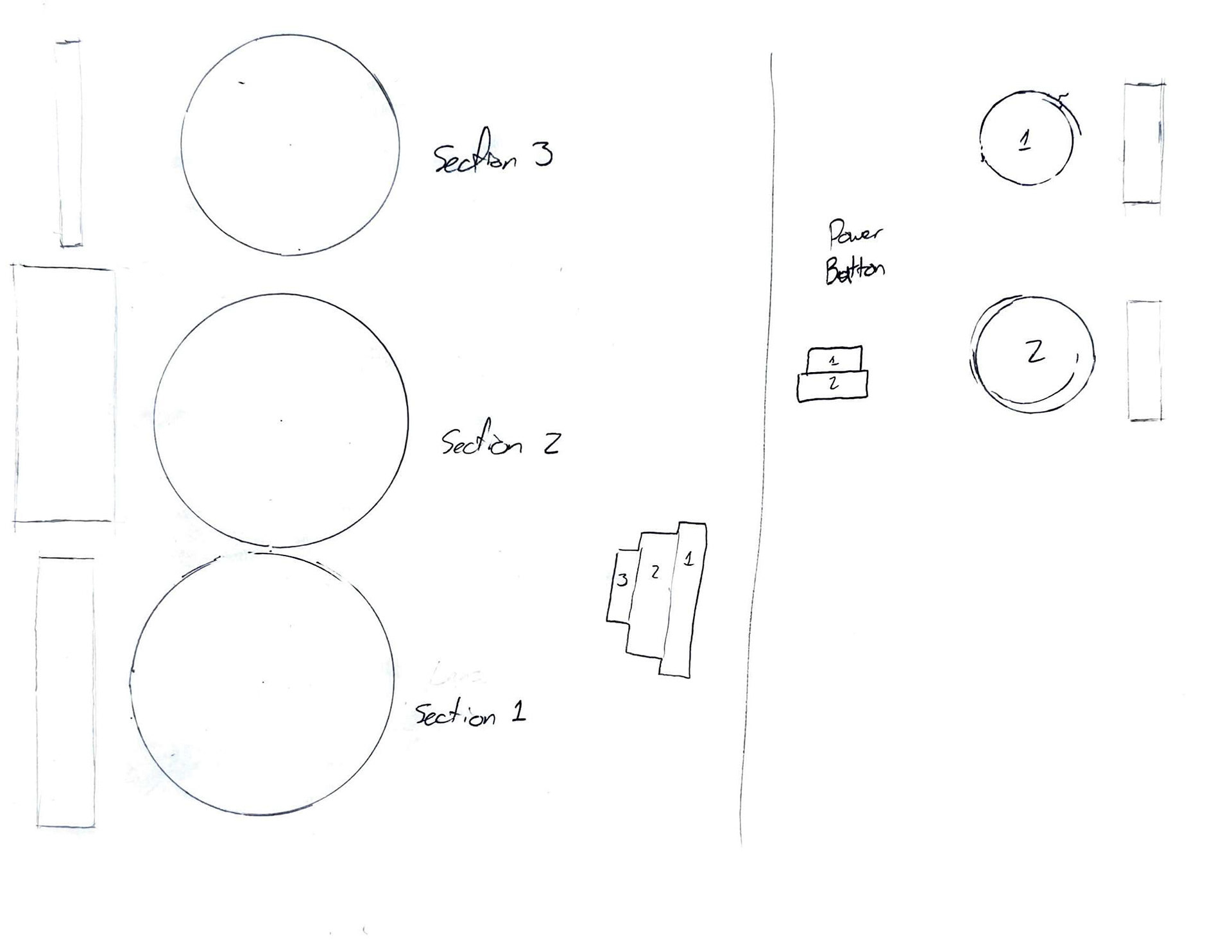

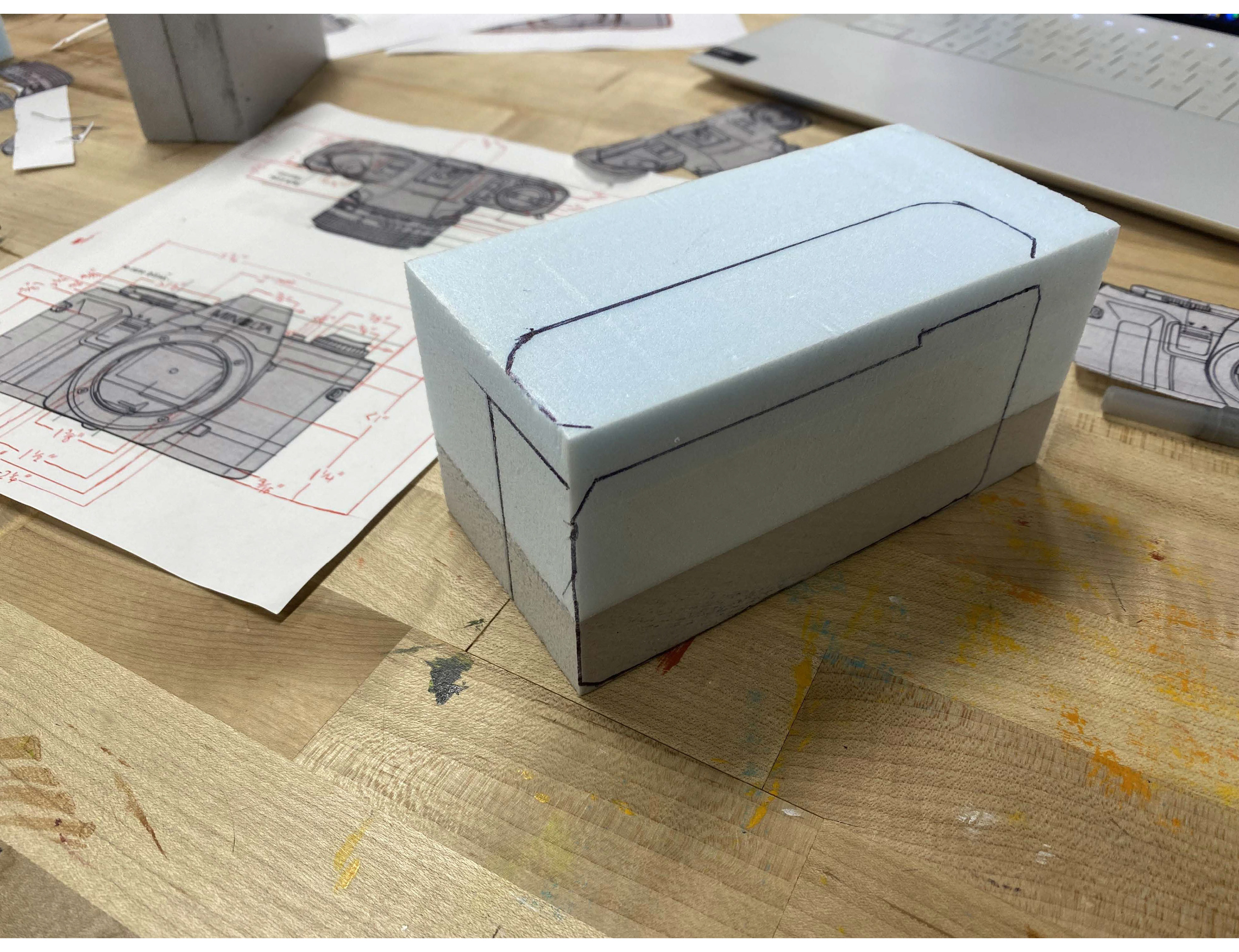

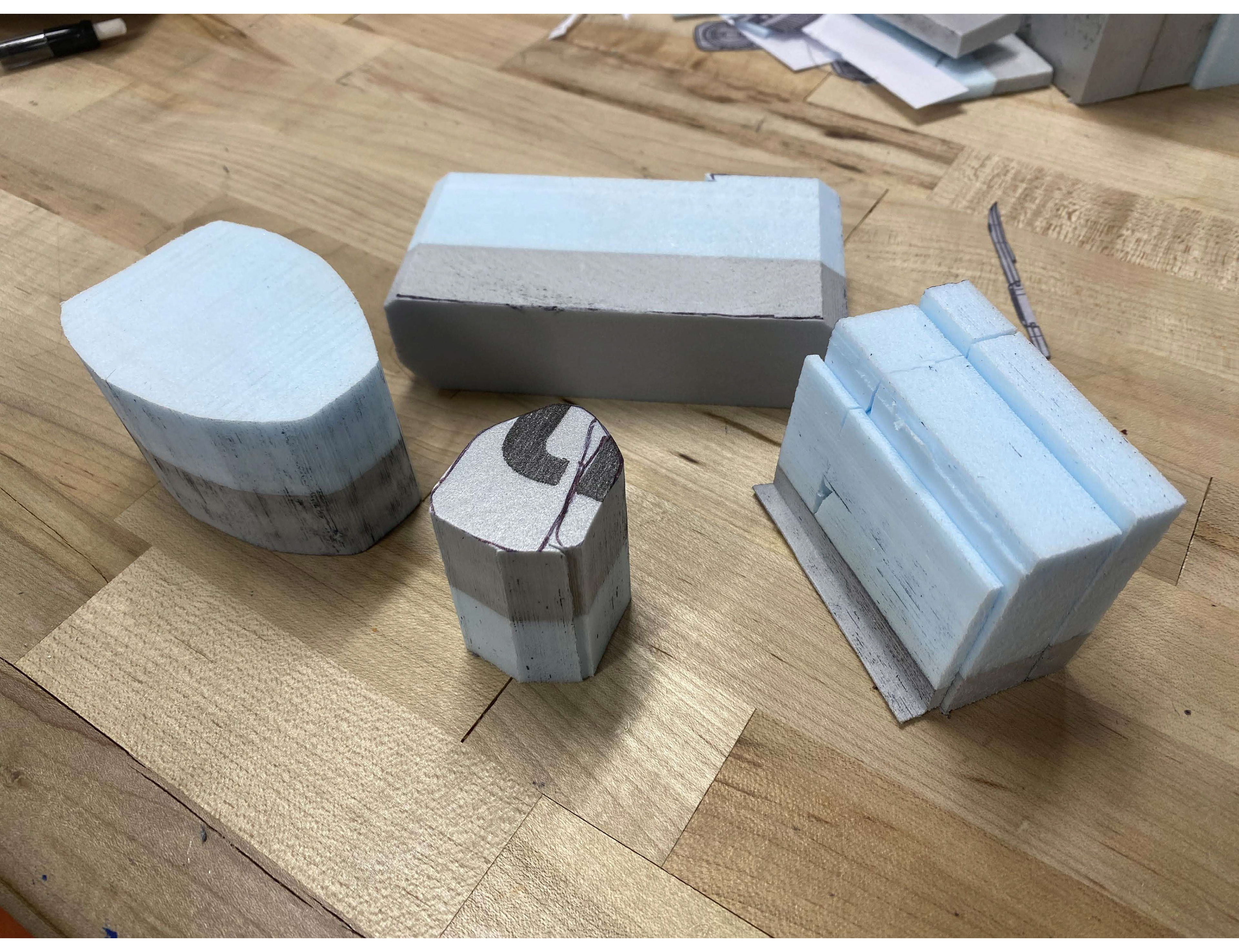

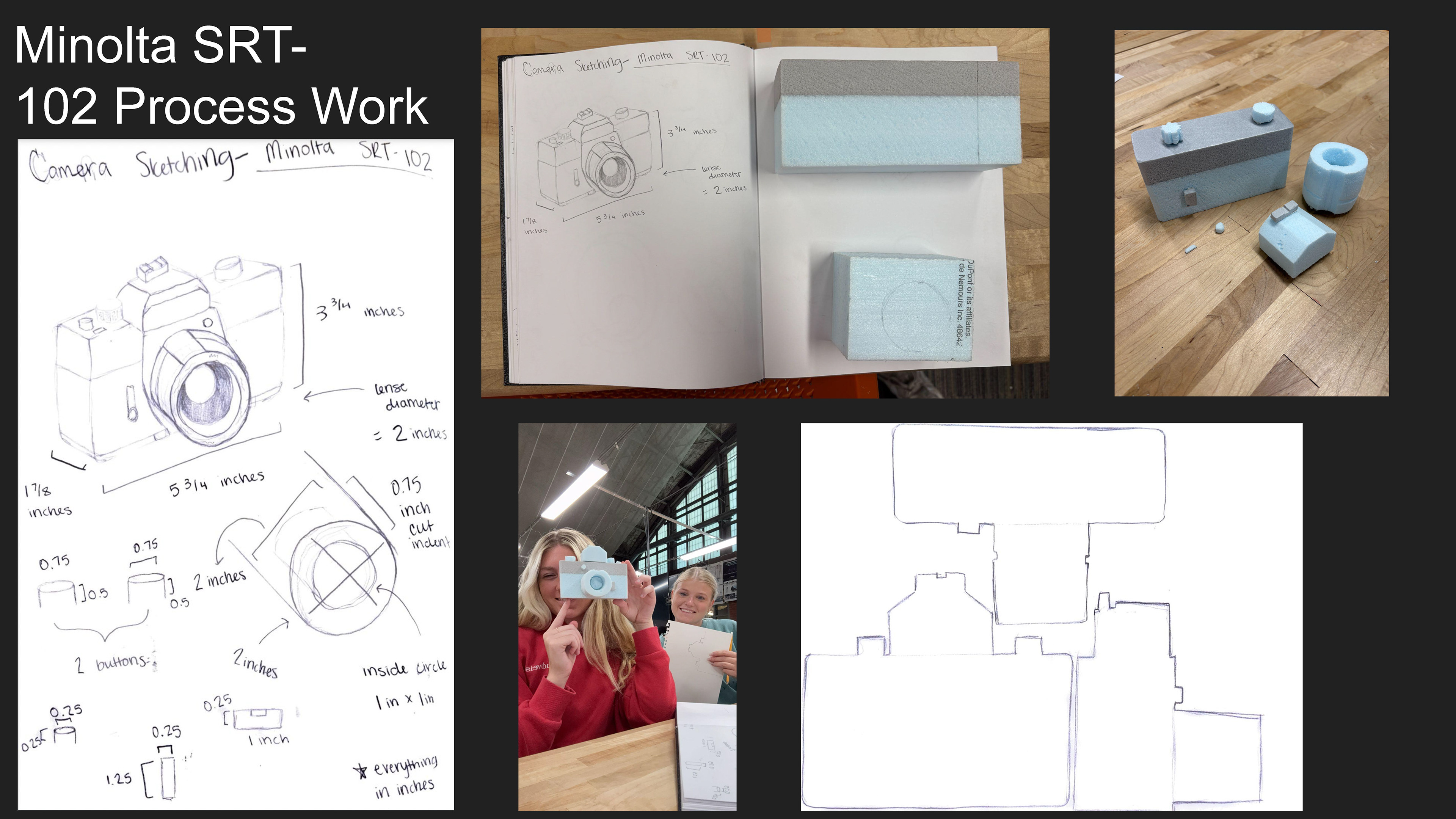

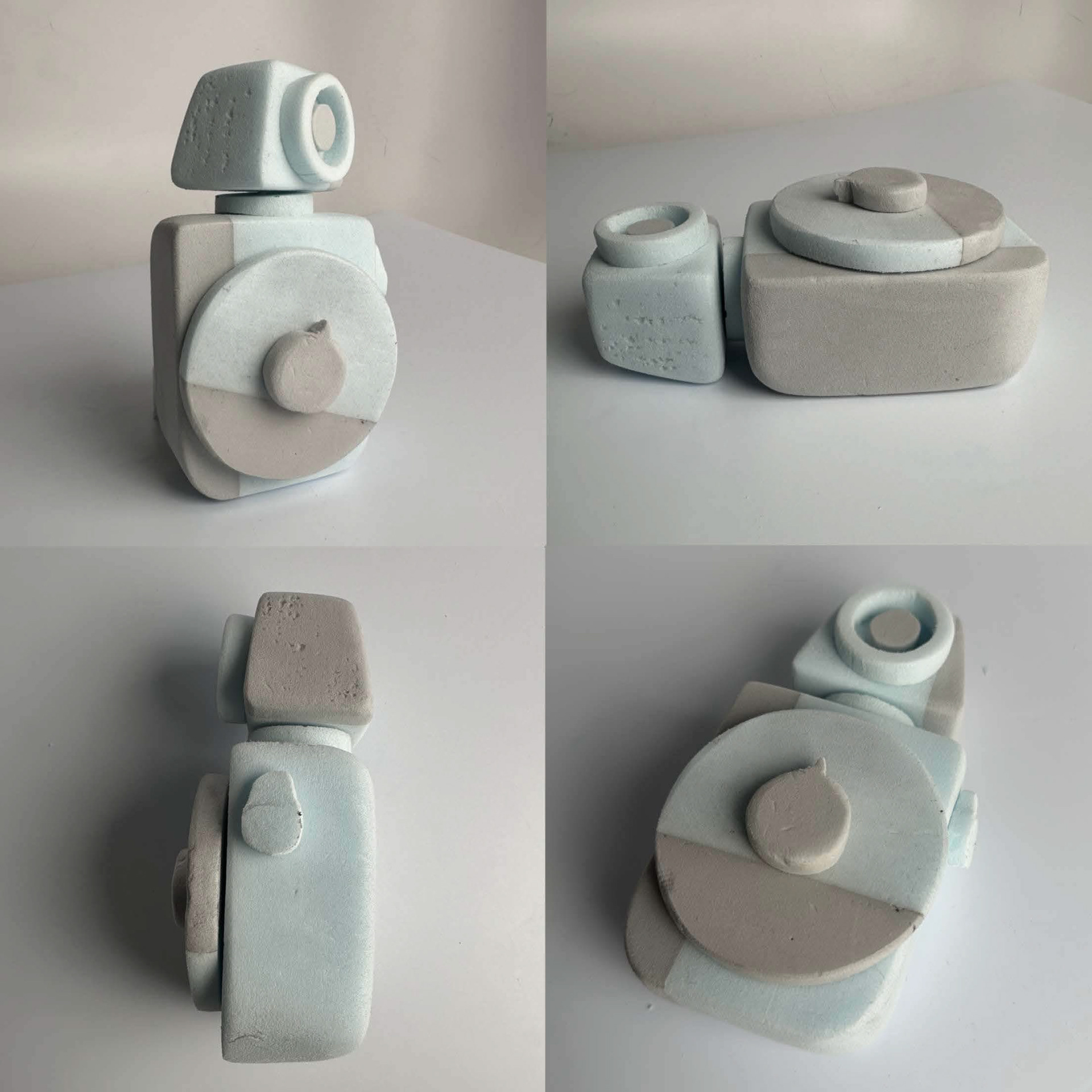

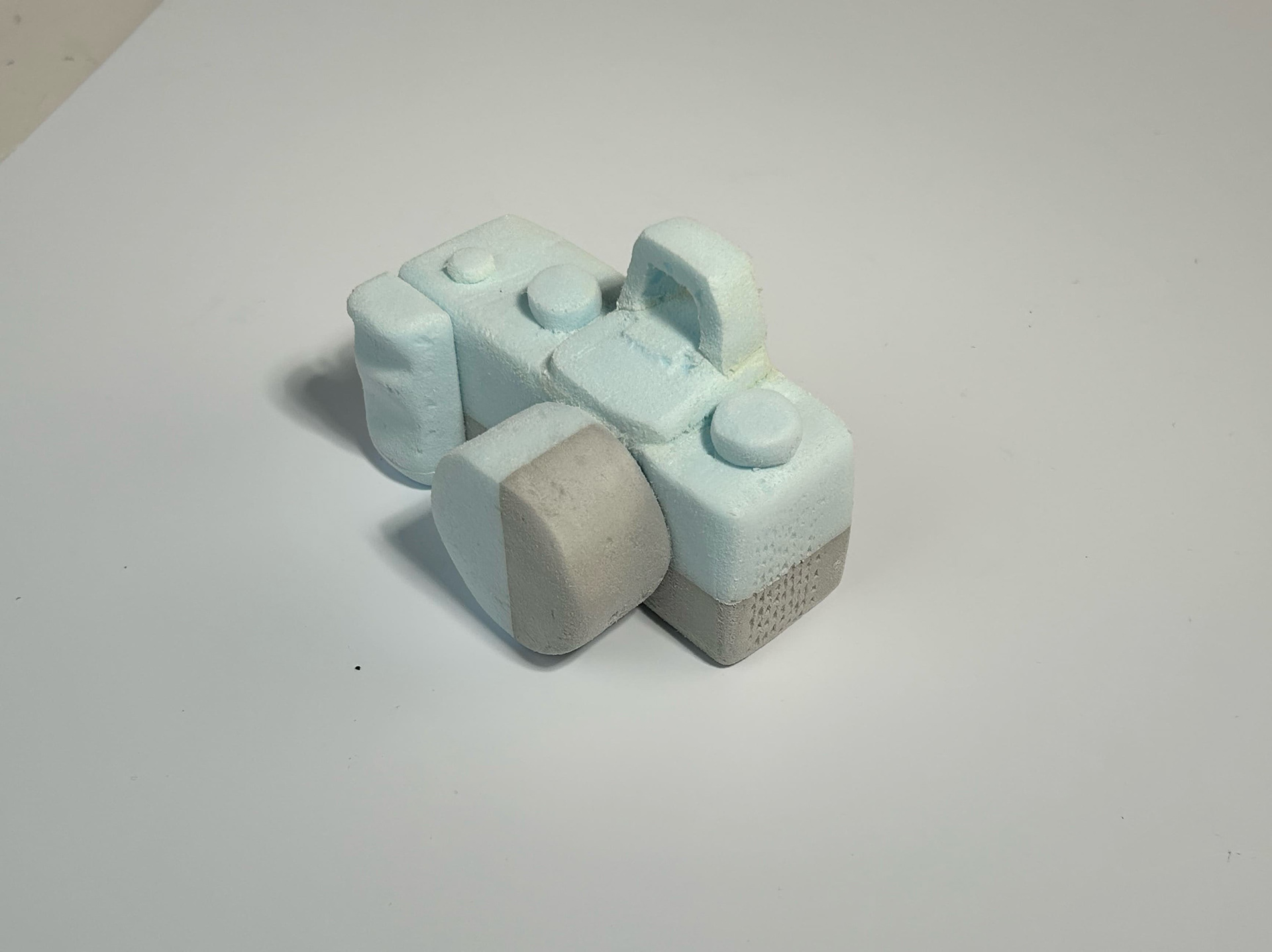

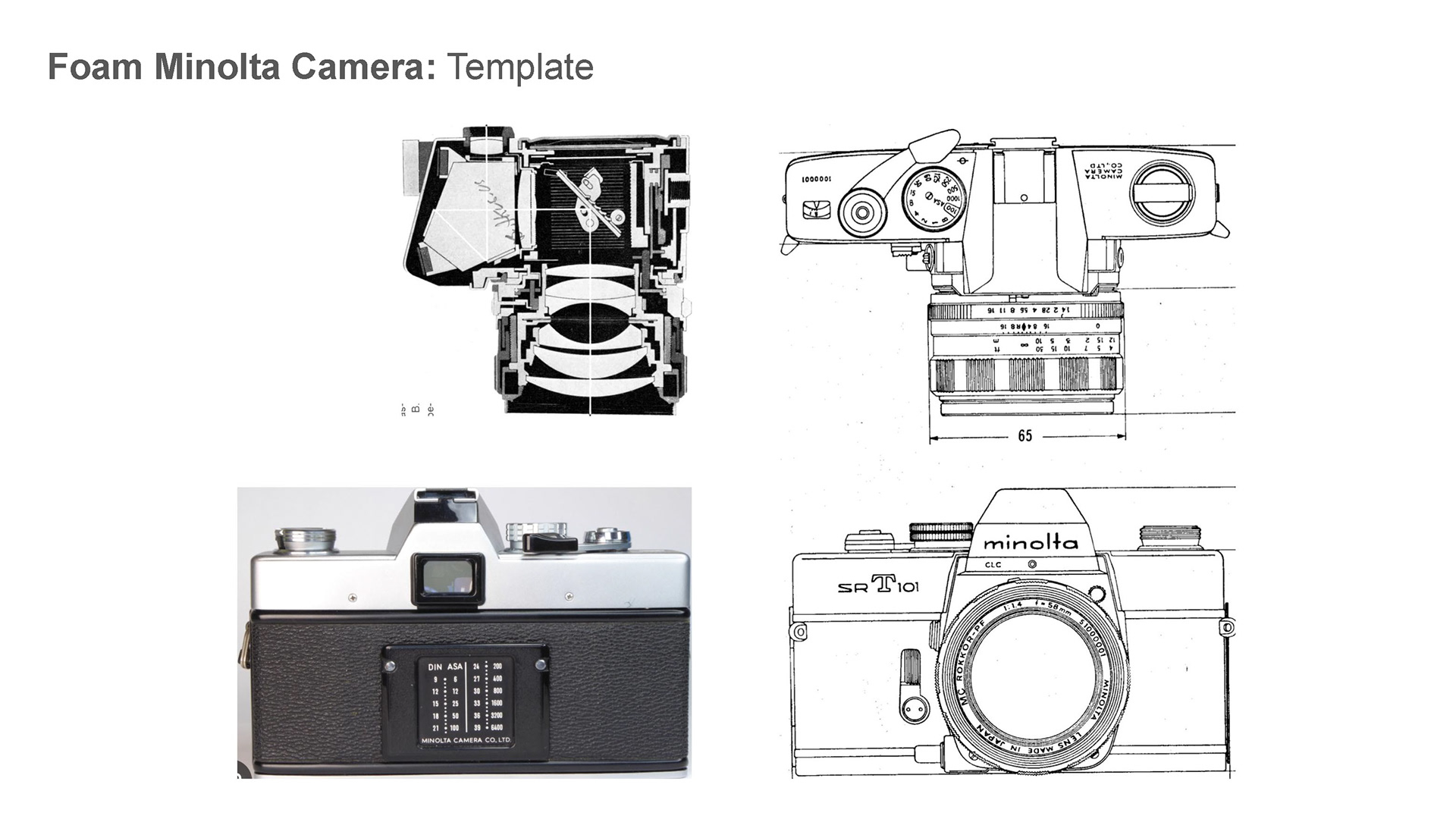

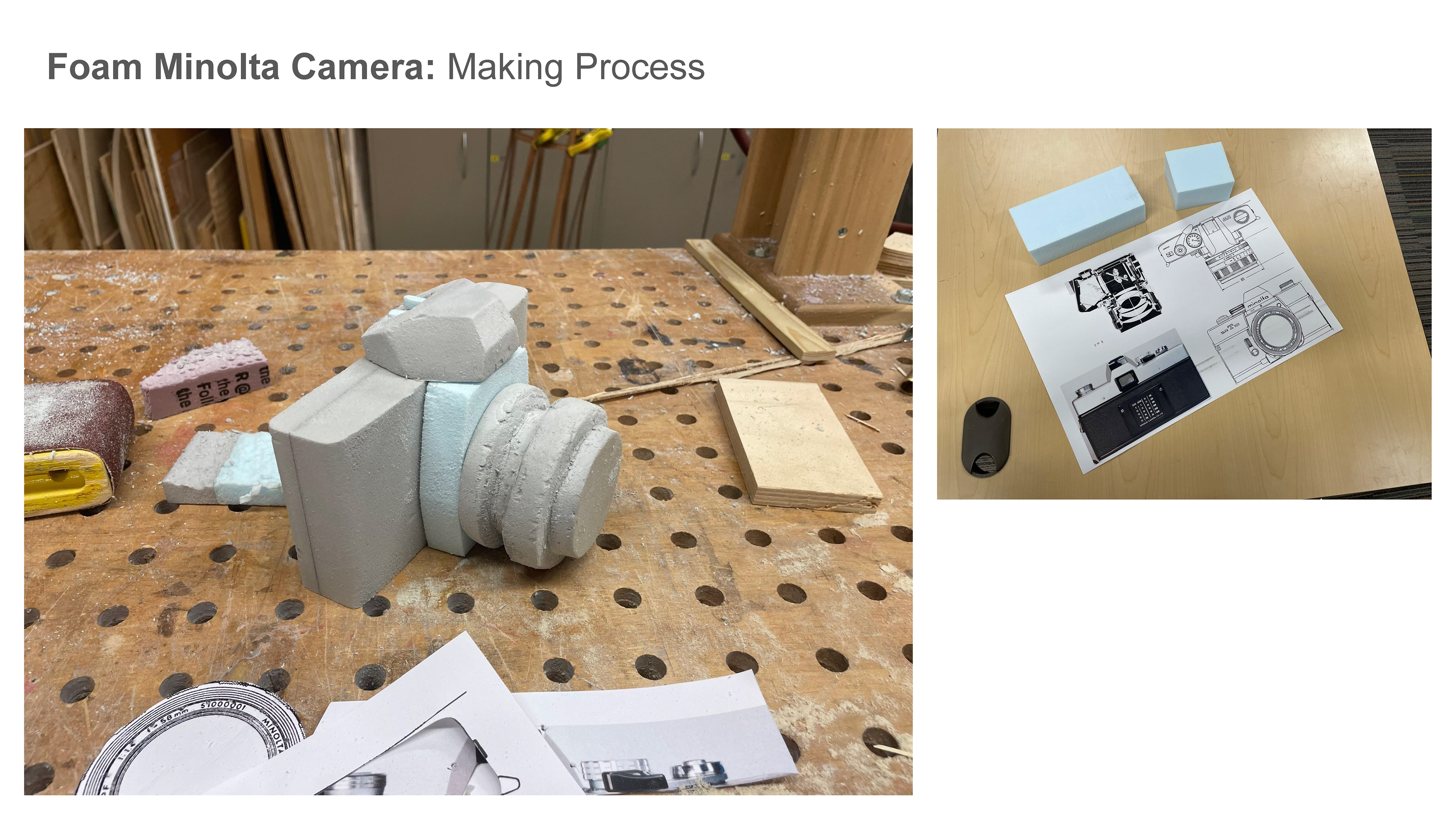

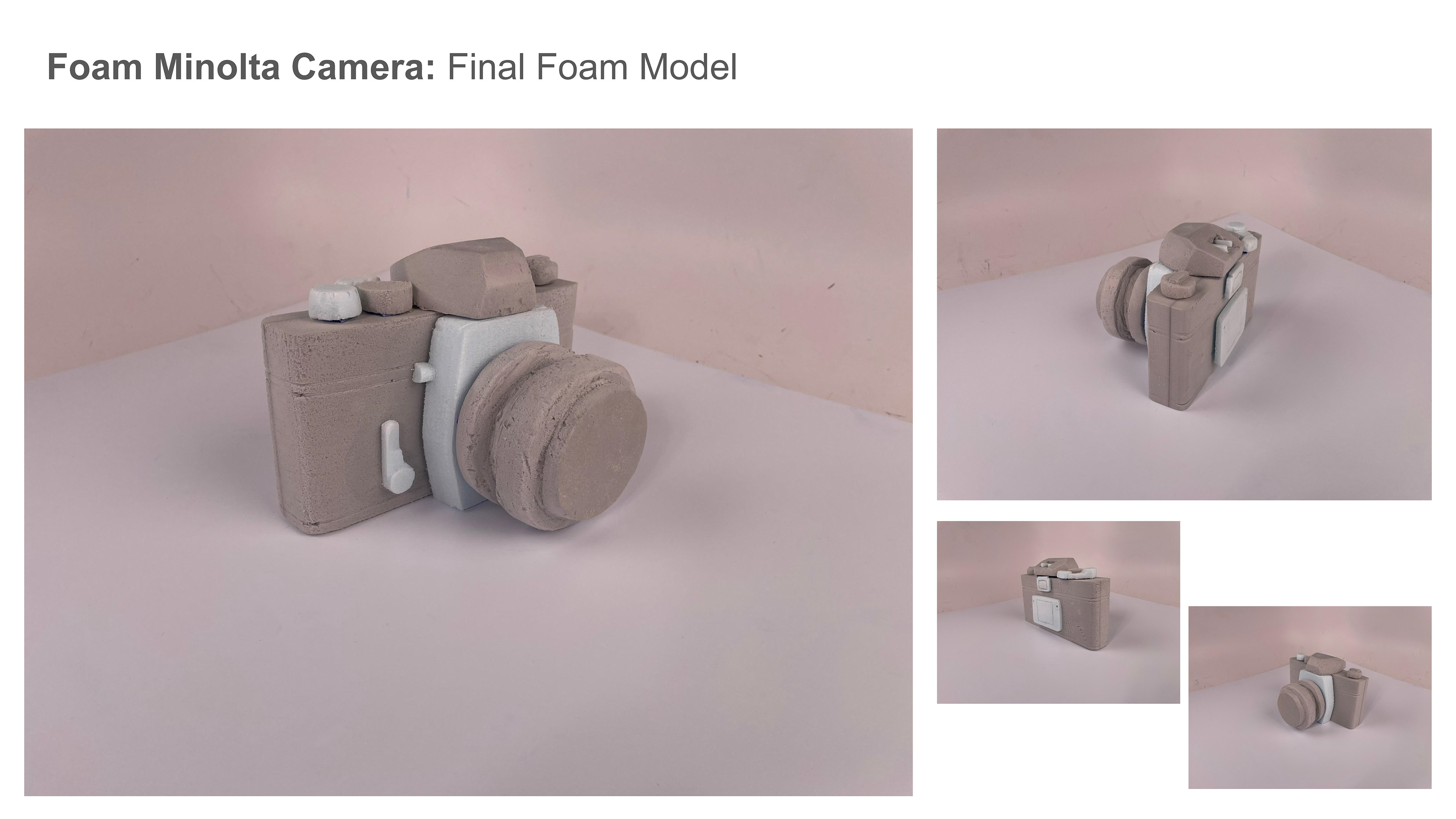

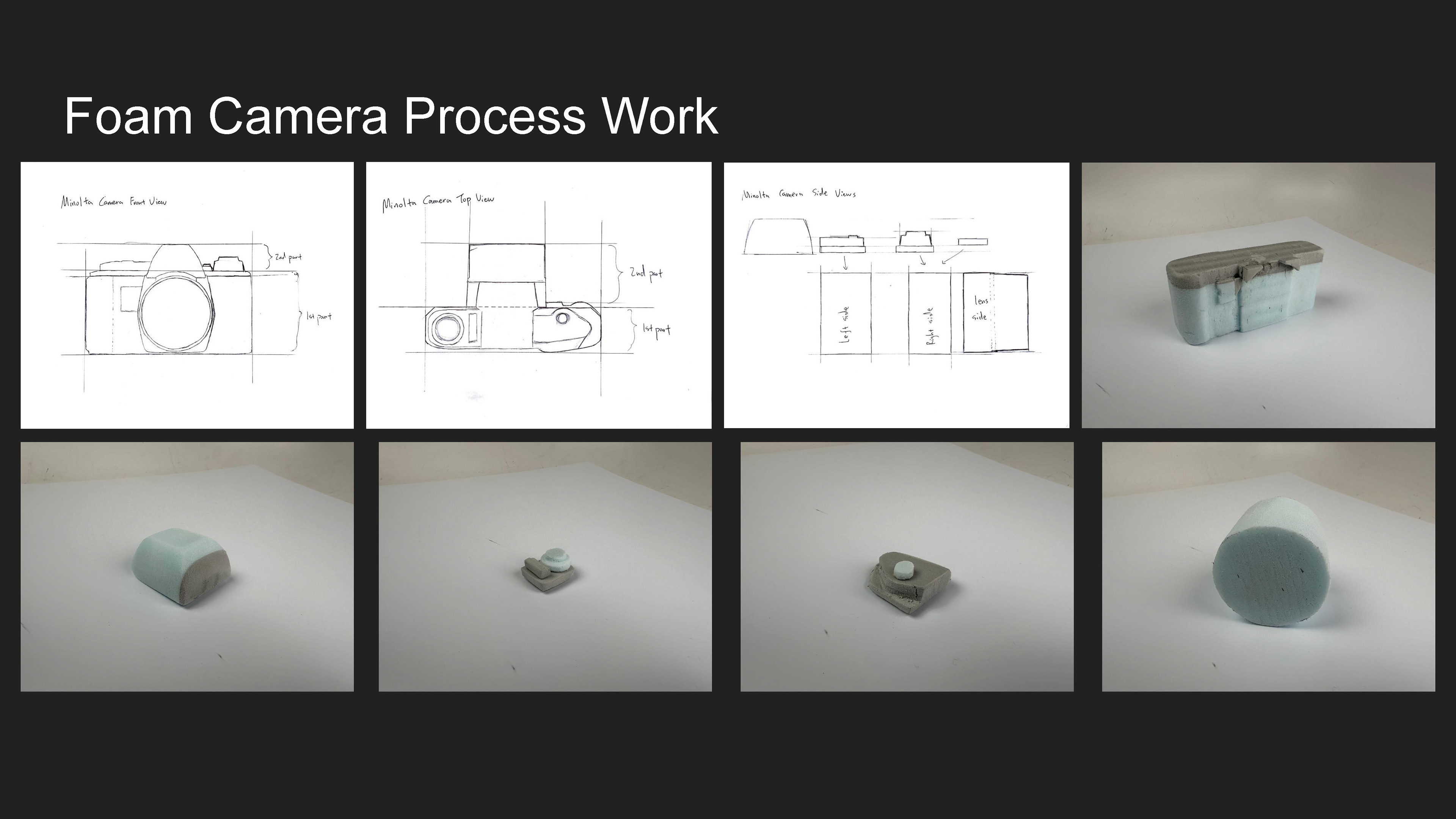

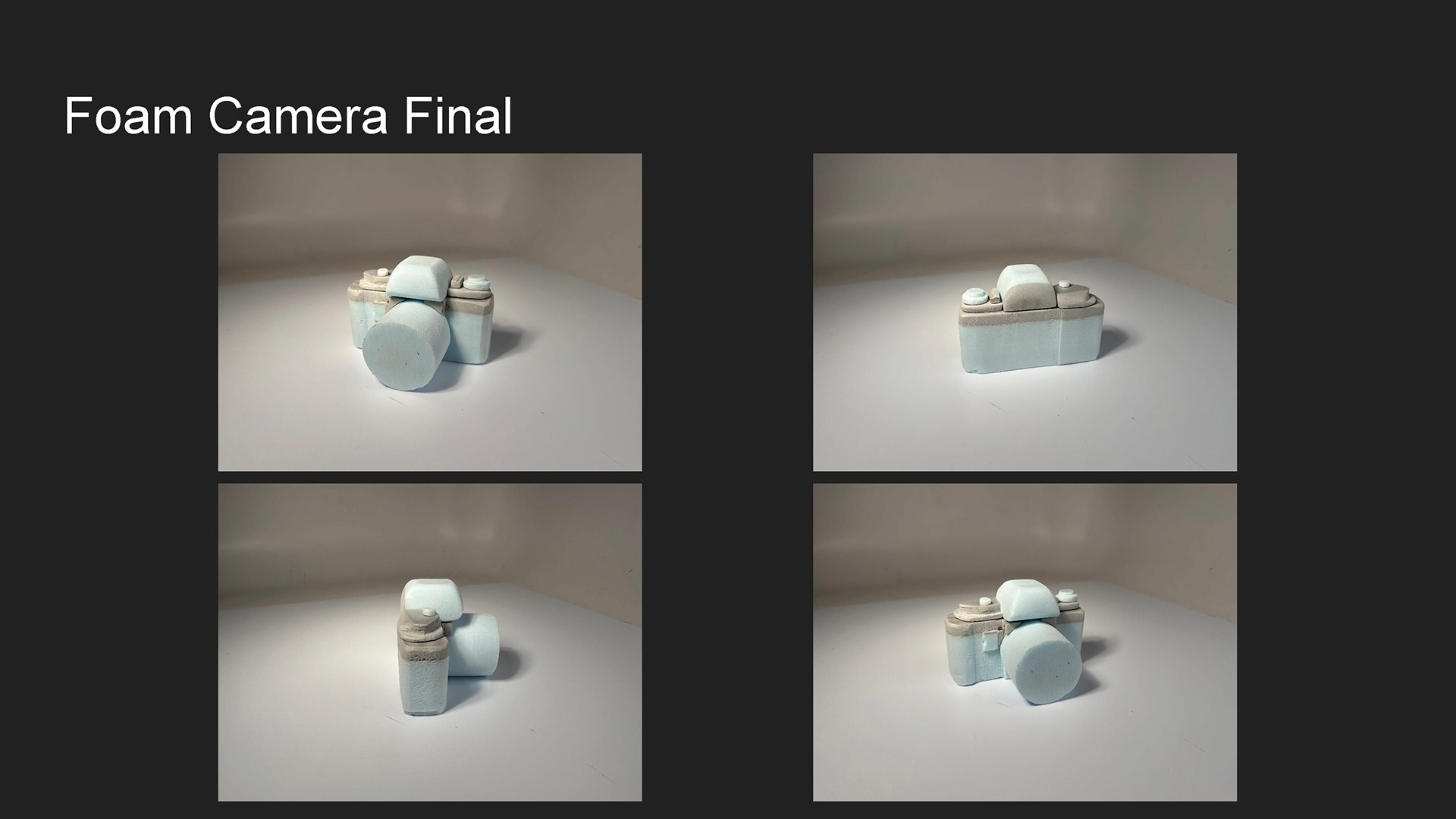

