The 21st Century brings technological advancements in the world of fabrication and making, so as designers we need to keep up with the fastest and most efficient ways of creating "Objects".

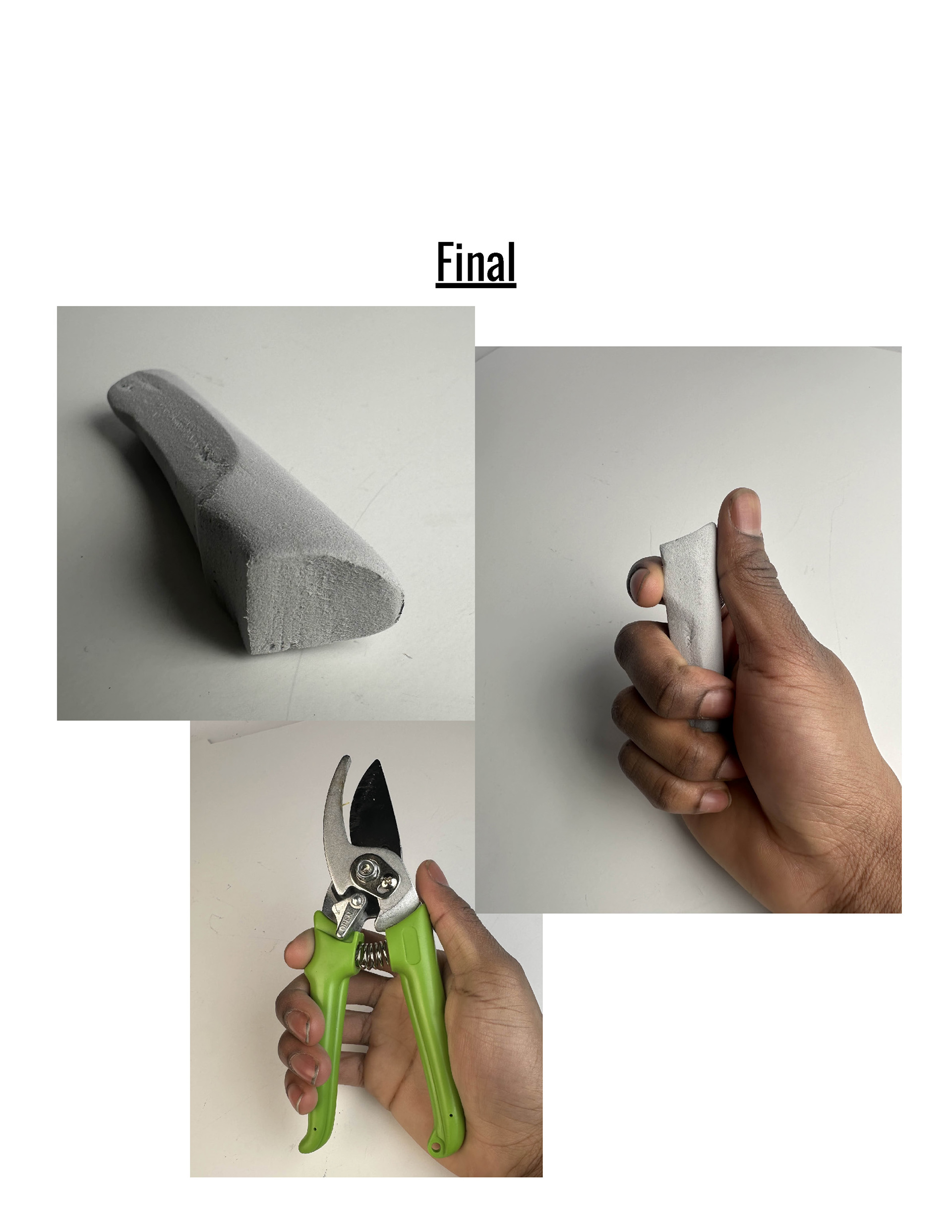

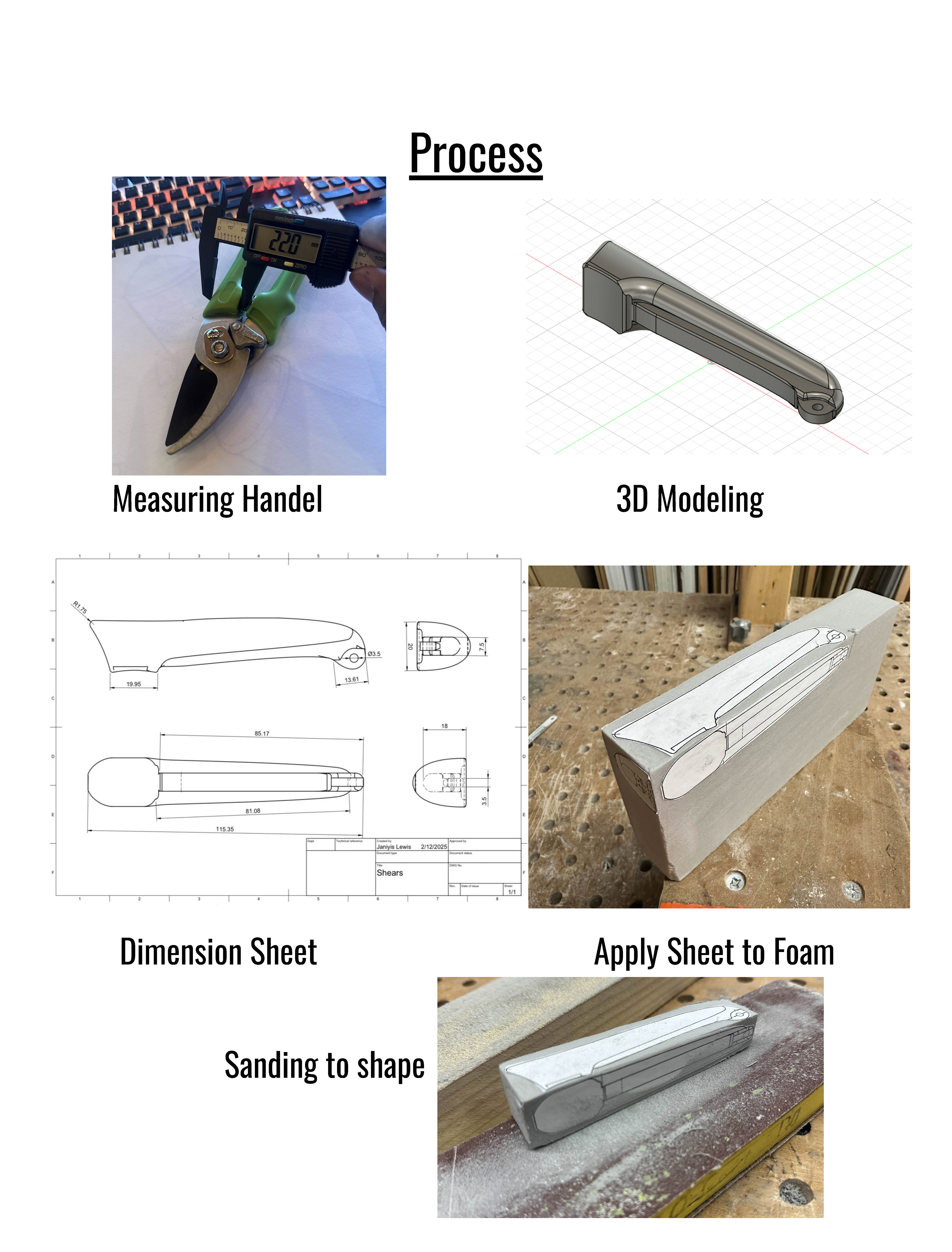

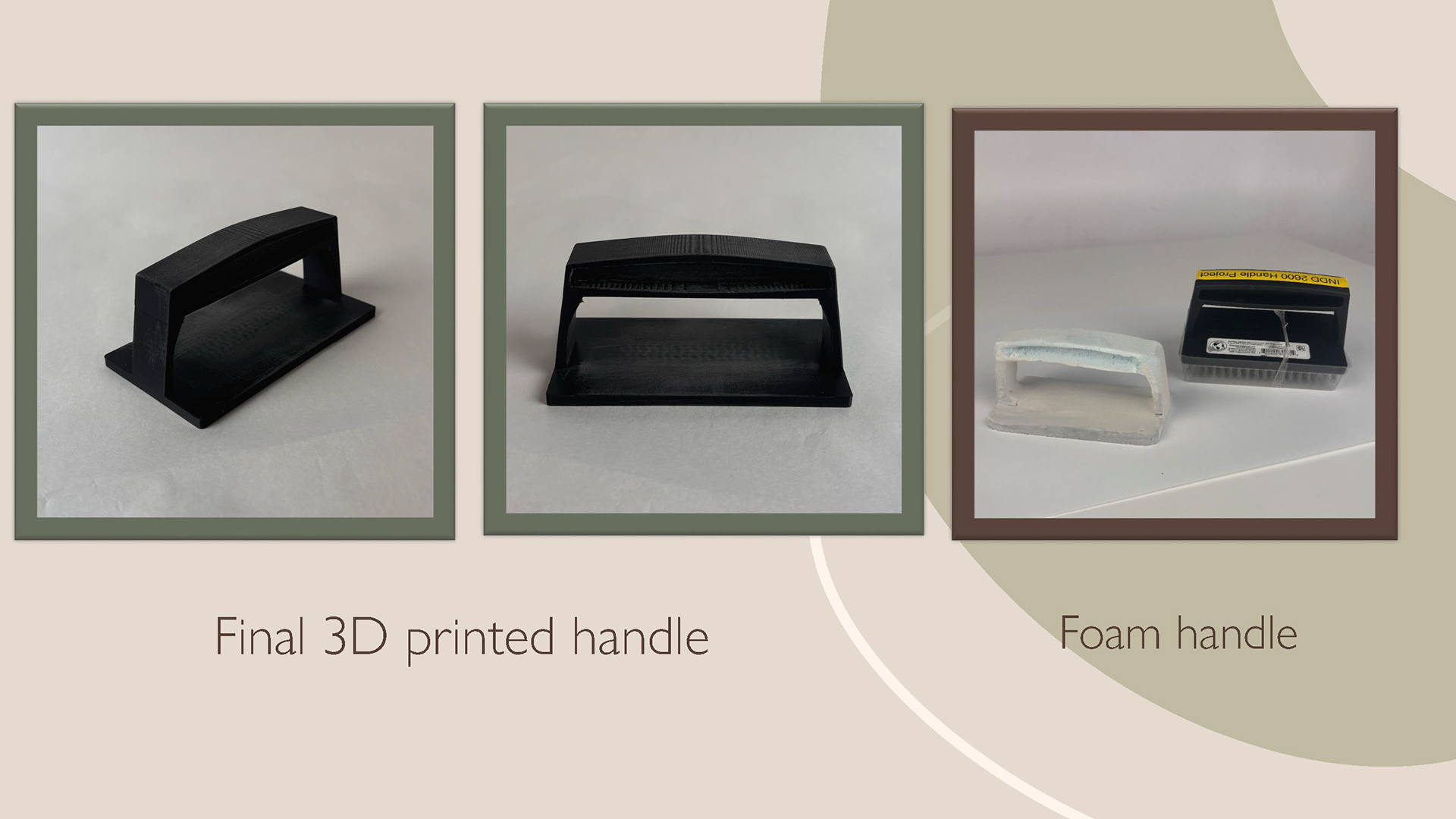

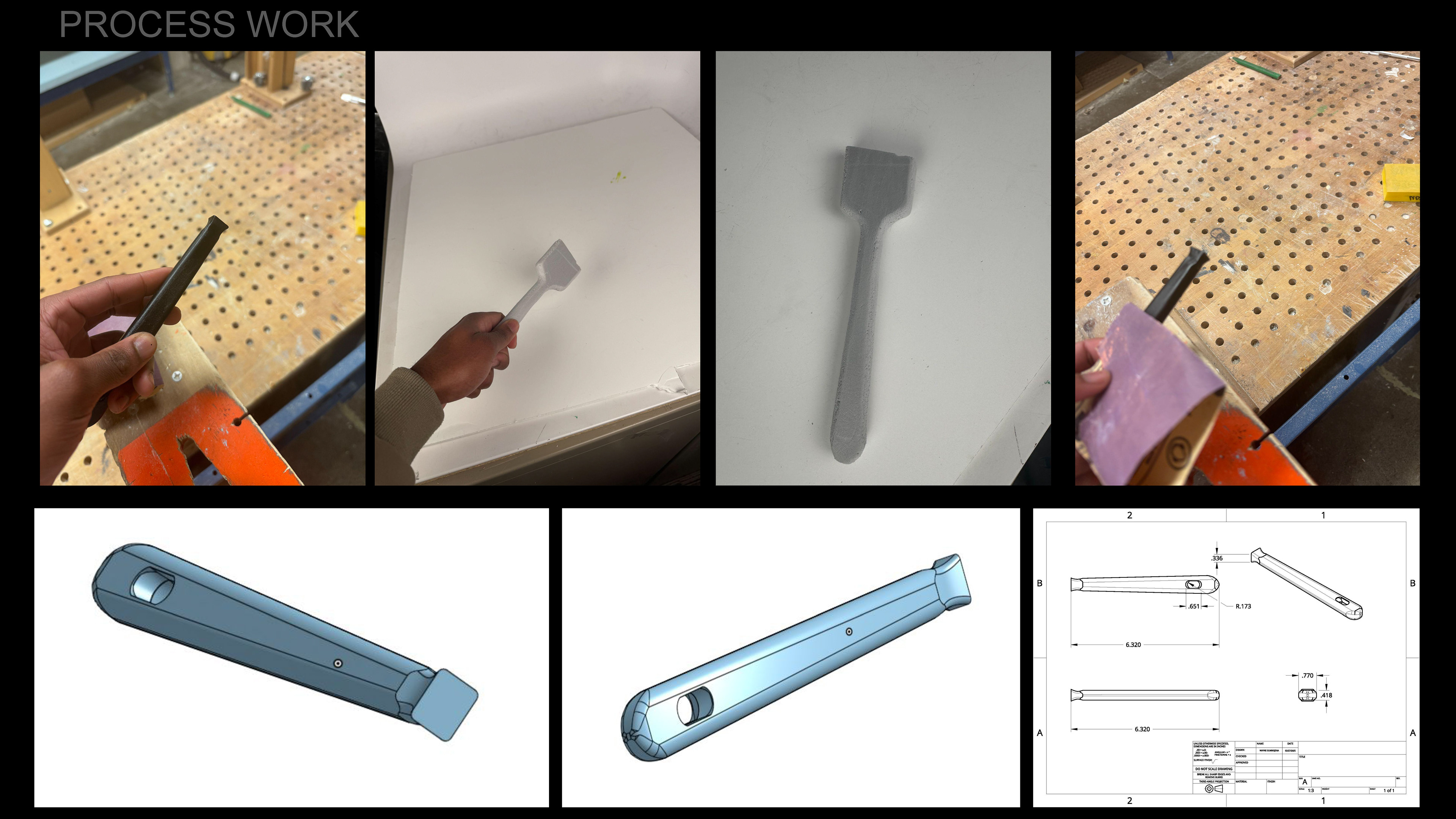

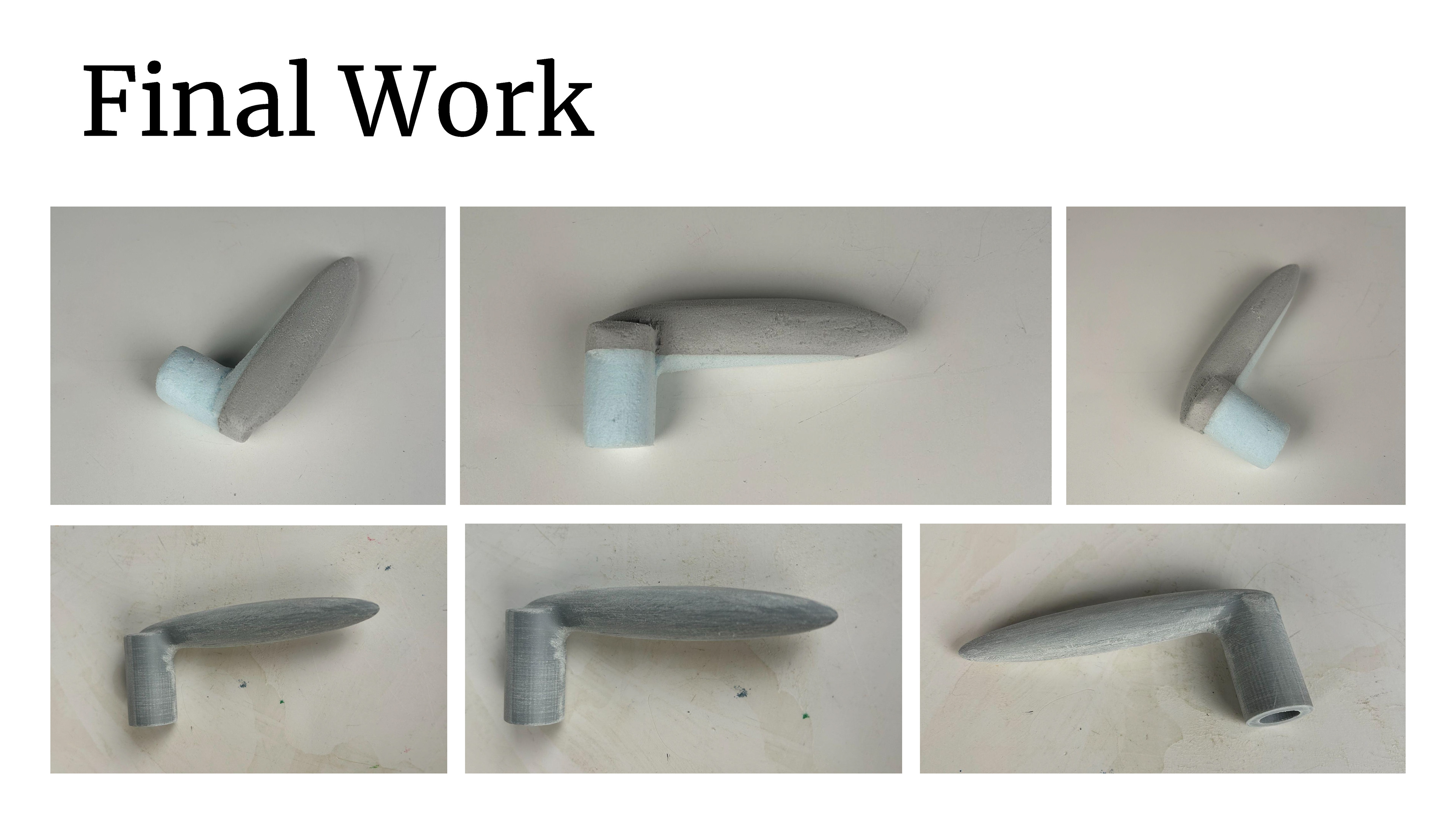