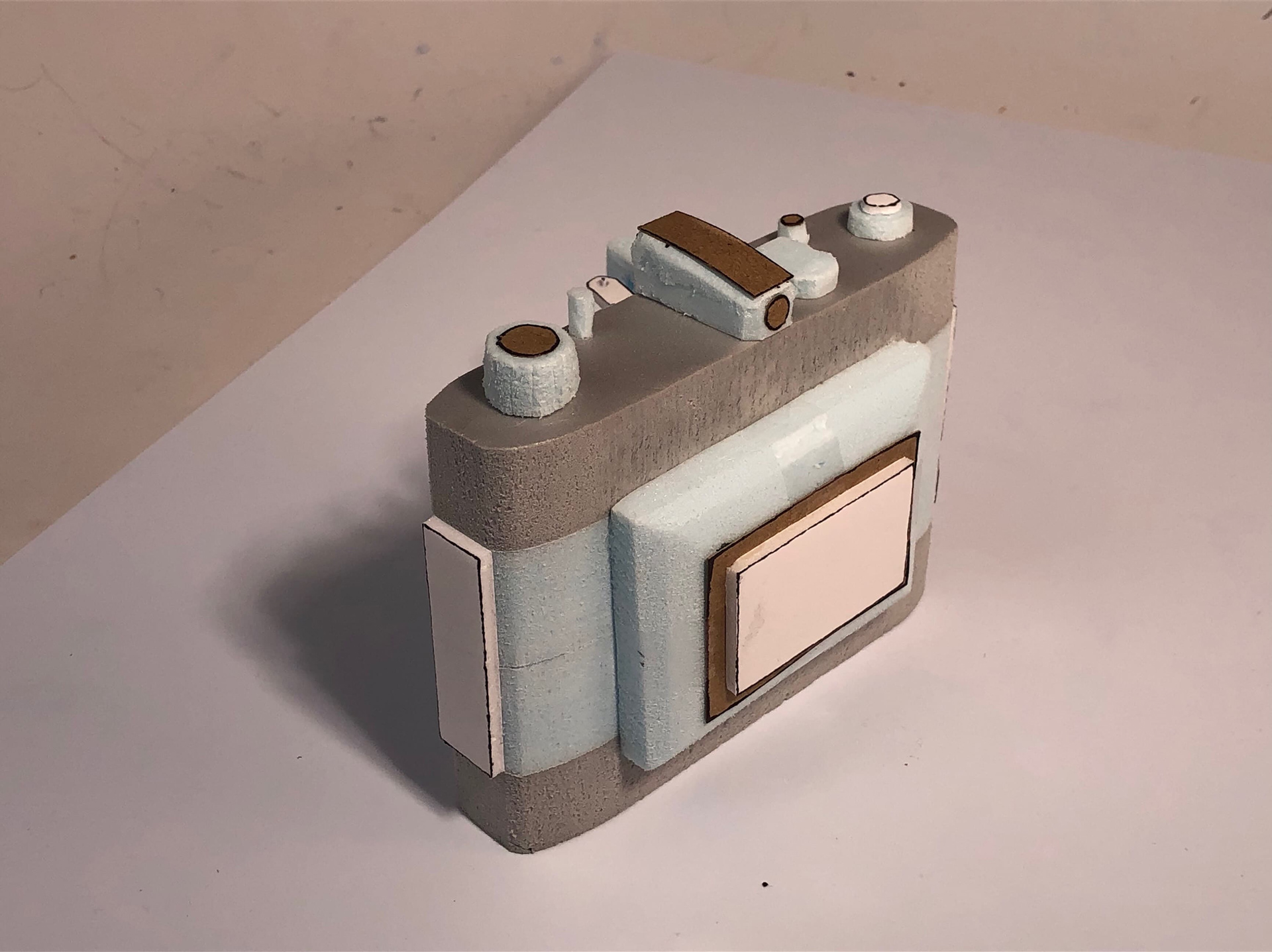

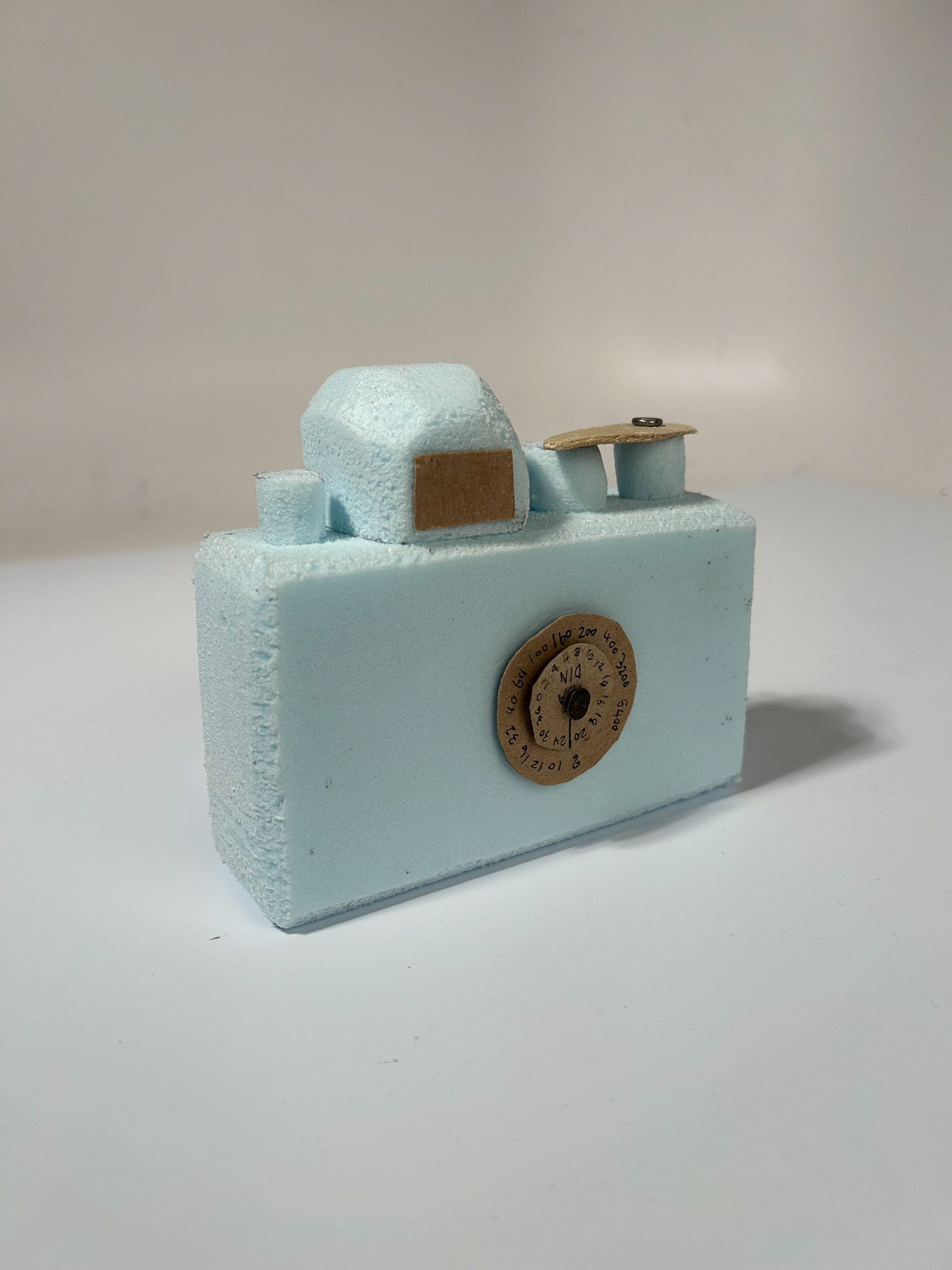

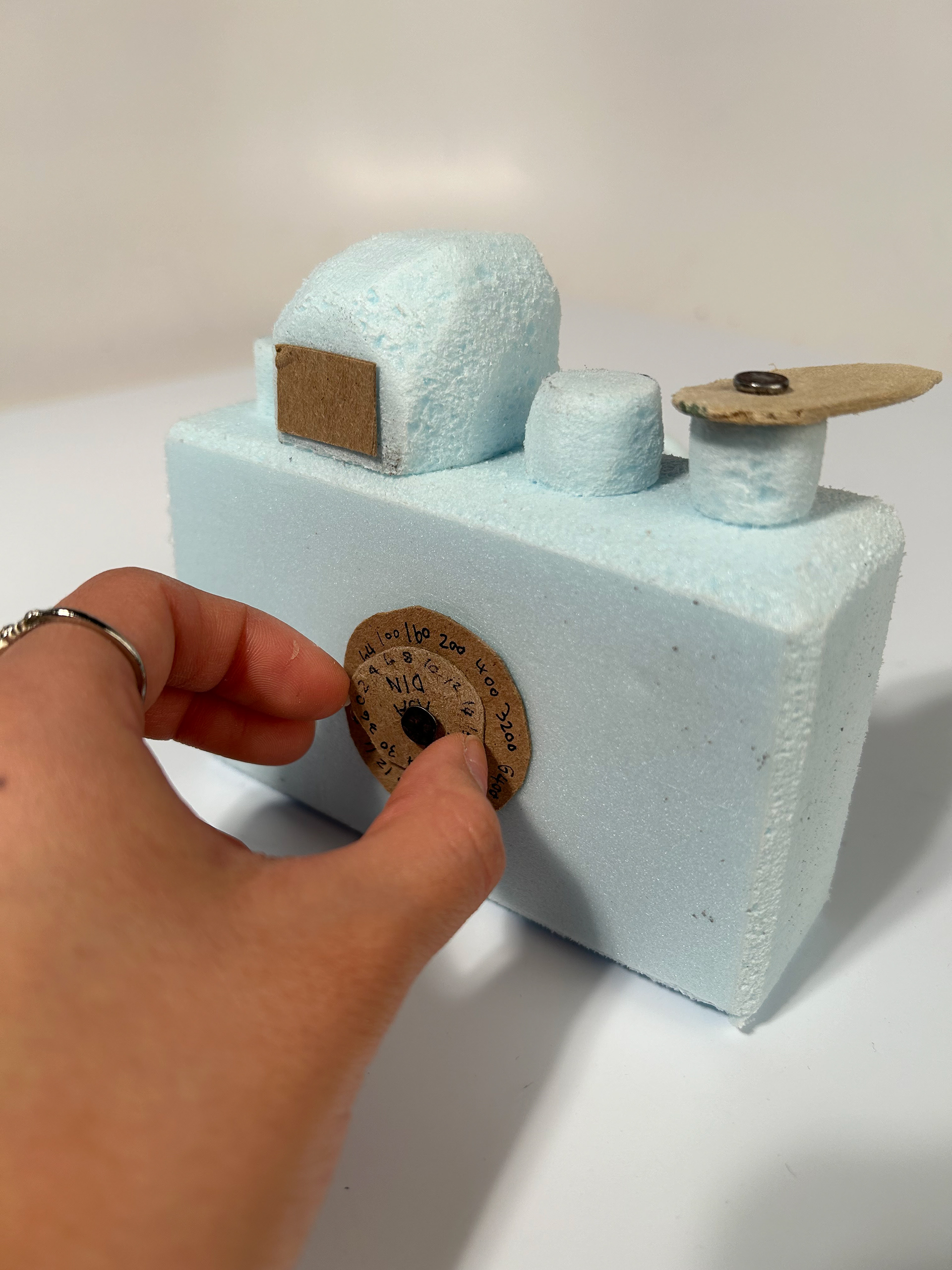

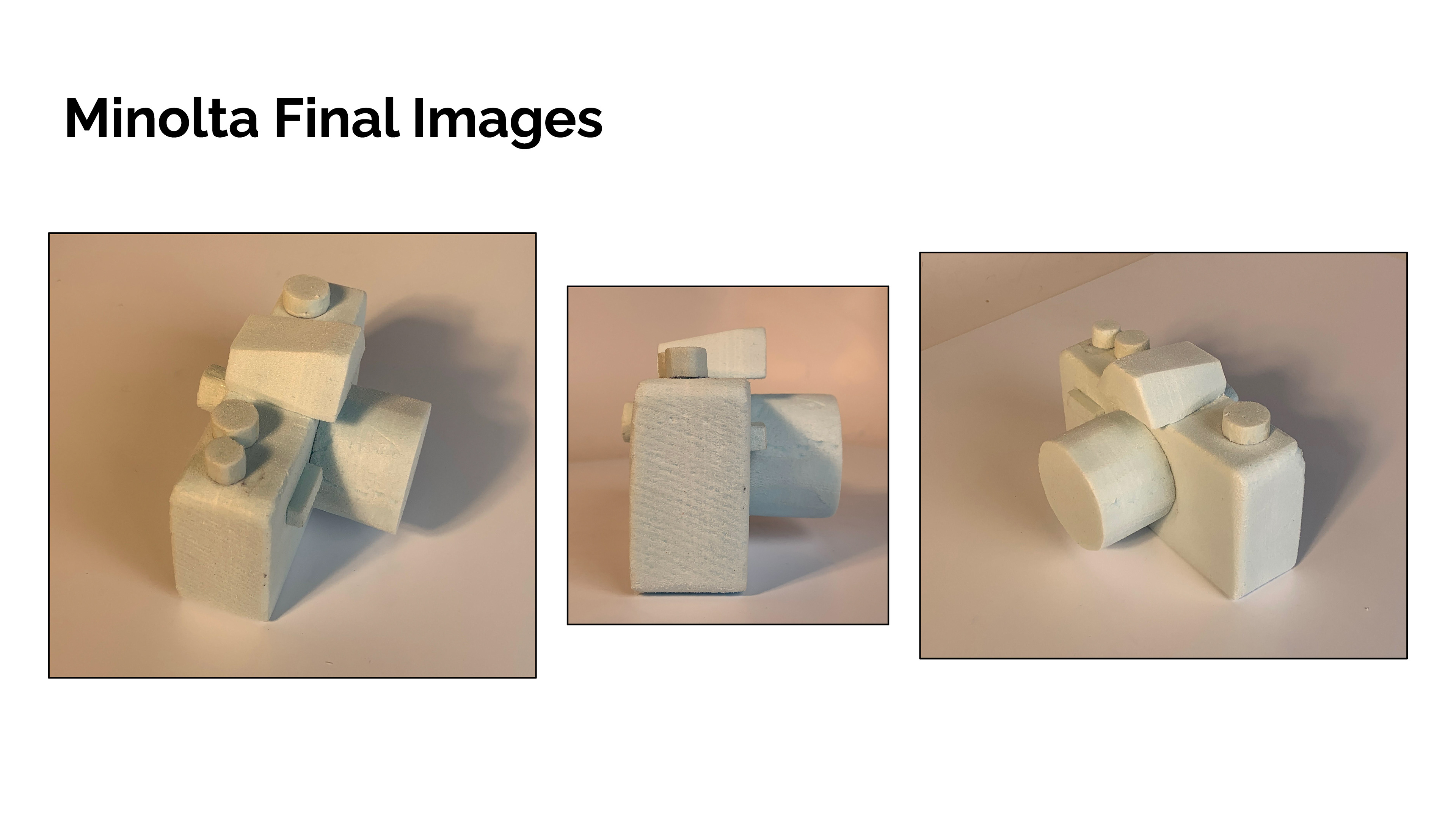

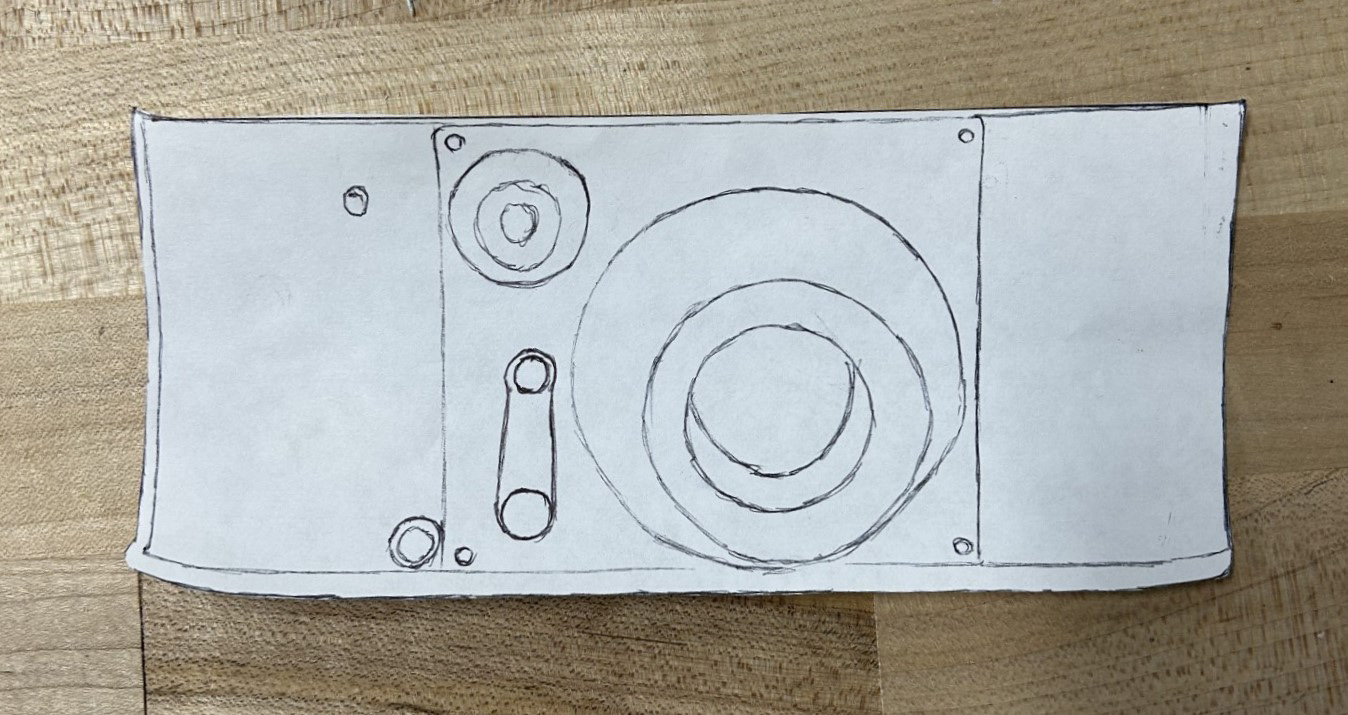

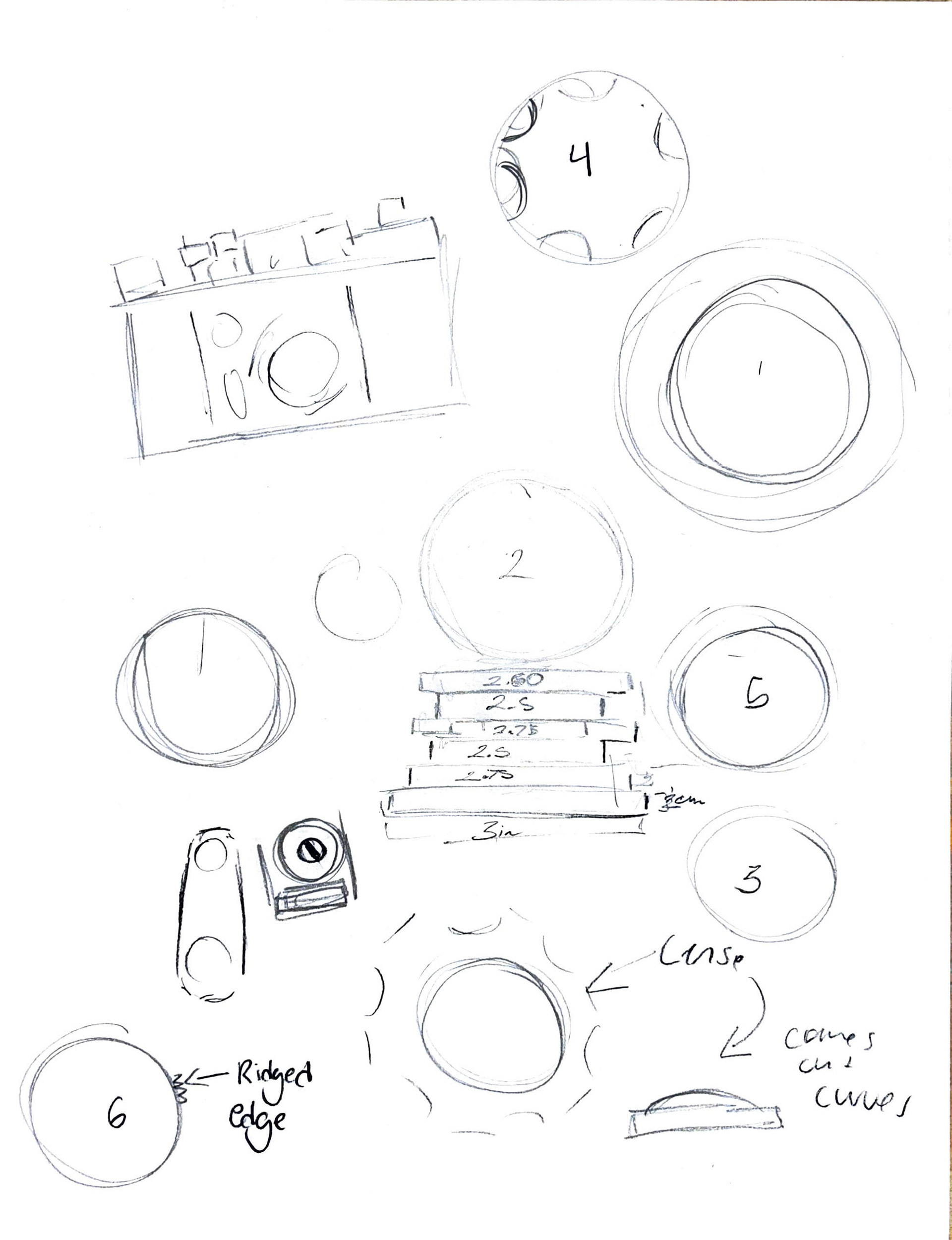

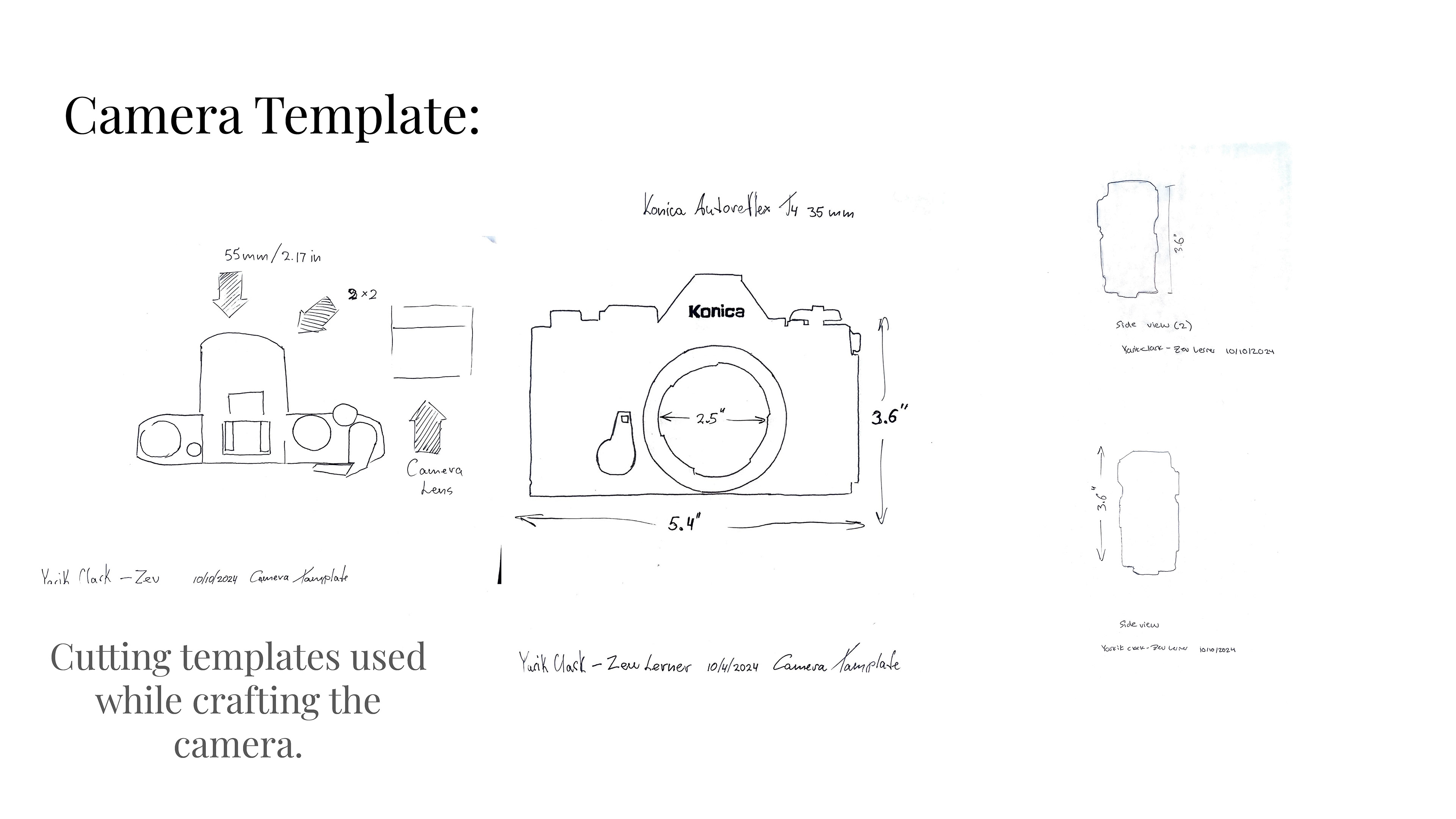

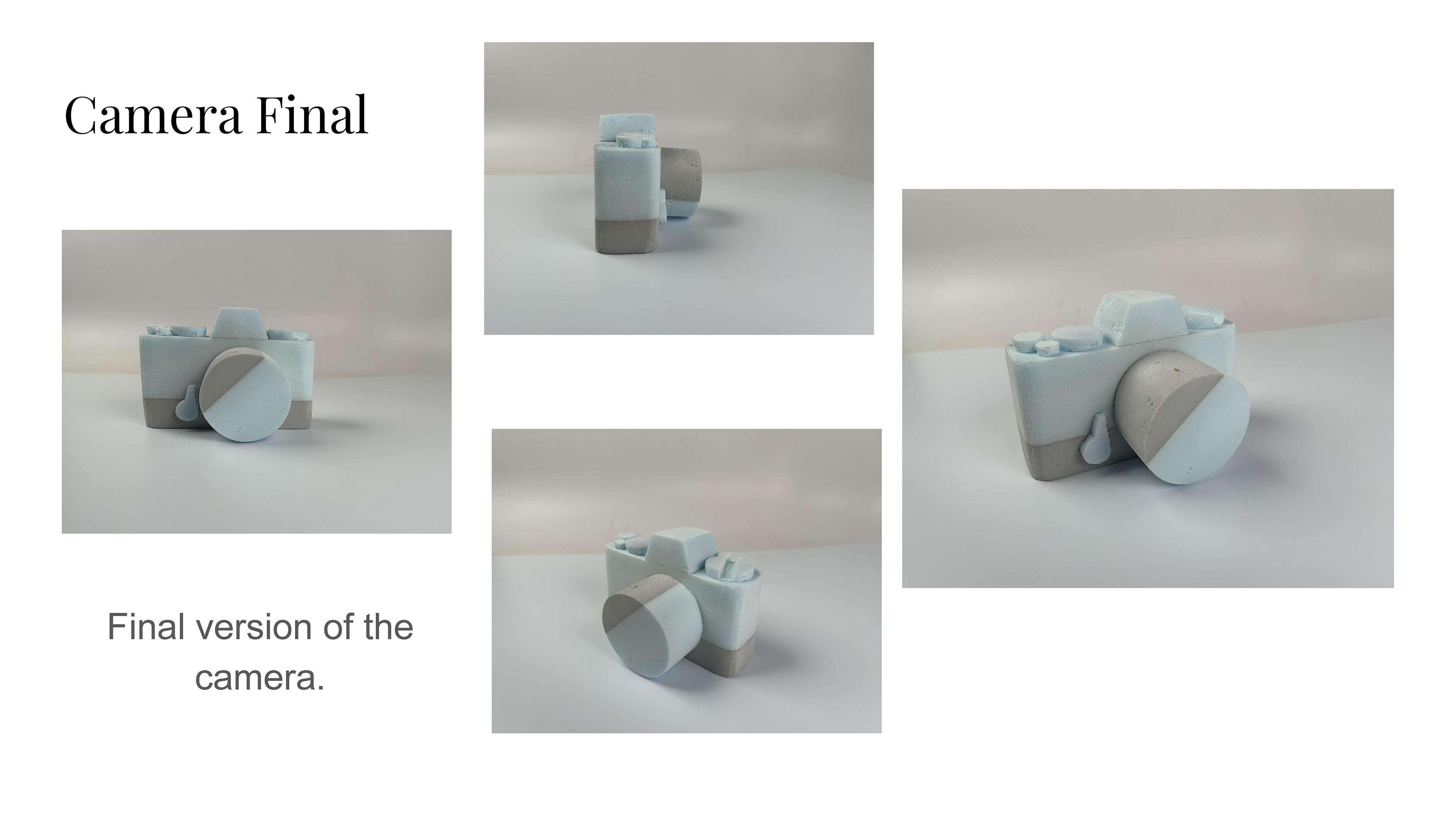

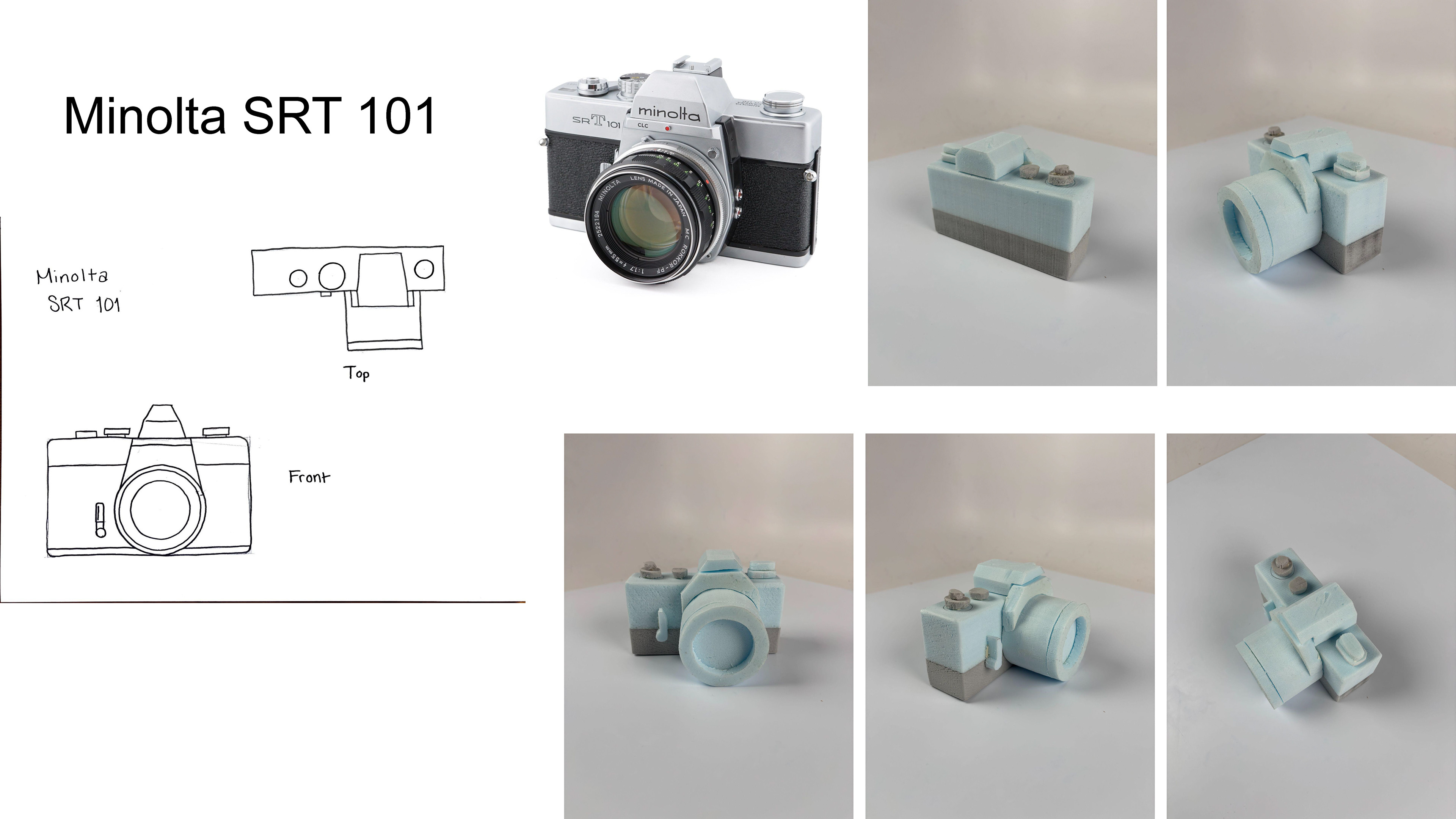

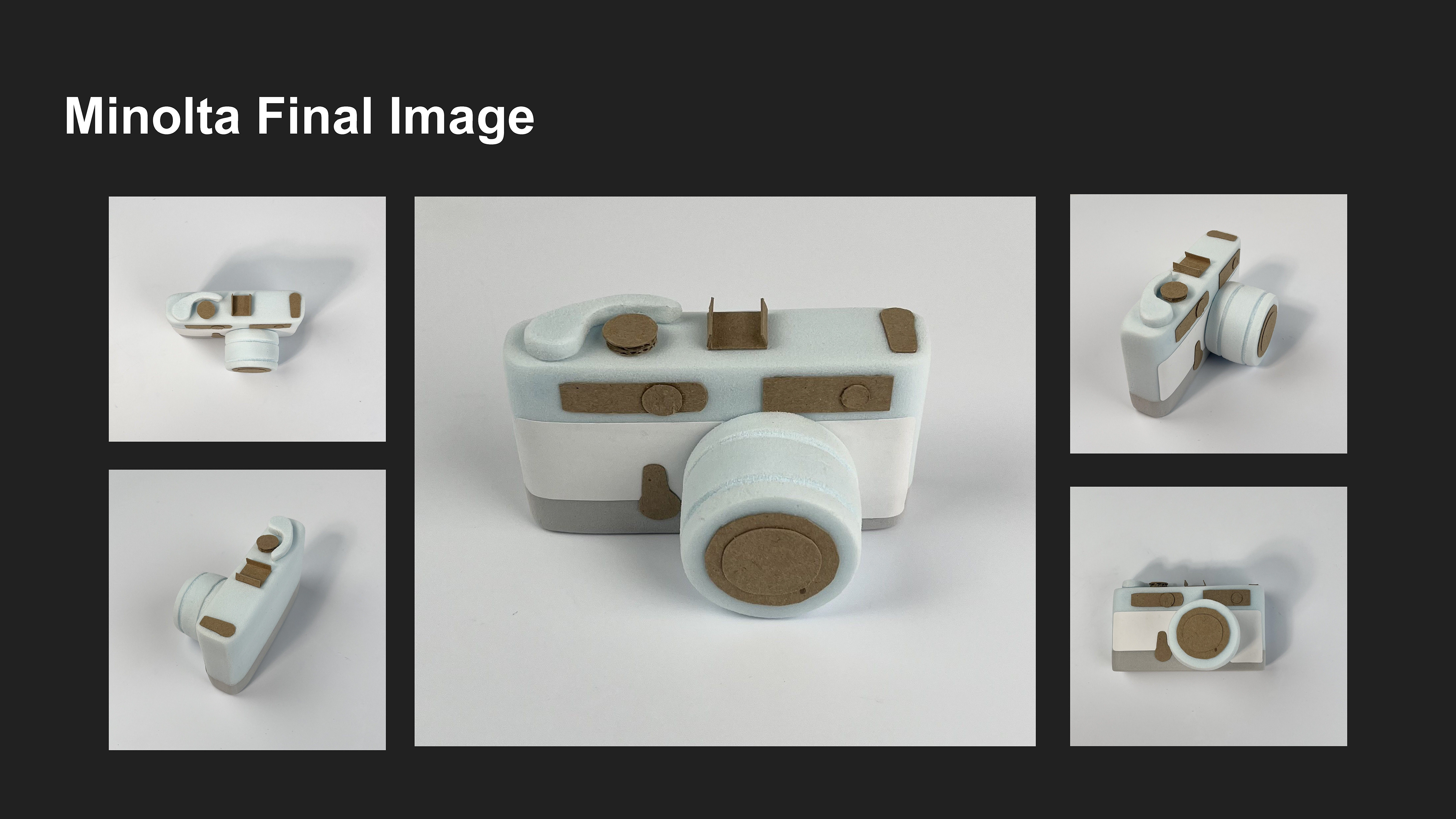

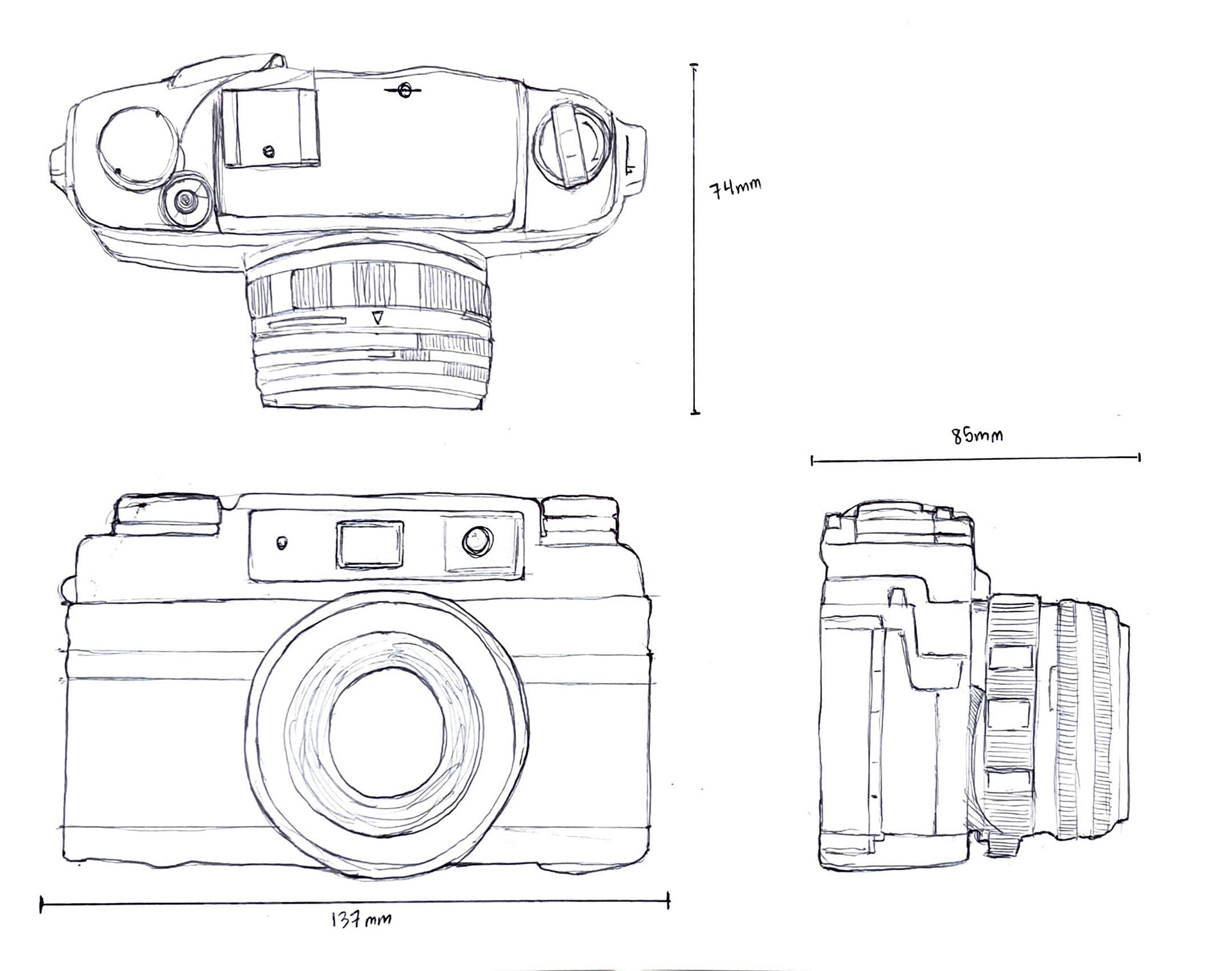

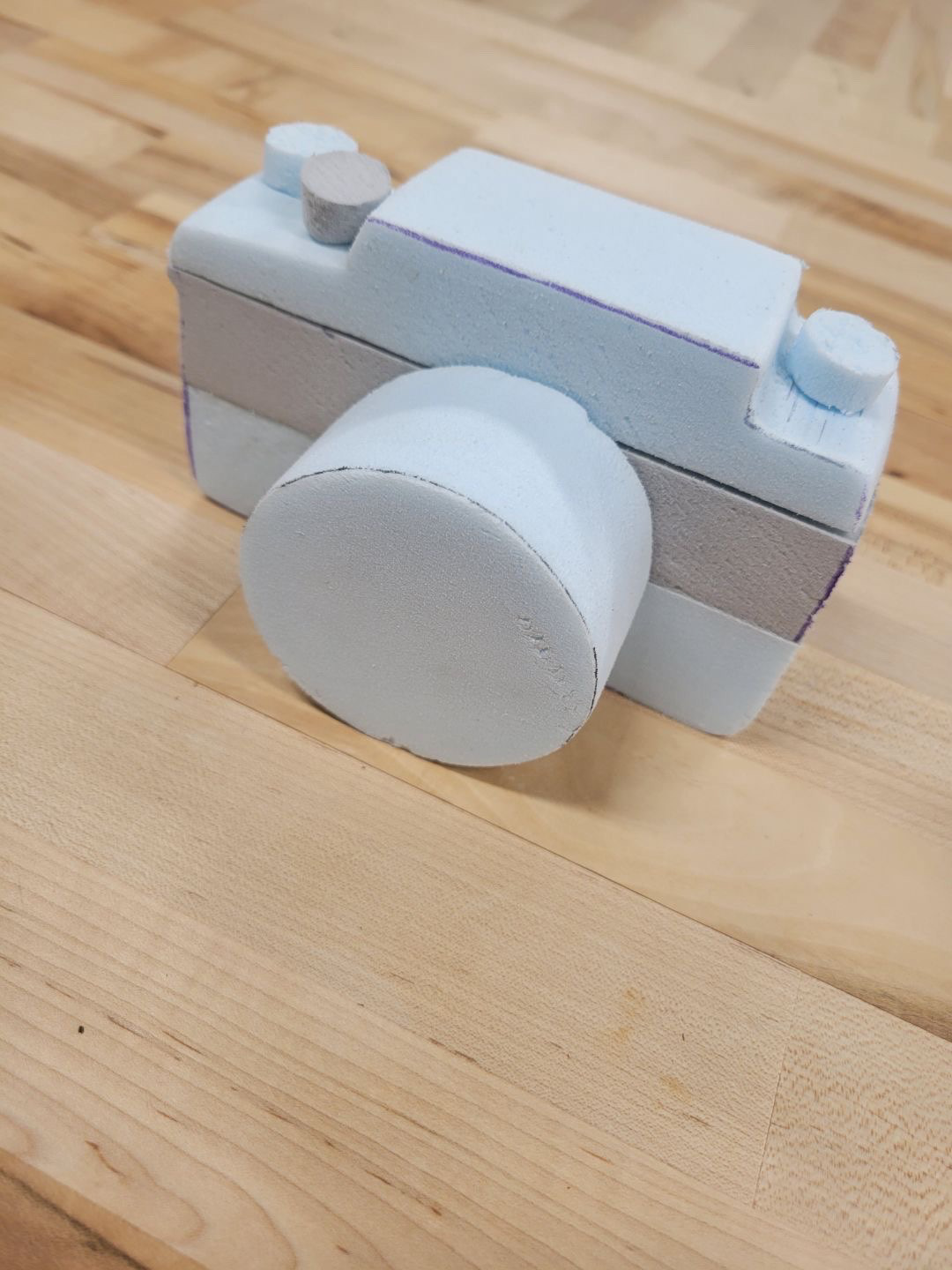

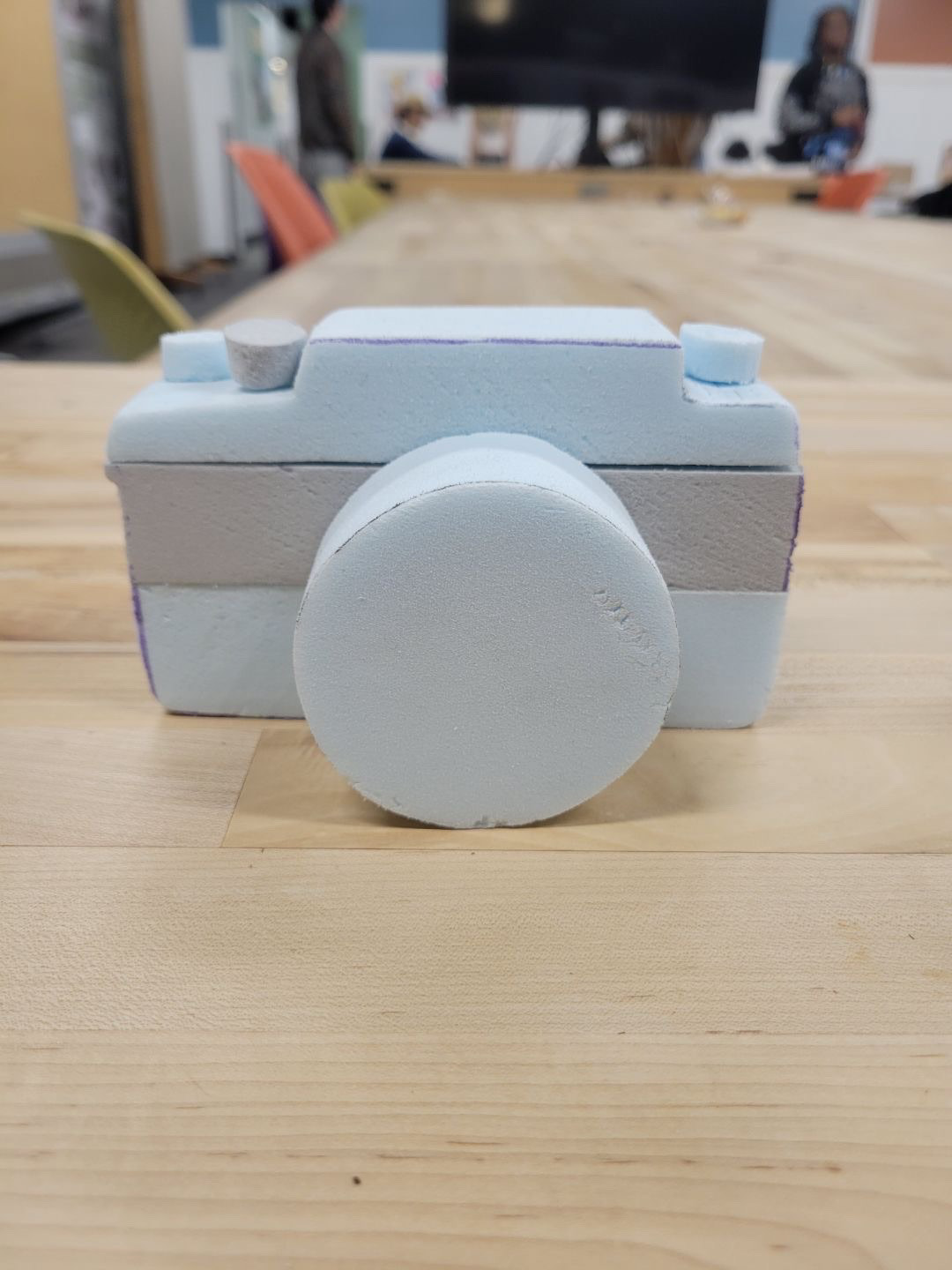

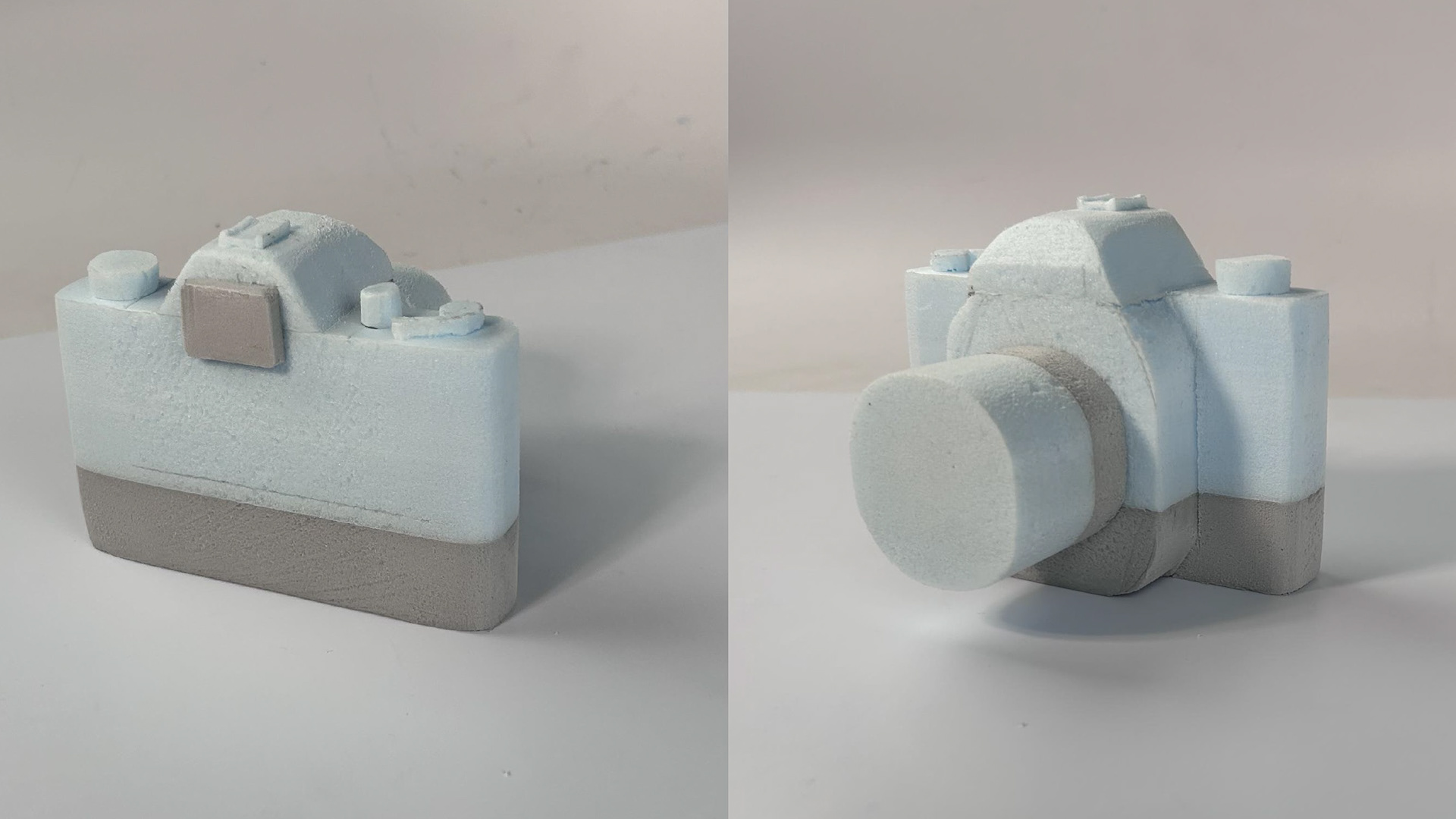

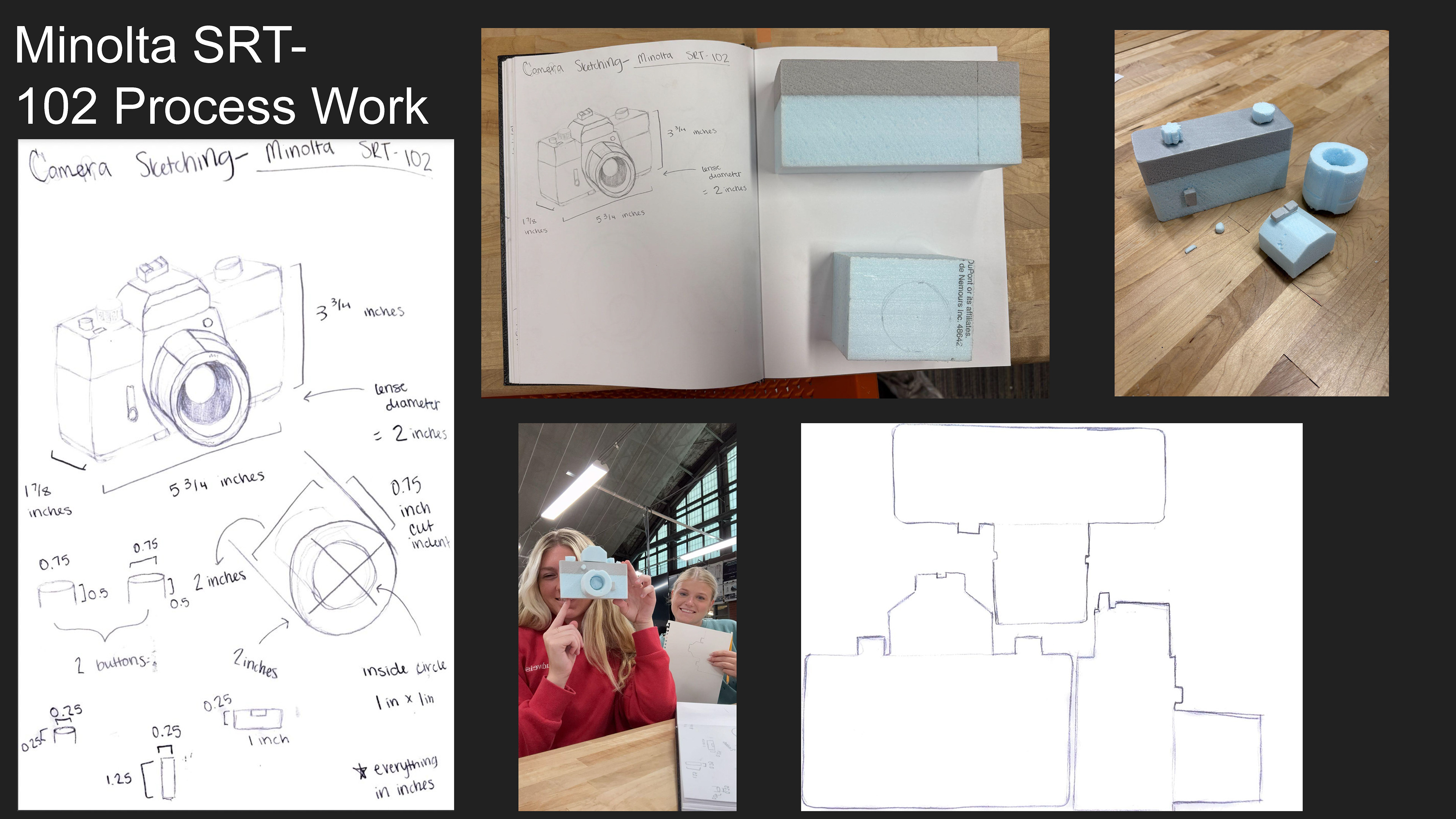

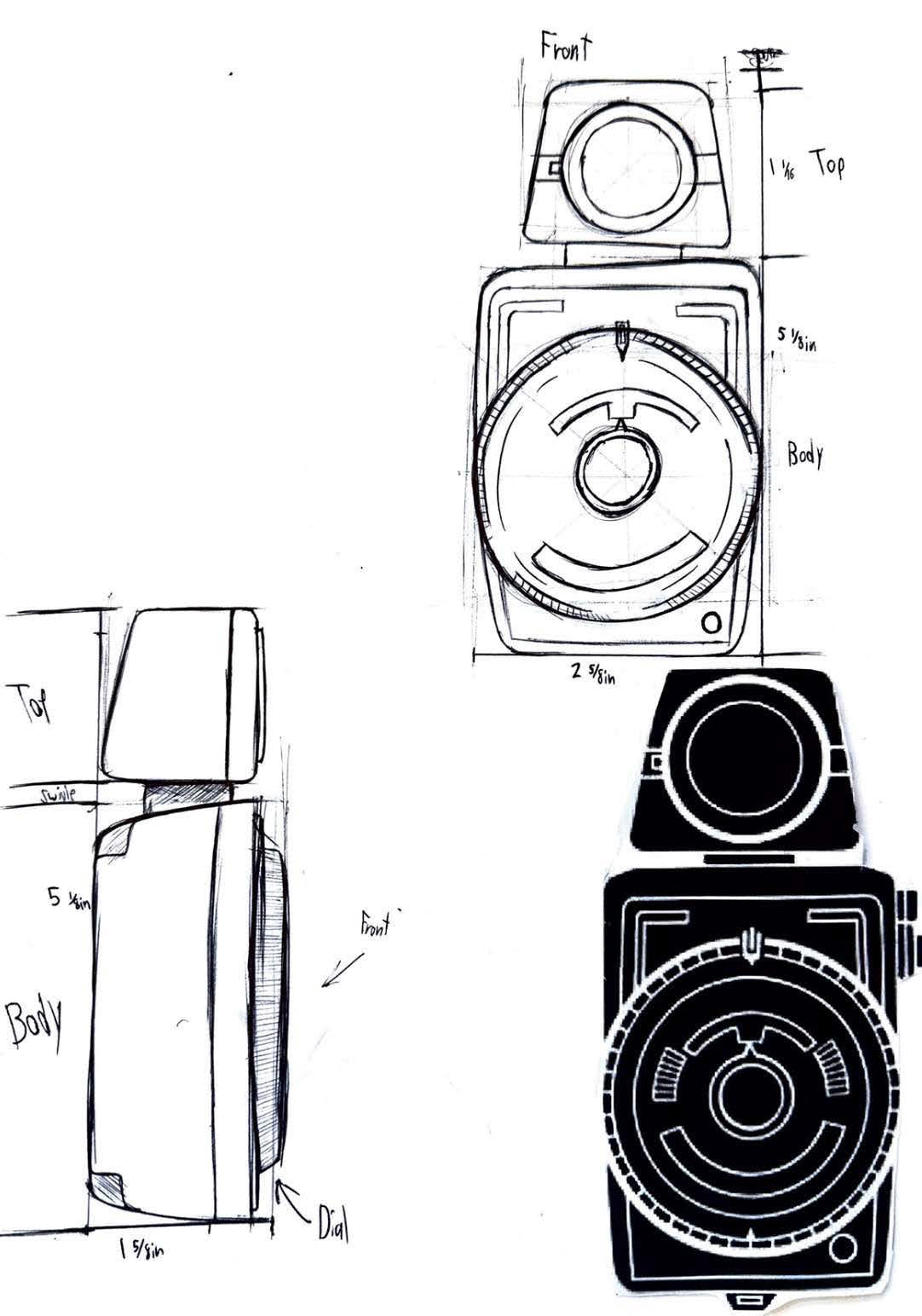

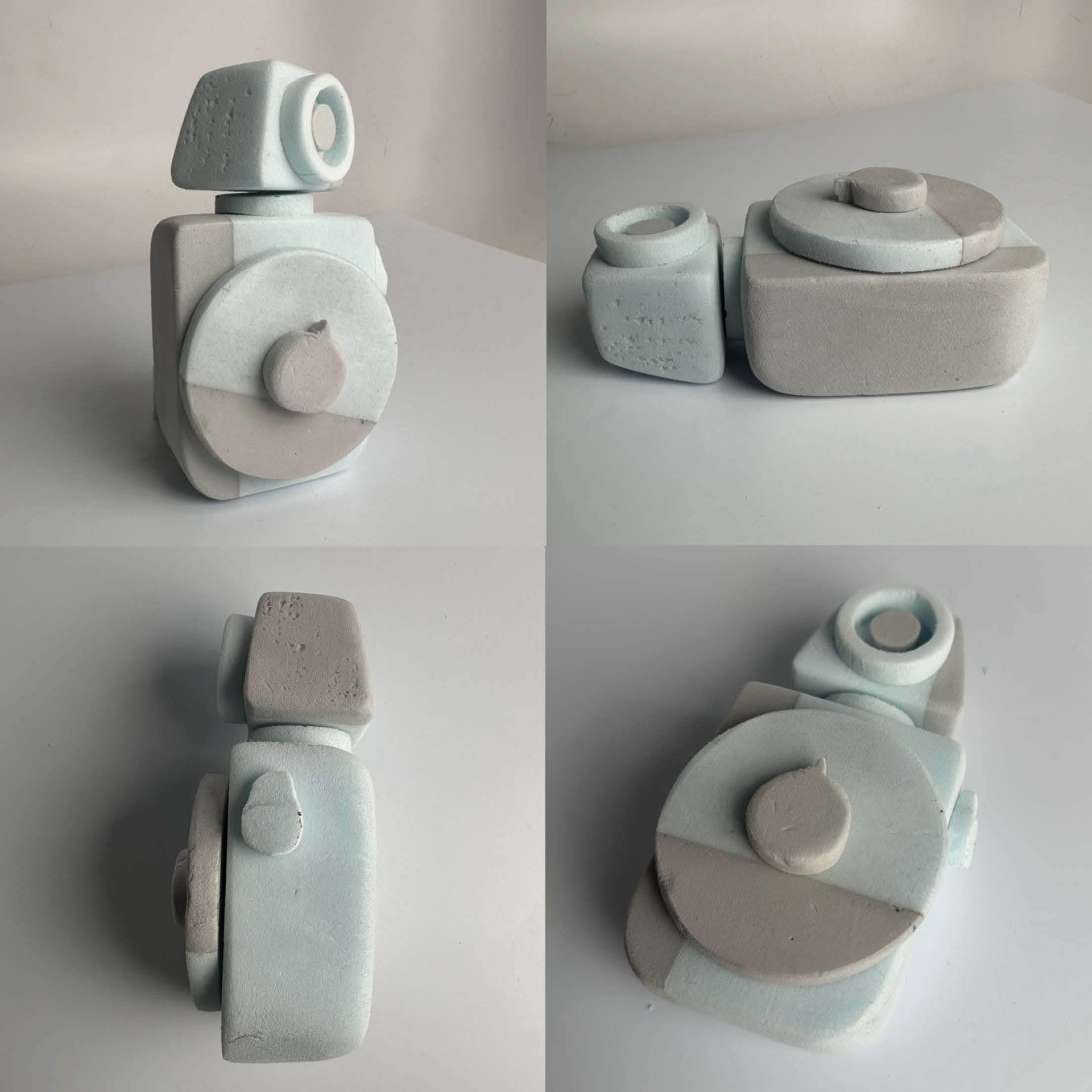

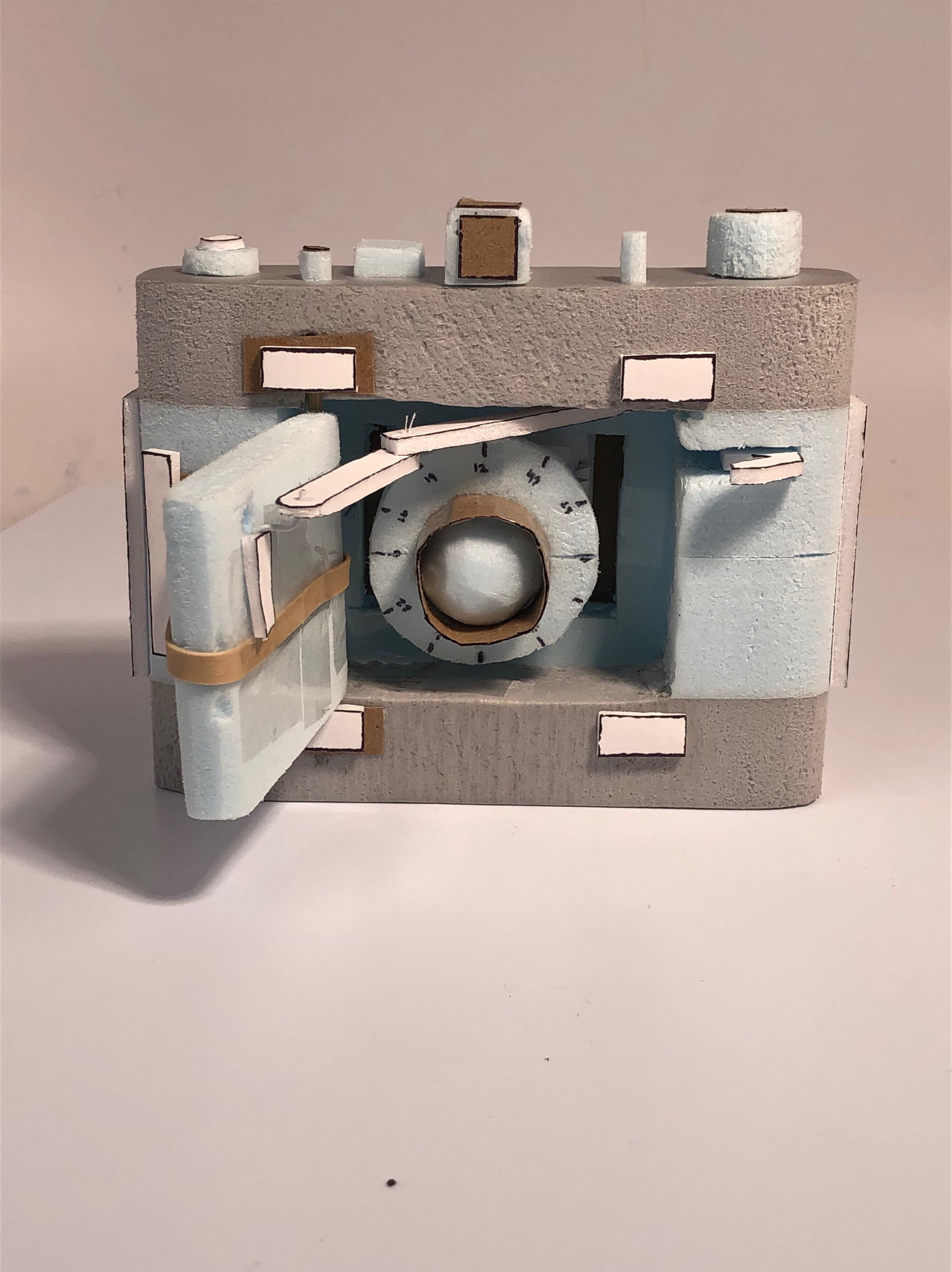

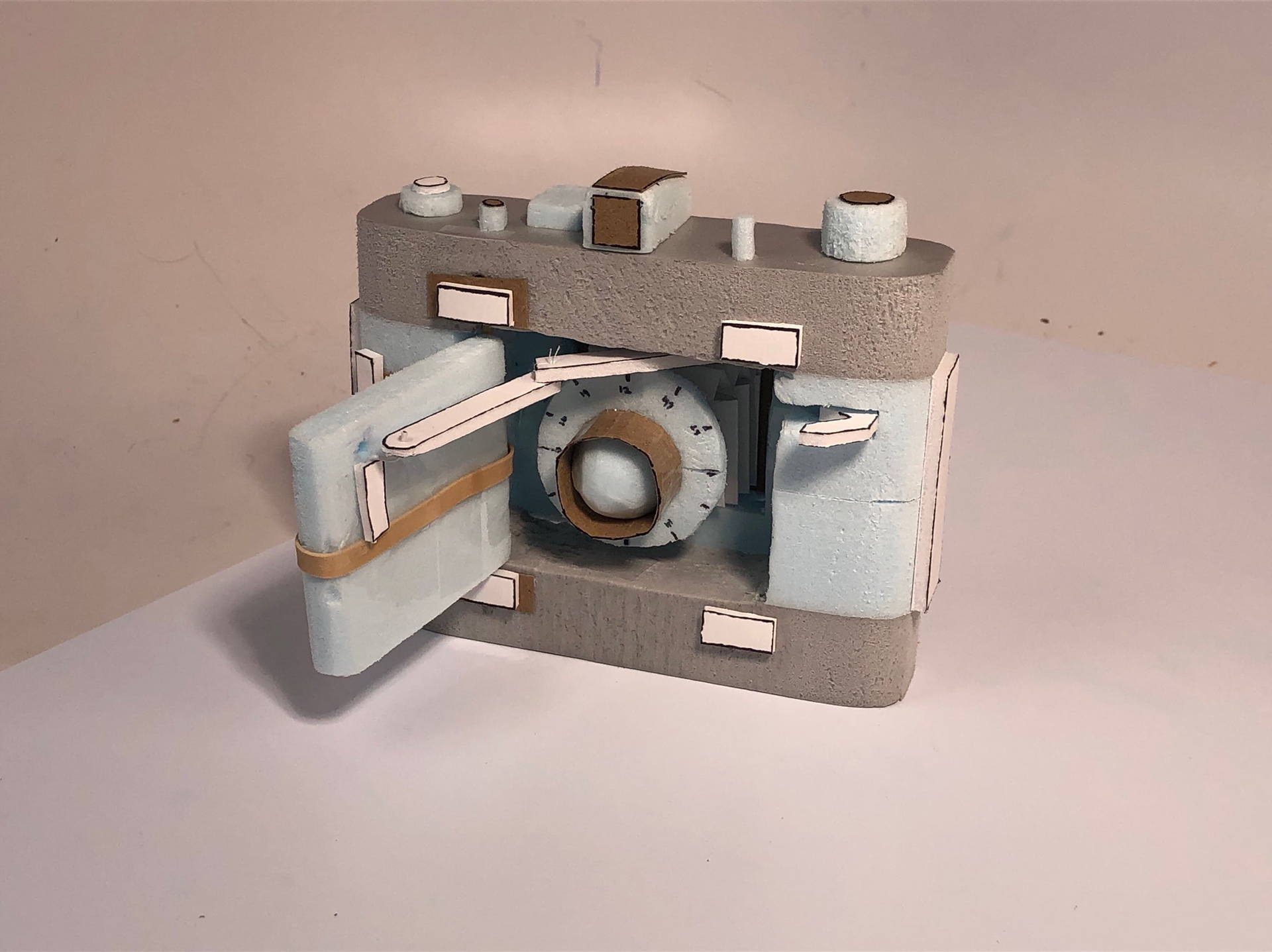

Scaling up the foam modelling process but keeping the same detailing work ethic is important when students work with Blue foam.