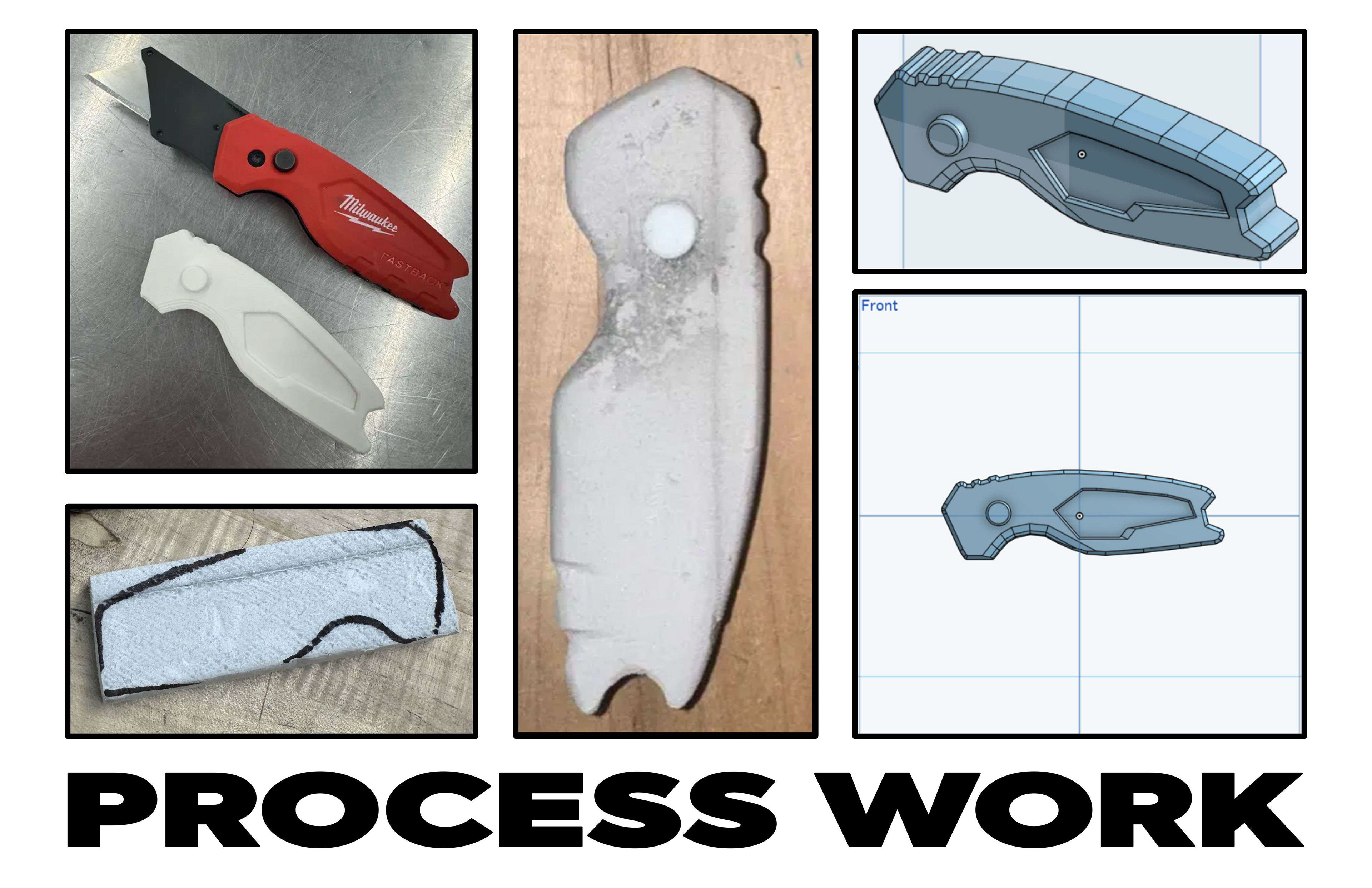

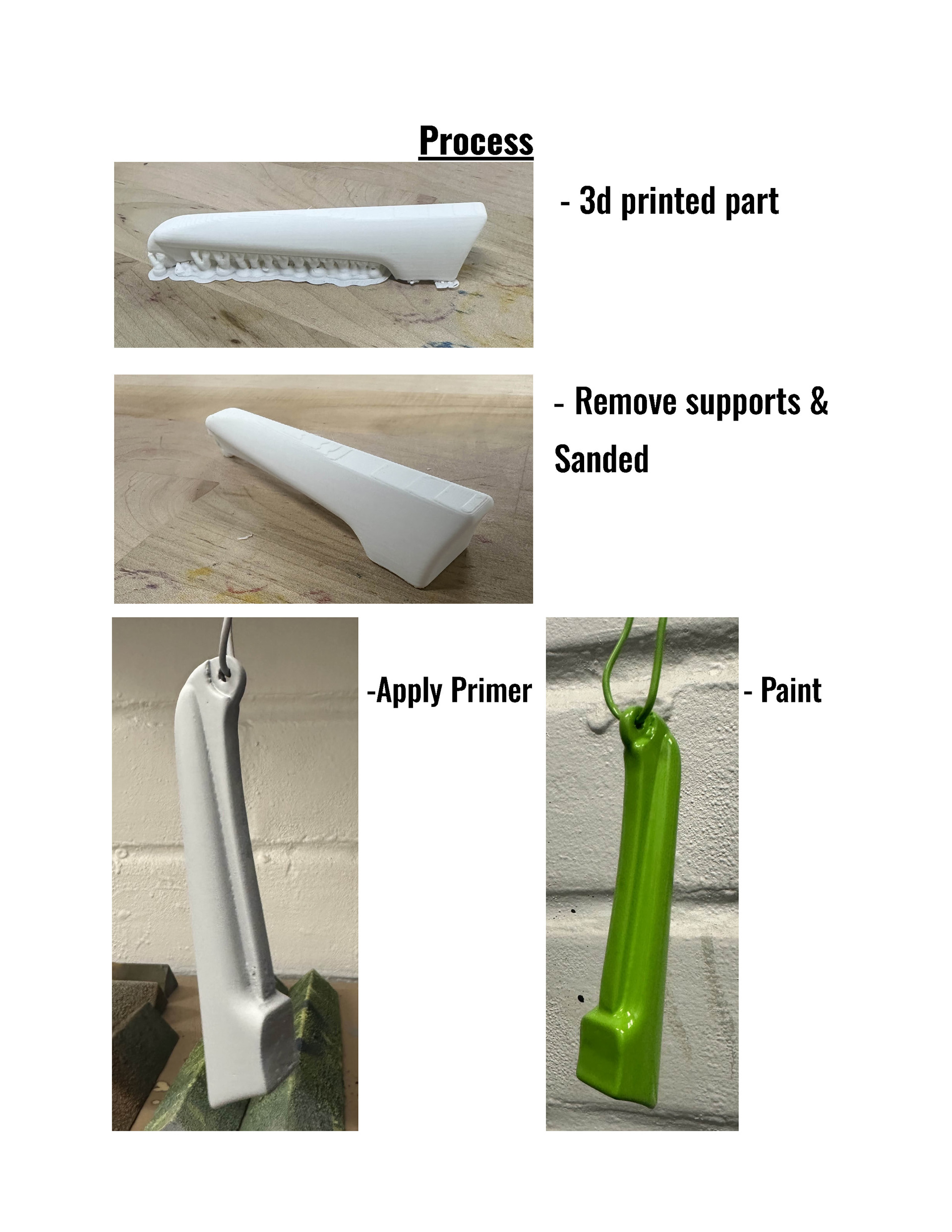

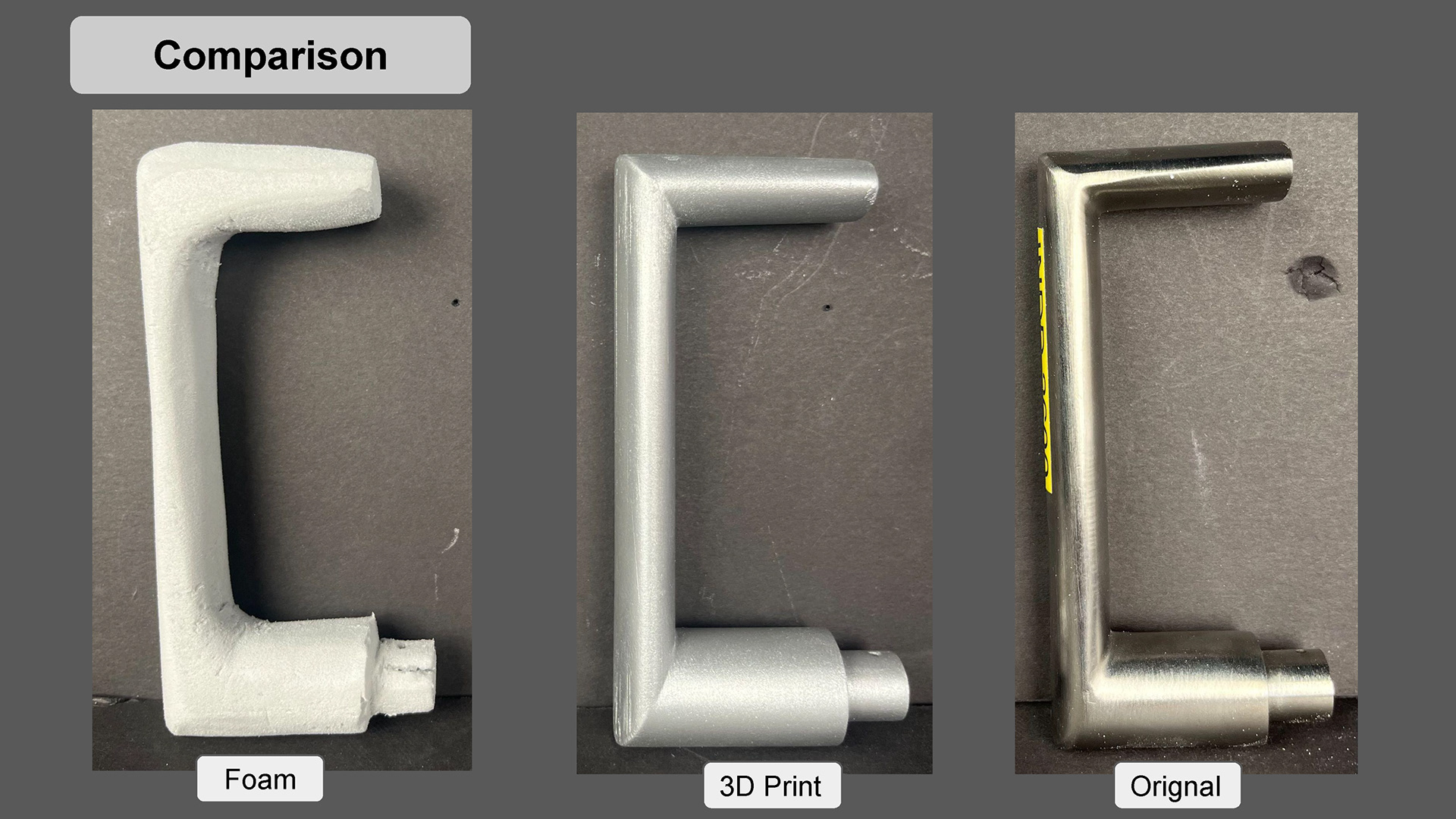

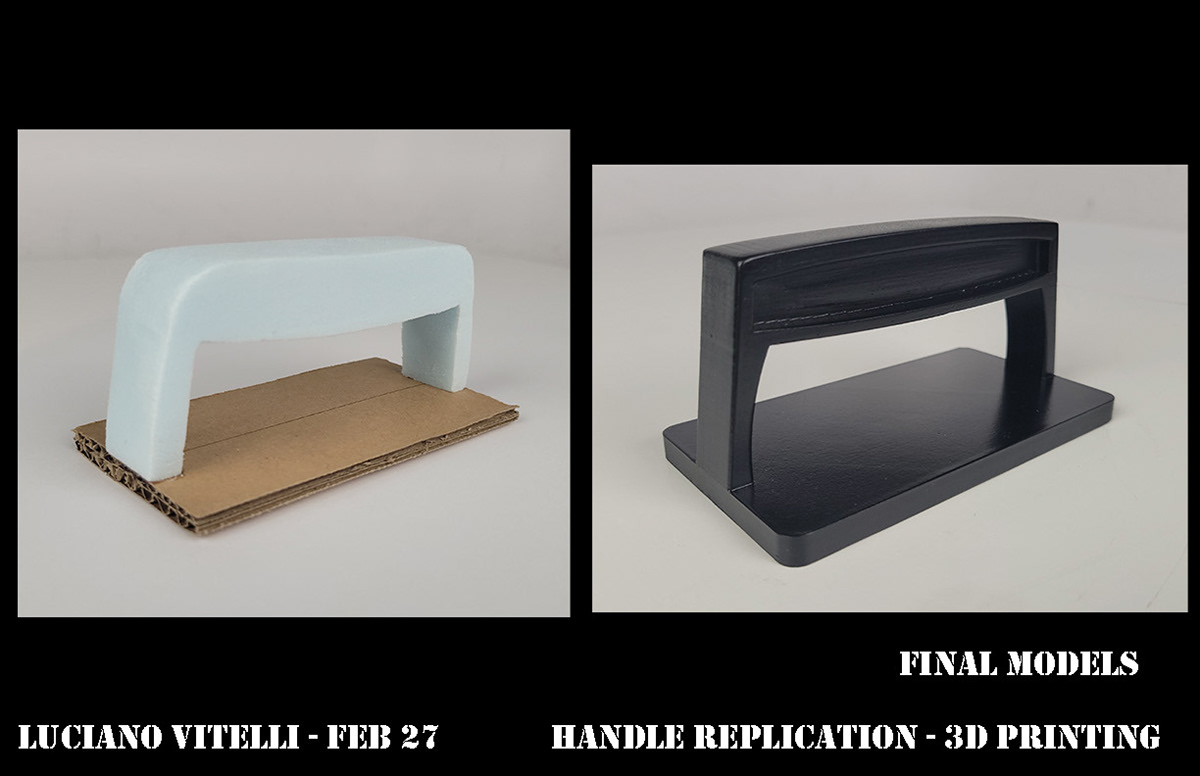

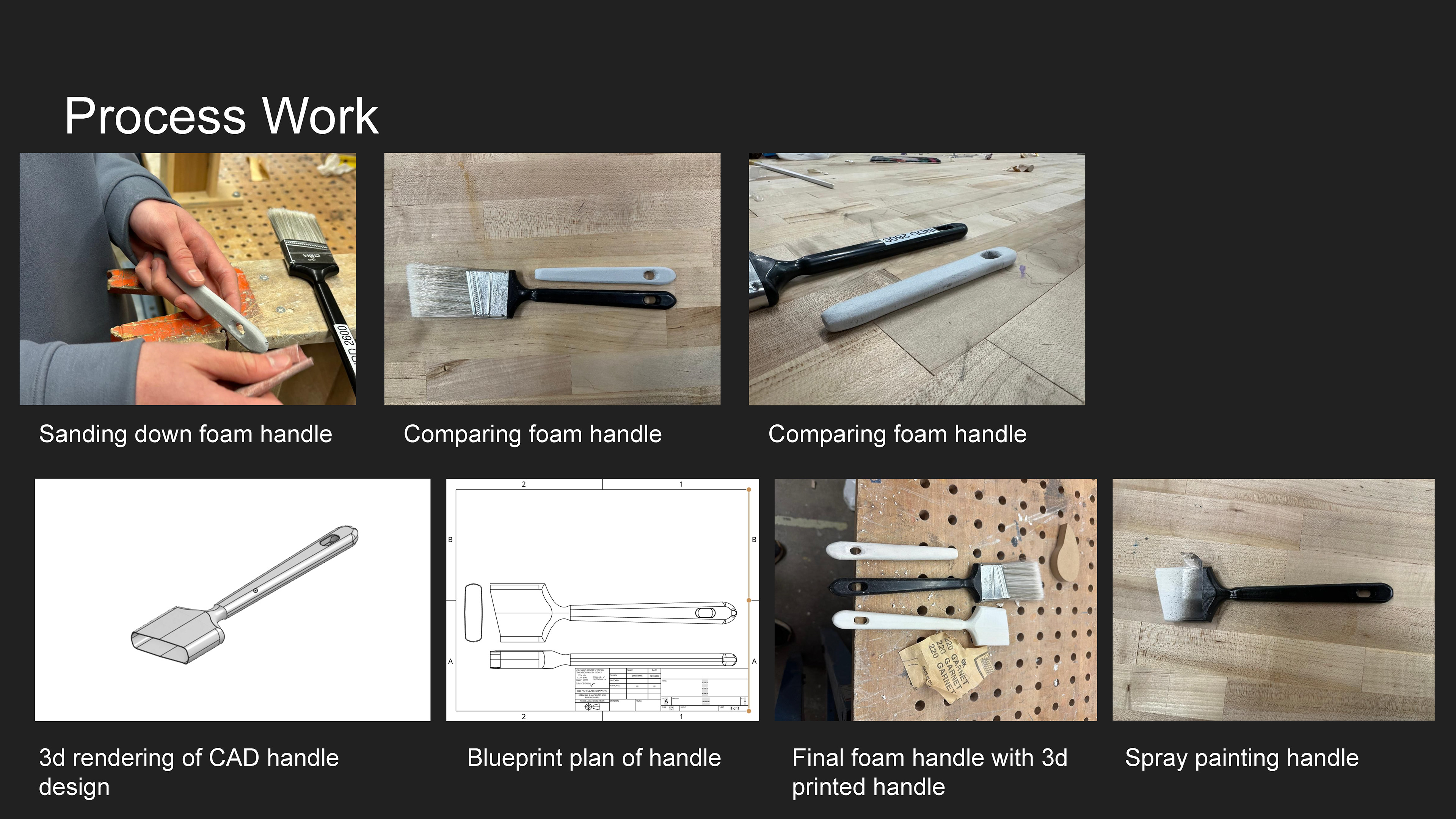

Here, students go through the process of learning how to replicate an ergonomically efficient handle. They have to choose a handle that can be found on the shelves of any retail store and be able to replicate it.

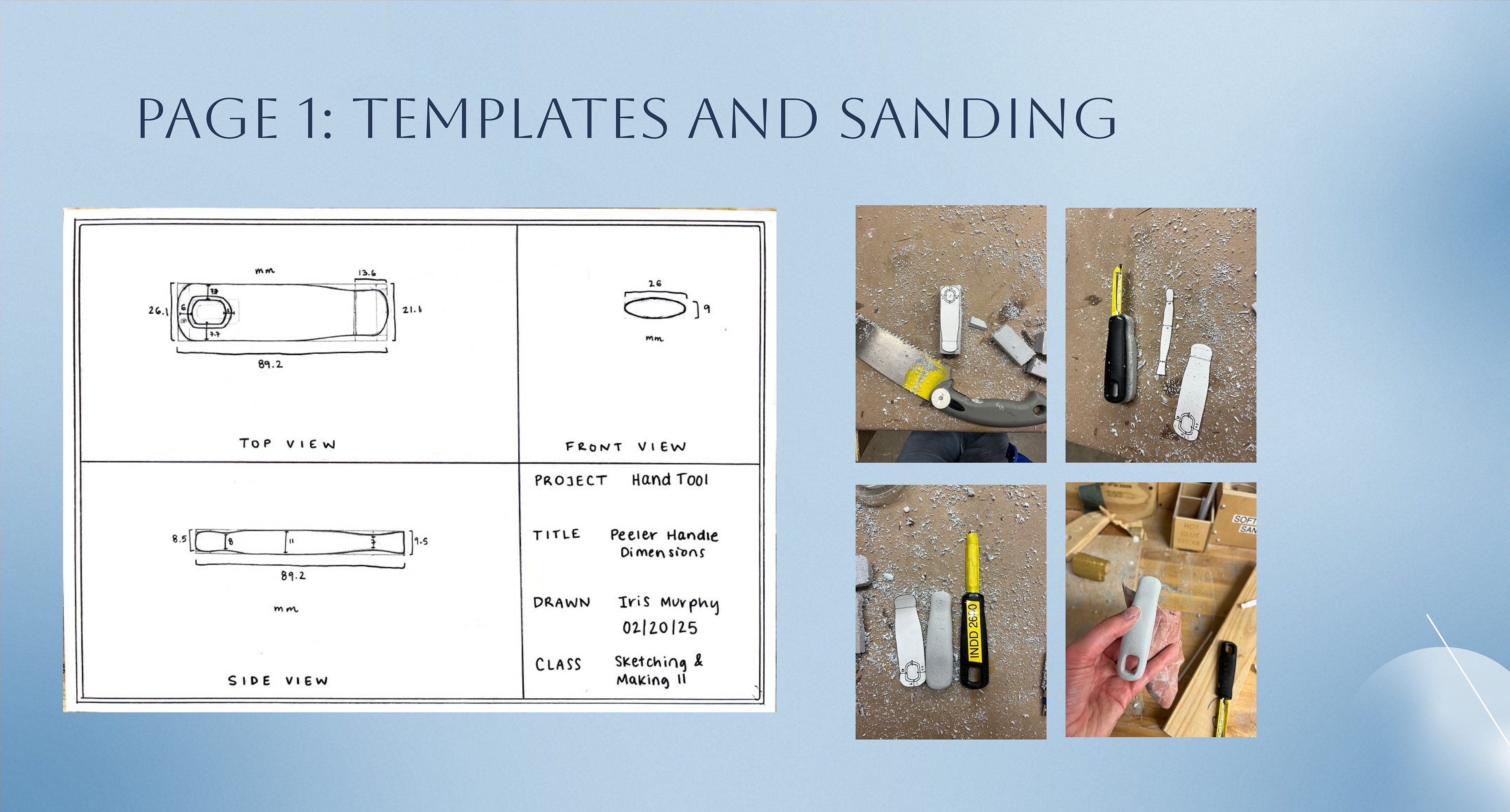

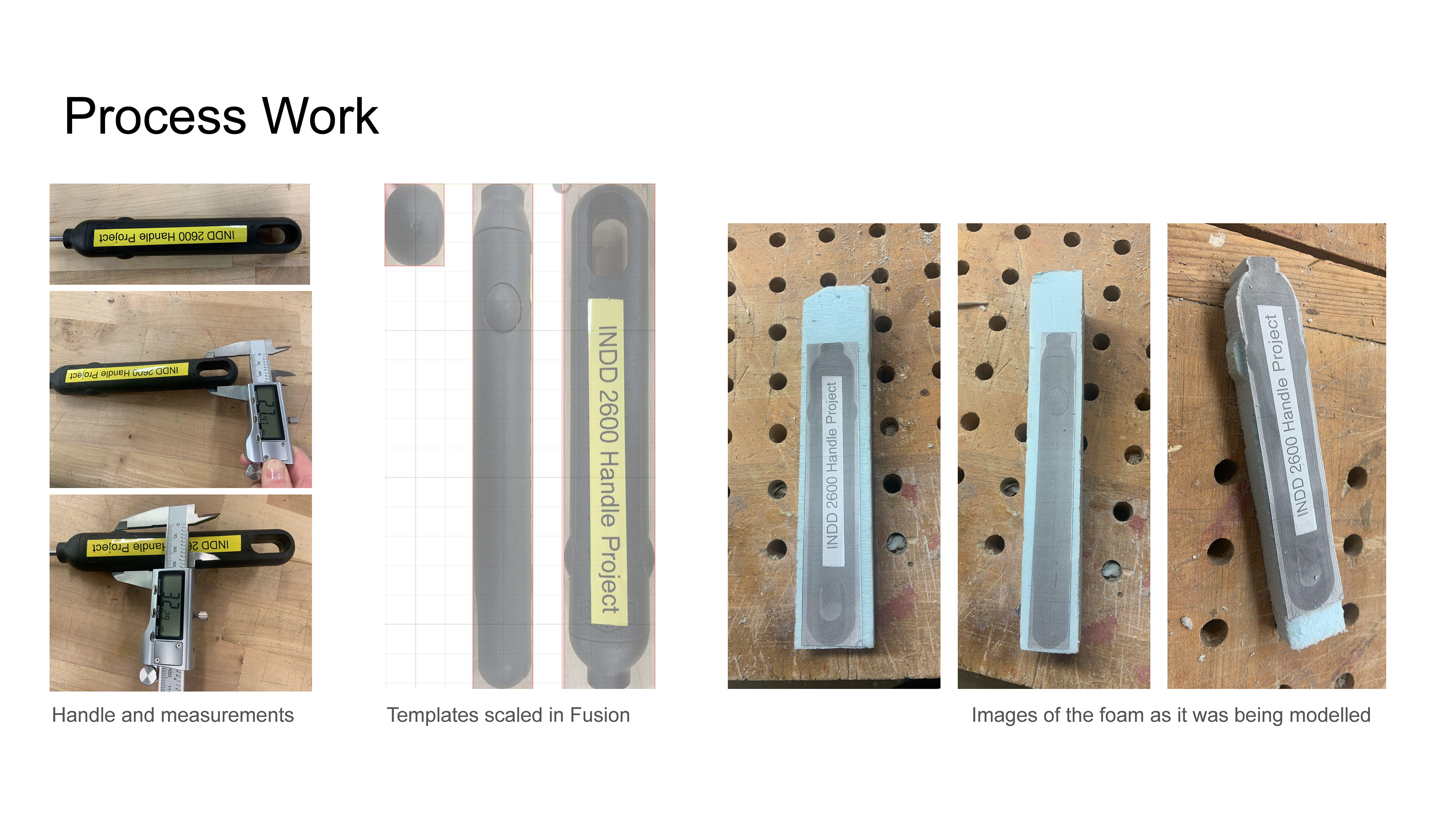

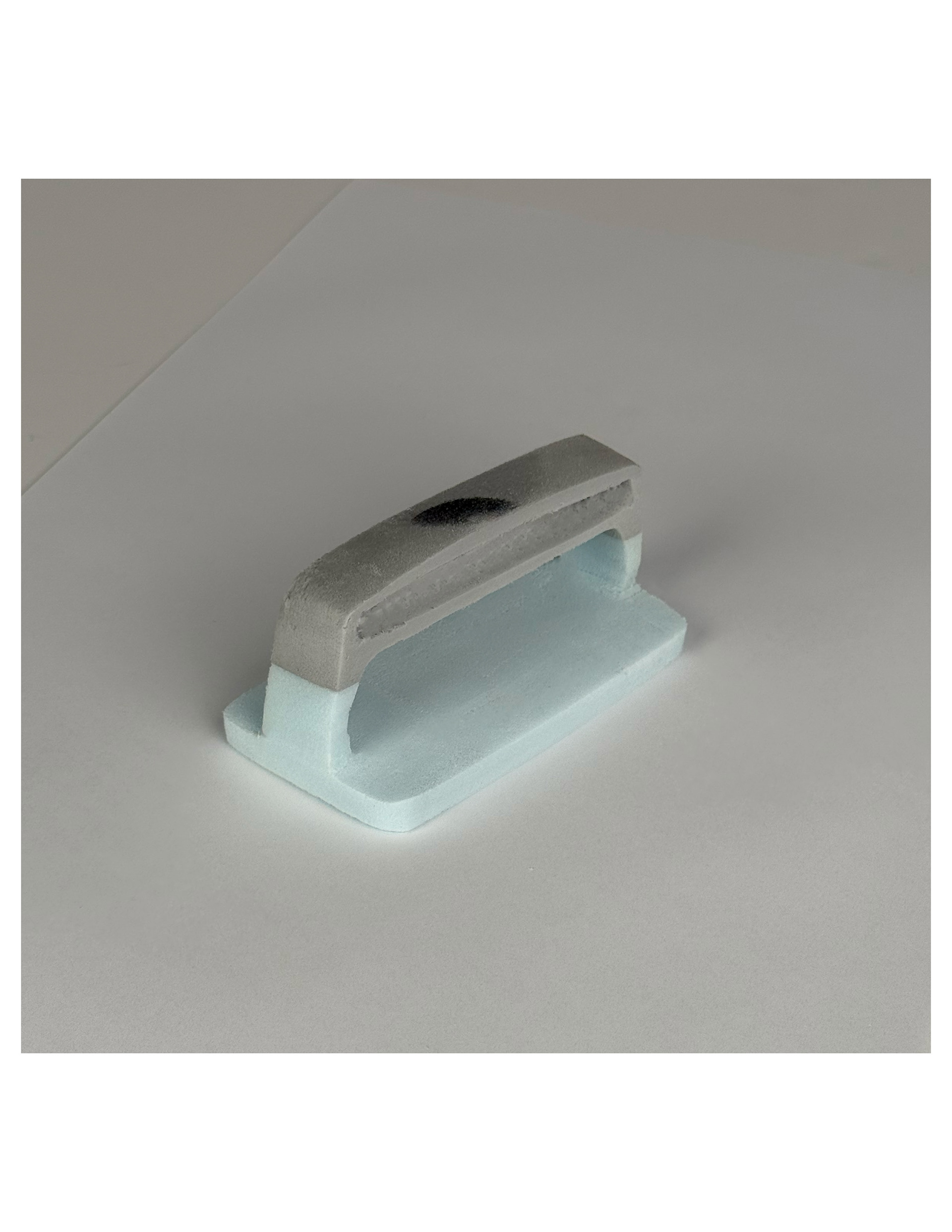

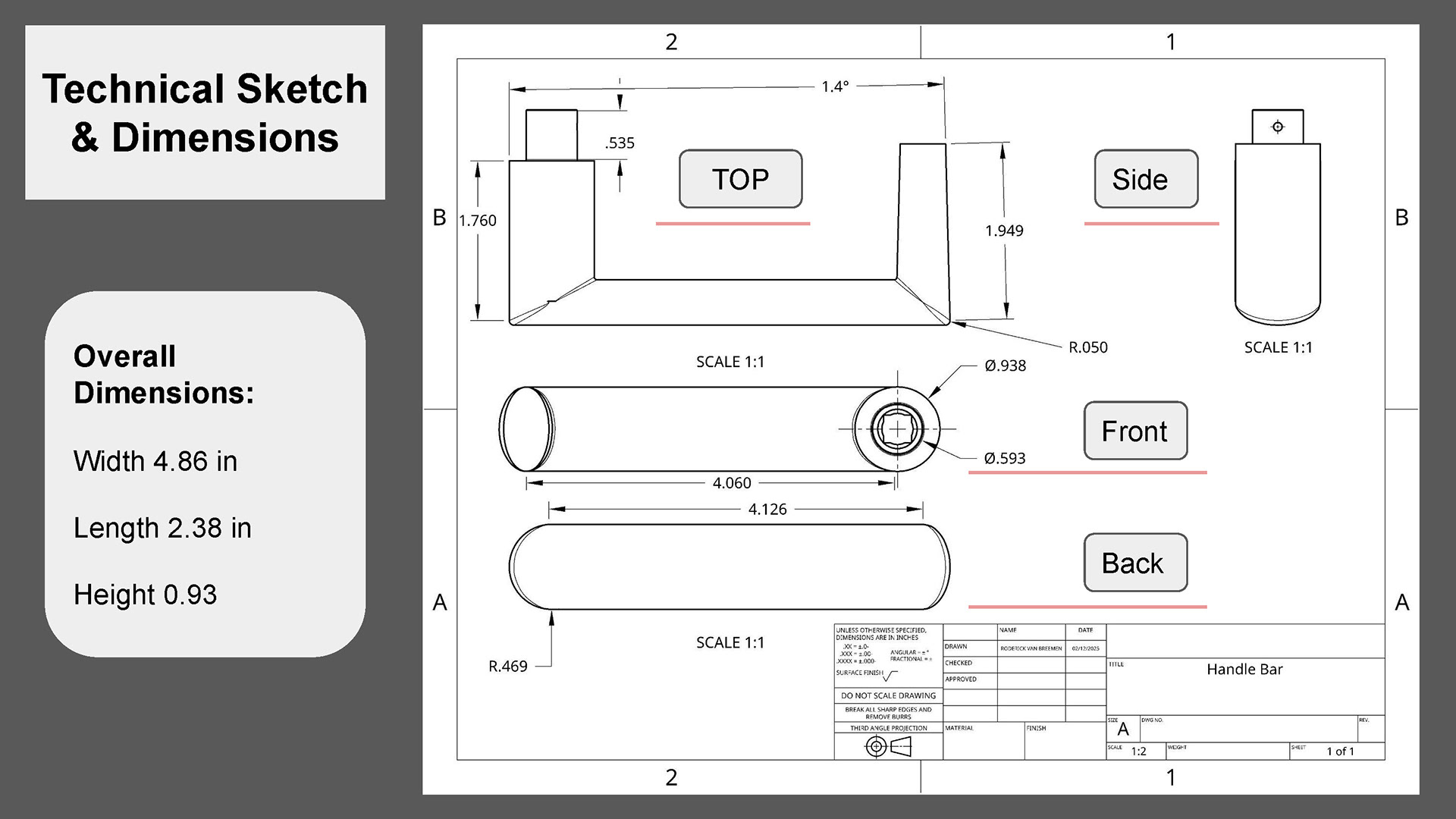

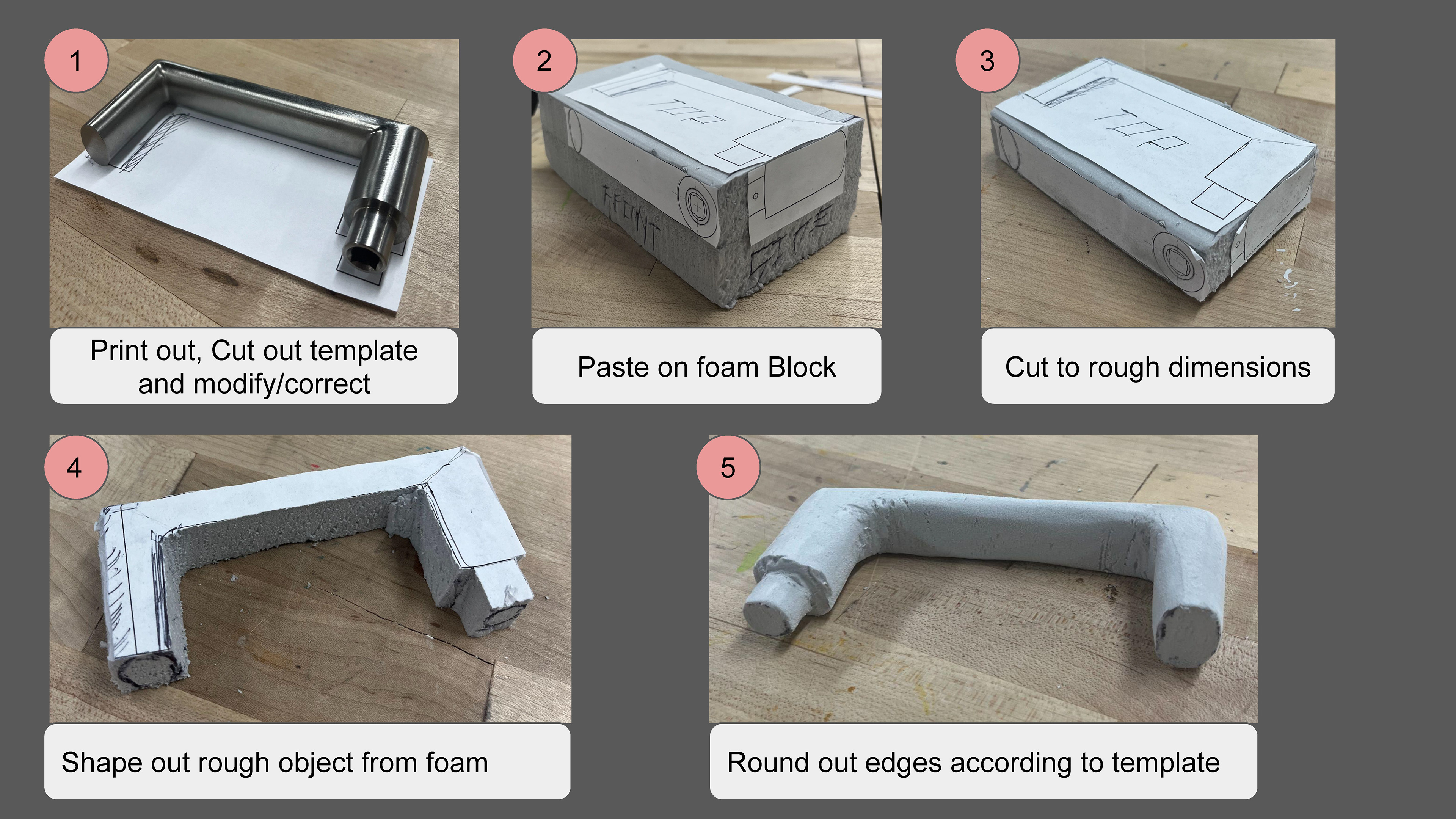