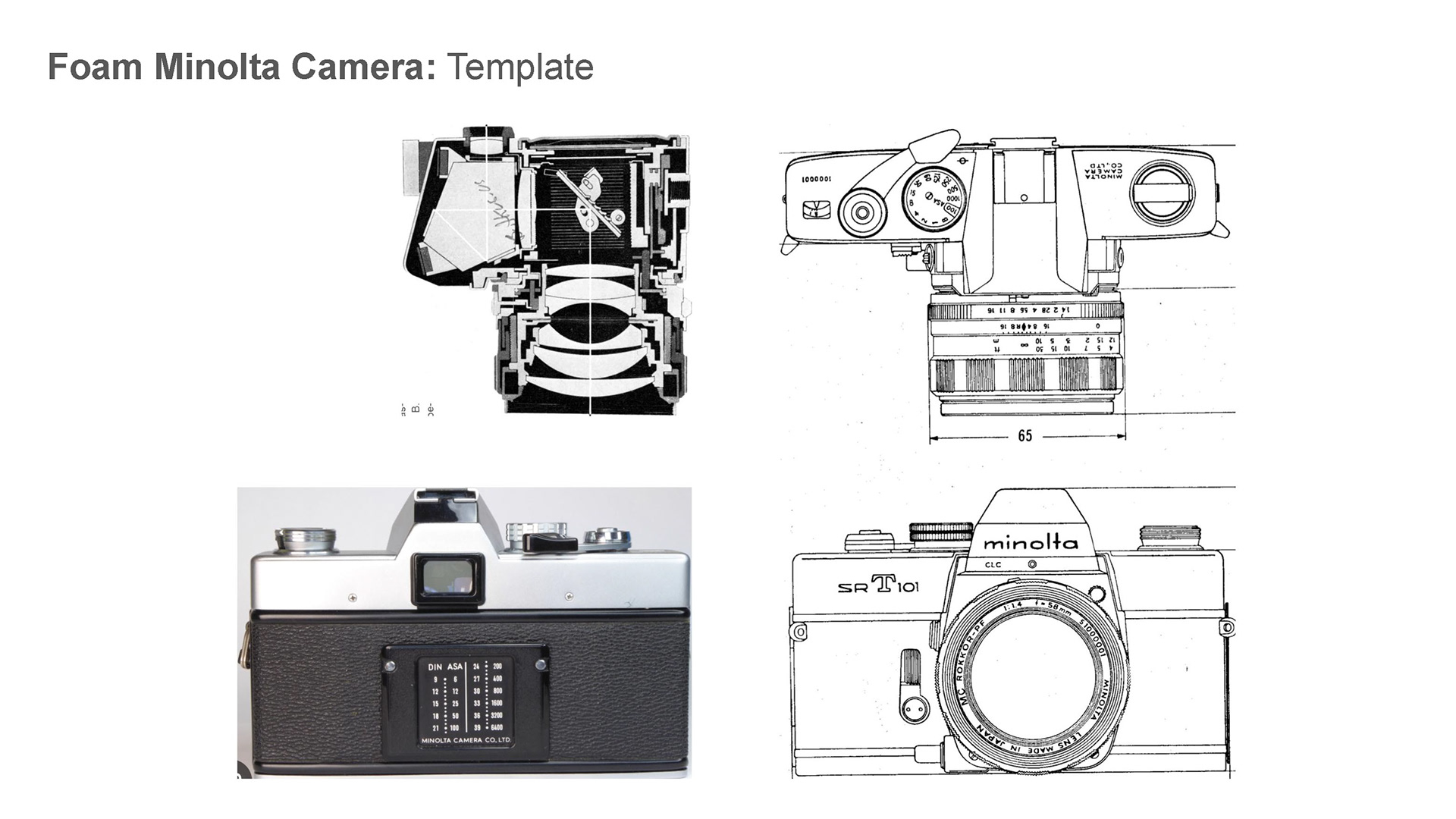

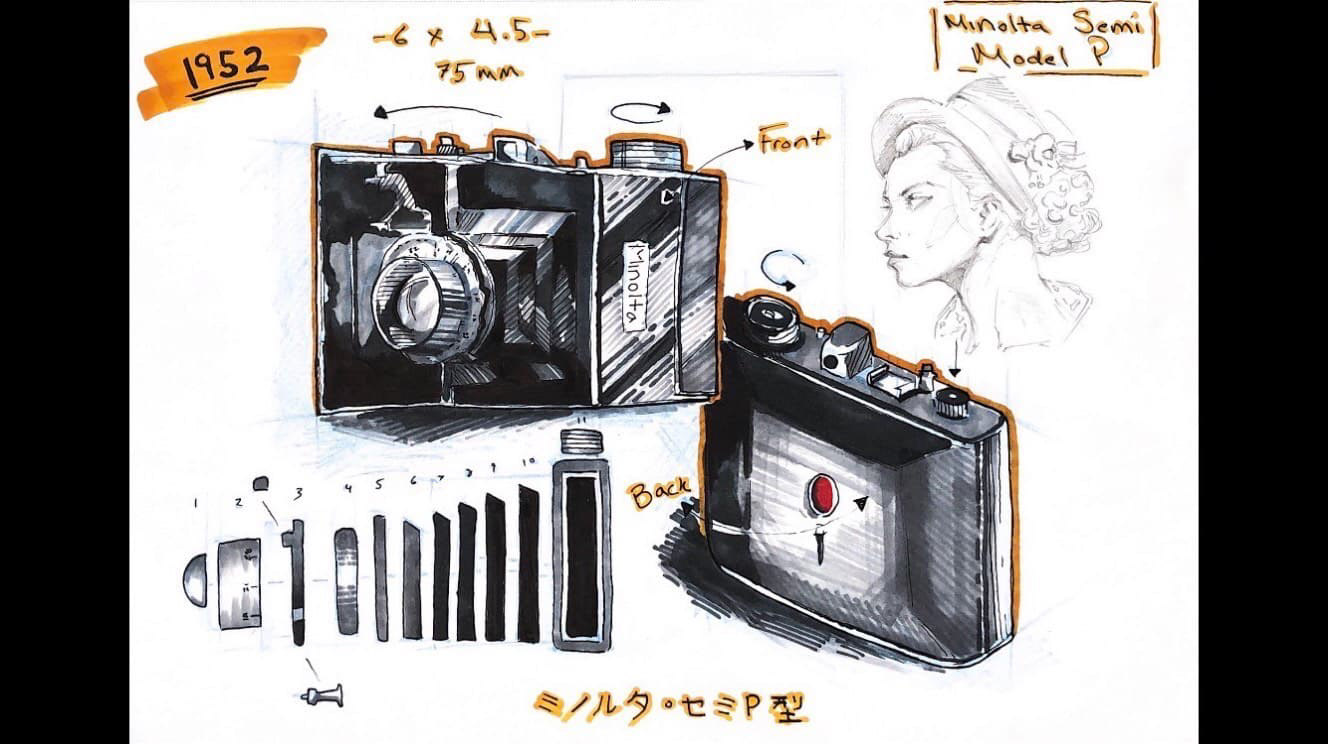

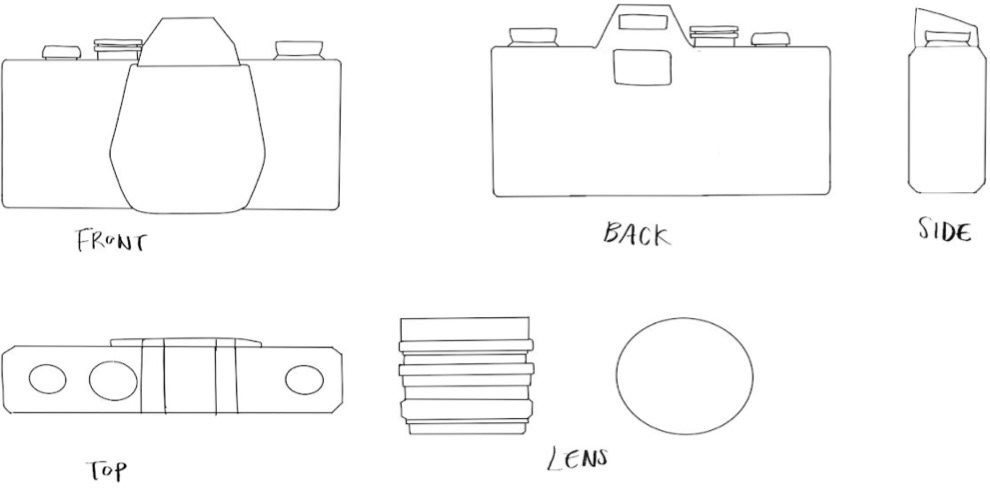

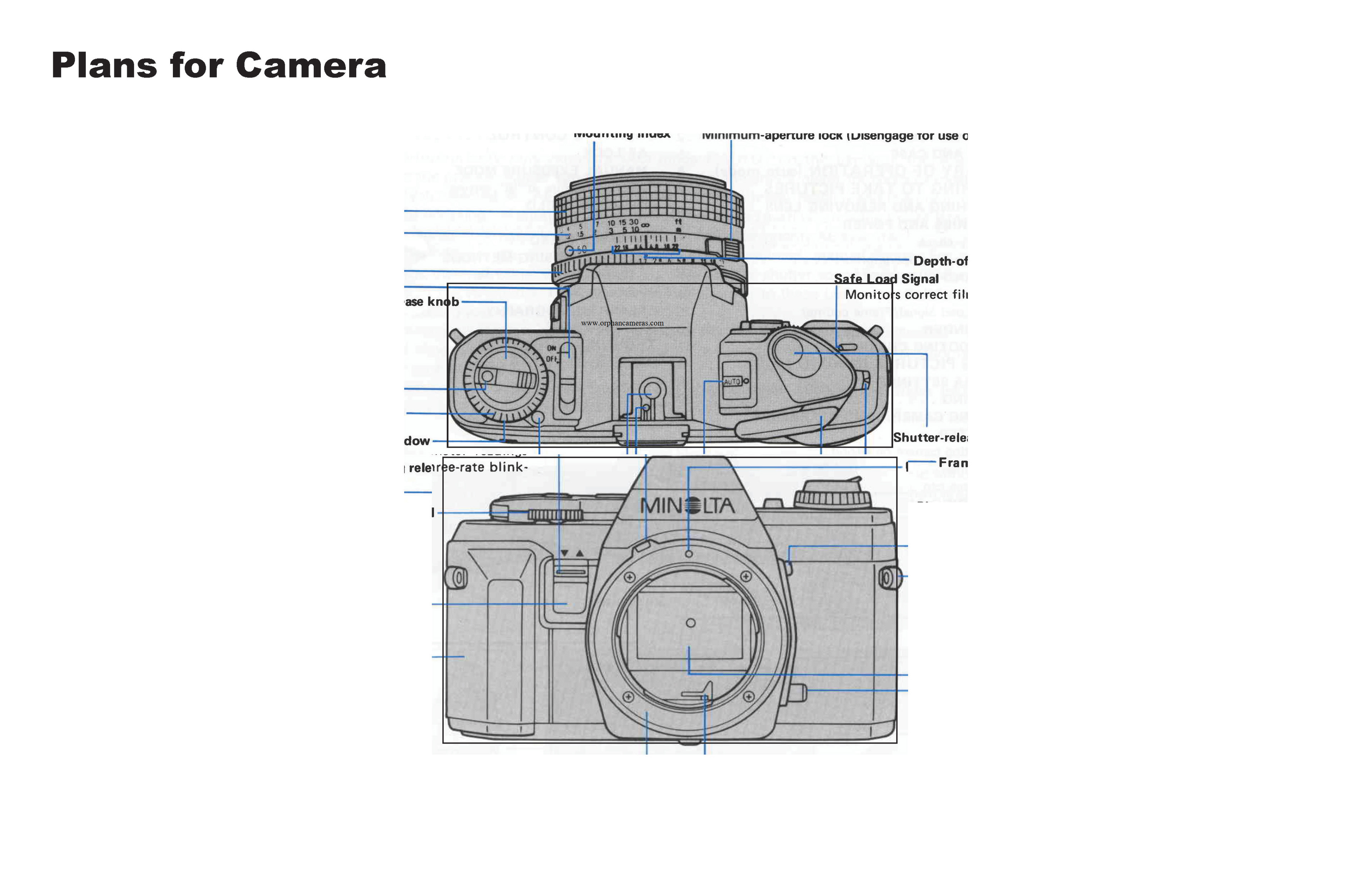

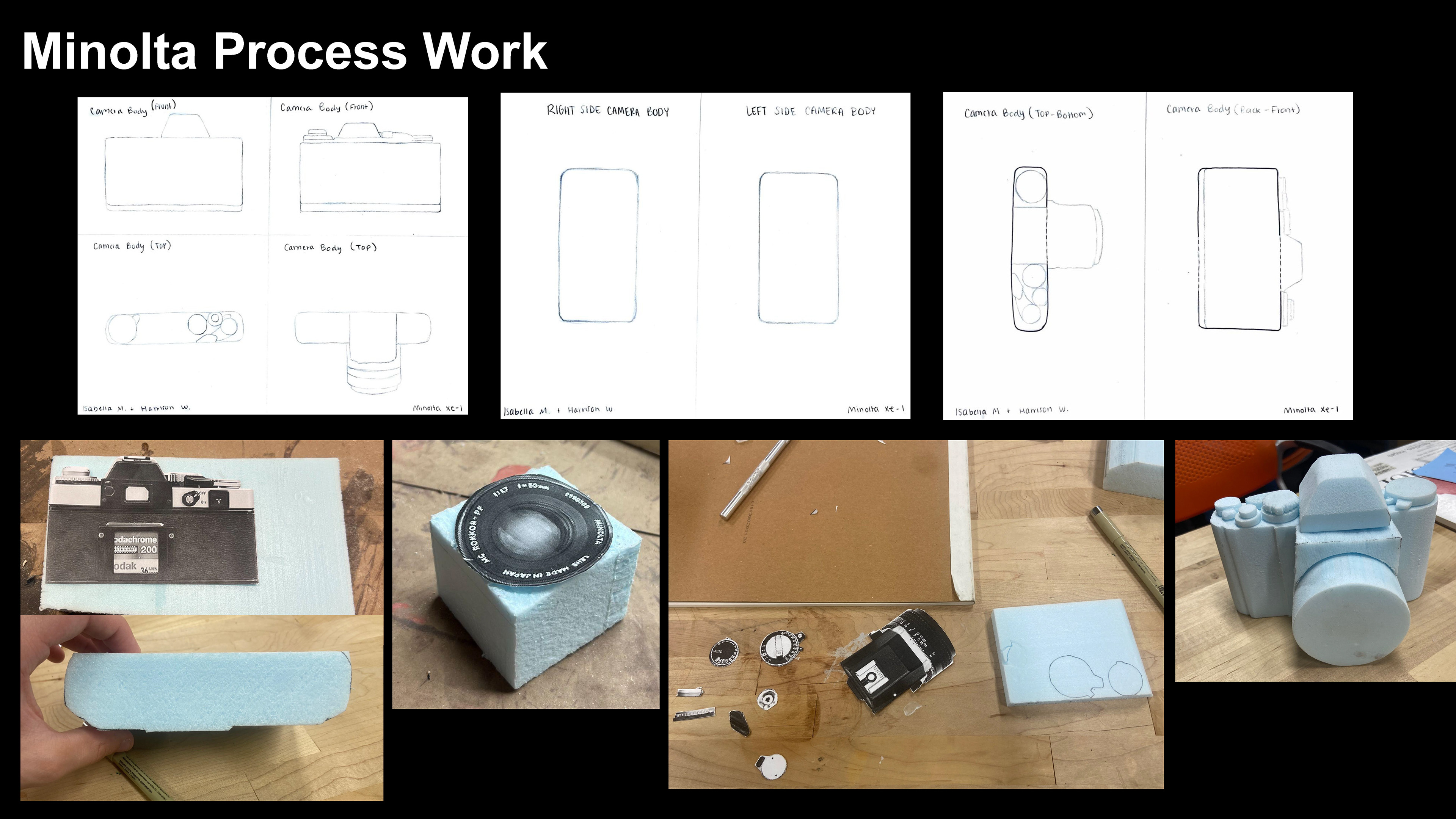

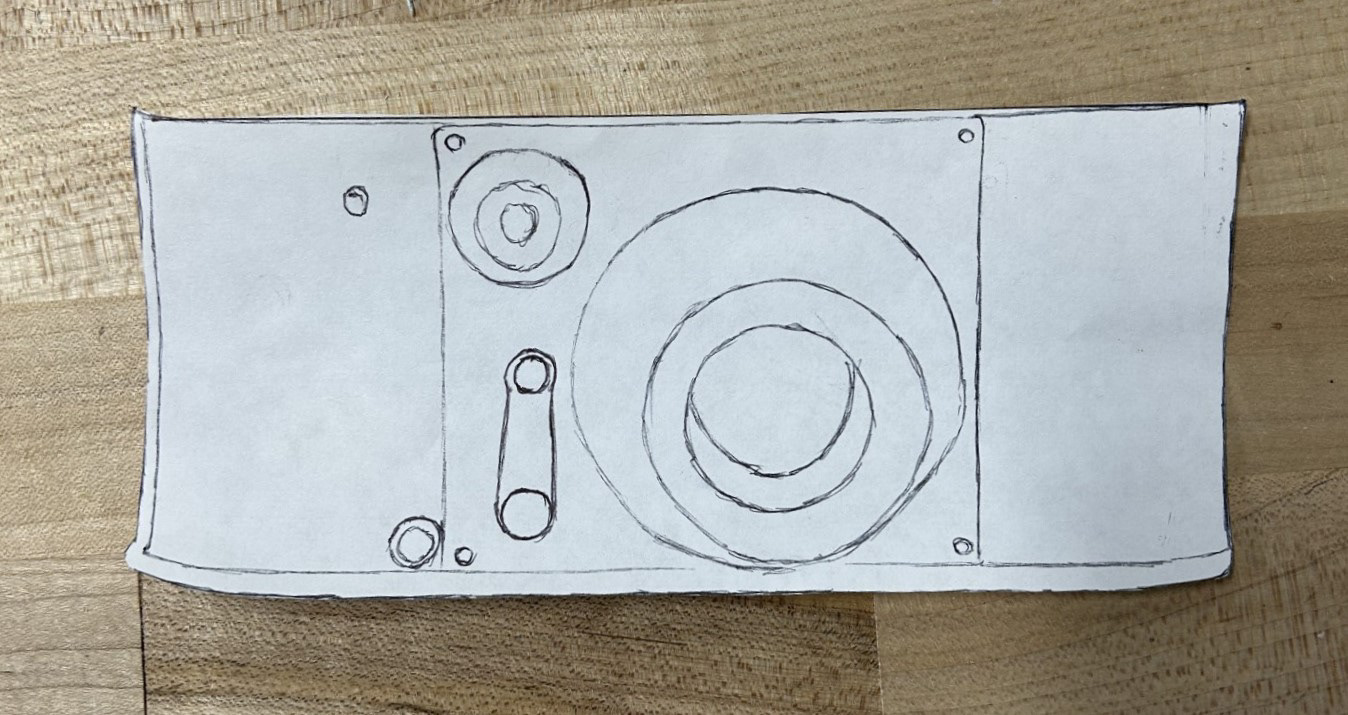

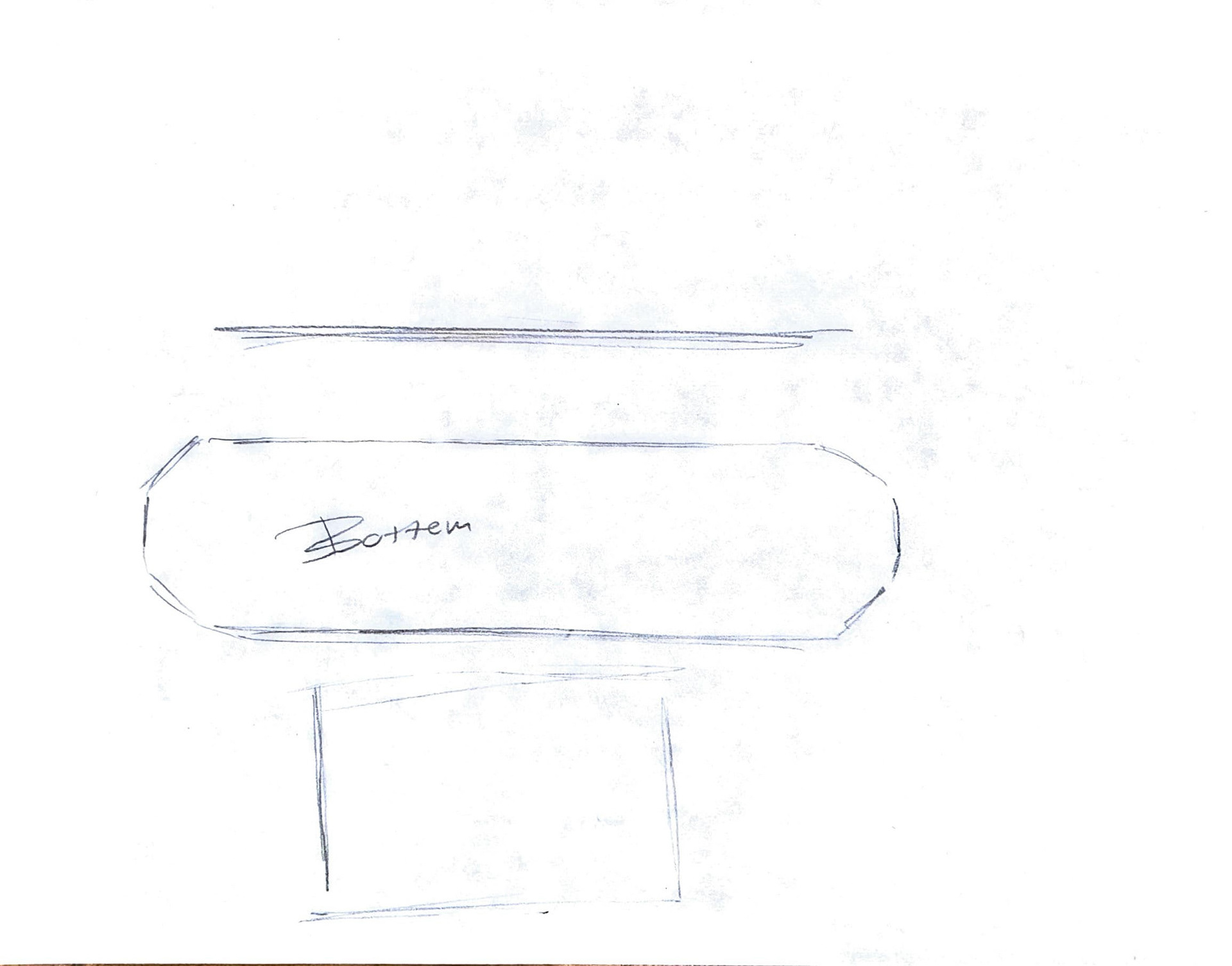

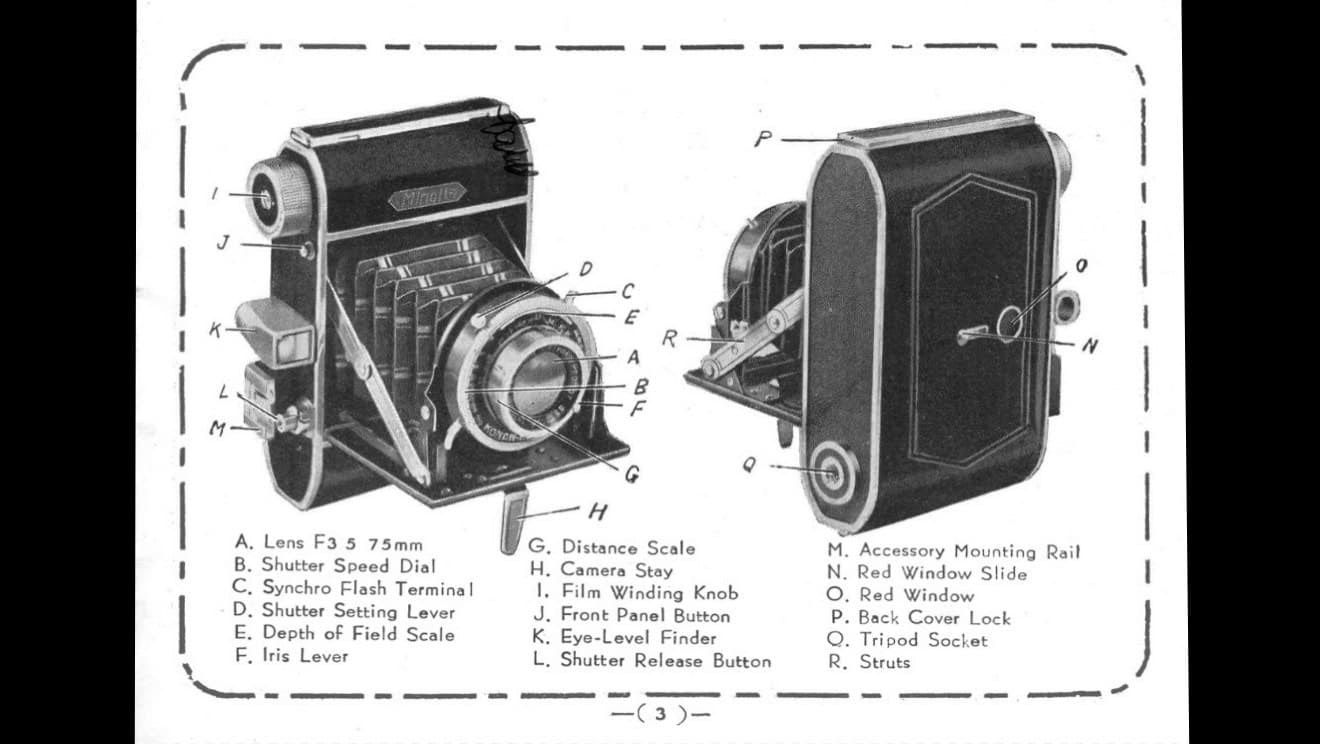

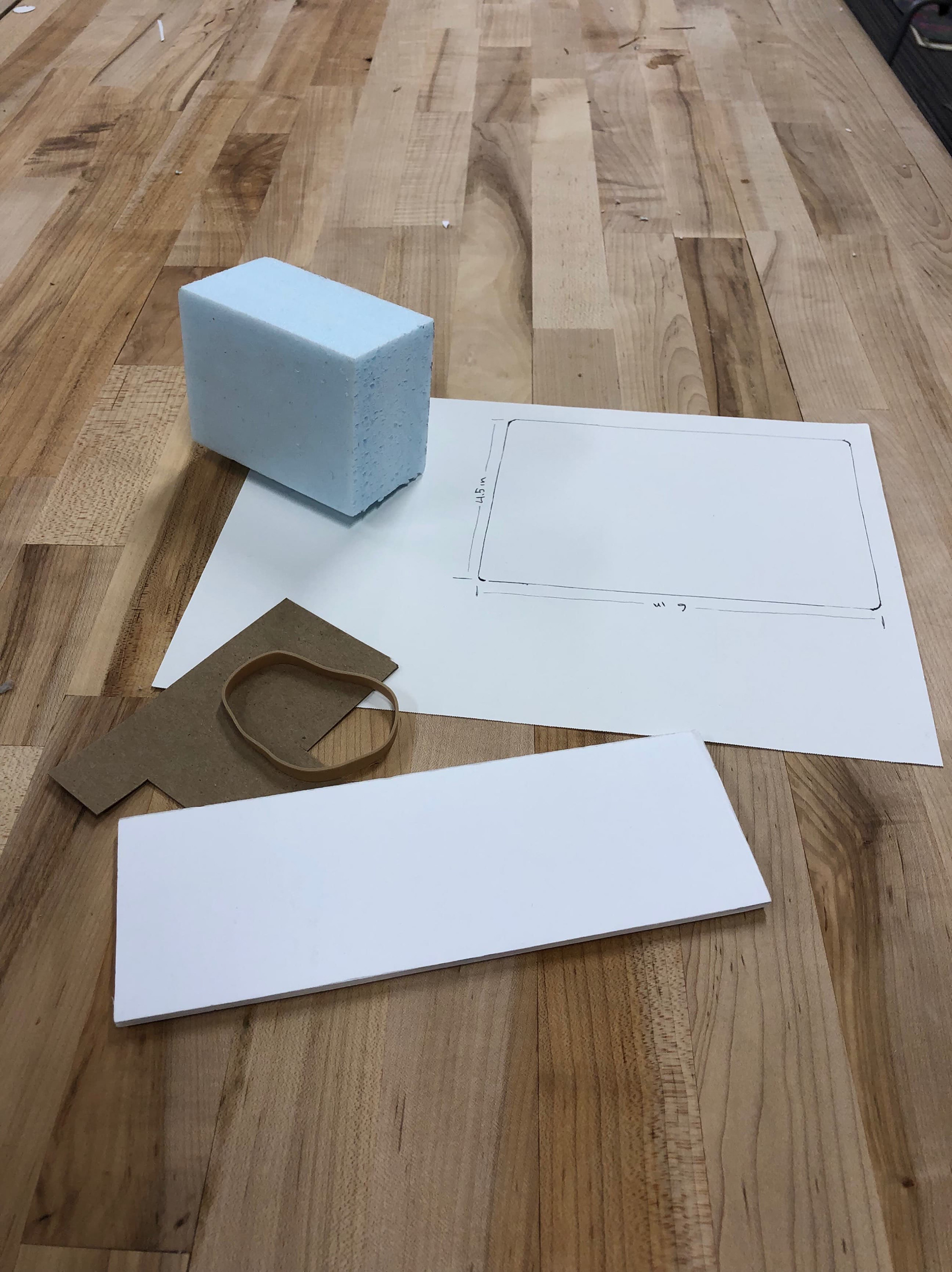

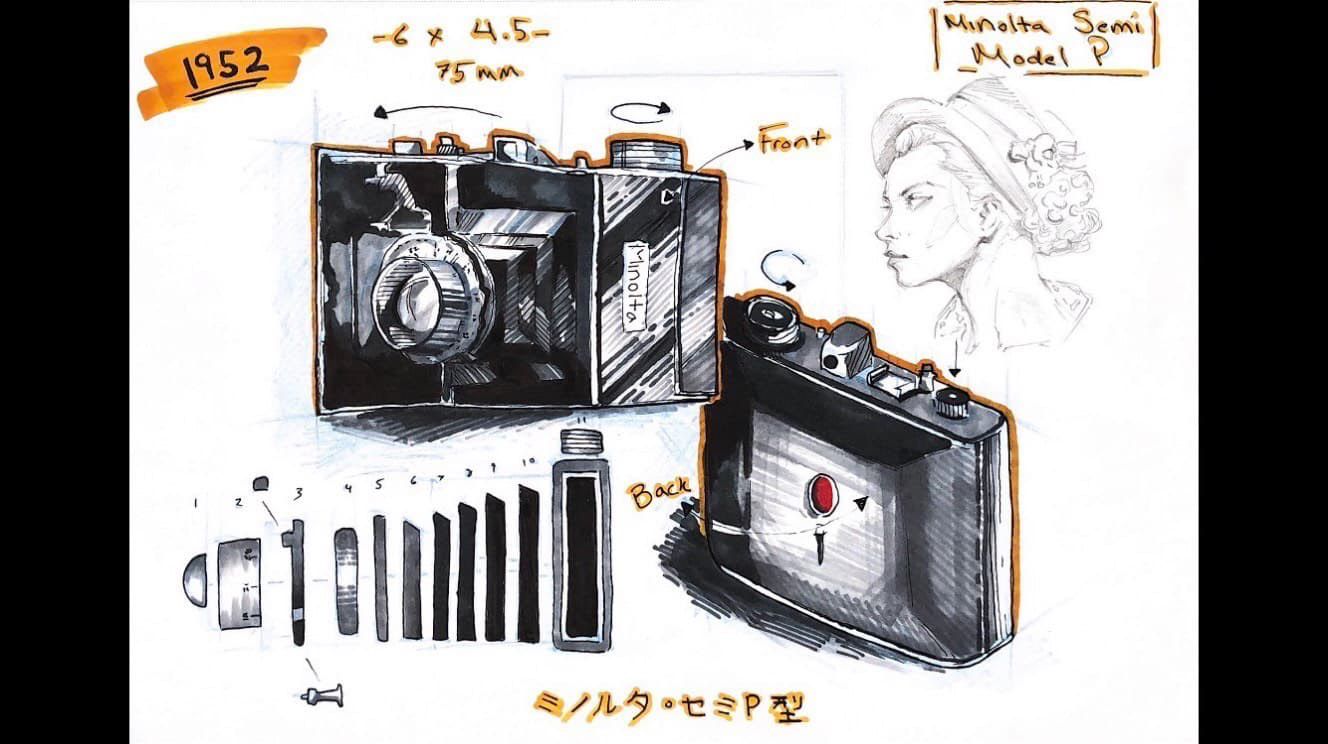

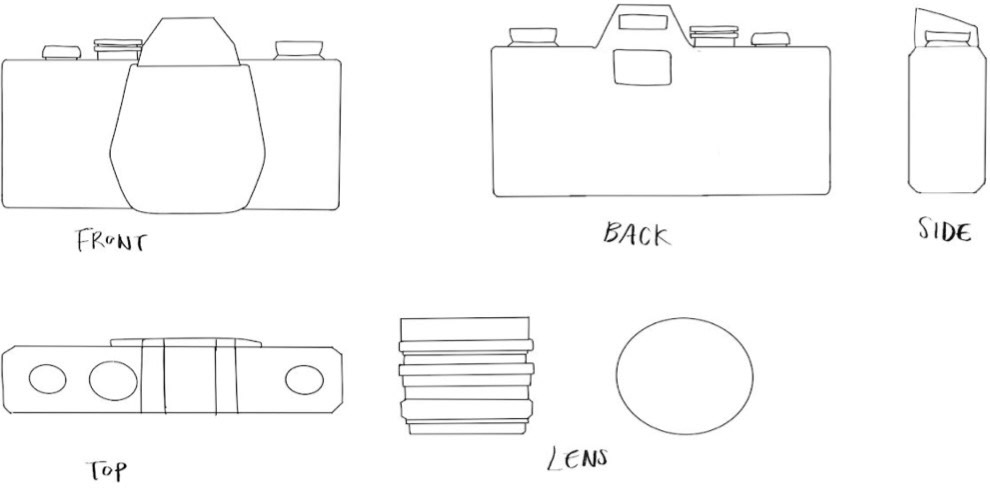

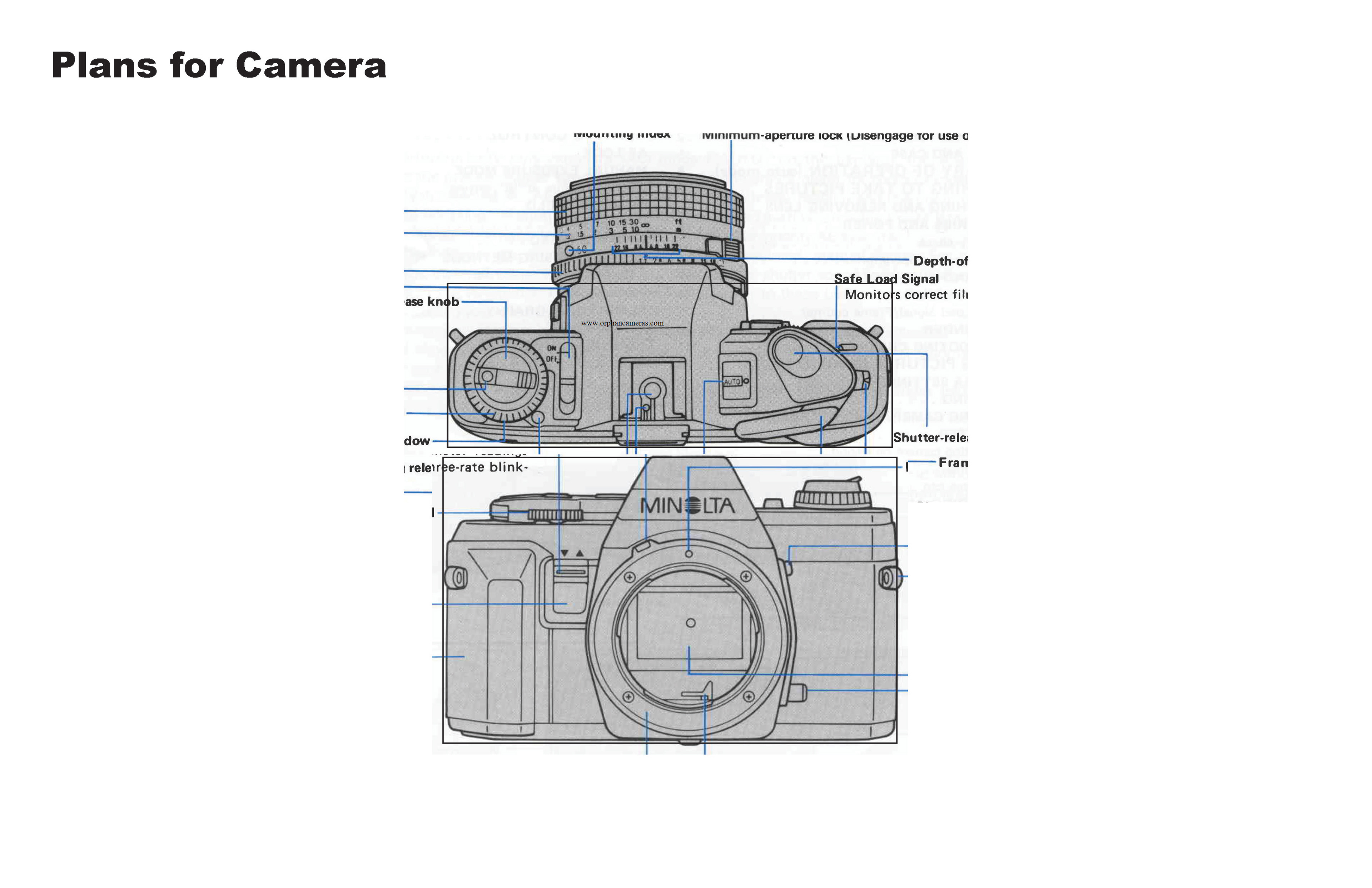

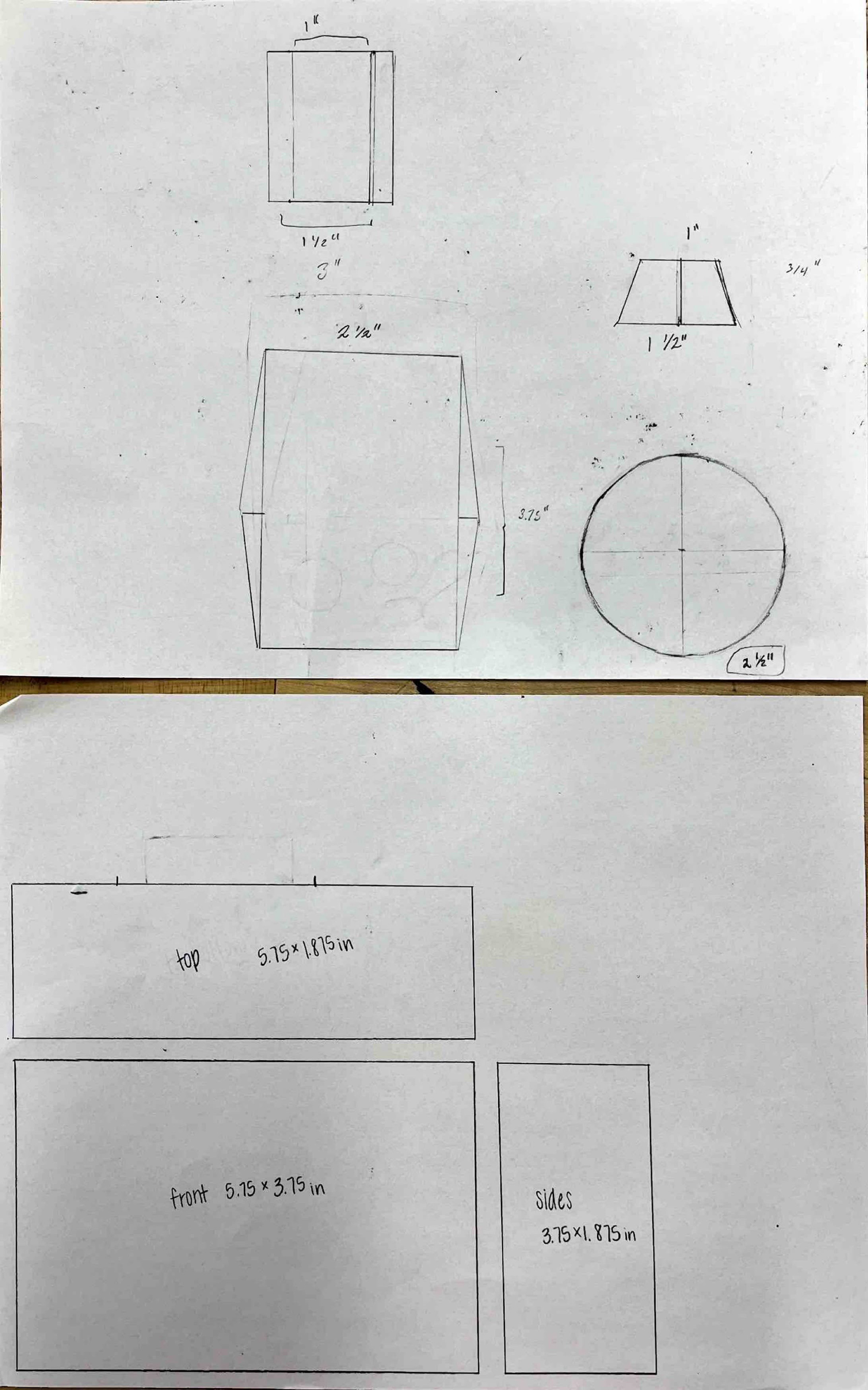

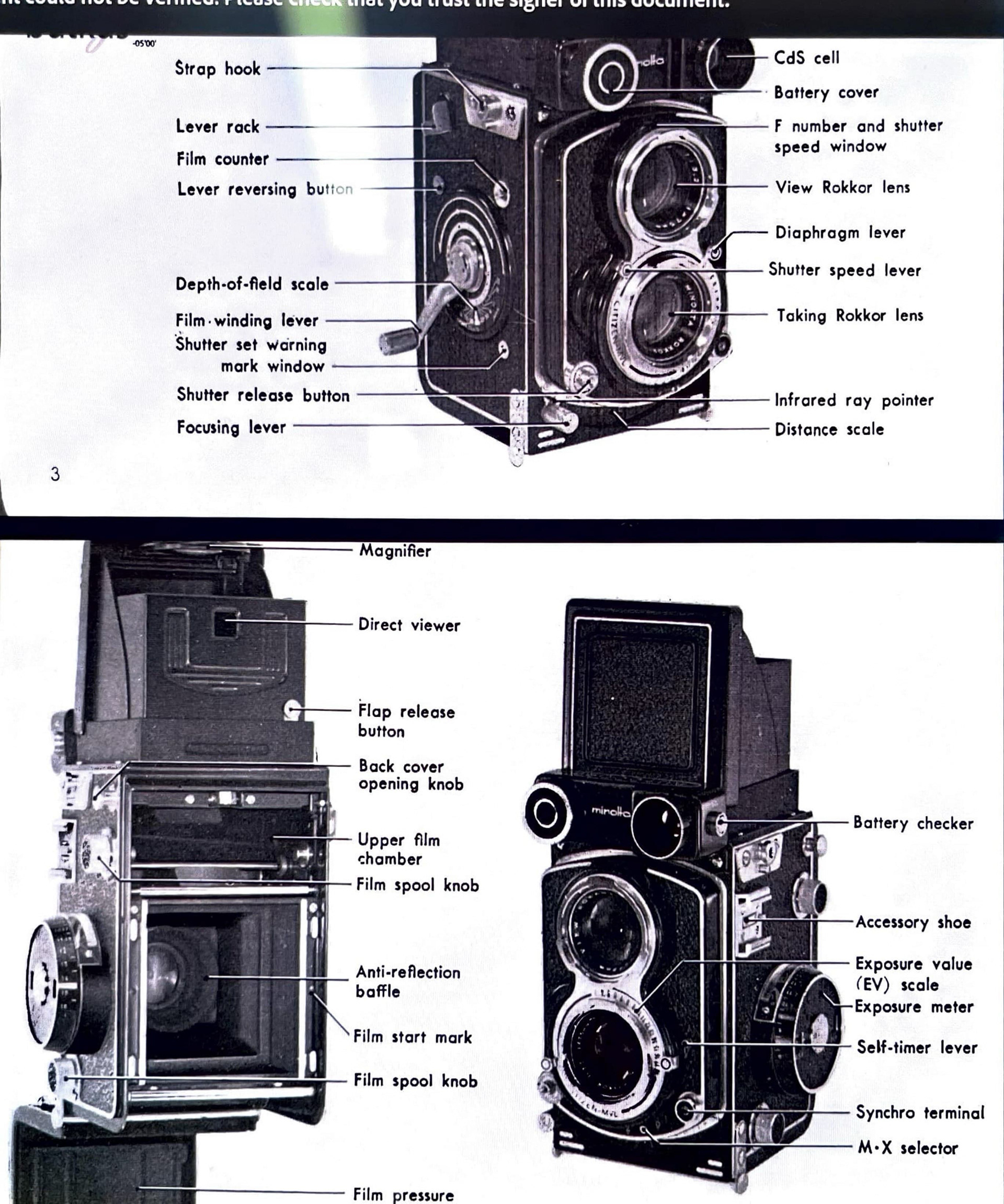

Here the students go from a small scaled Go-Pro camera to a large detailed scale of a Film camera. This allows them to work with a lot of material but be able to show more details in the carving work and prototyping.

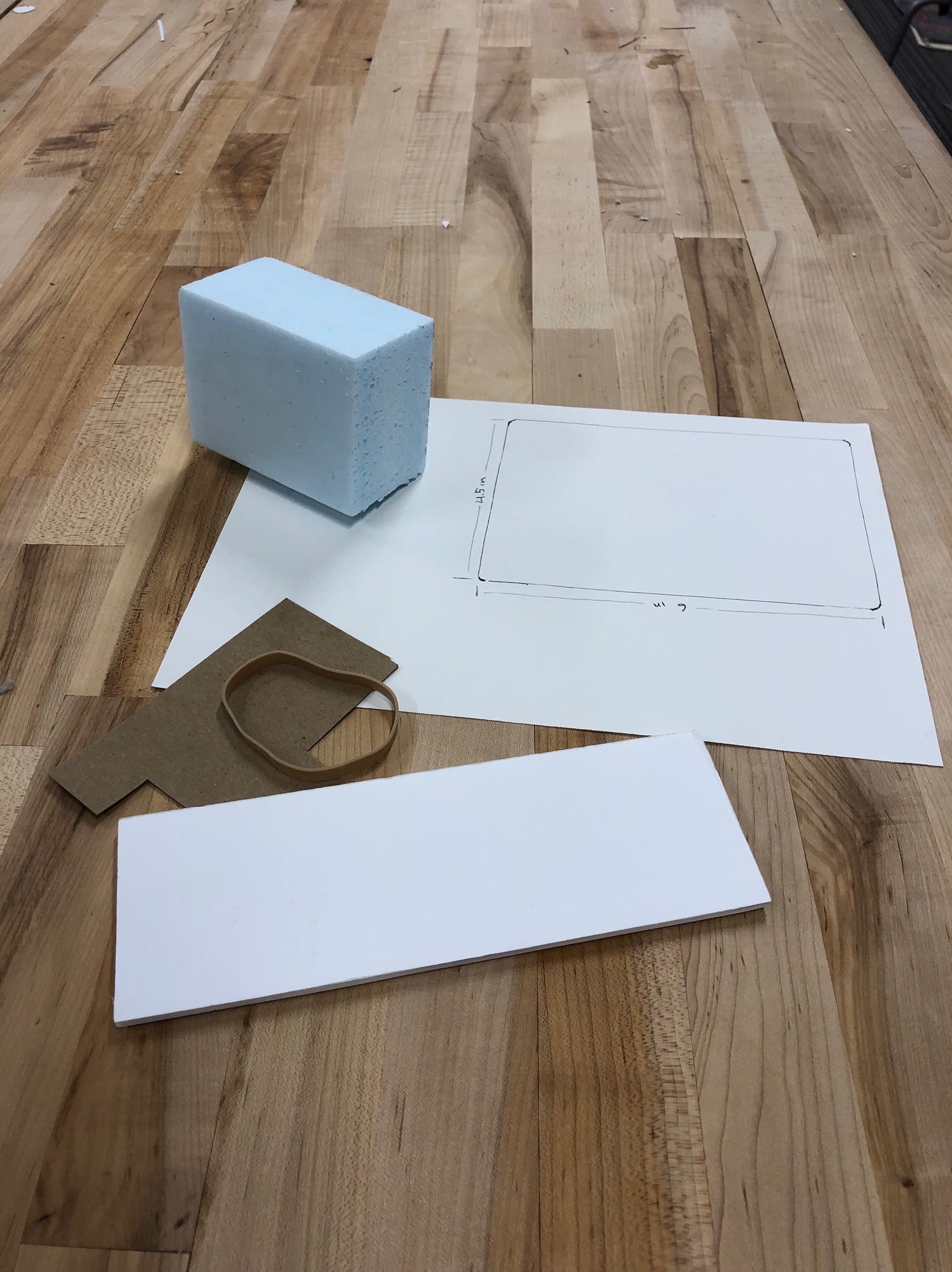

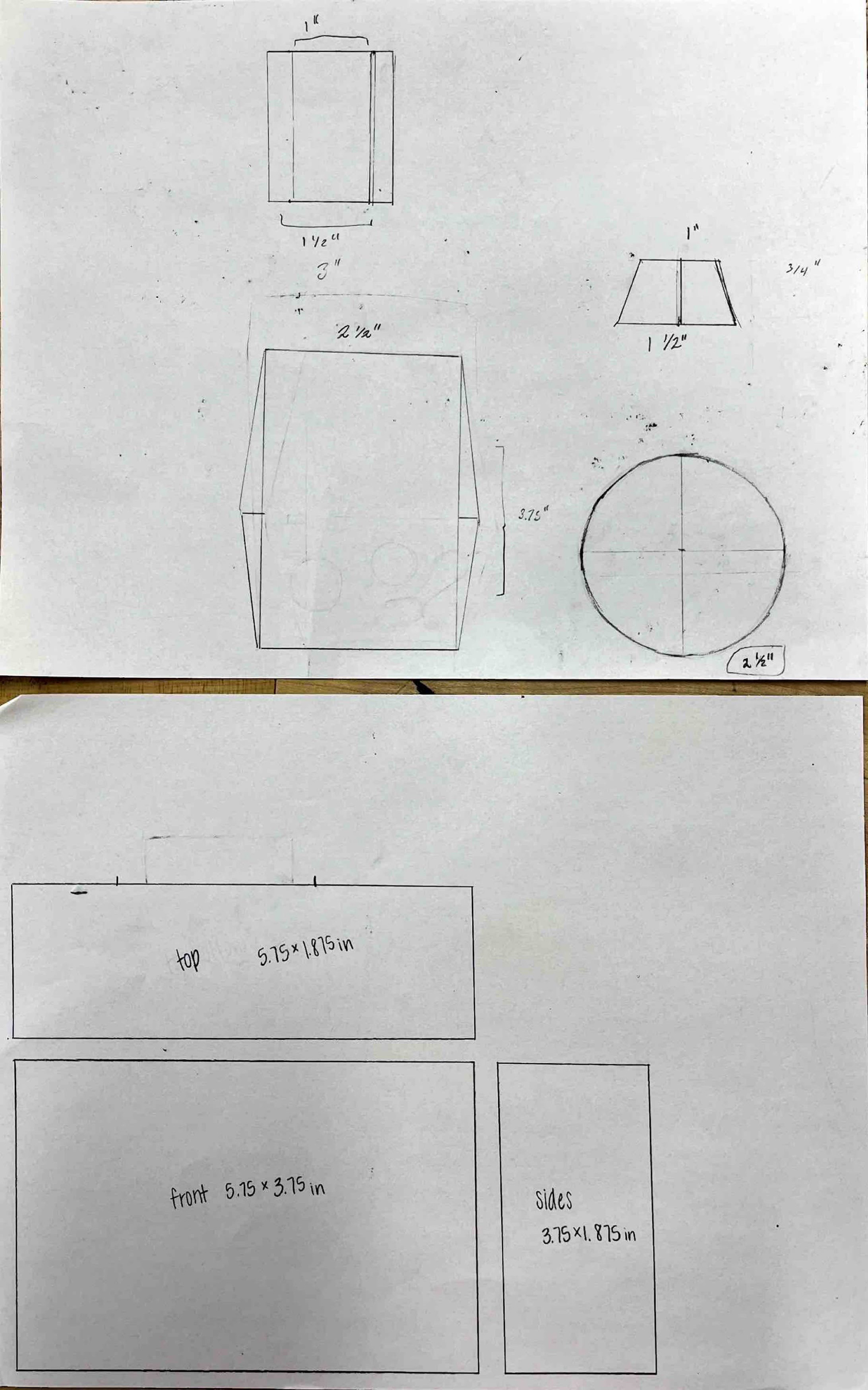

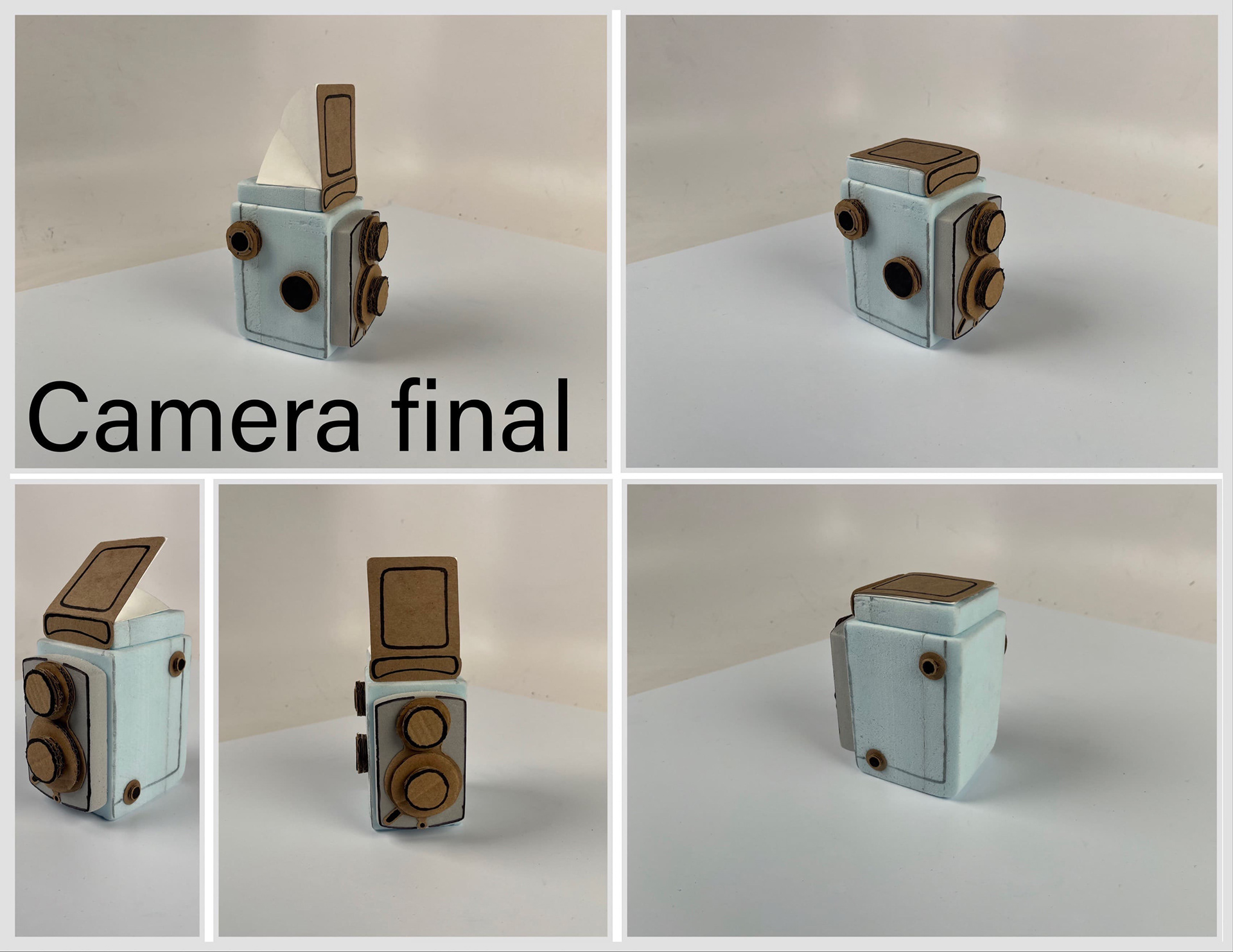

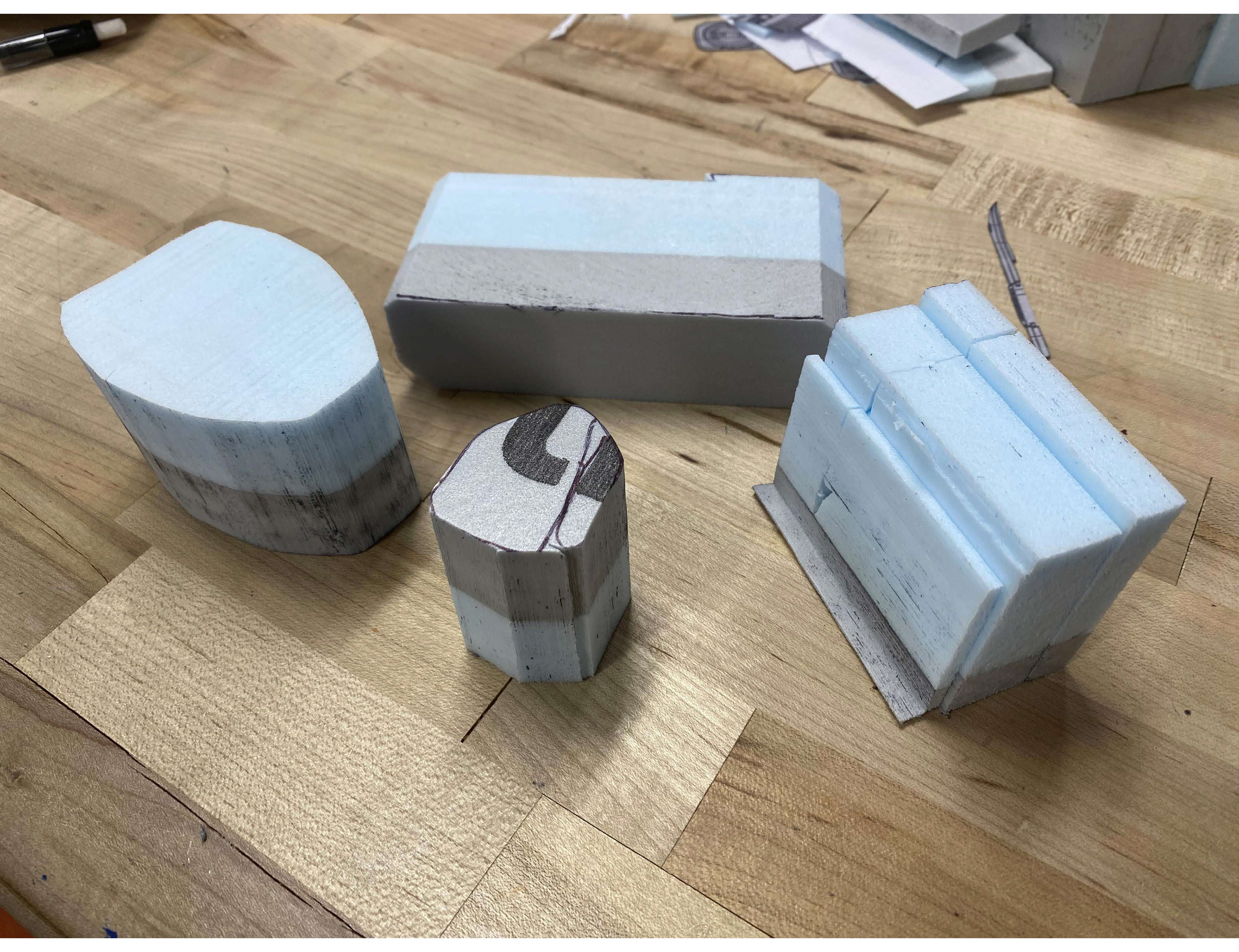

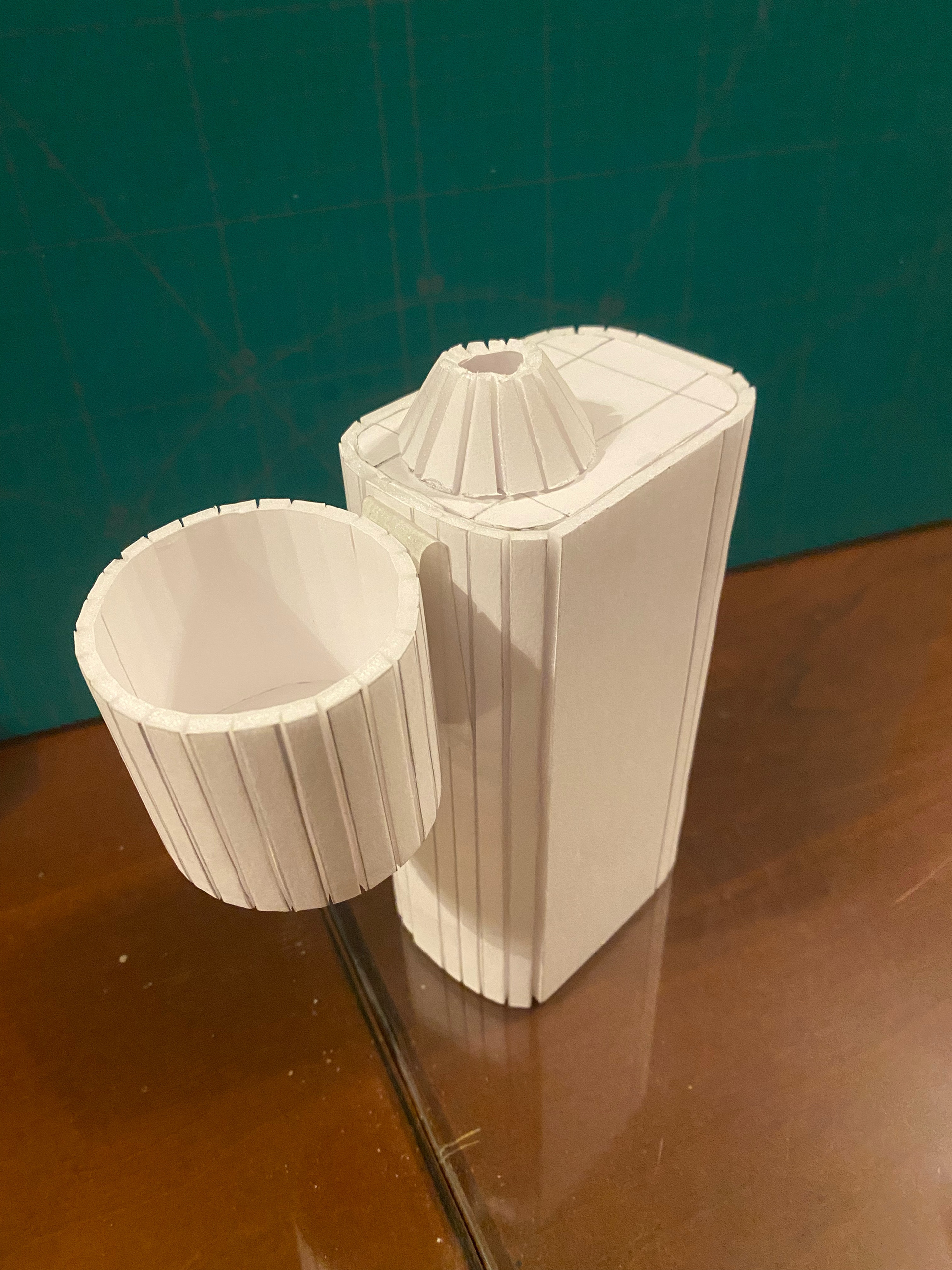

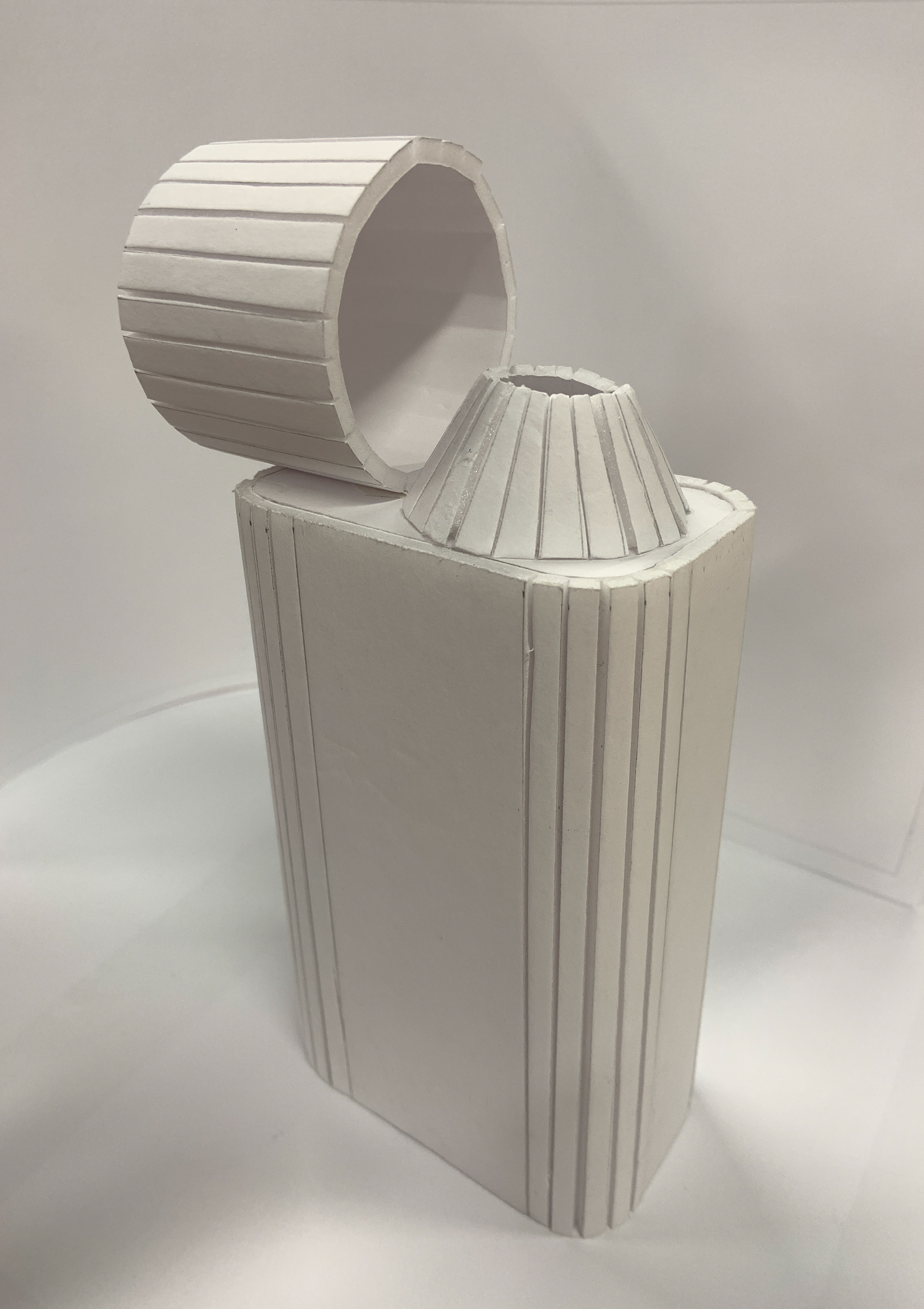

Creating 3D shapes and forms from a 2D sheet is a common practice in a lot of different industries, being able to measure shapes, template them on a flat sheet , engrave, score and cut out, and finally glue and form the shapes is a good skill to have on hand.

Here, the students are assigned to create 3 shapes in particular, a Cylinder, a sphere-o-cube (Cube with filleted edges), and a Truncated cone. They are provided a template with measurements (they can change the measurements if they want), and a familiar material Foam-core.