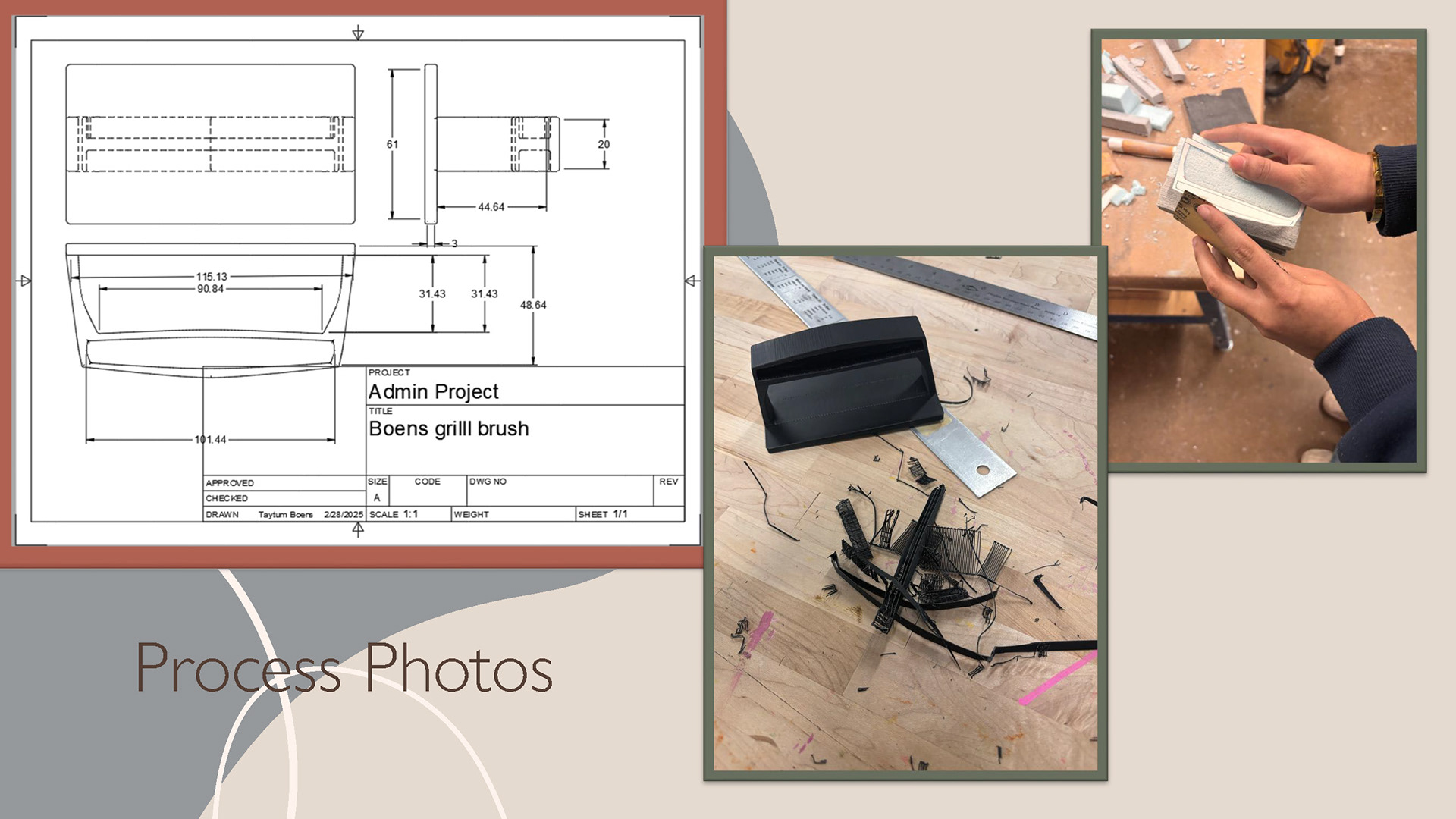

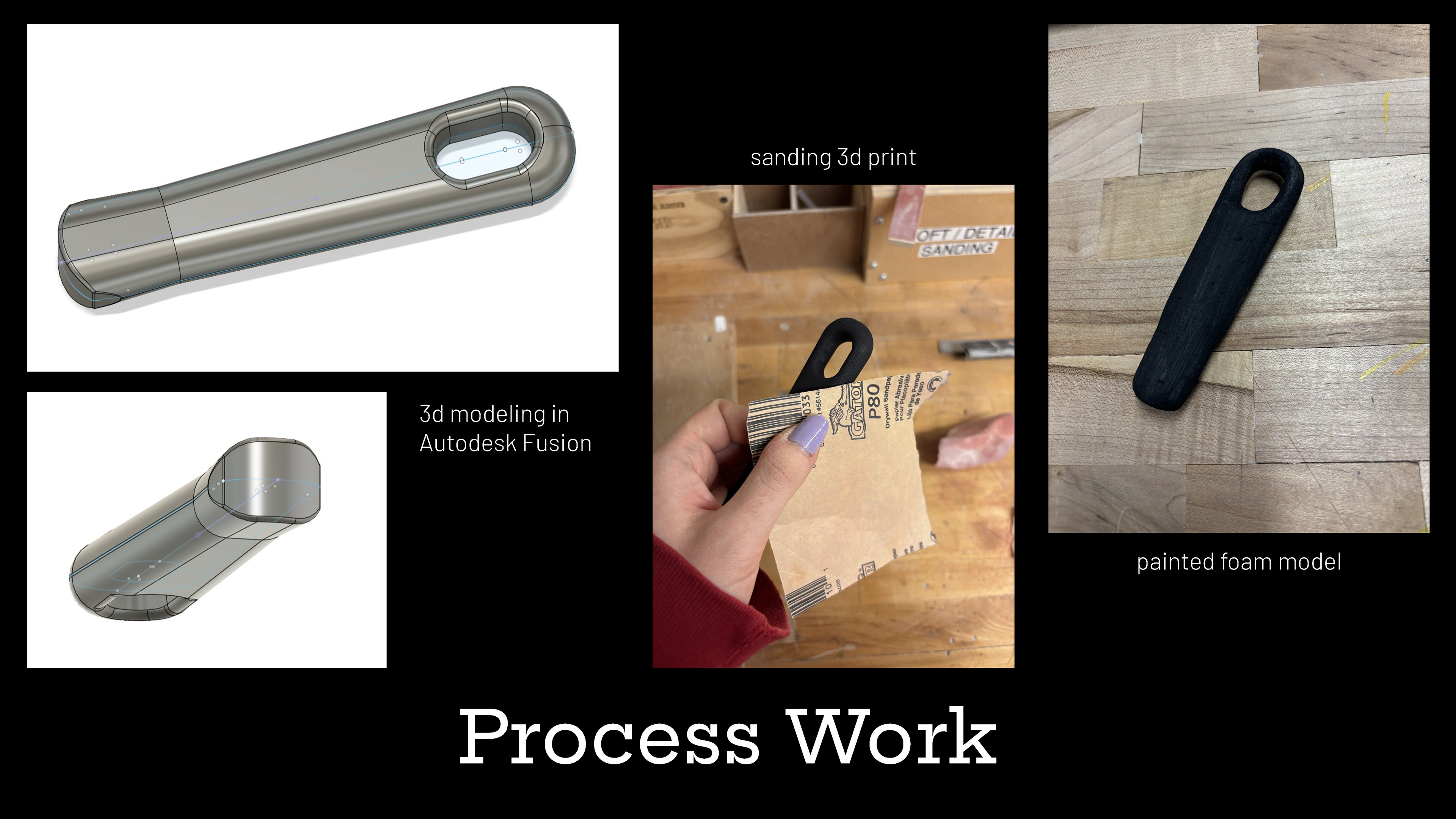

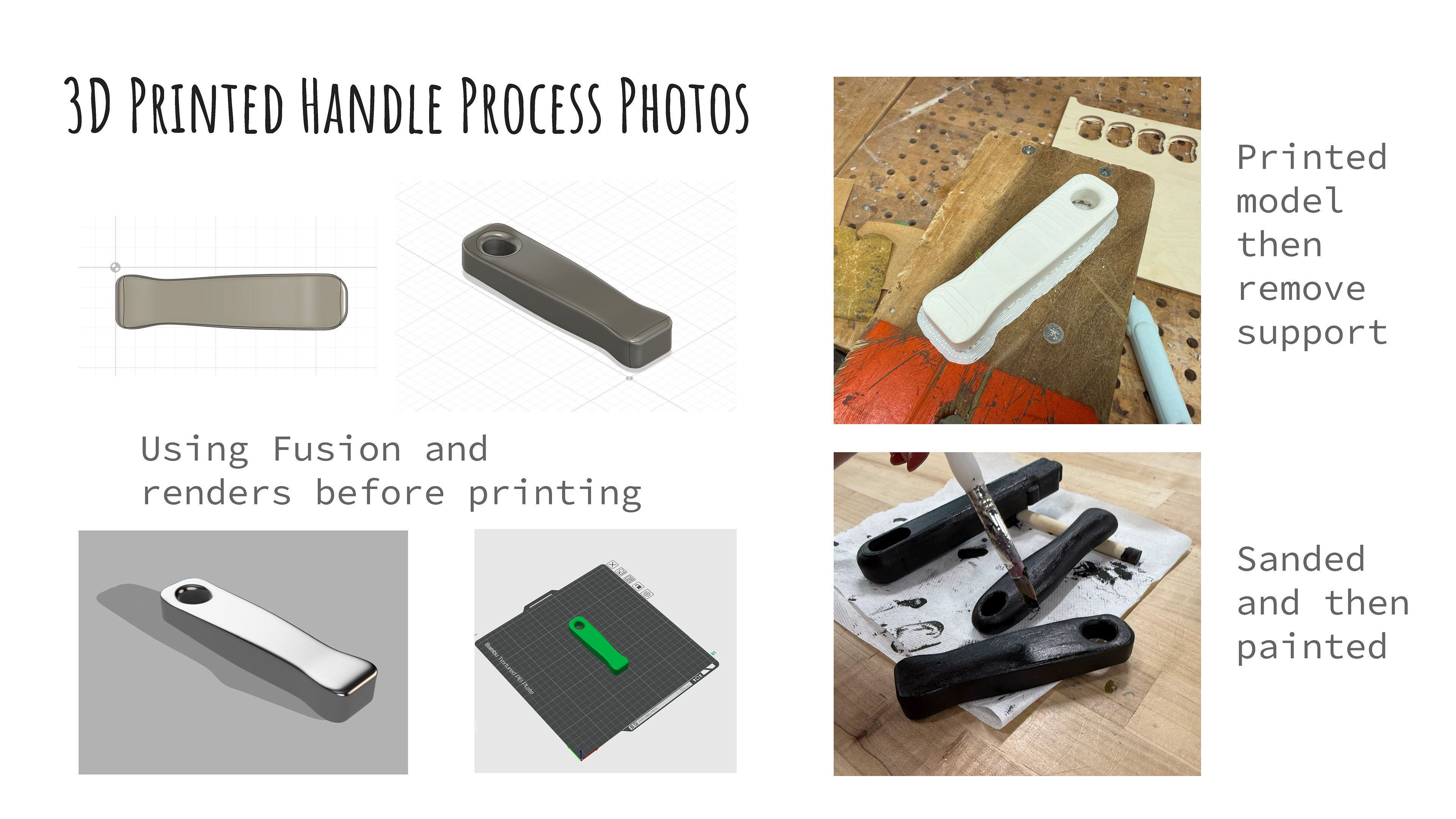

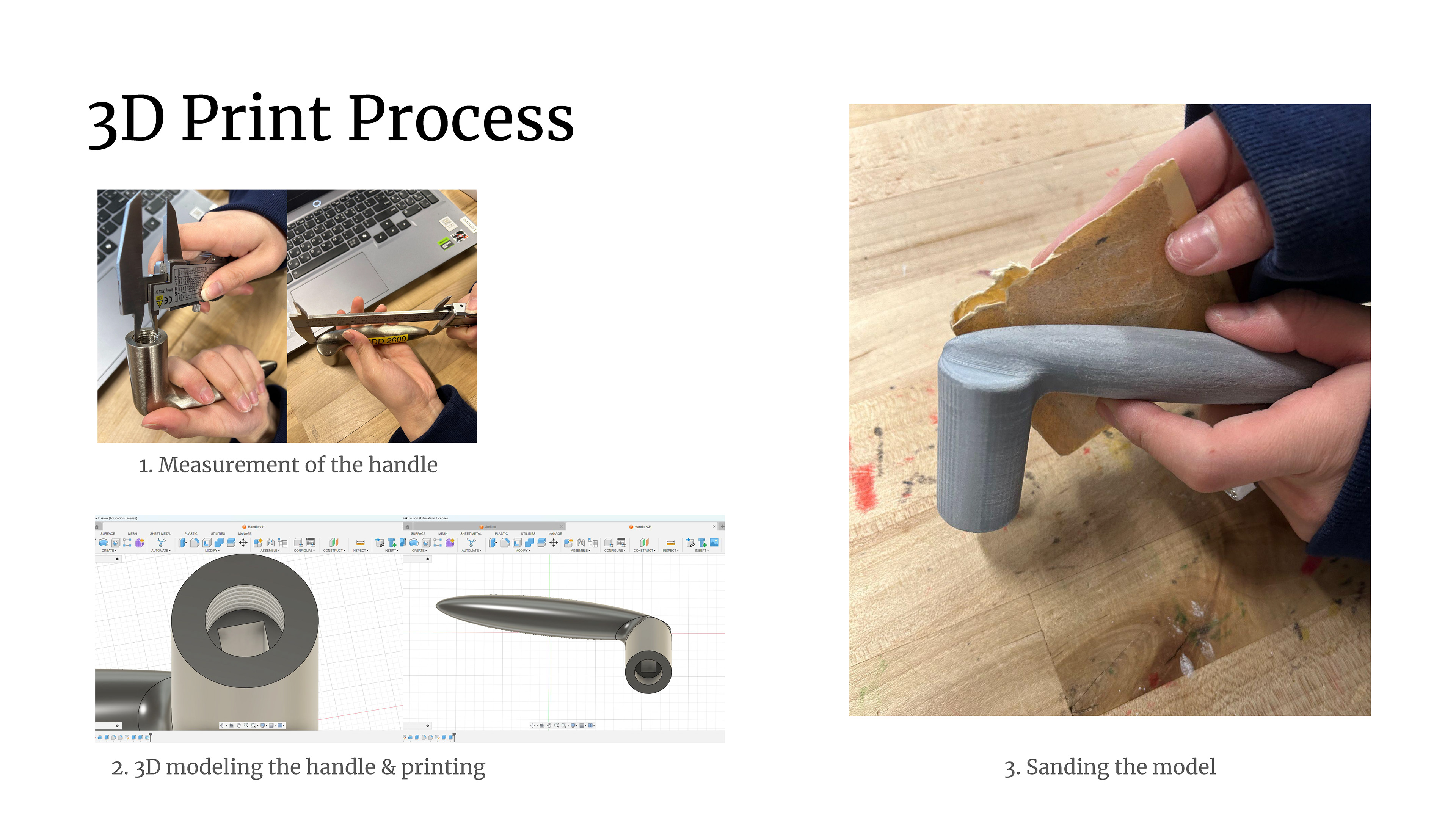