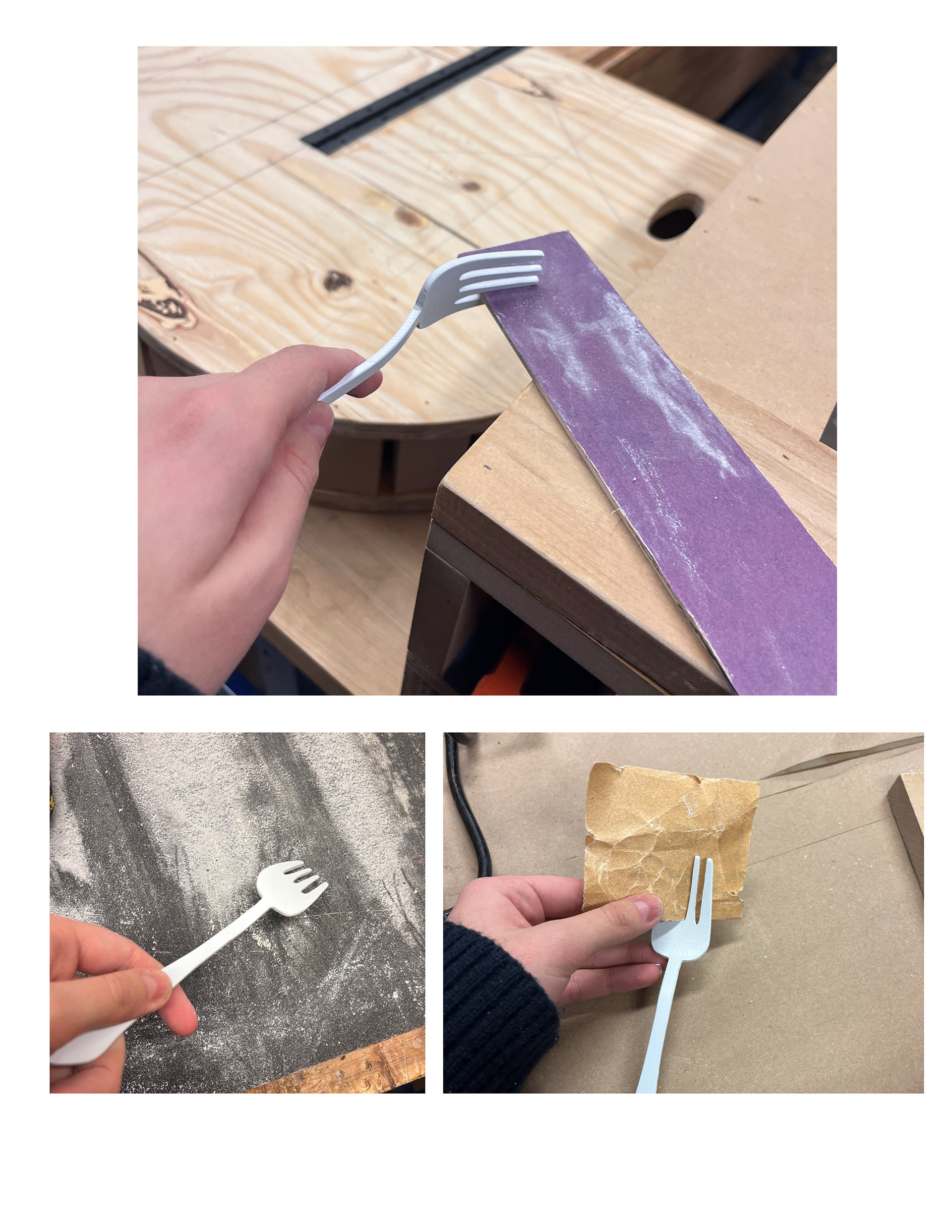

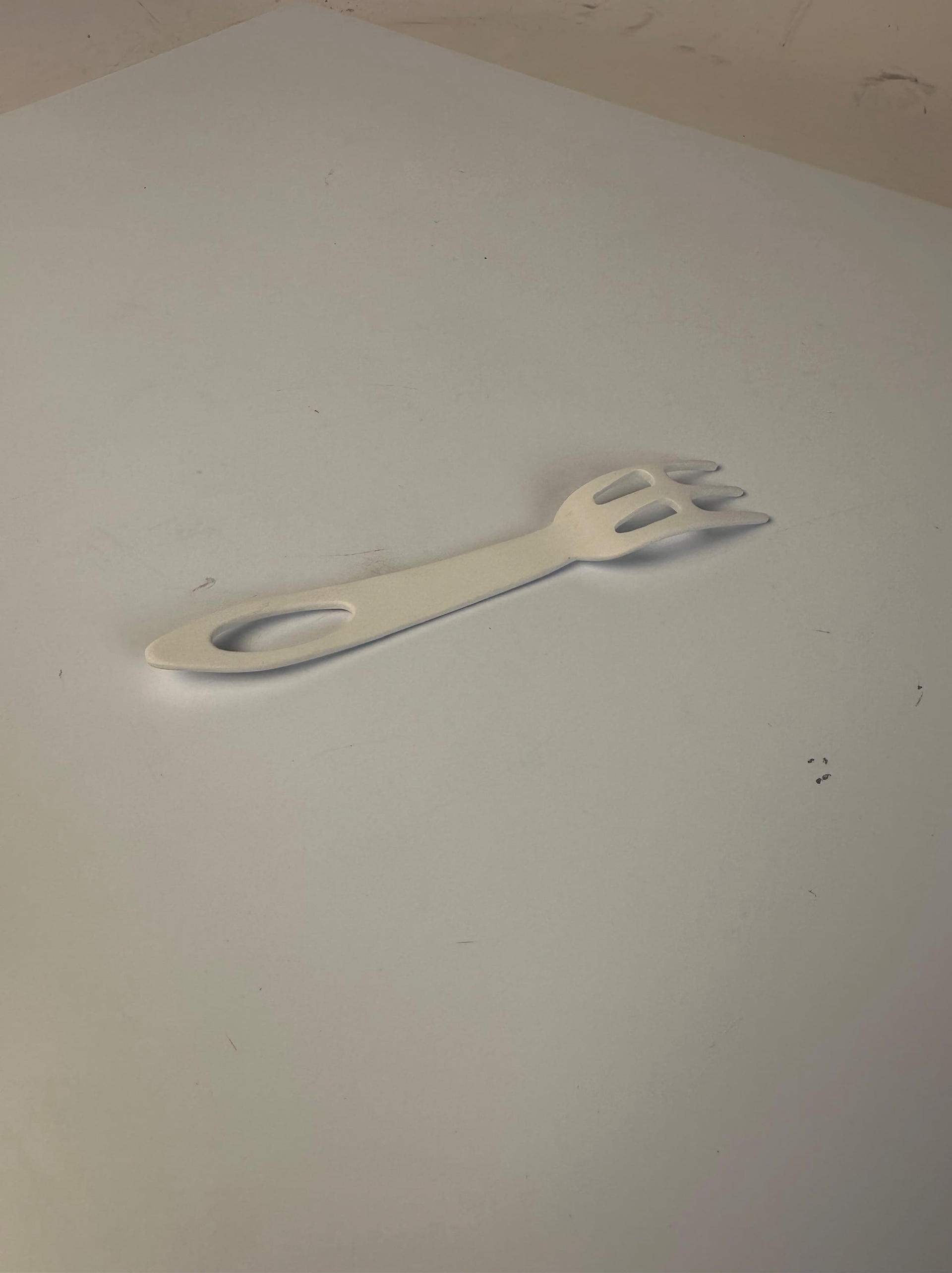

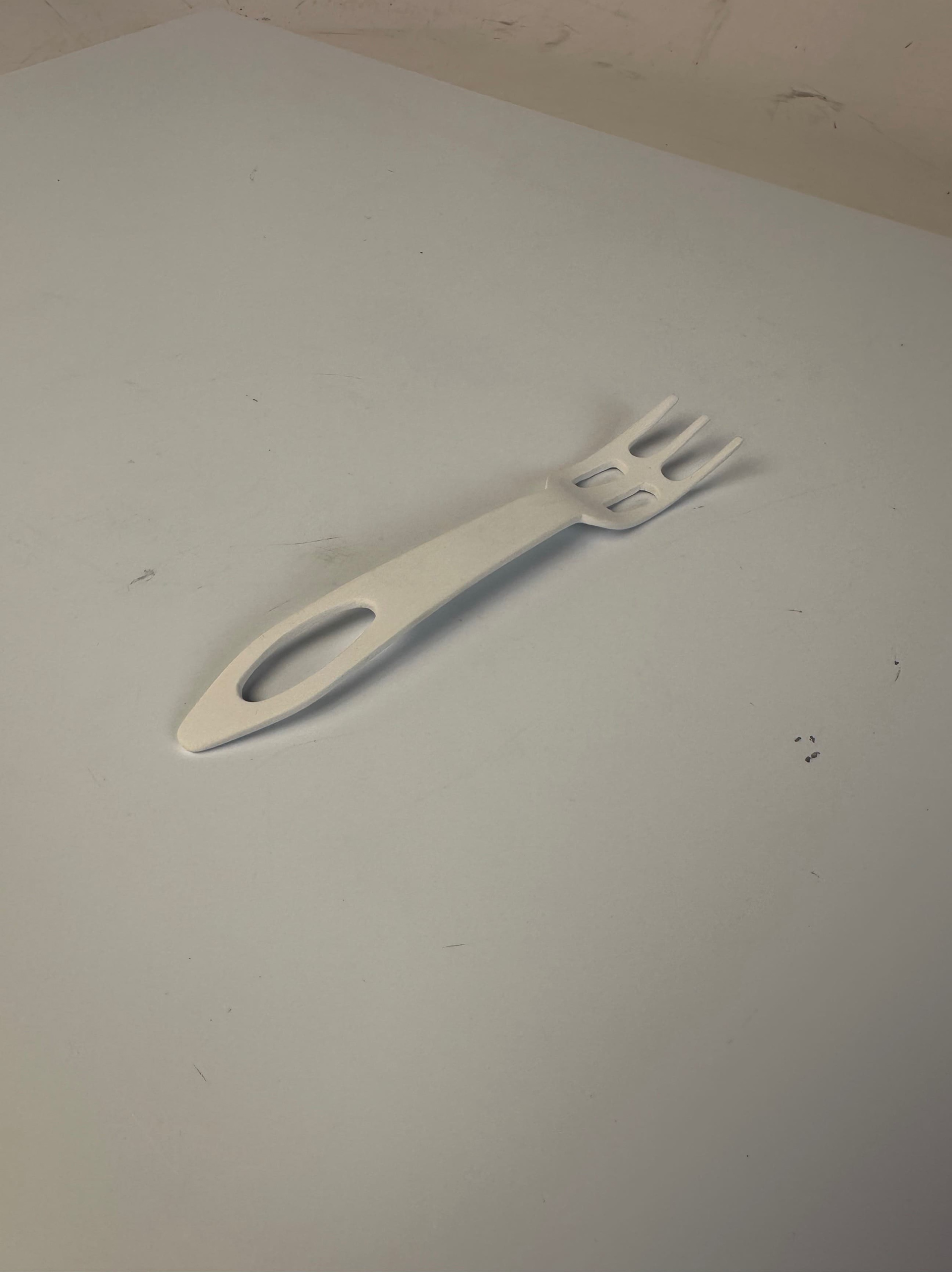

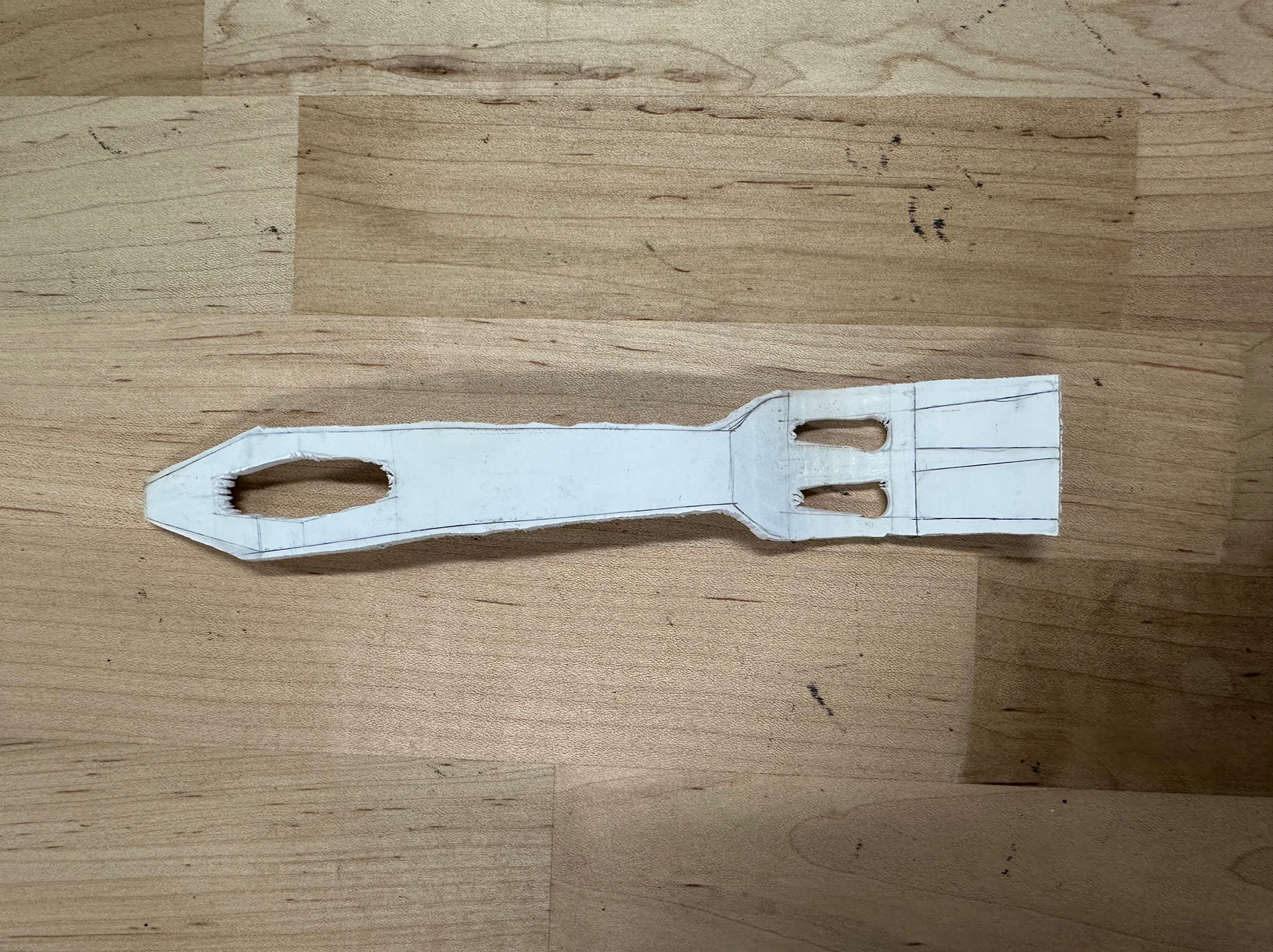

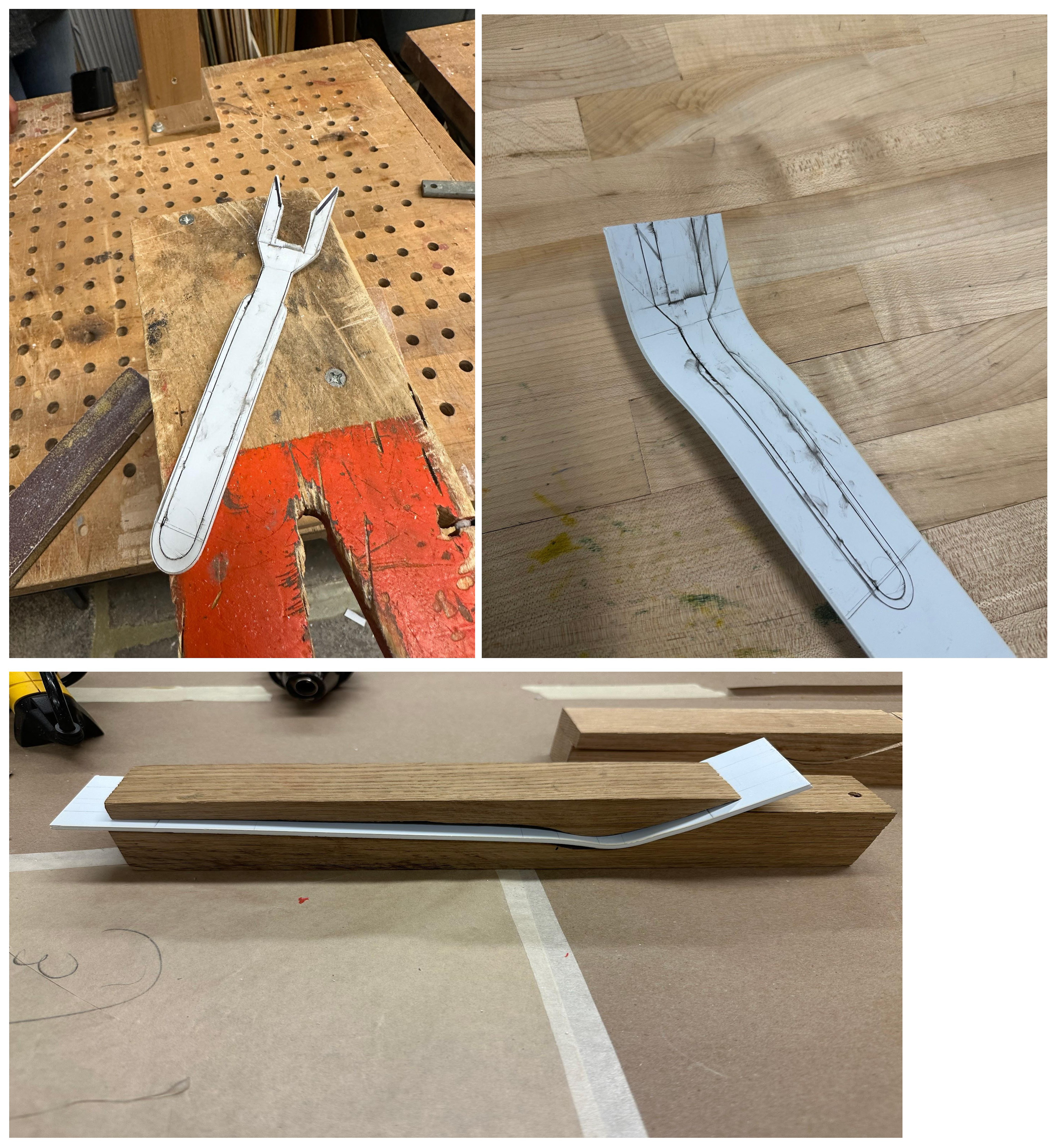

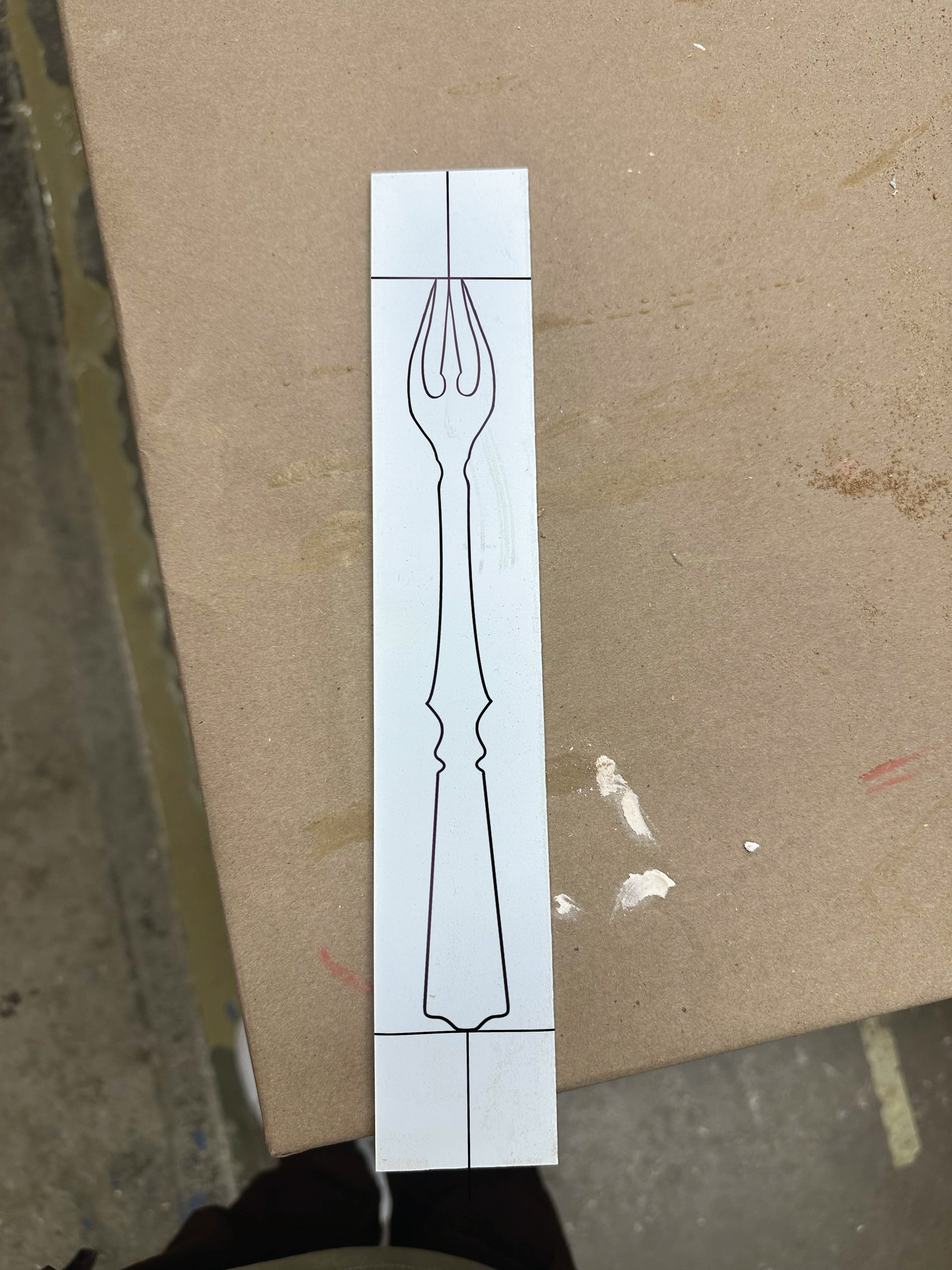

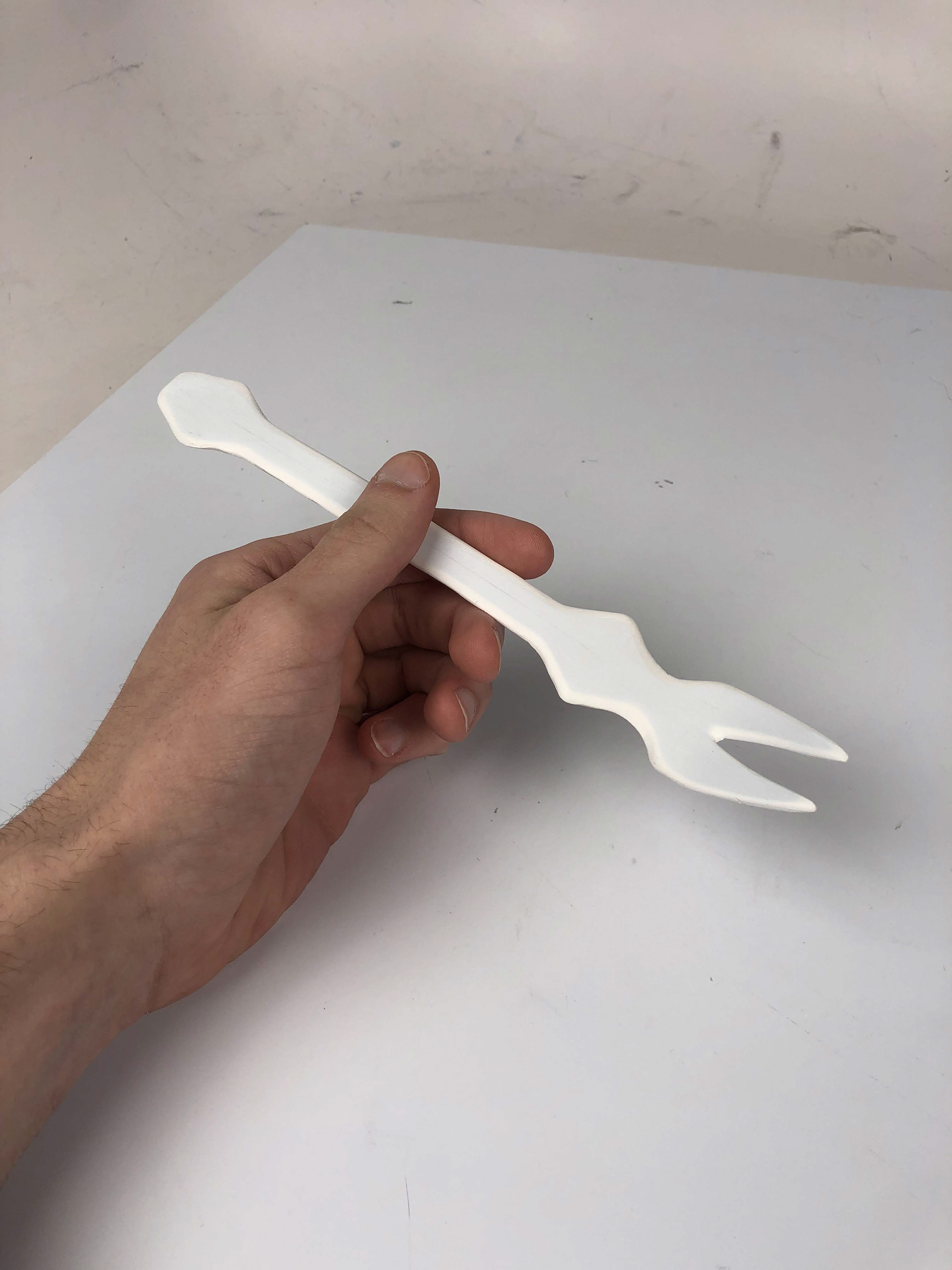

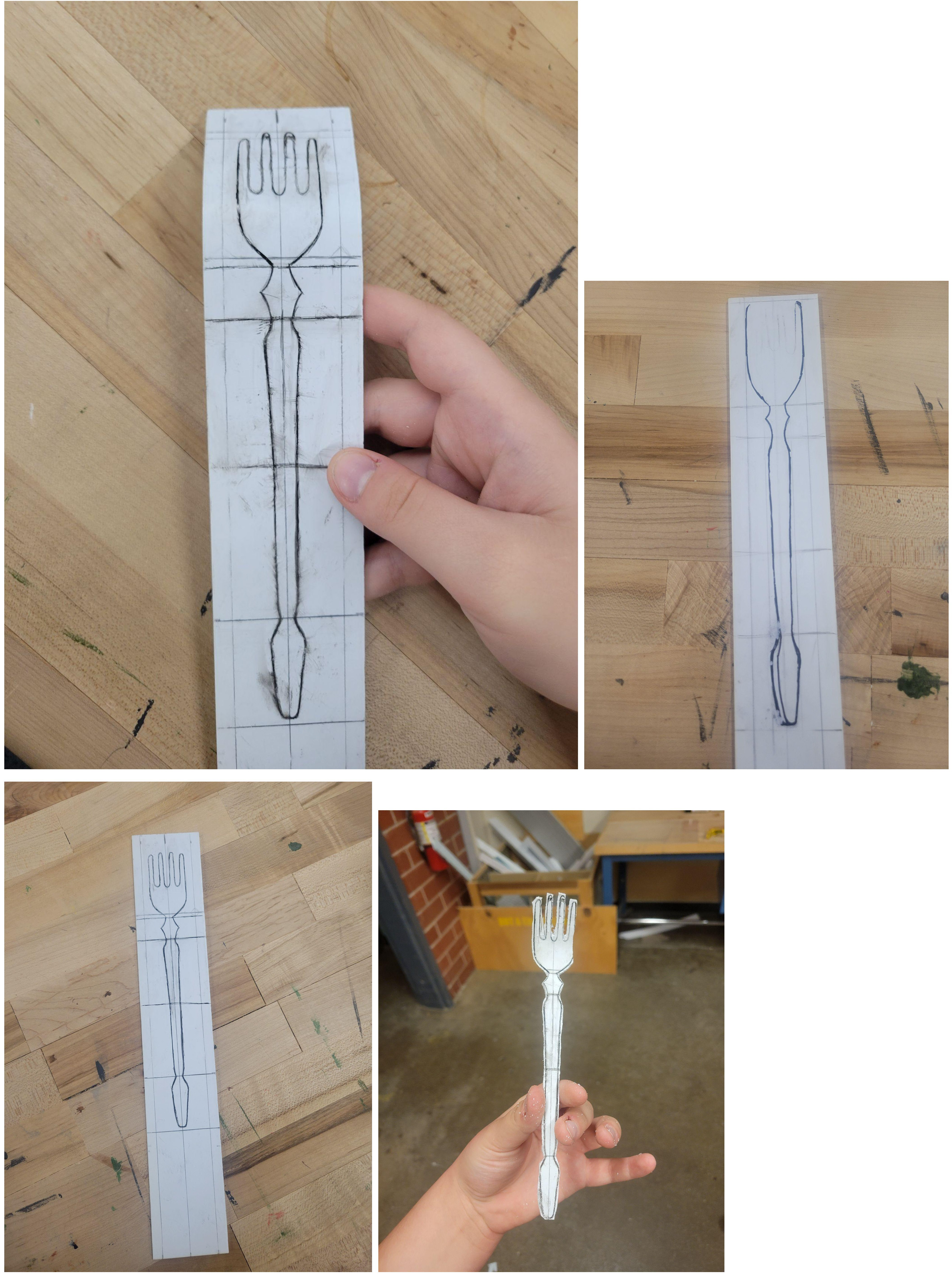

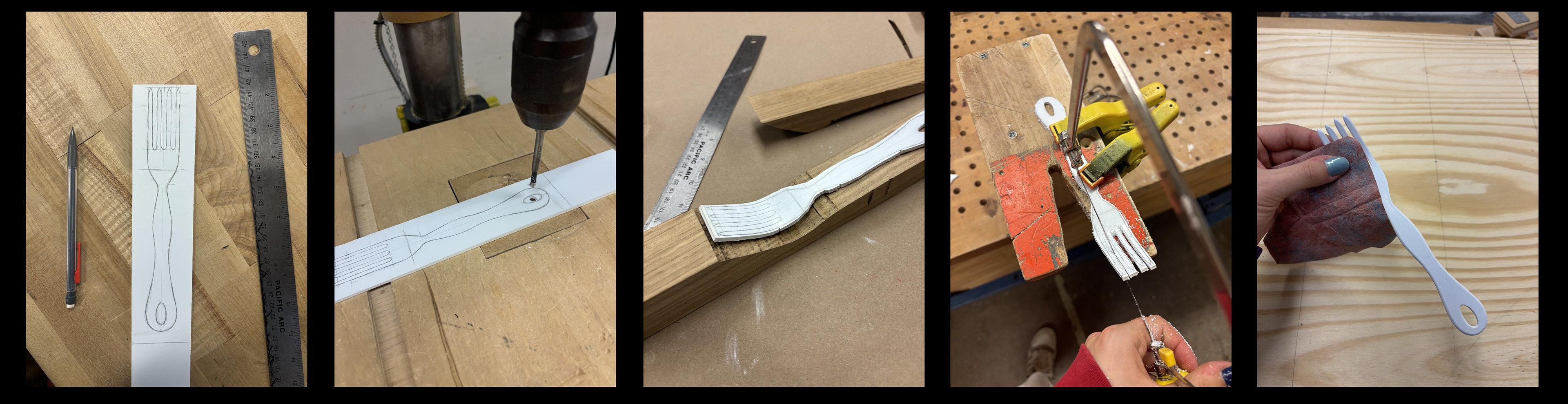

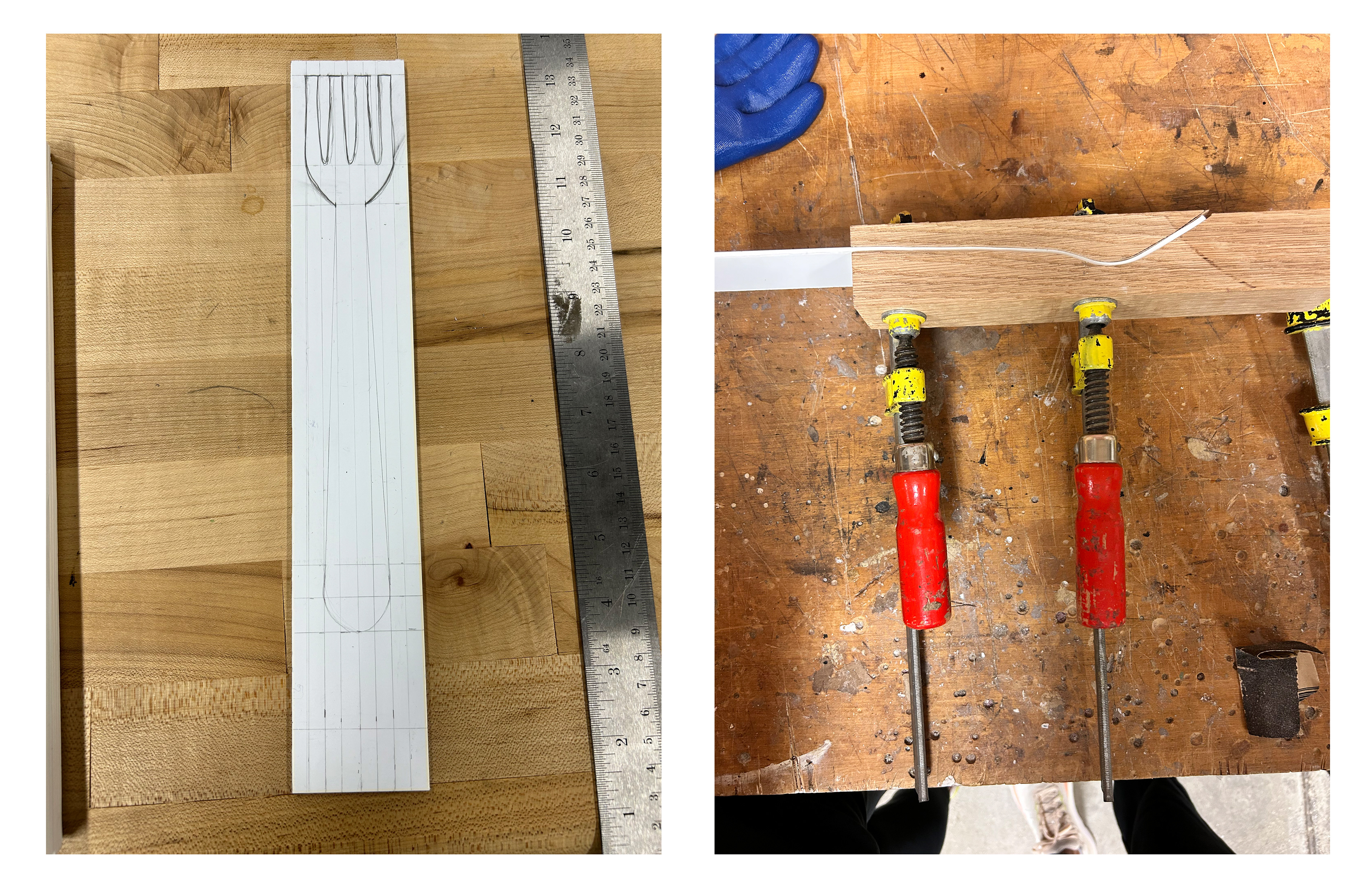

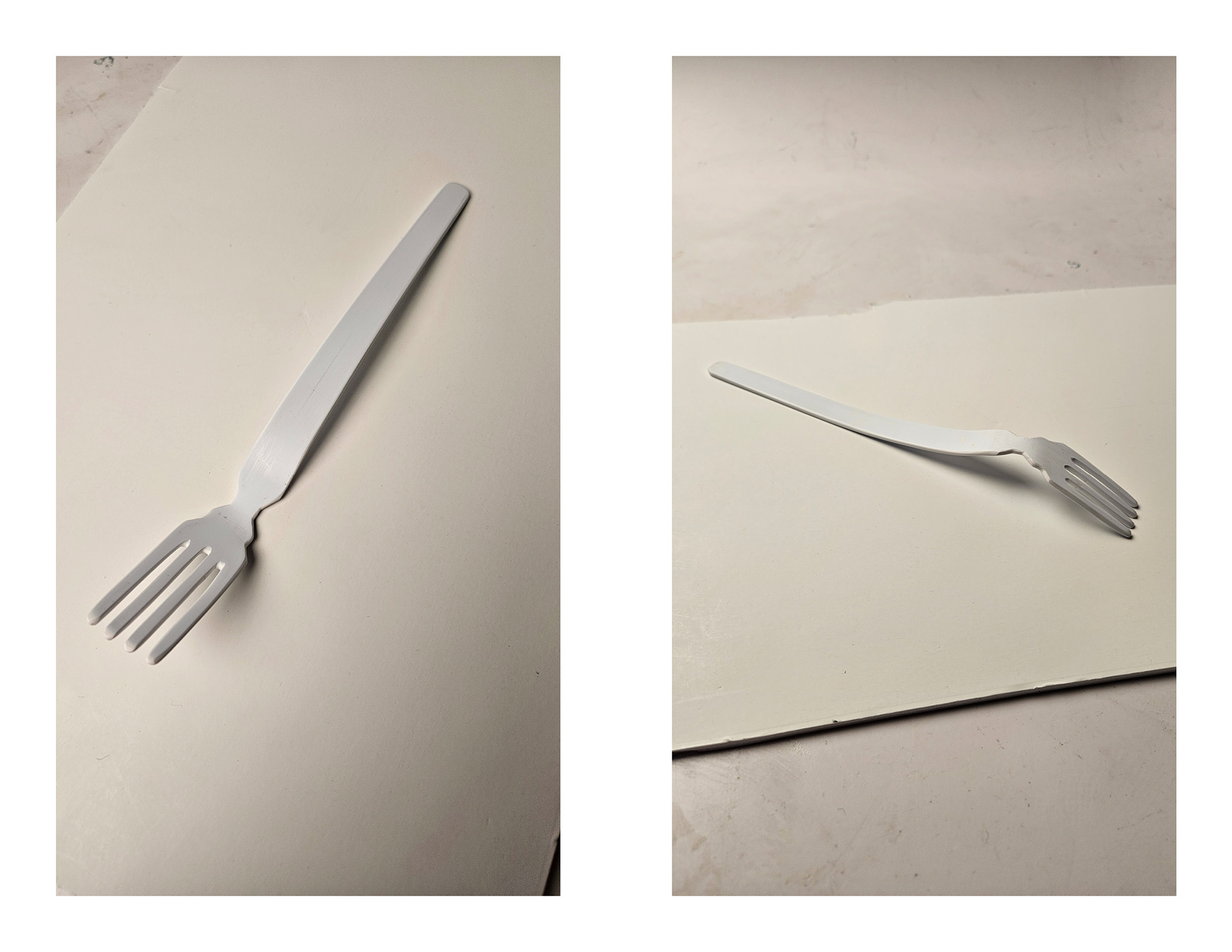

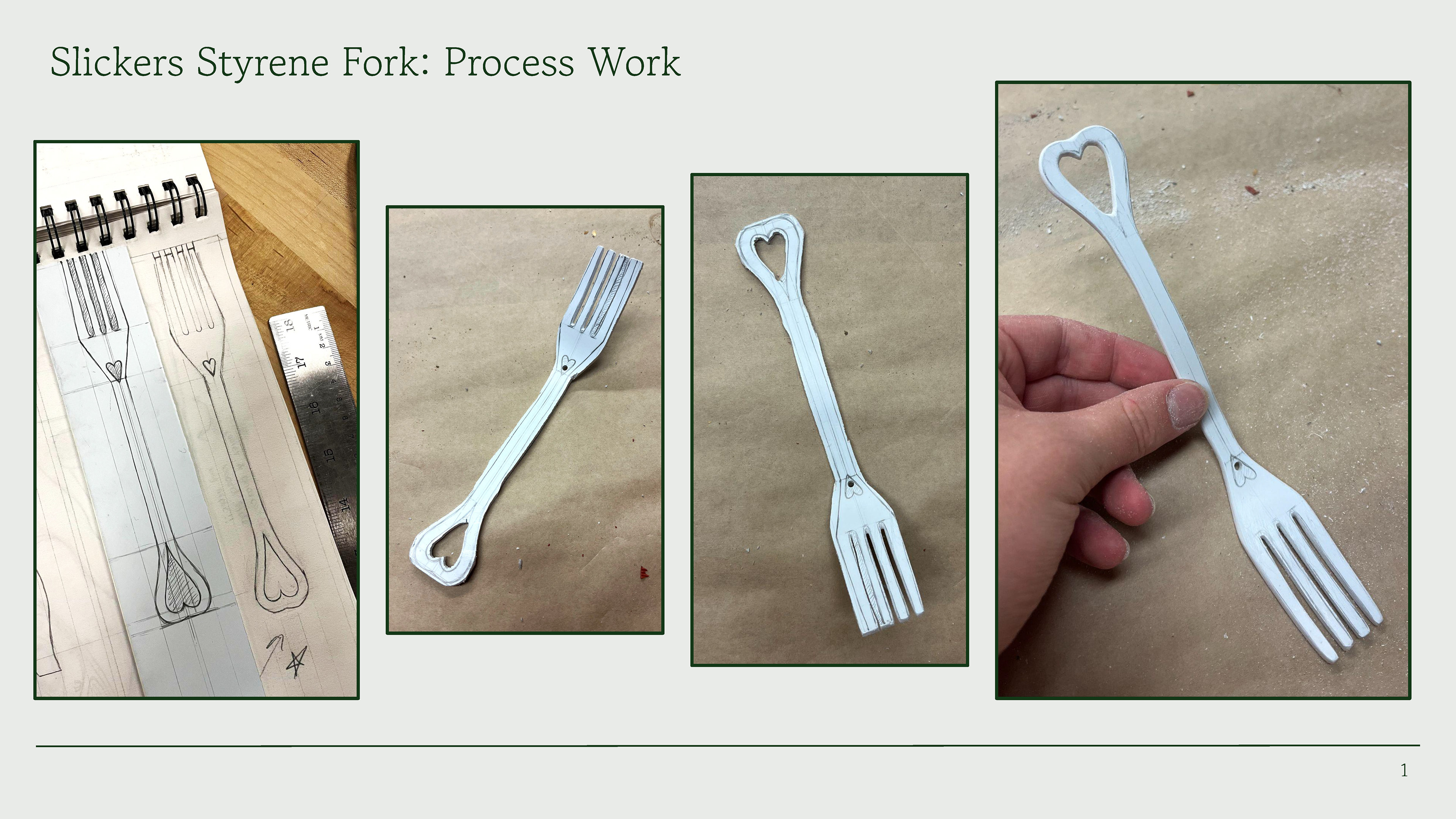

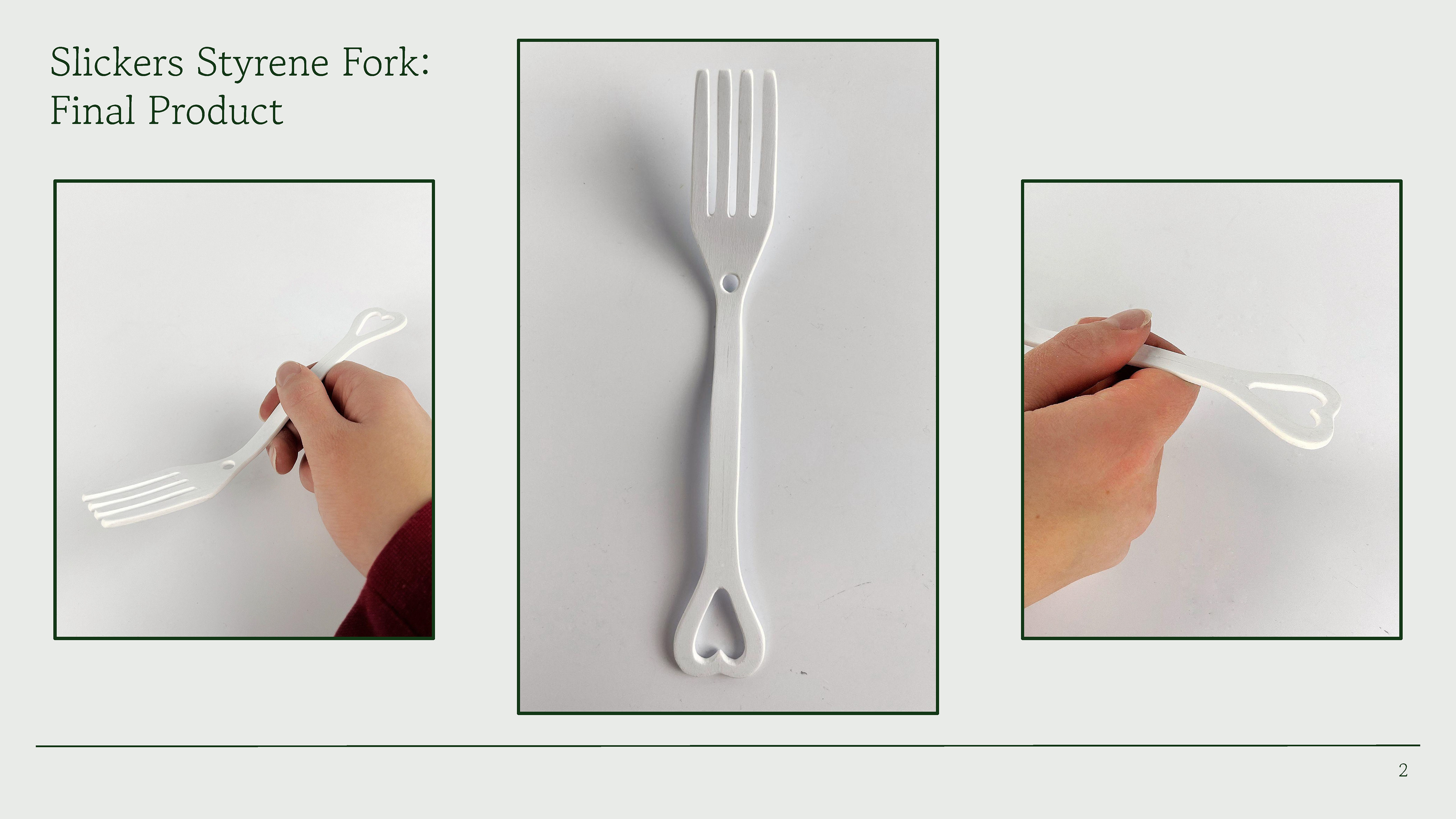

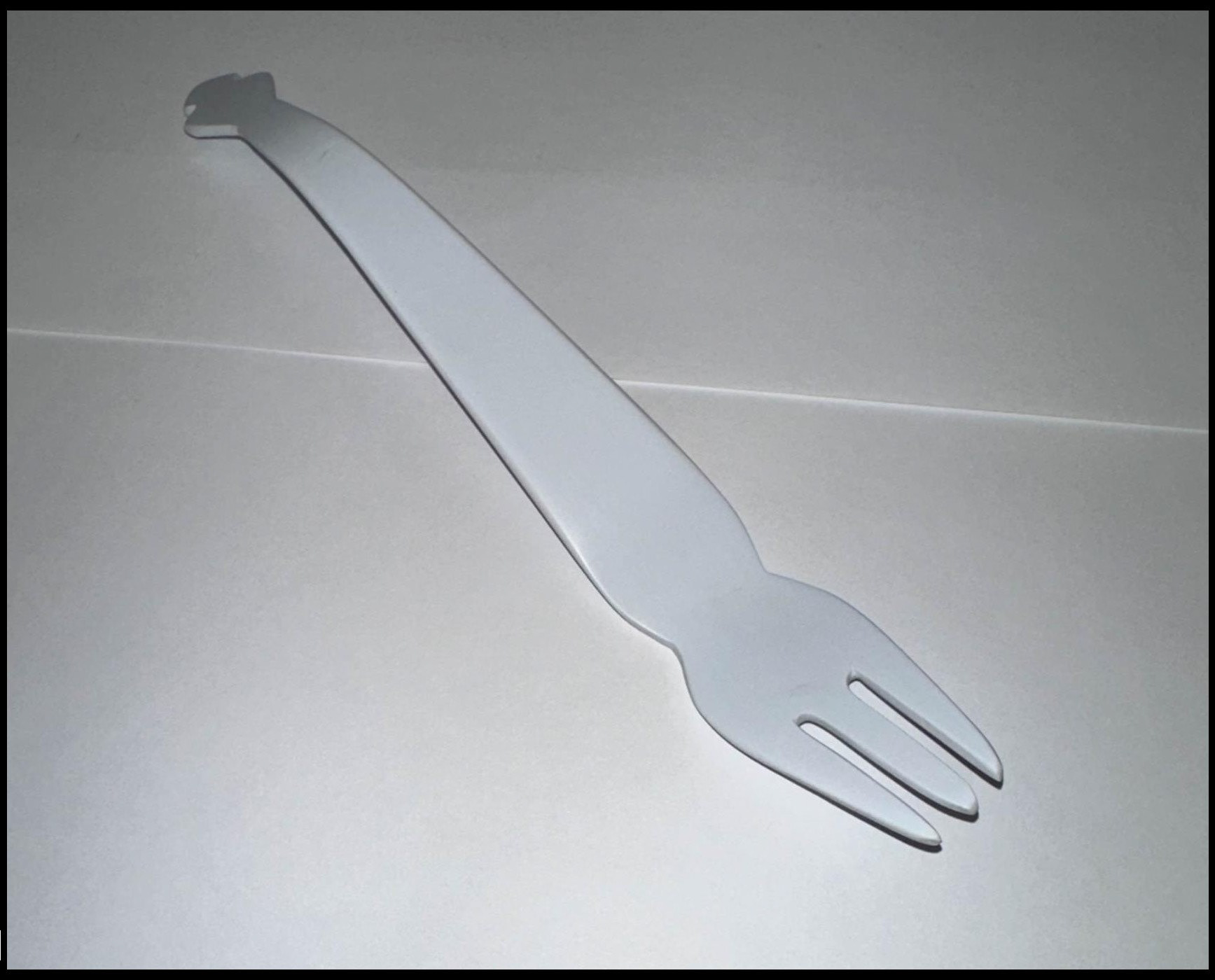

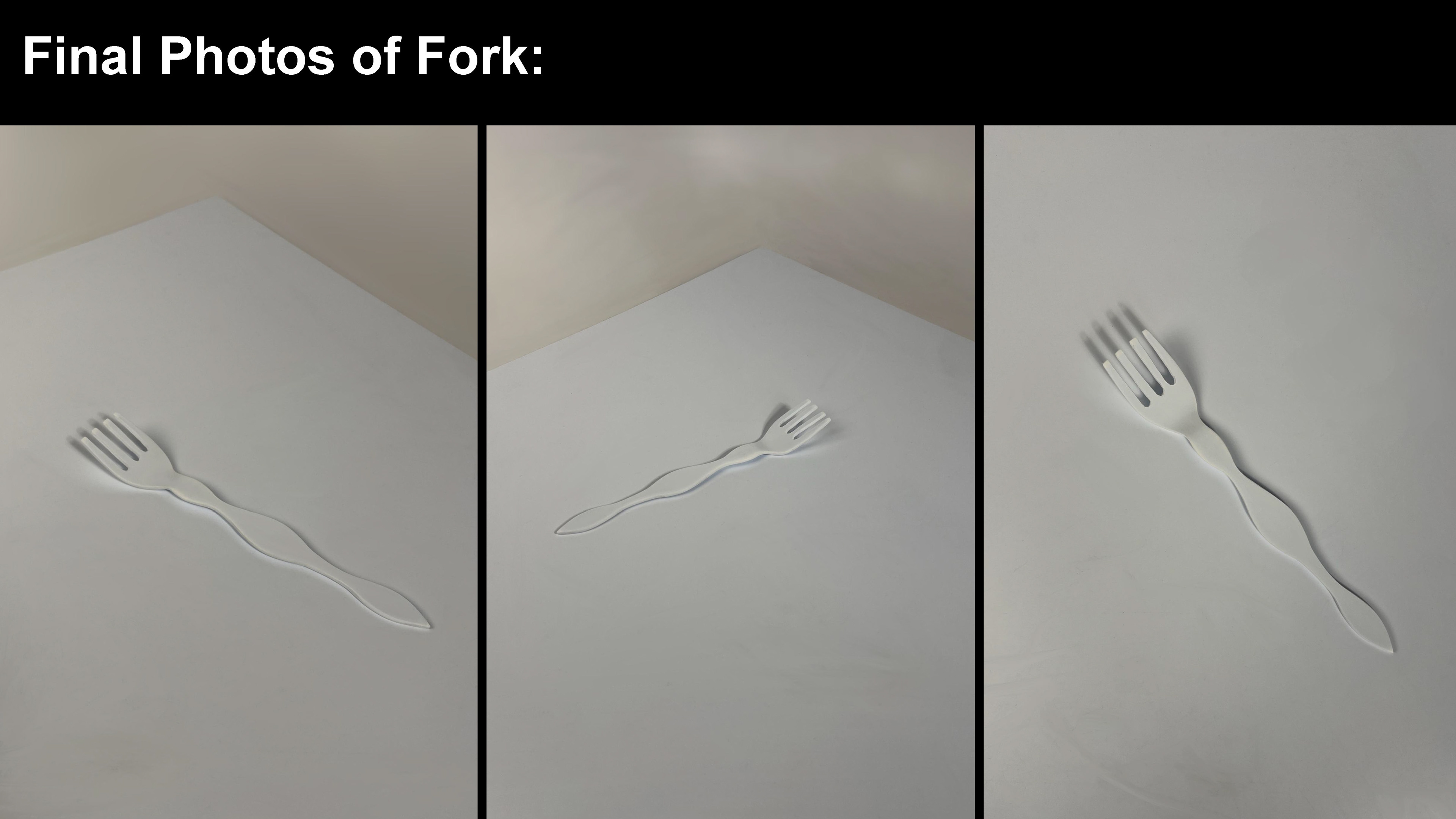

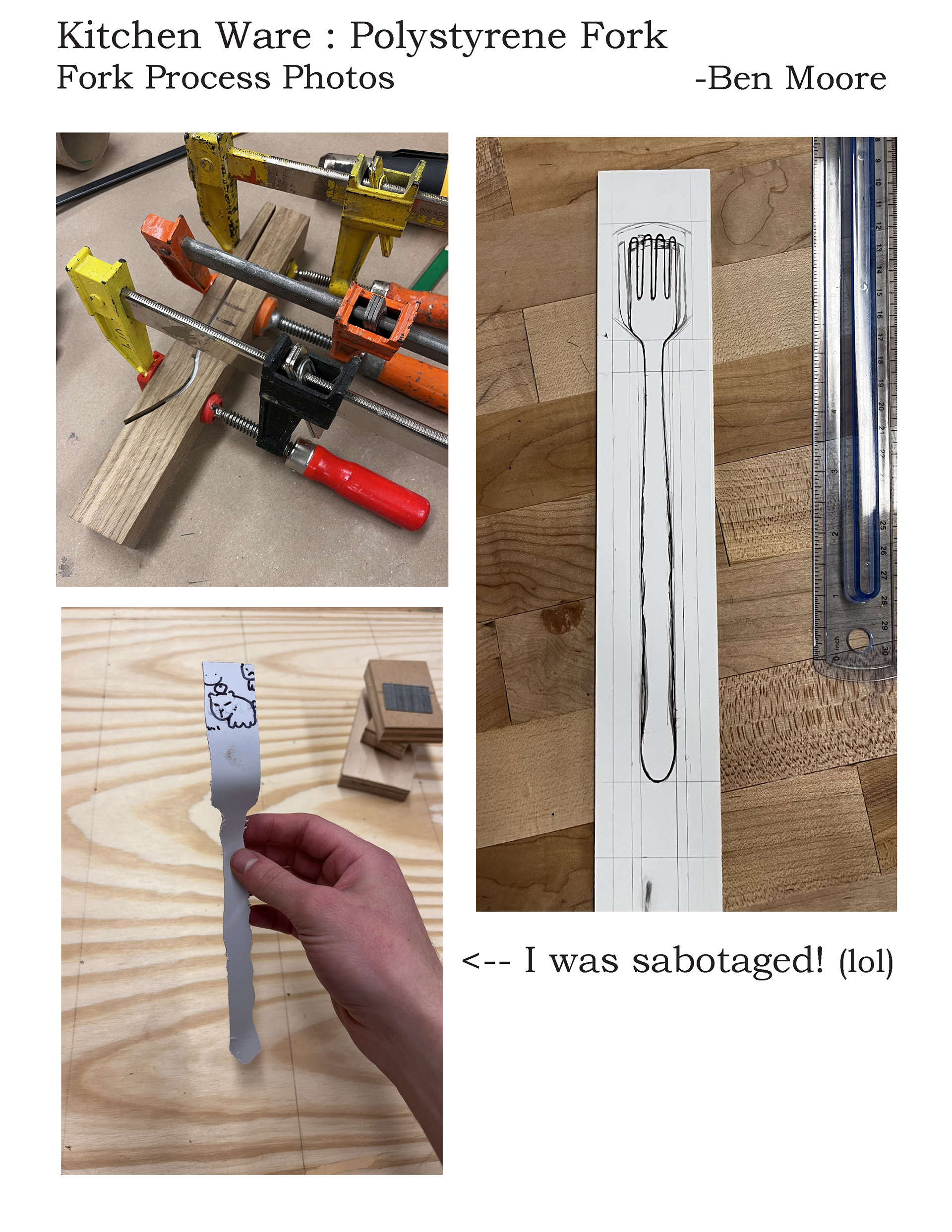

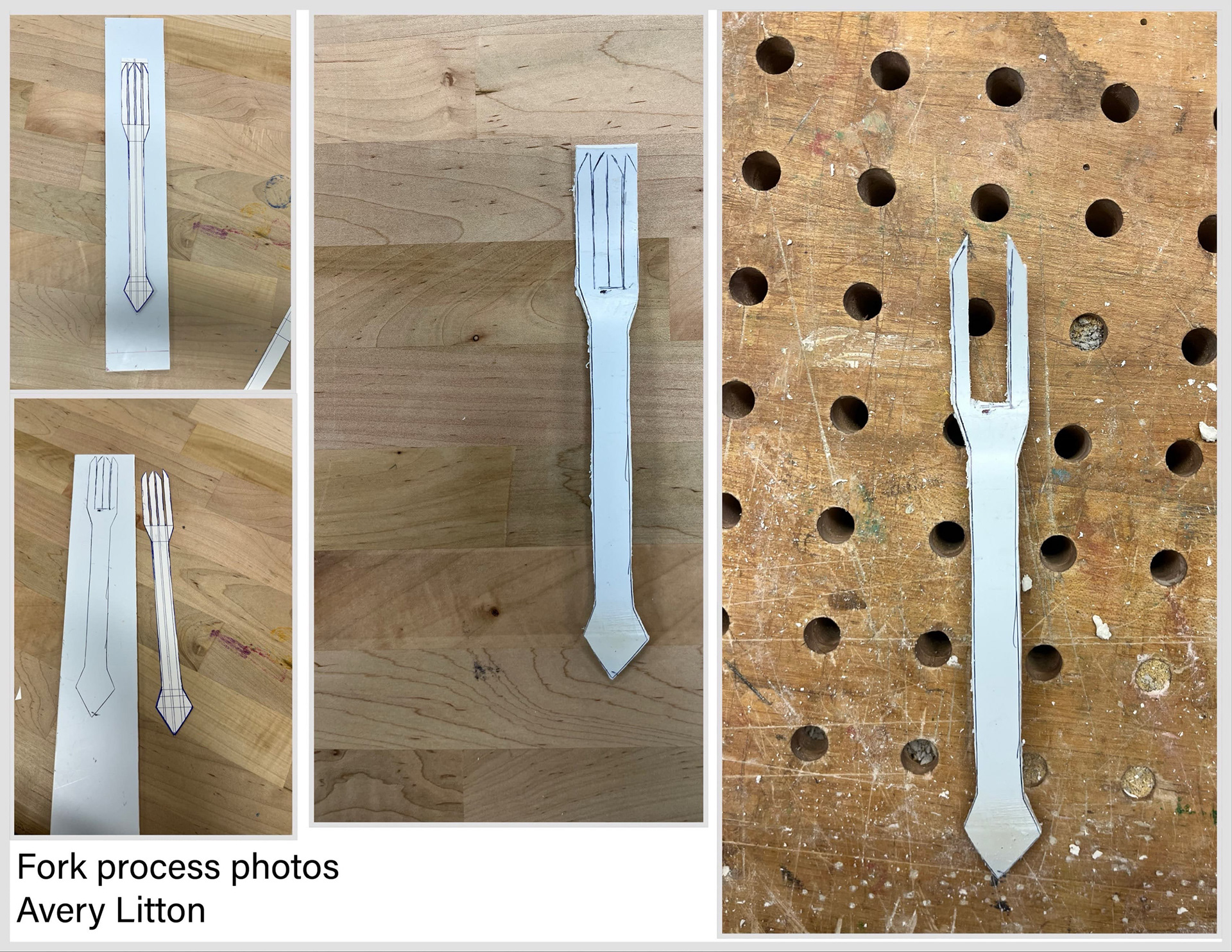

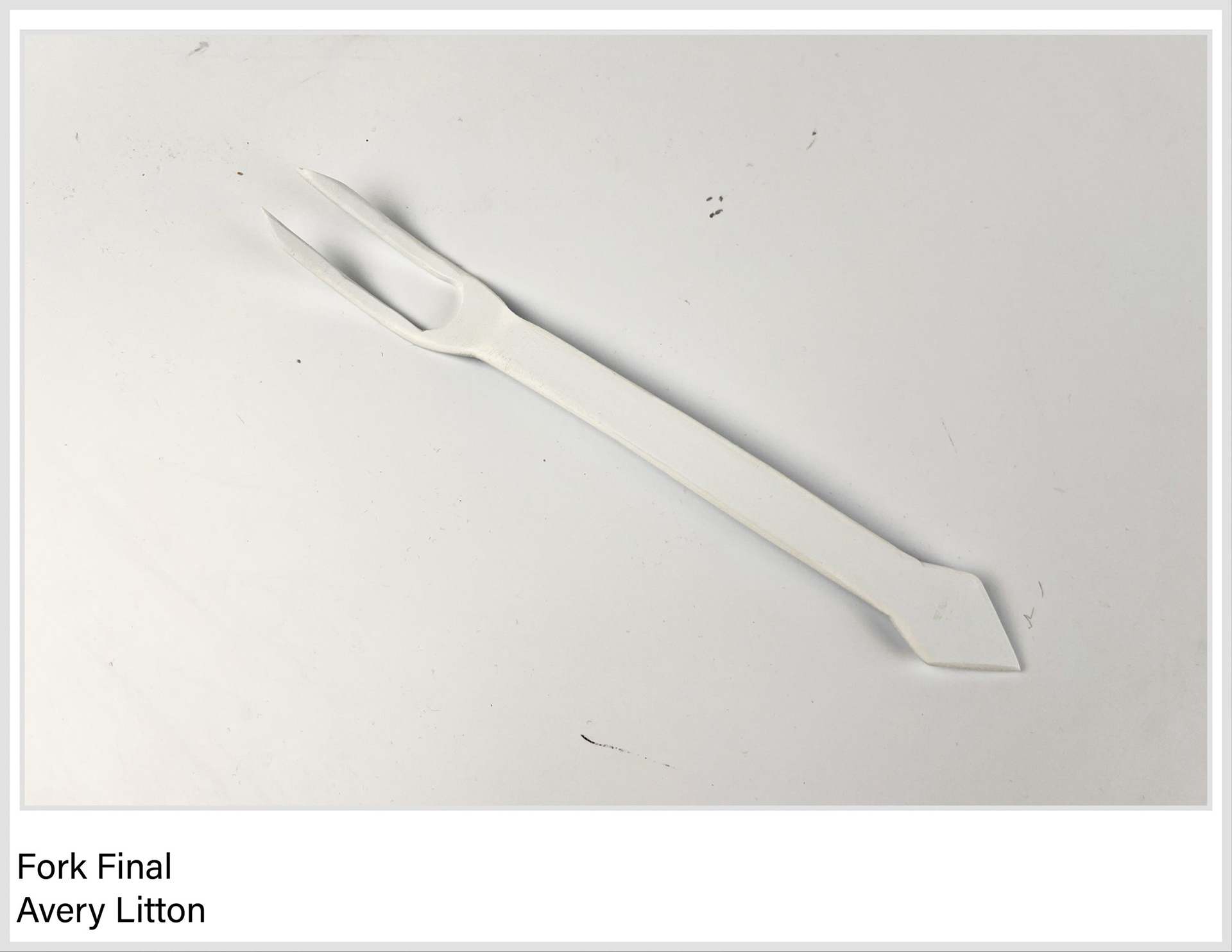

One of the first basic hand tools to study for new Industrial Design students is a utensil they have used and use daily. A Fork. Studying the ergonomic angles, curves and textures of a fork to understand the basic design of cutlery.

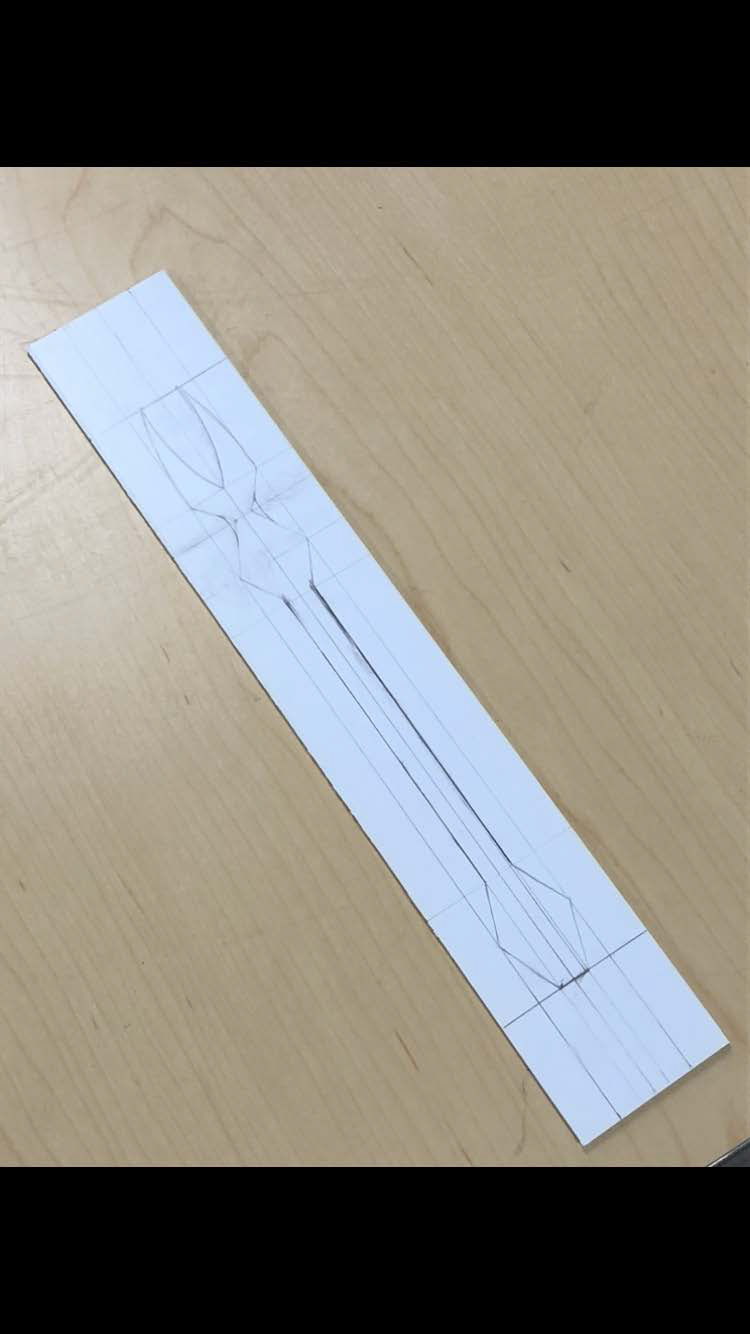

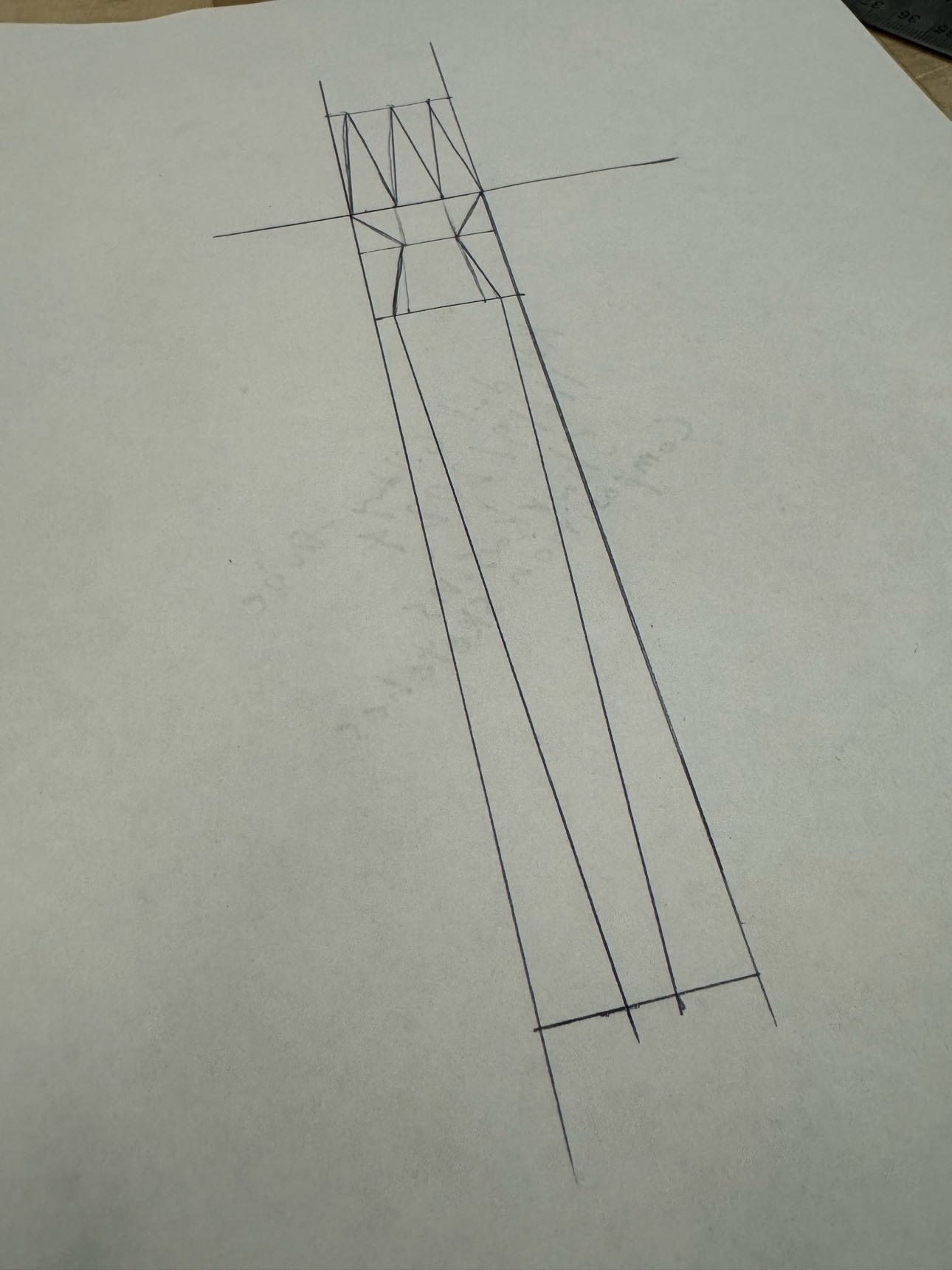

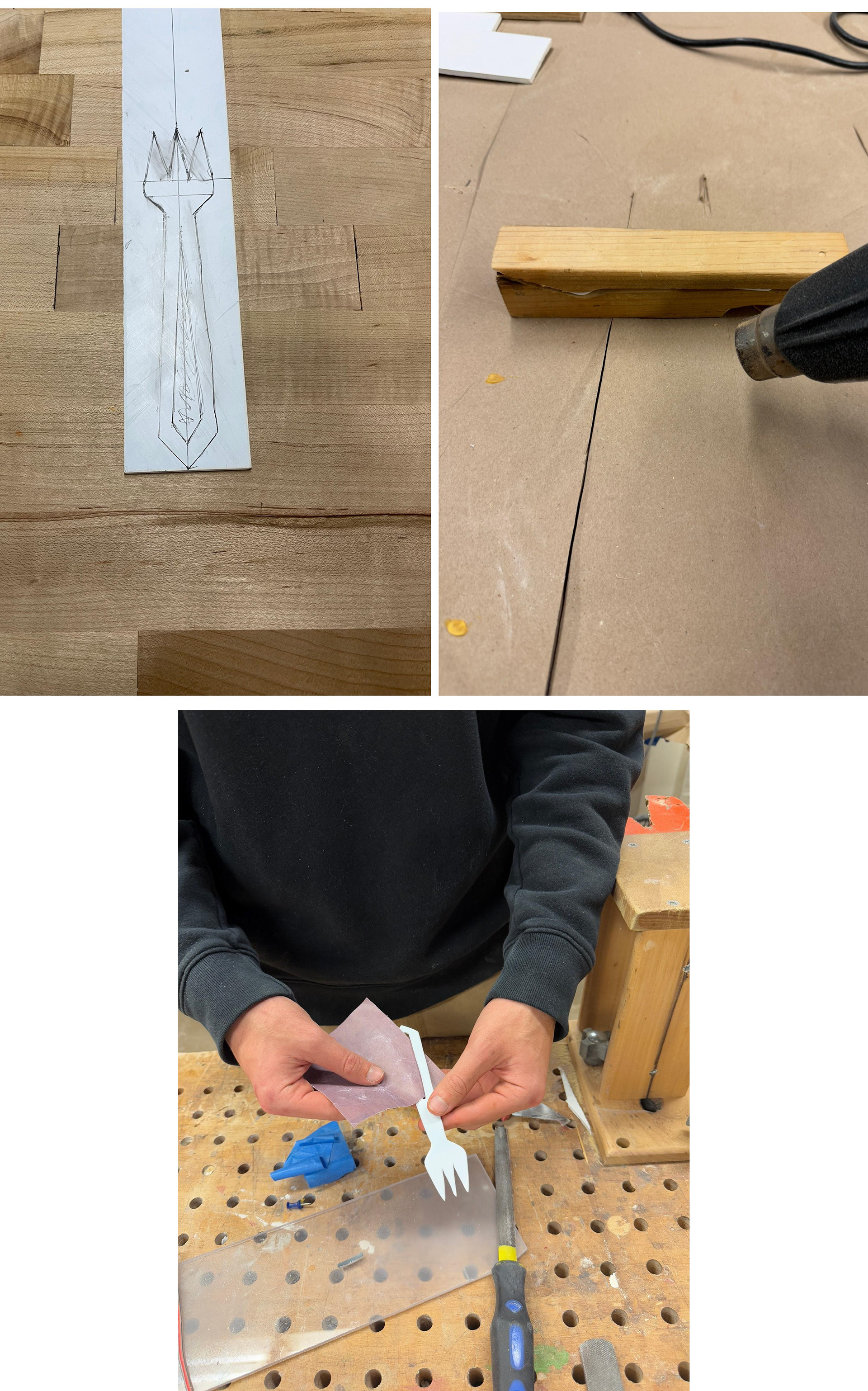

Here the students are given dimensions of the box their fork design has to fit into, they are provided with molds for forming the fork curves and finally the Material that can be heat formed, Styrene plastic sheet.

The students design their fork template, they place the template on a flat sheet of styrene sheet, heat form the styrene plastic in the mold, then cut out the tines and the template of their fork.

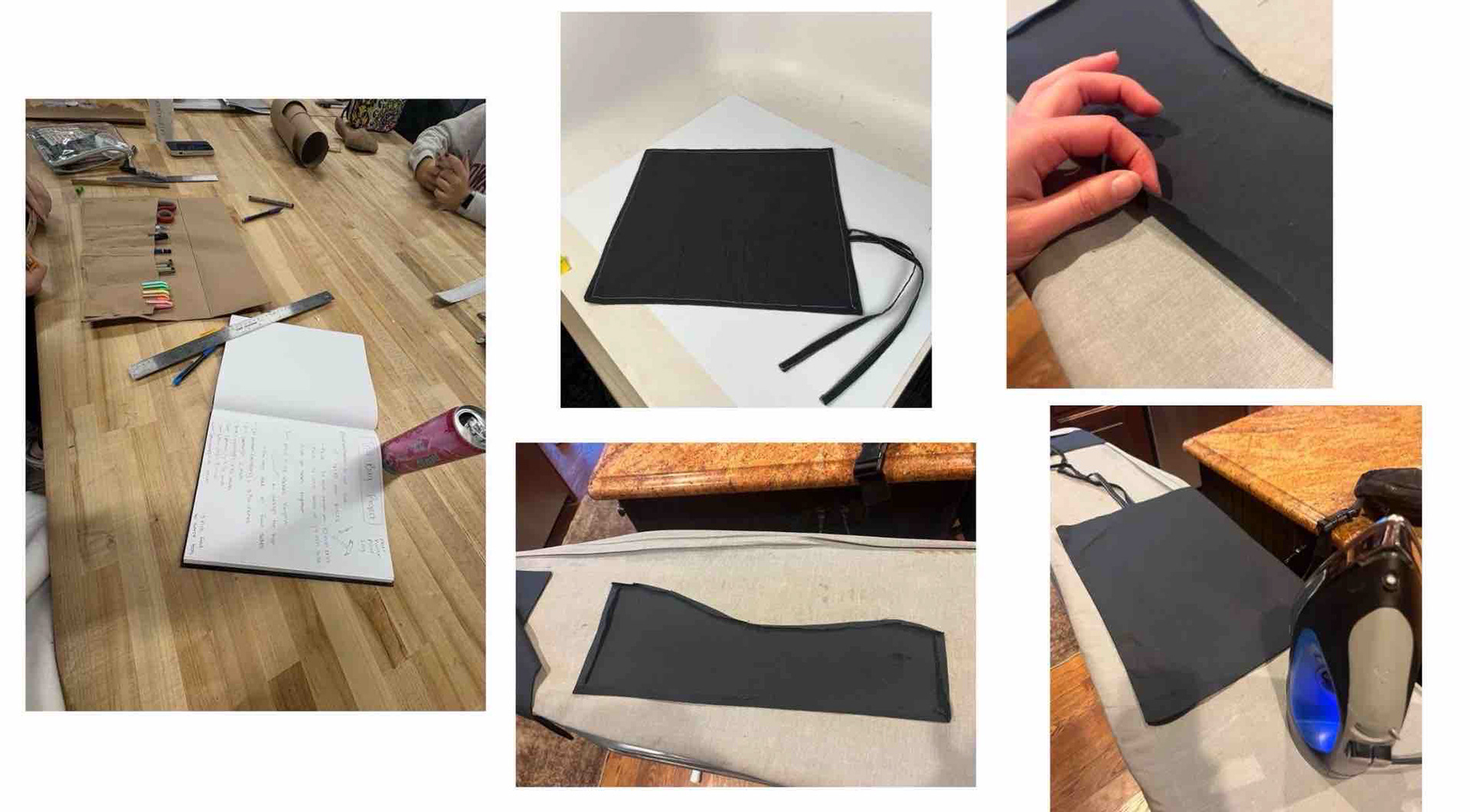

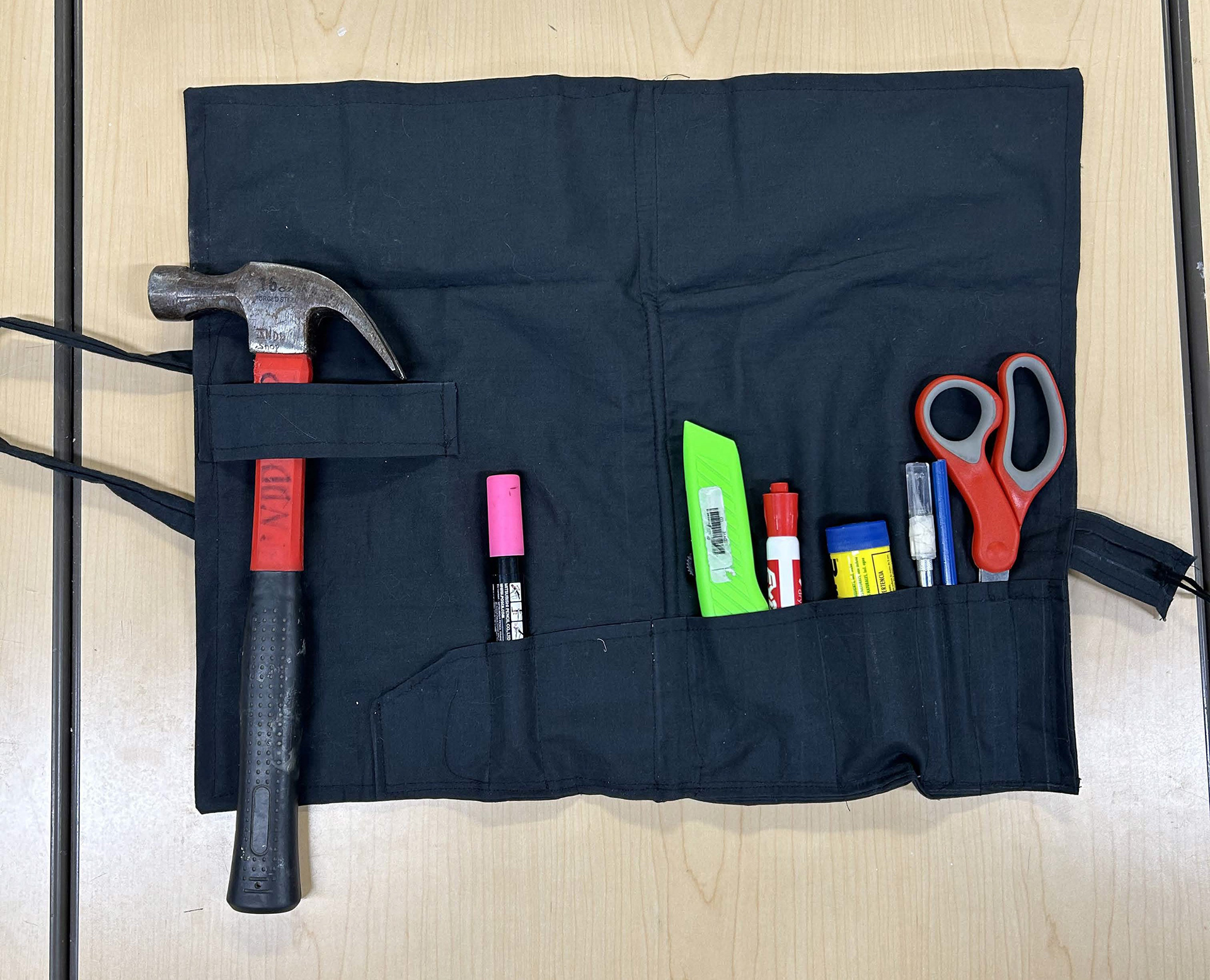

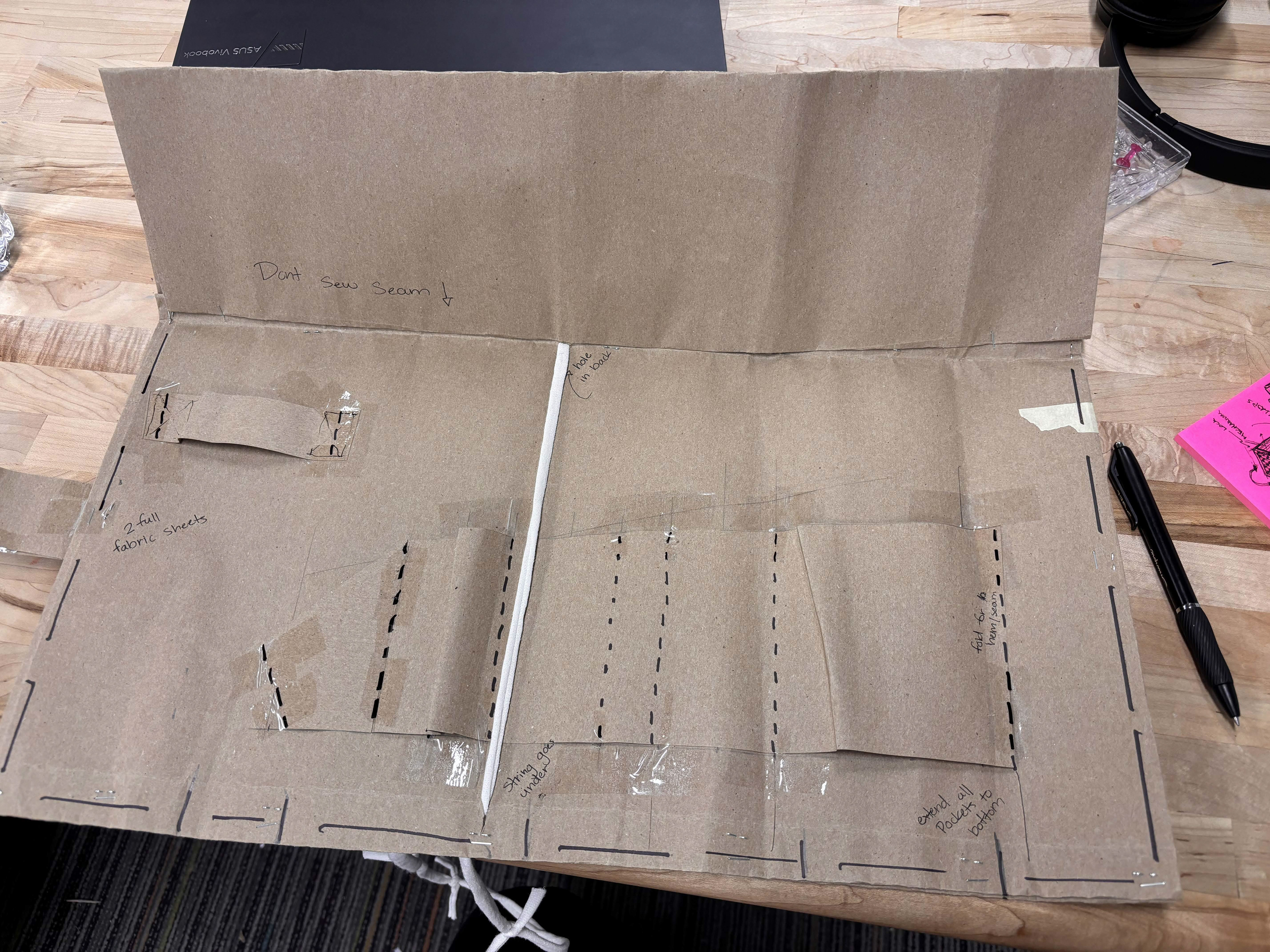

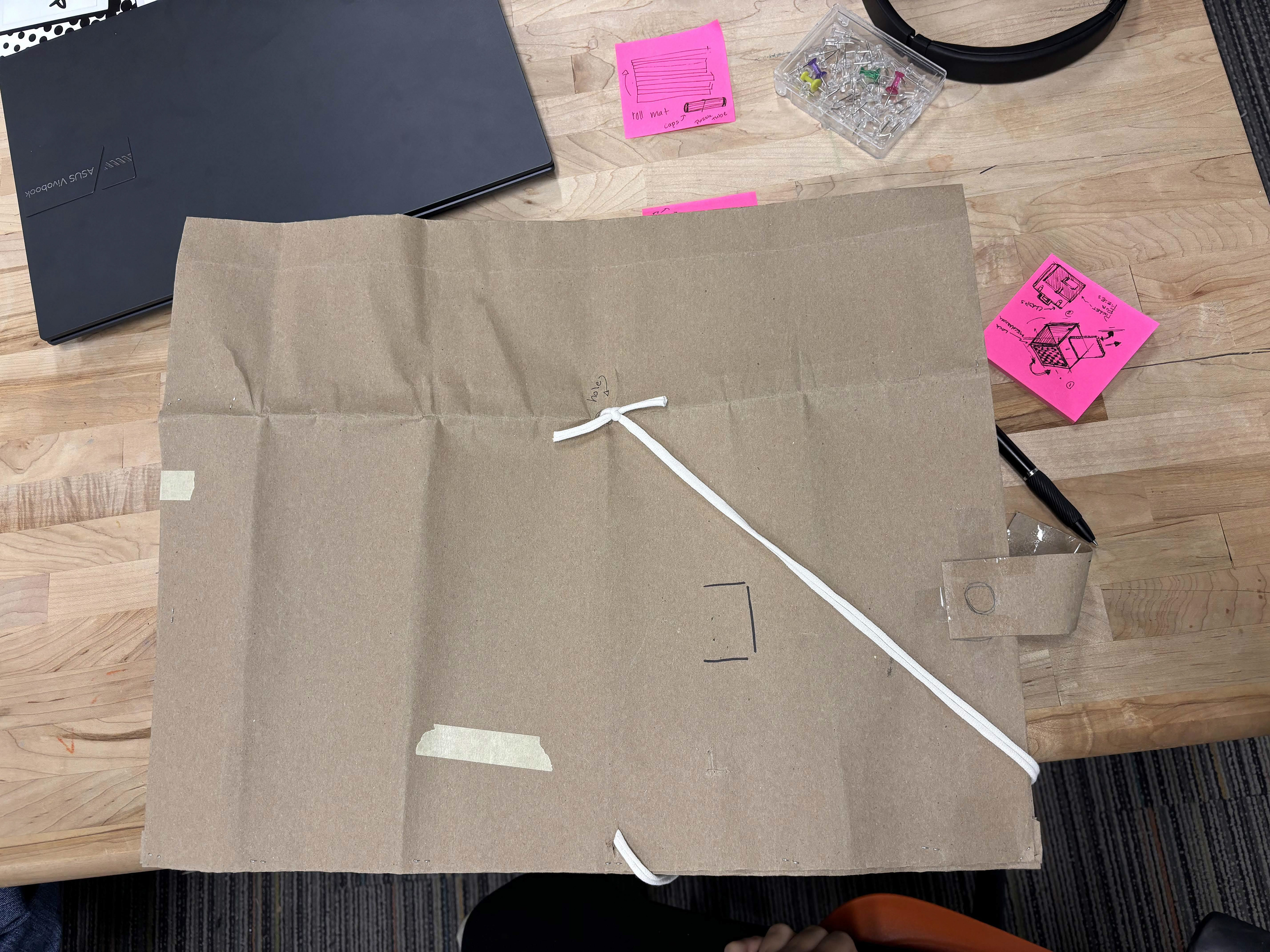

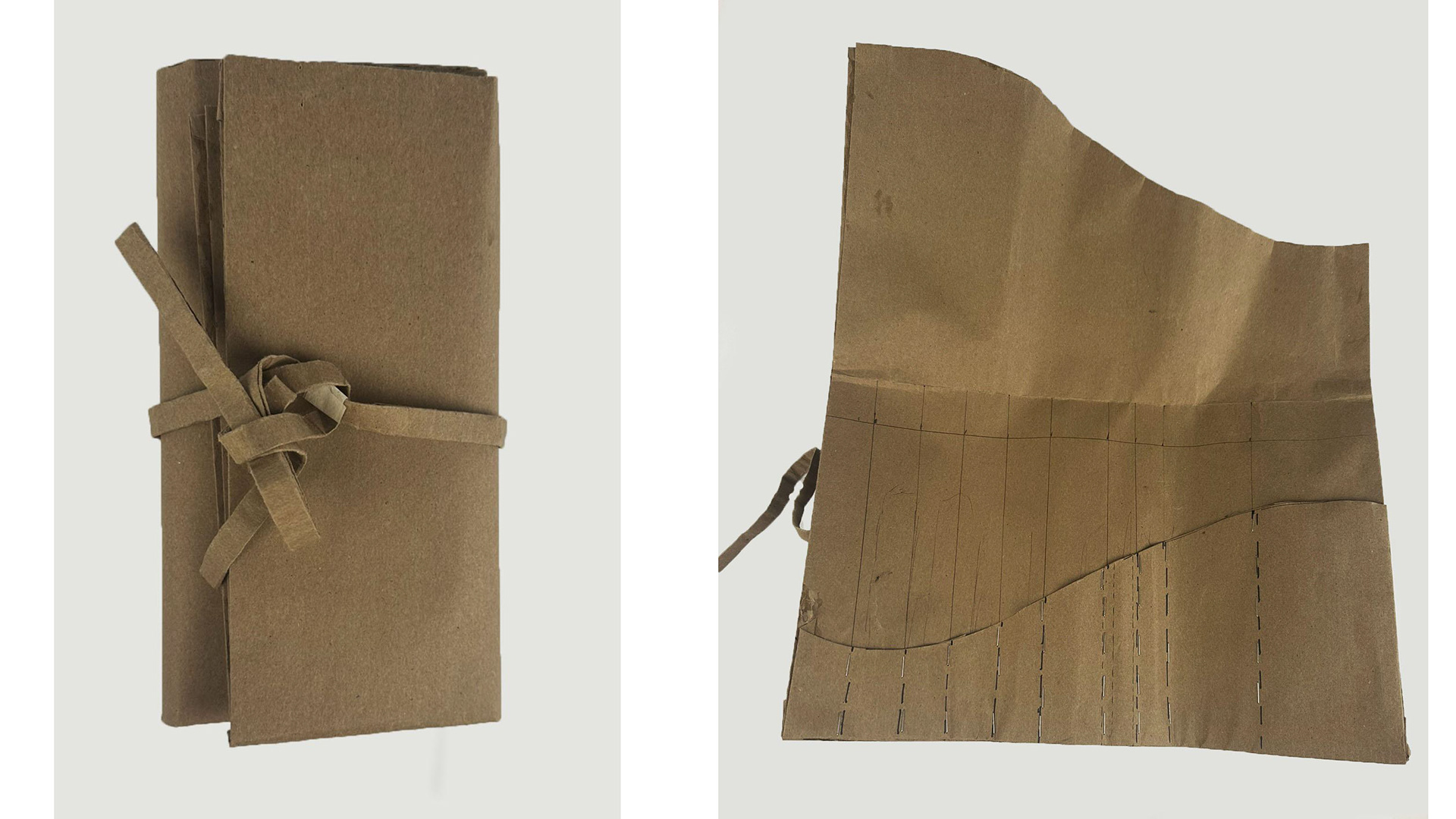

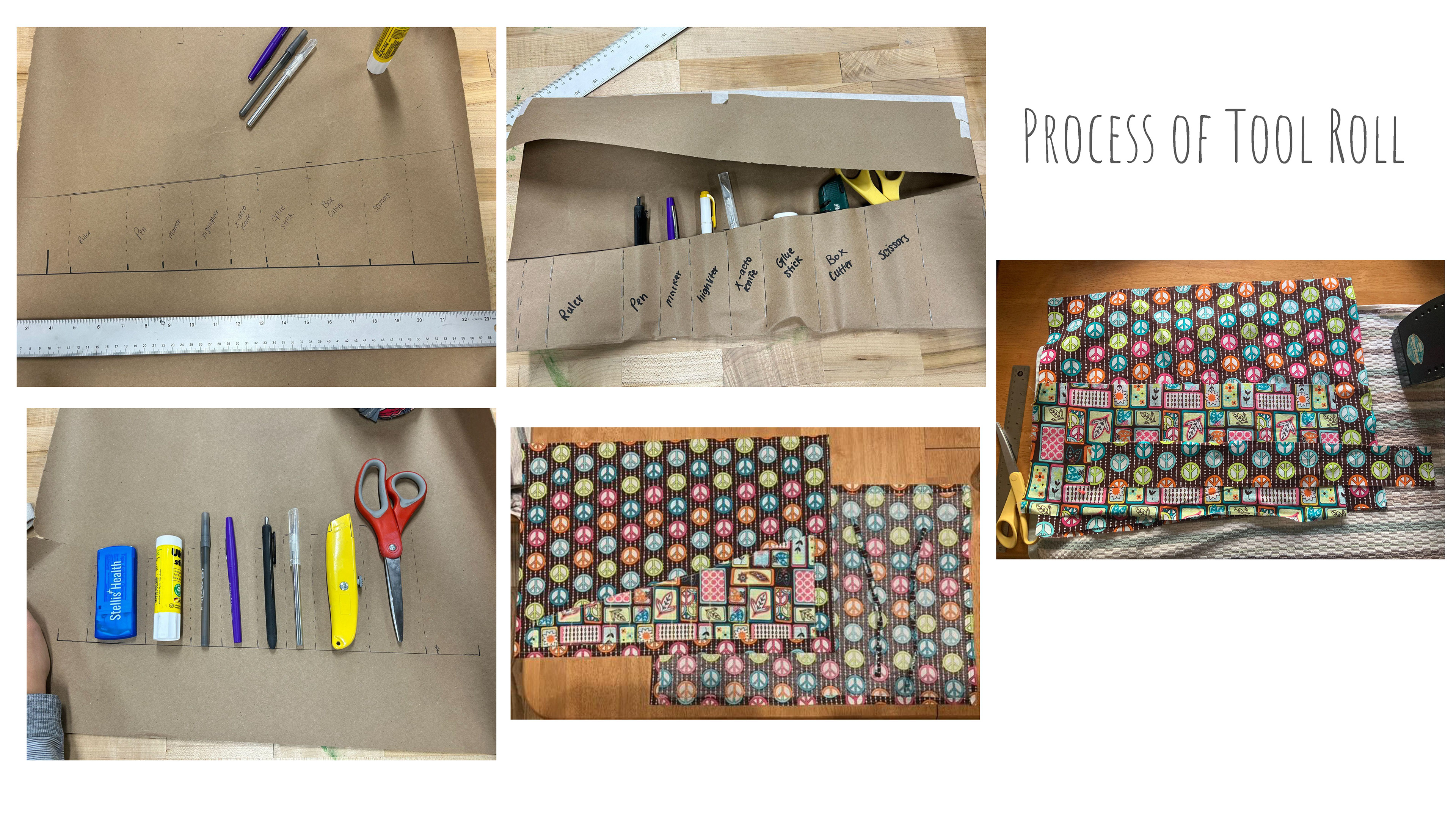

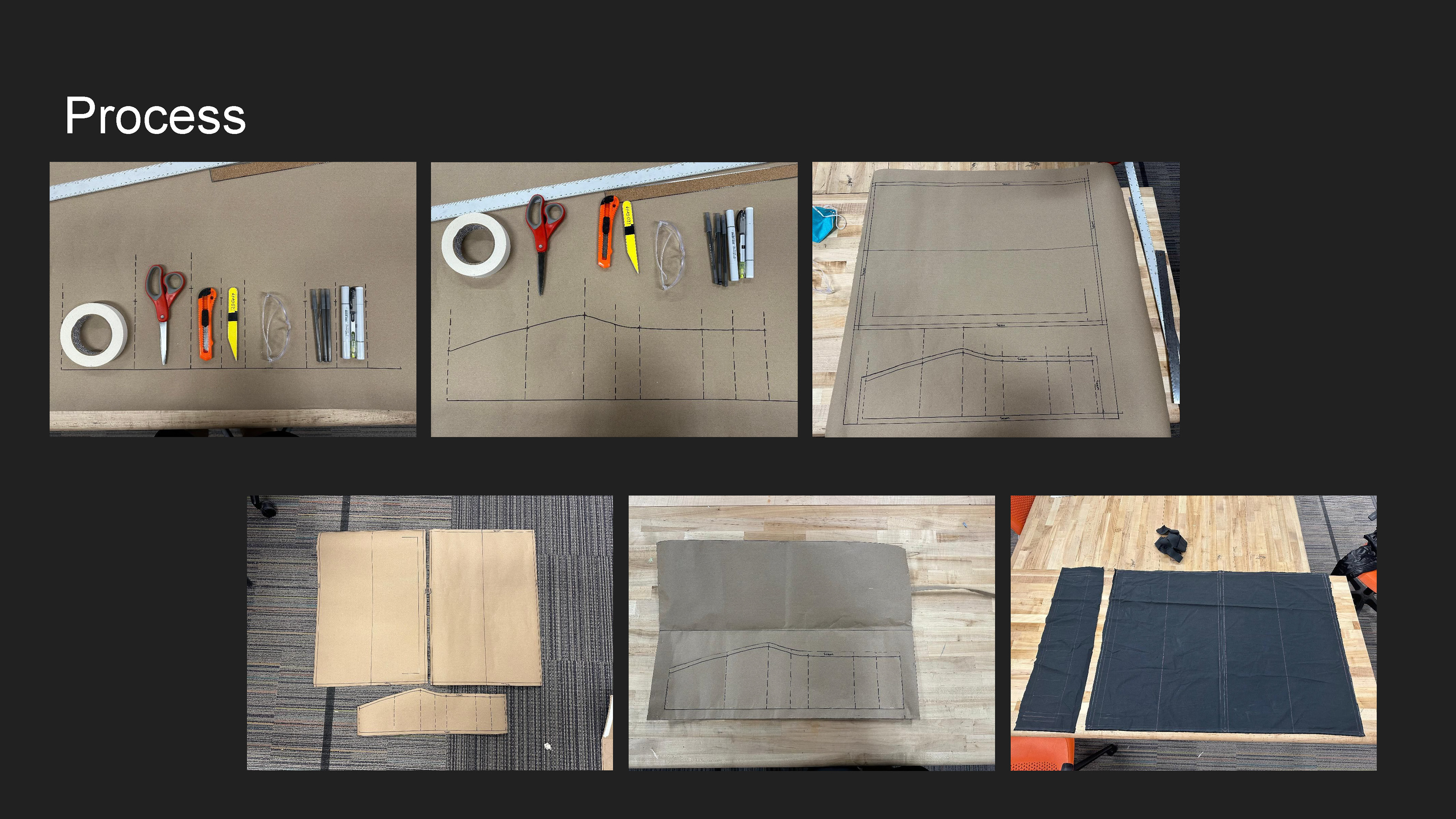

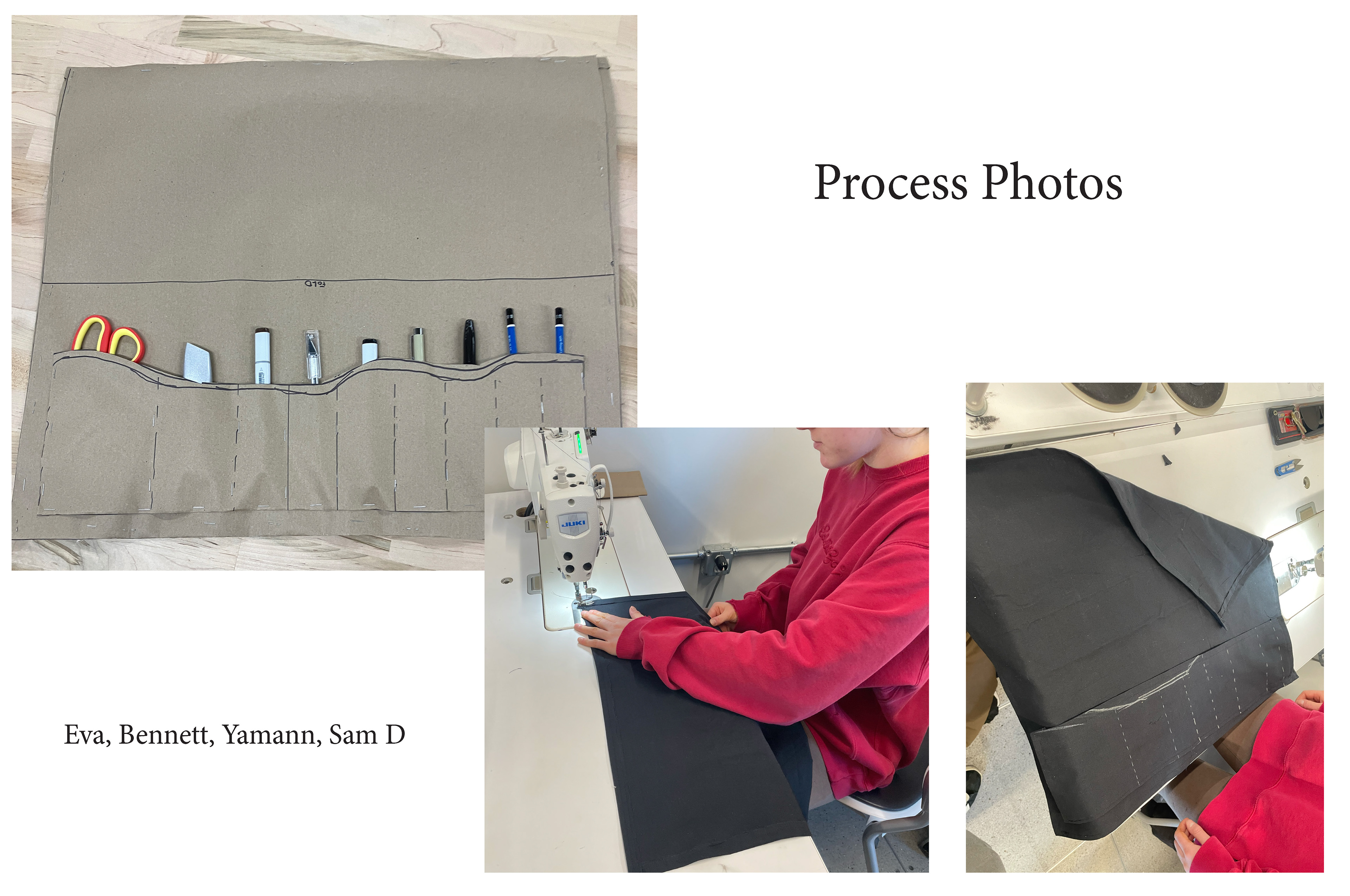

A large part of the industrial design discipline is Fashion and Apparel design, this asks for students to be able to understand the basics of prototyping and making soft good products.

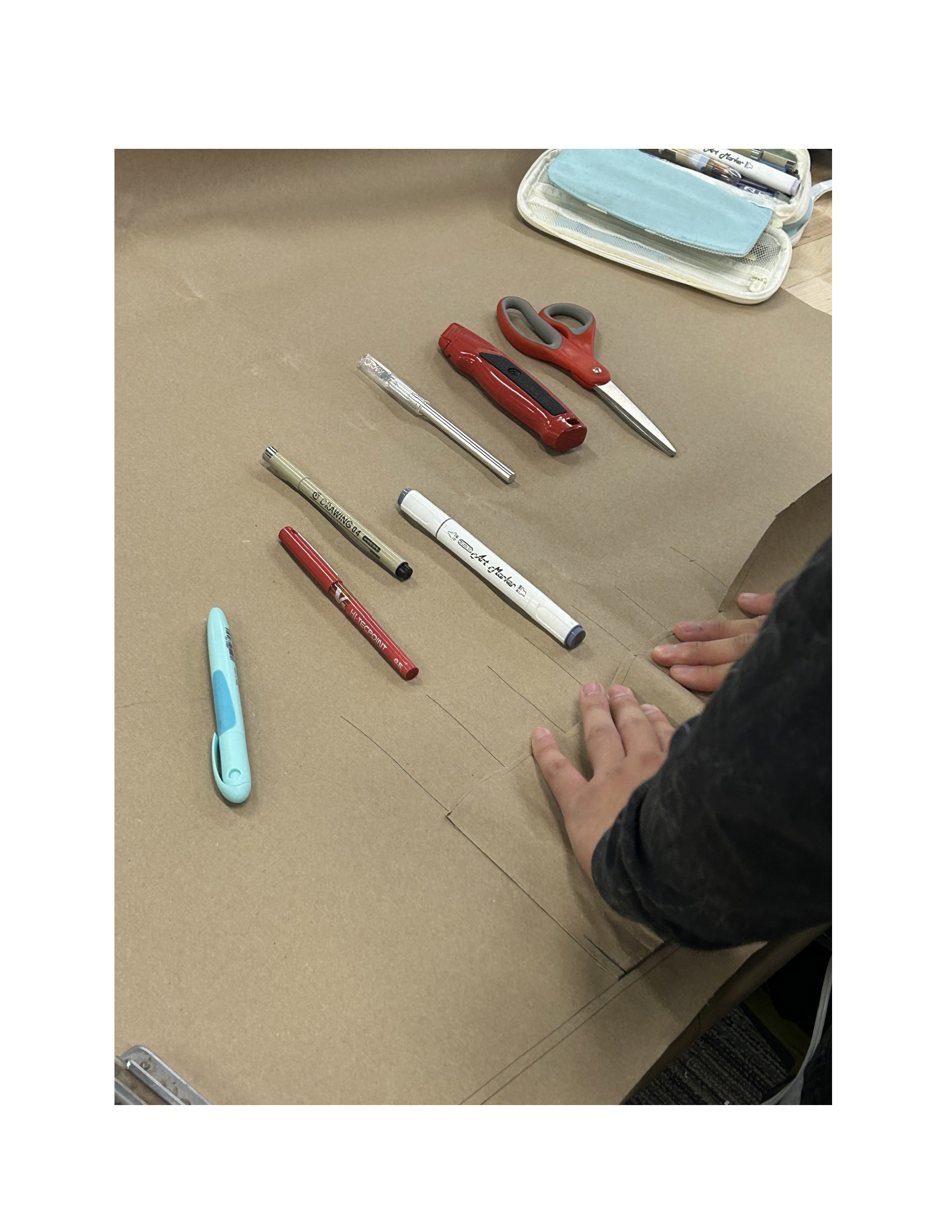

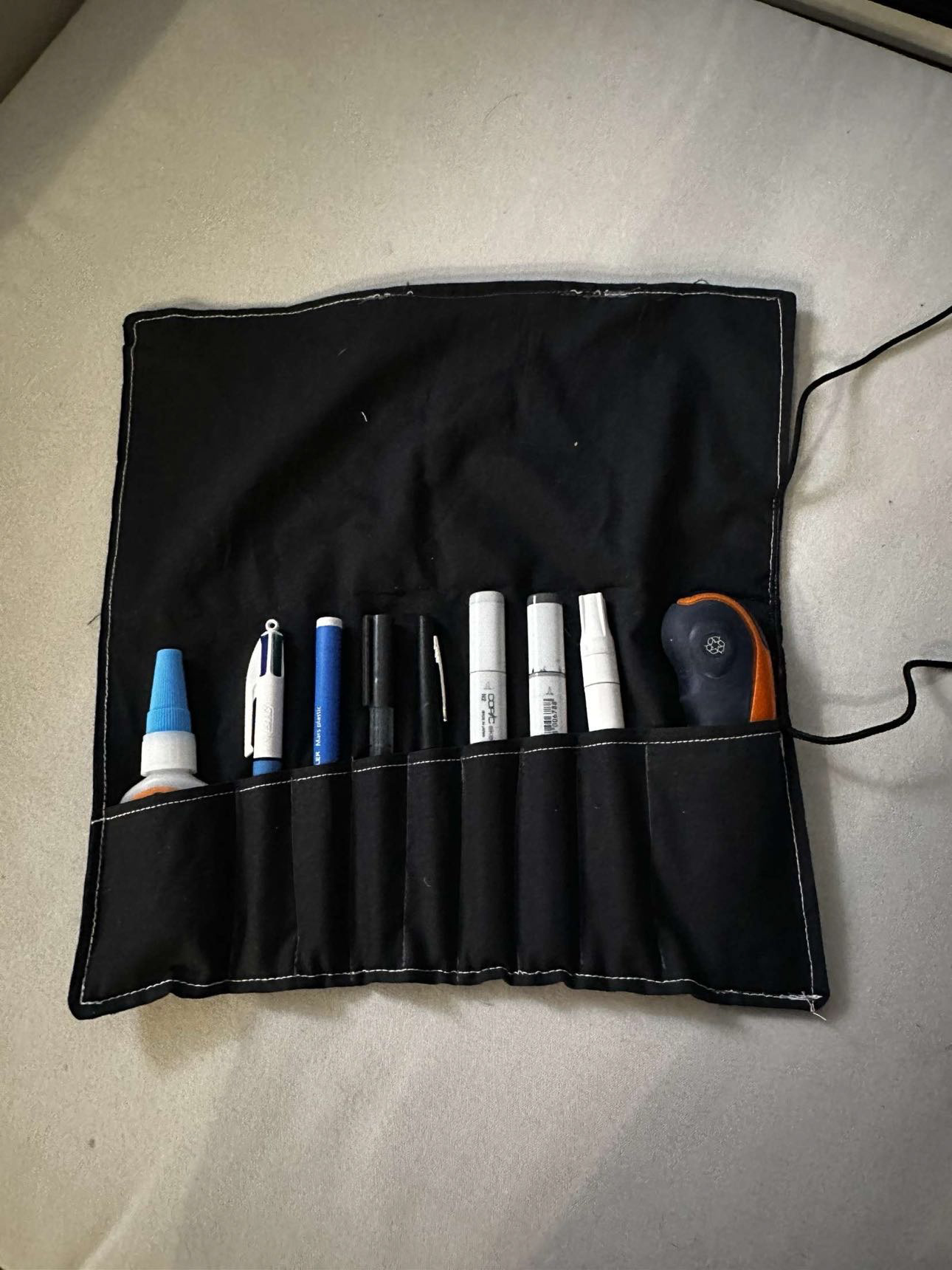

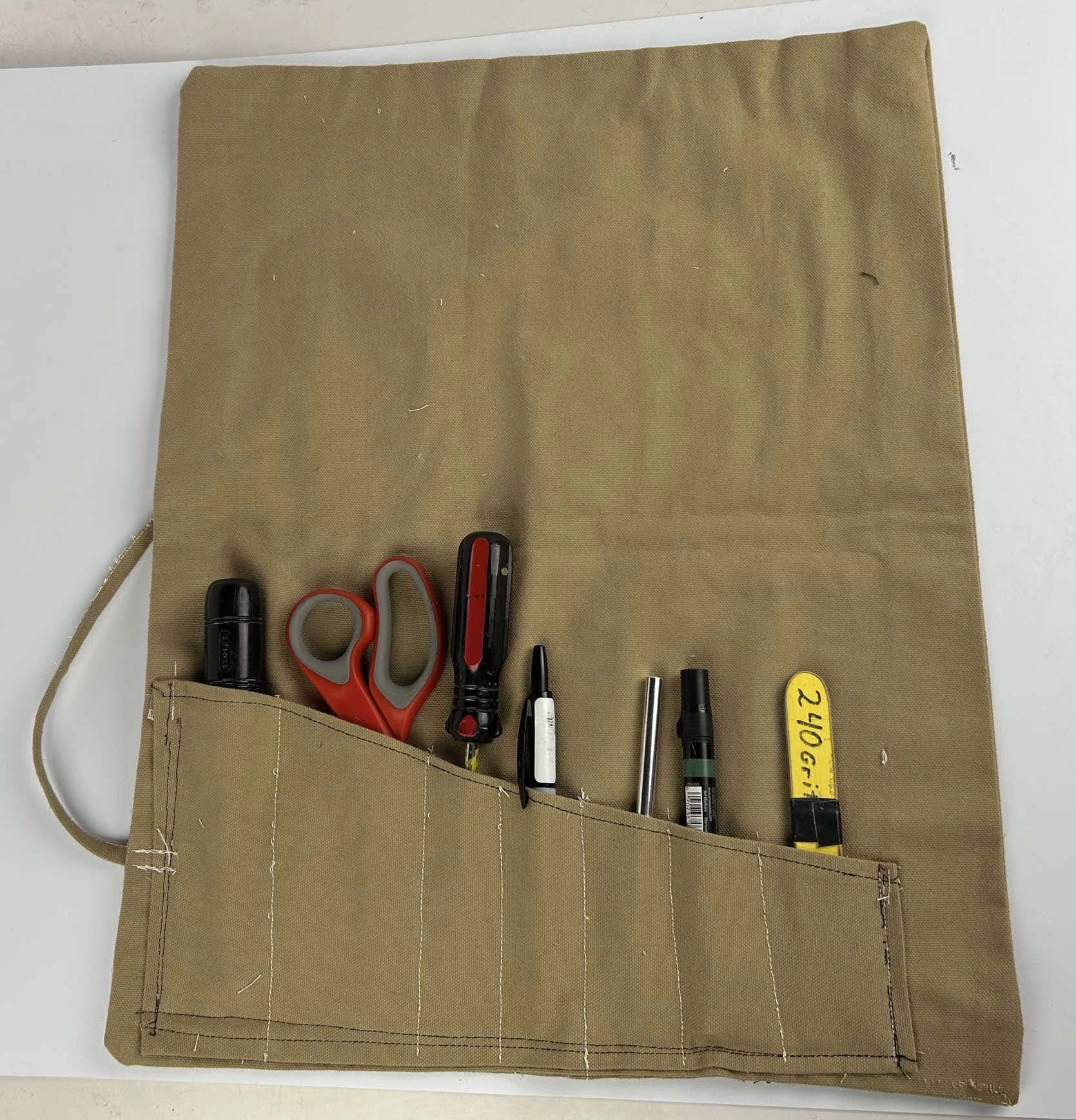

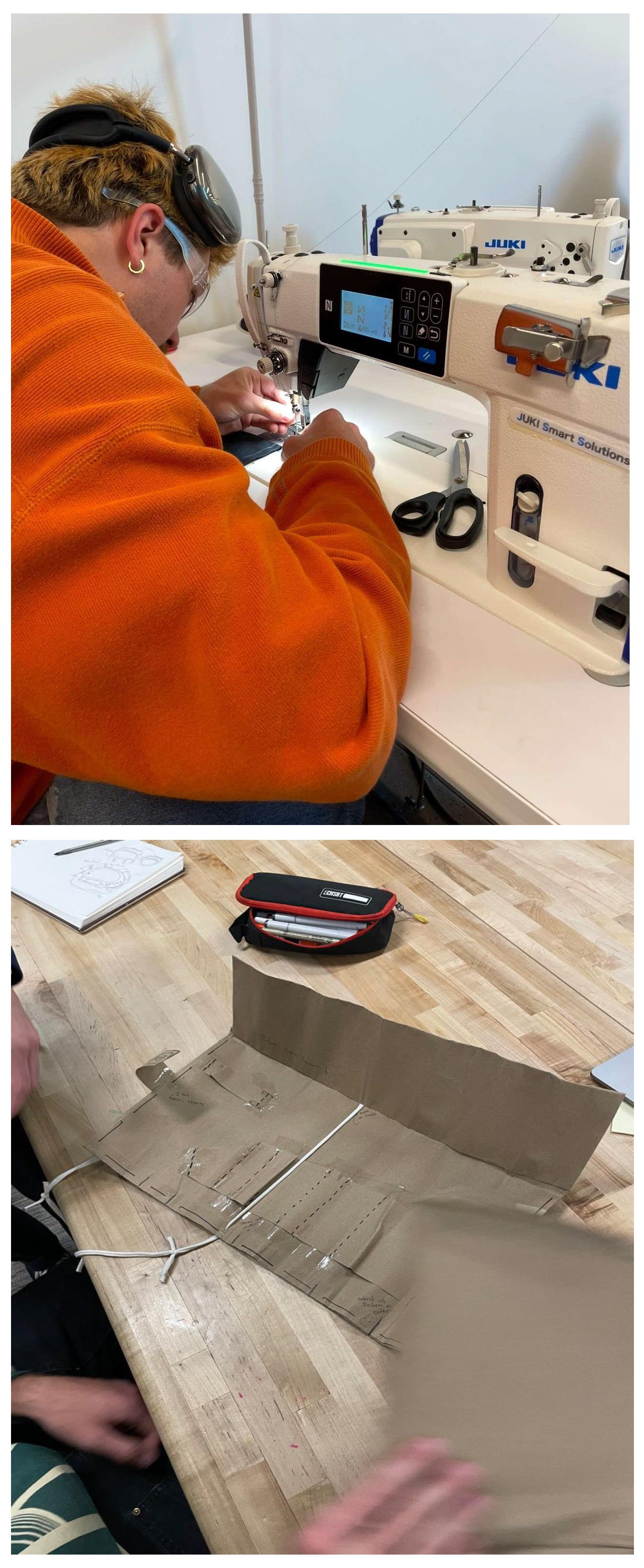

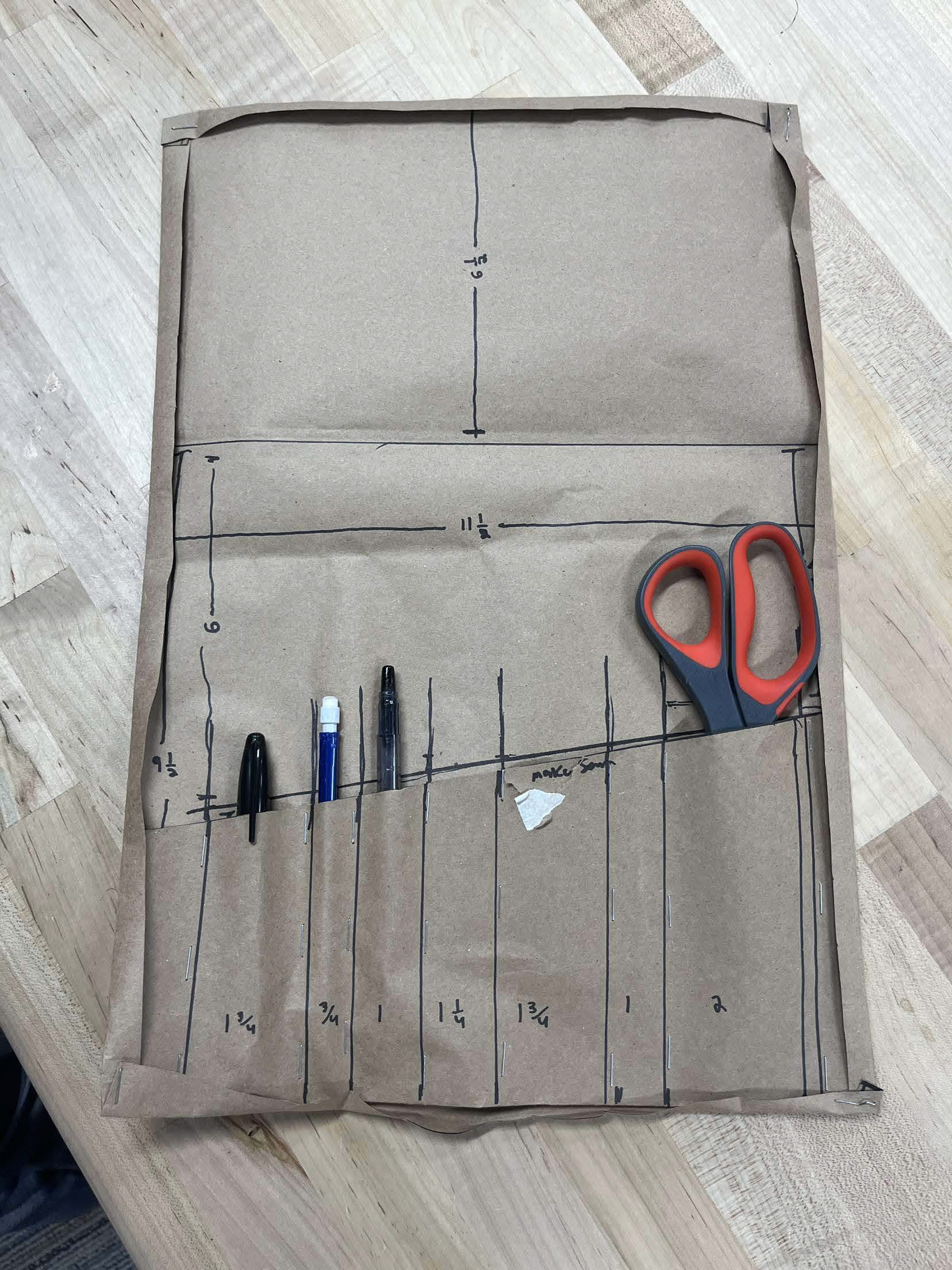

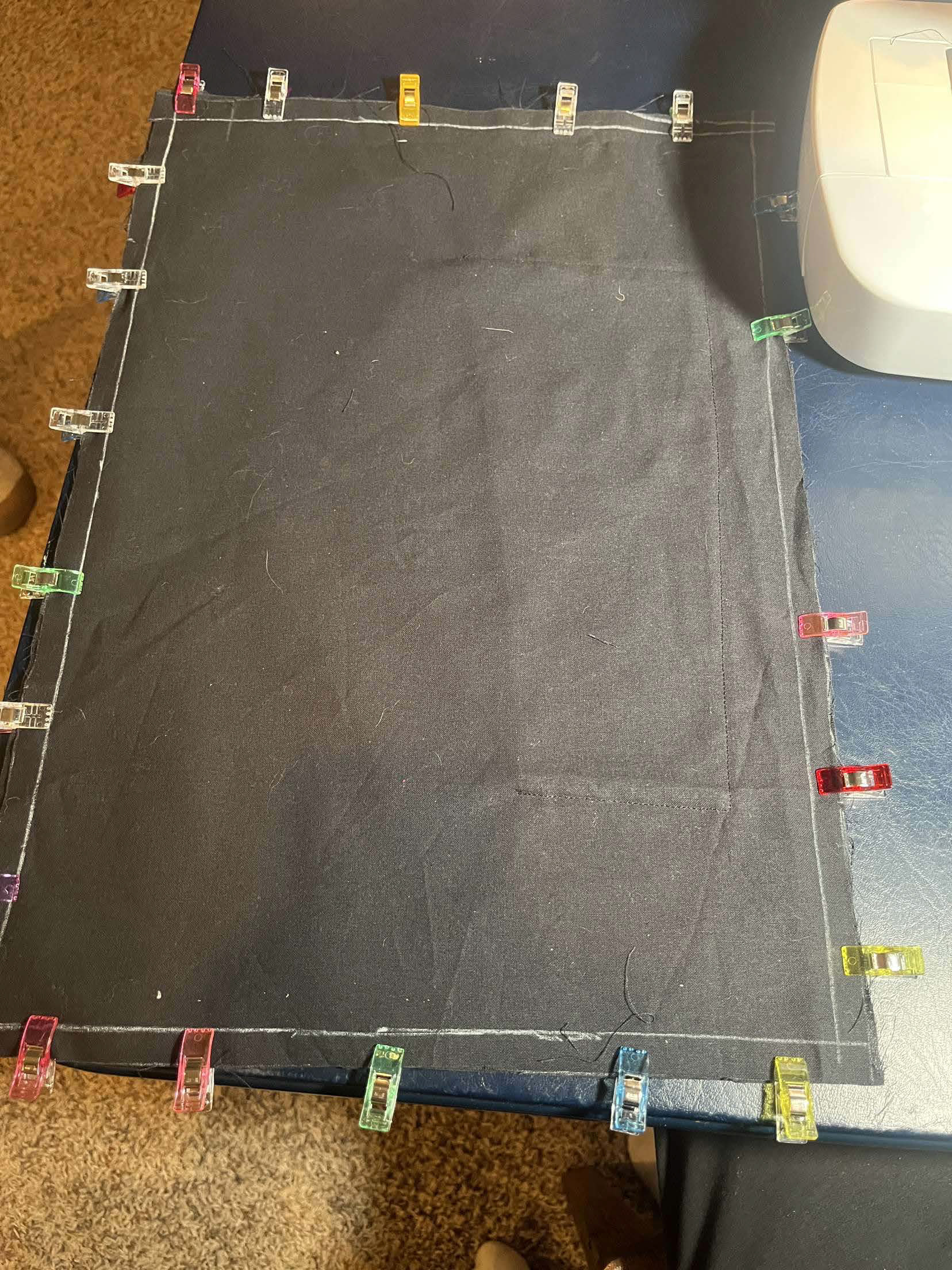

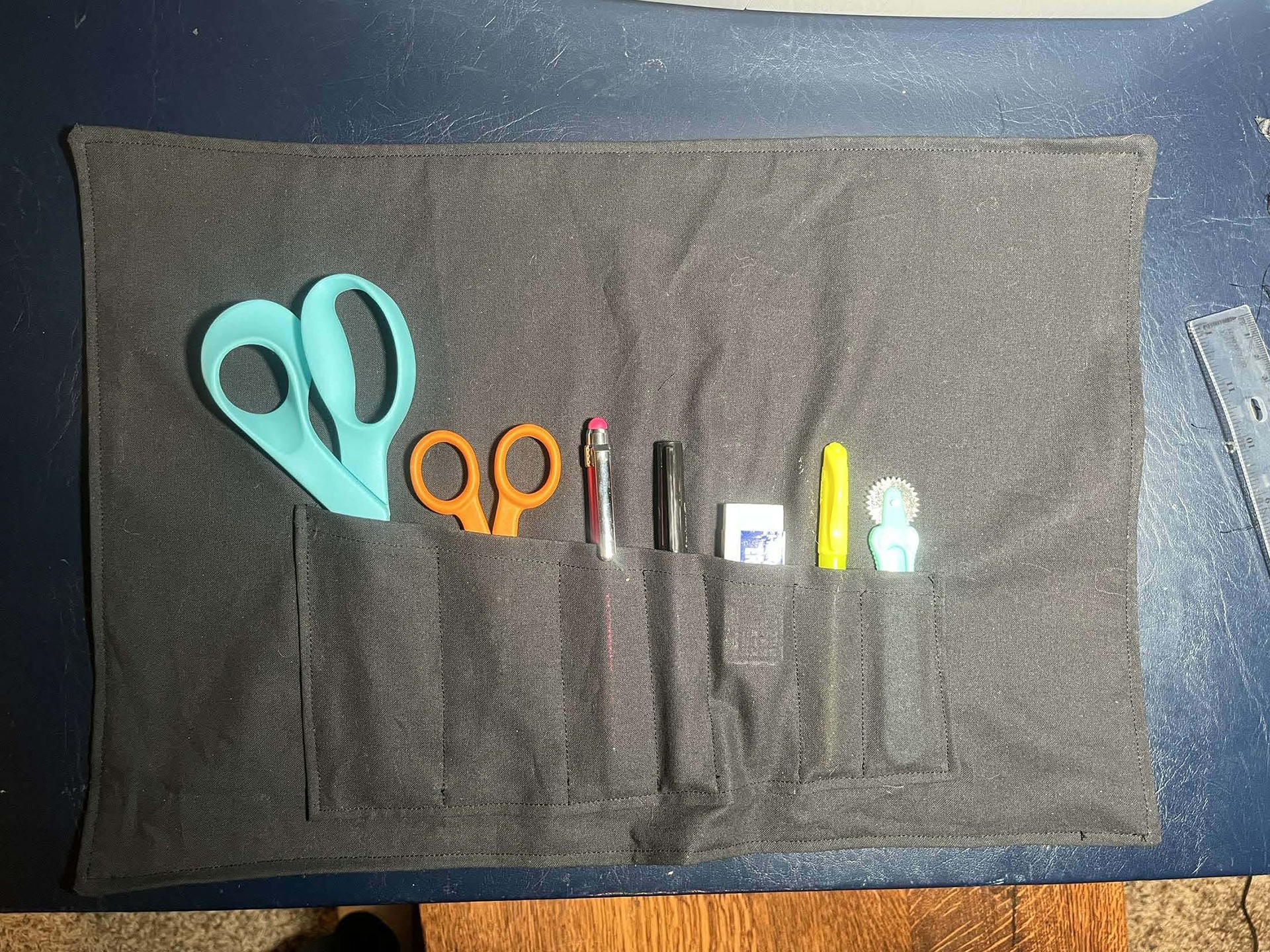

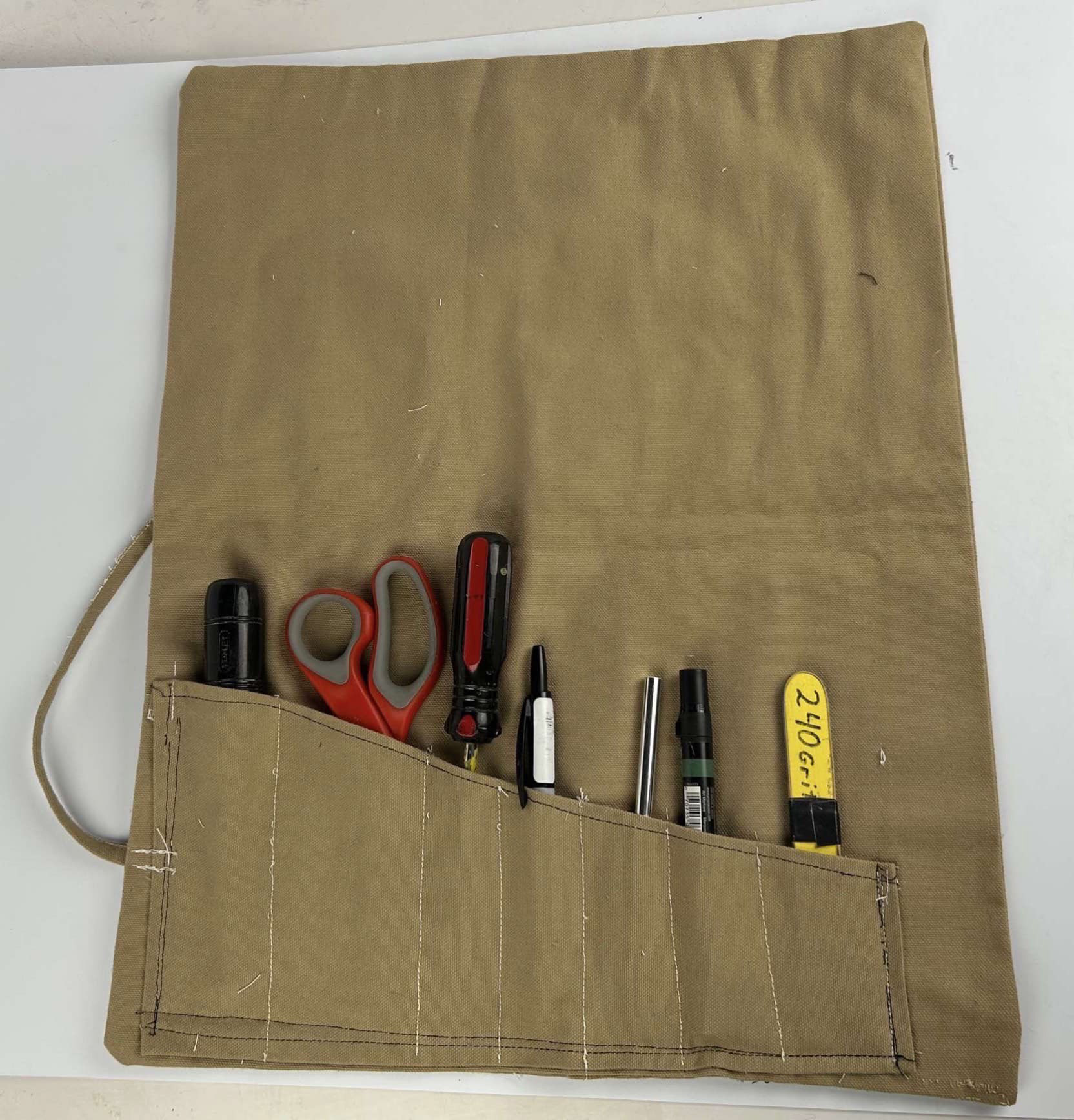

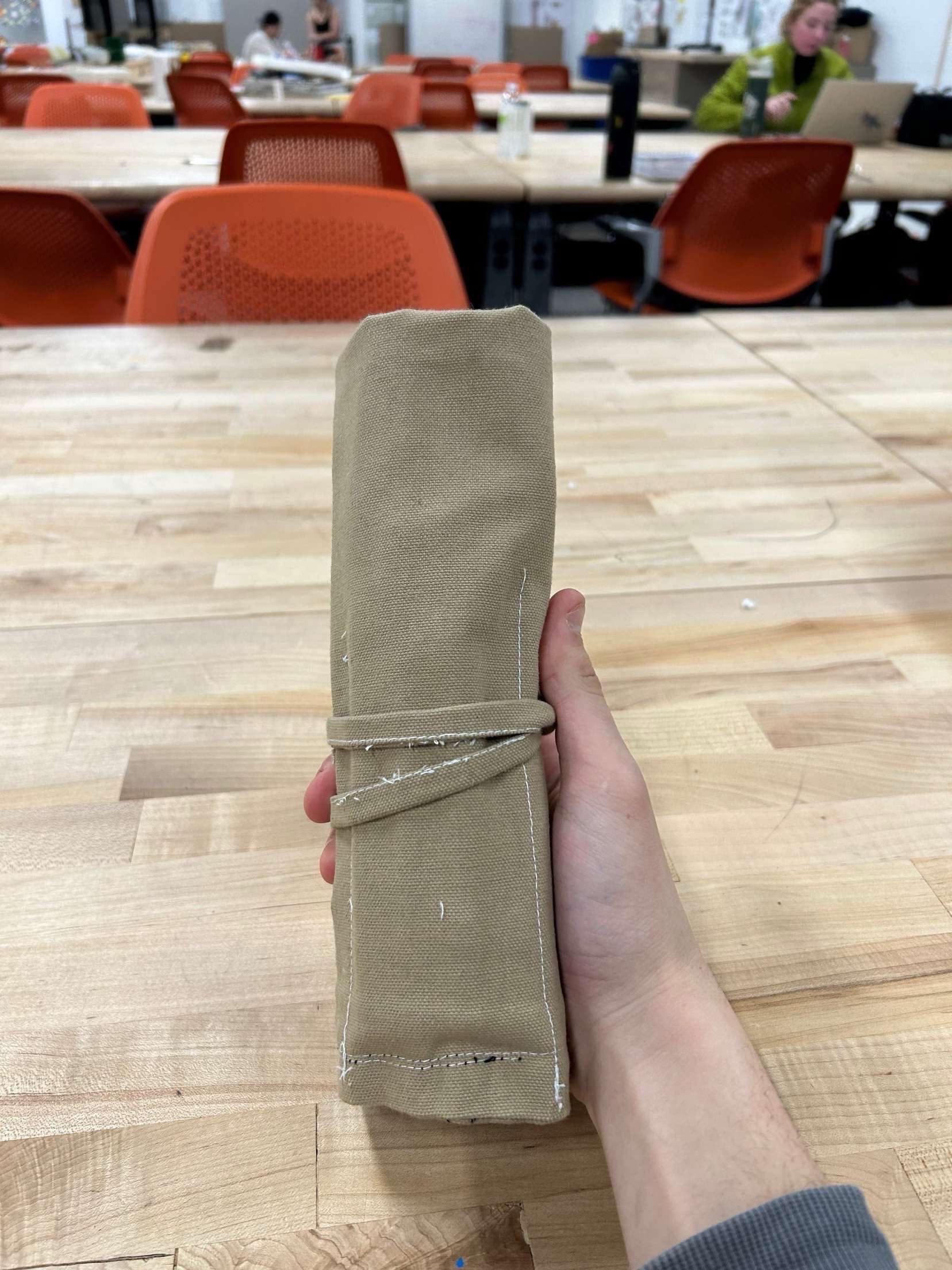

Here, the students are instructed to create a tool roll, they have to start with pattern making and paper prototypes. The students are able to form a good idea of how to make make 3 Dimensional objects using the foam core and so making patterns for a soft goods product is easier to understand with a little instruction about seams and folds in case of fabric.

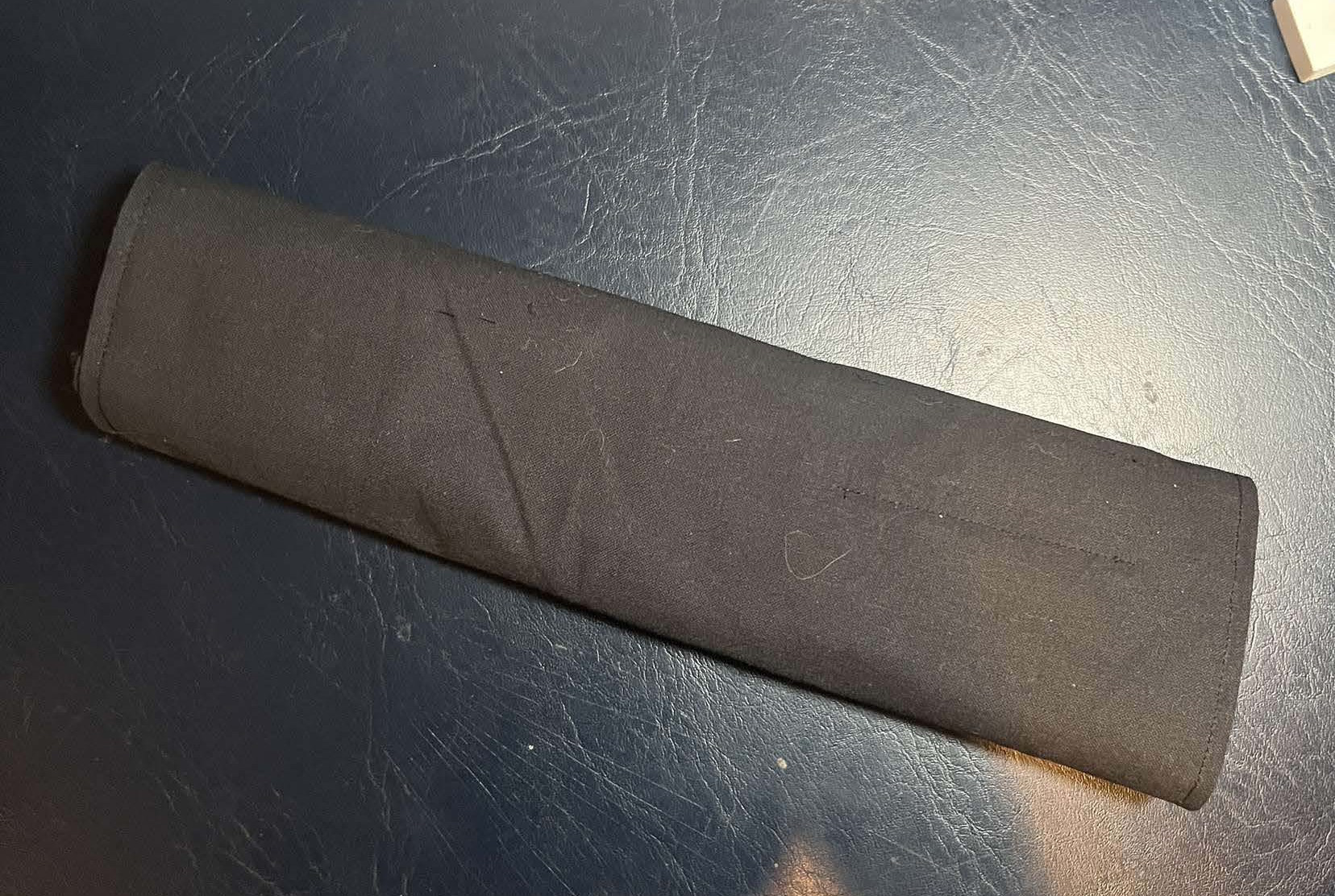

The students are then provided the fabric once the paper prototype is flawless. This fabric is then sewed and made into a tool roll.