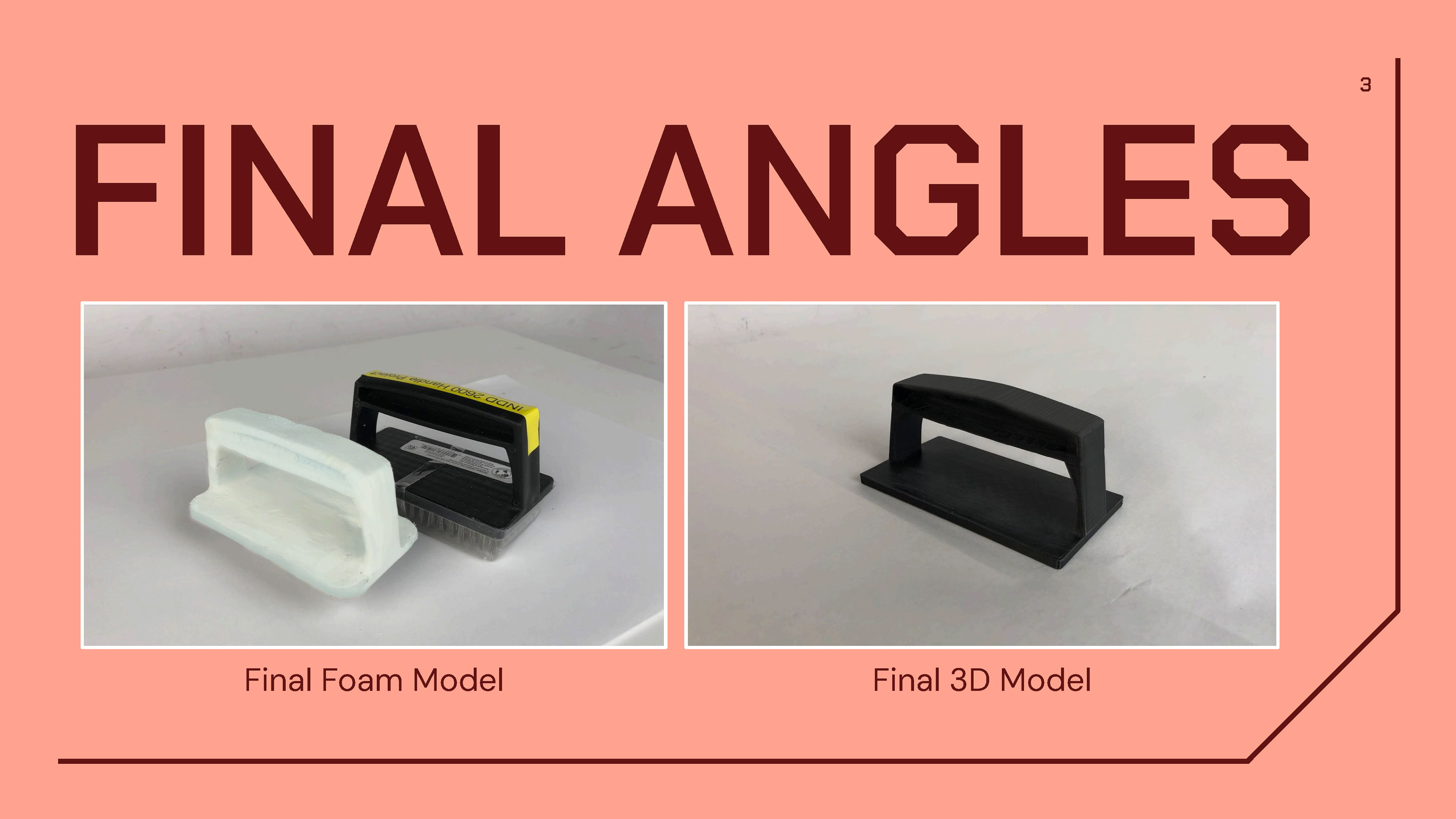

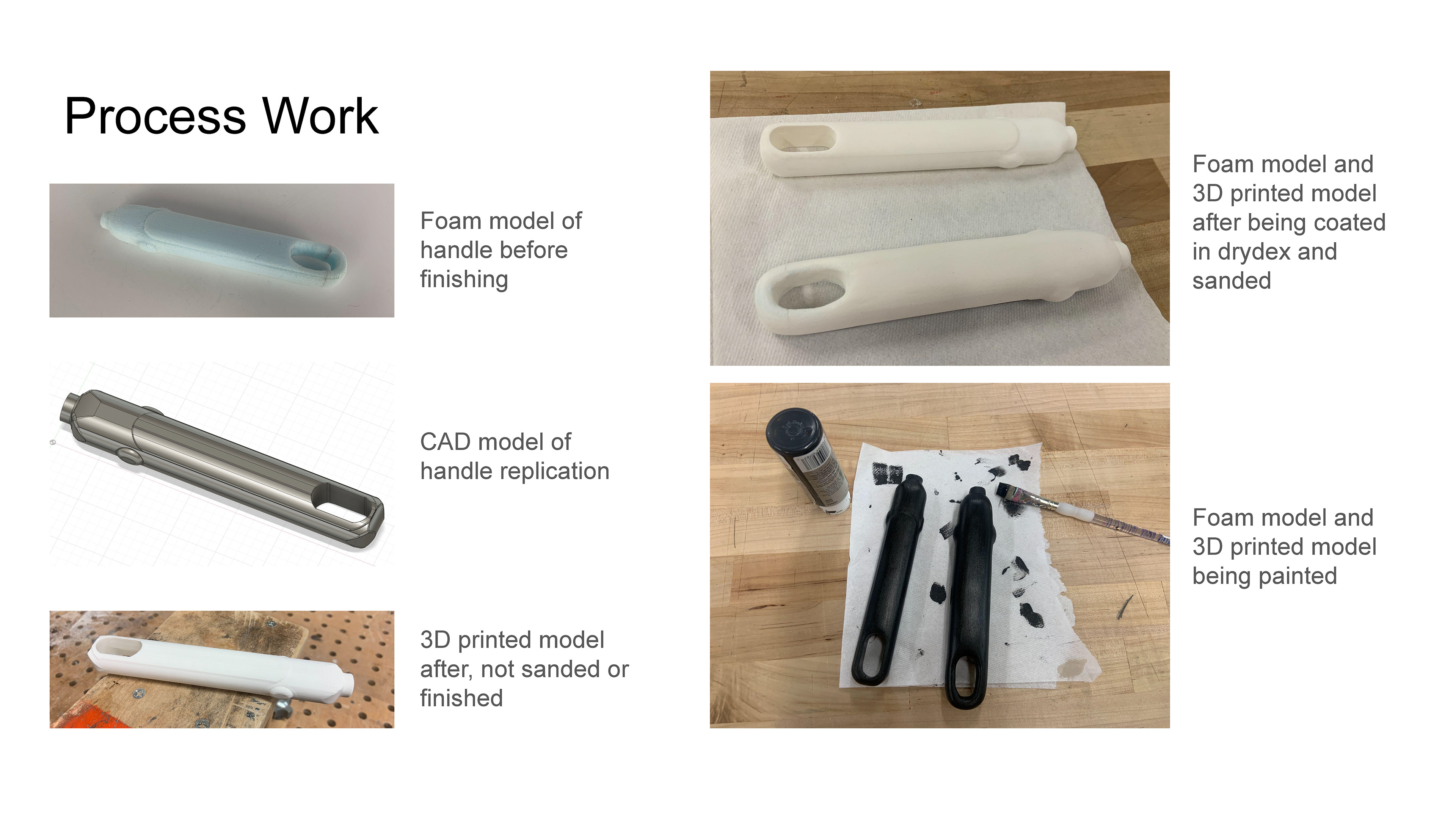

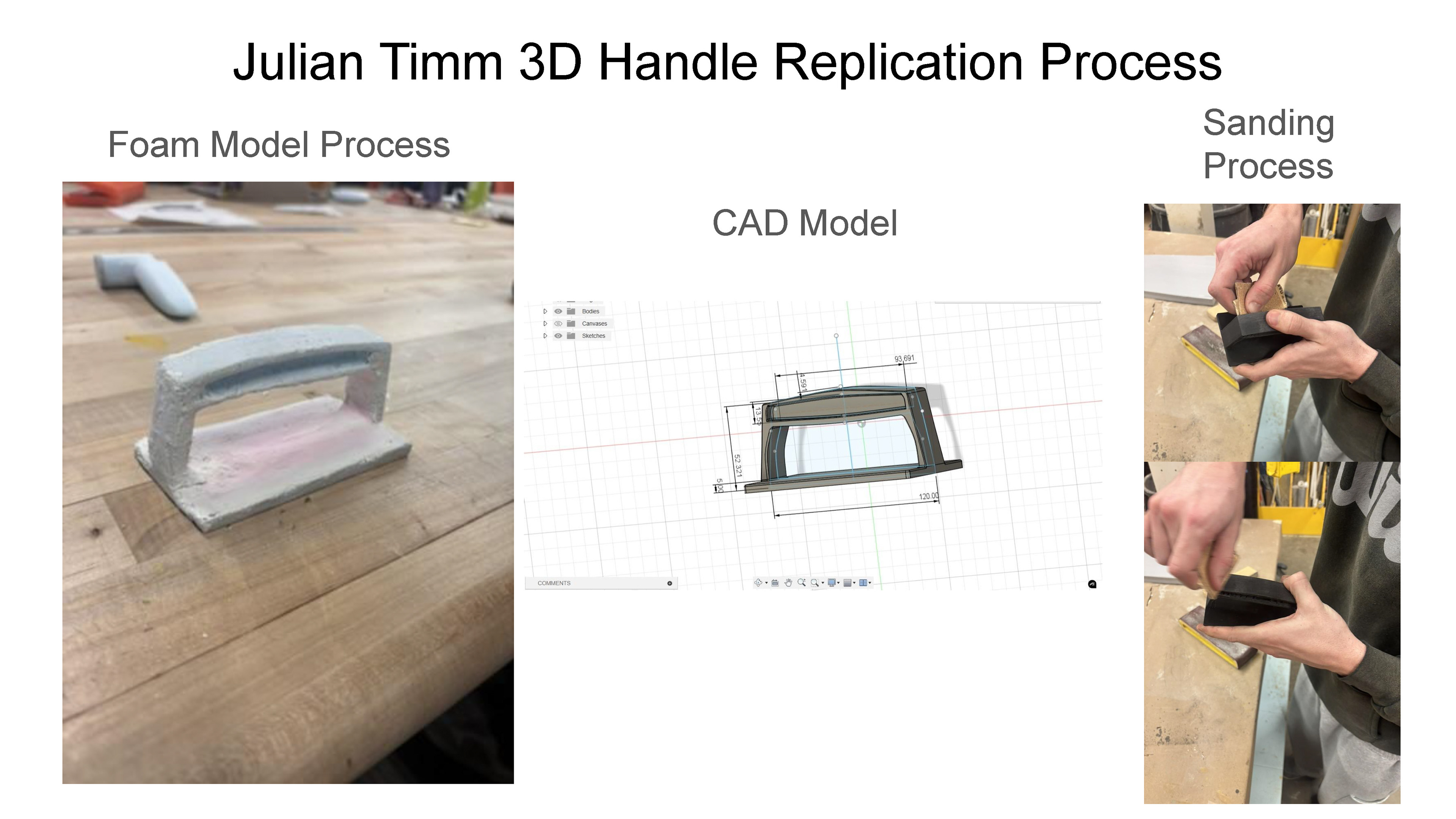

They are taught to measure the original store bought handle, make Technical drawings for templating, then using these tech drawings to shape and form foam. This gives them a good idea of how to replicate and understand each curve, fillet and hole in the handle.

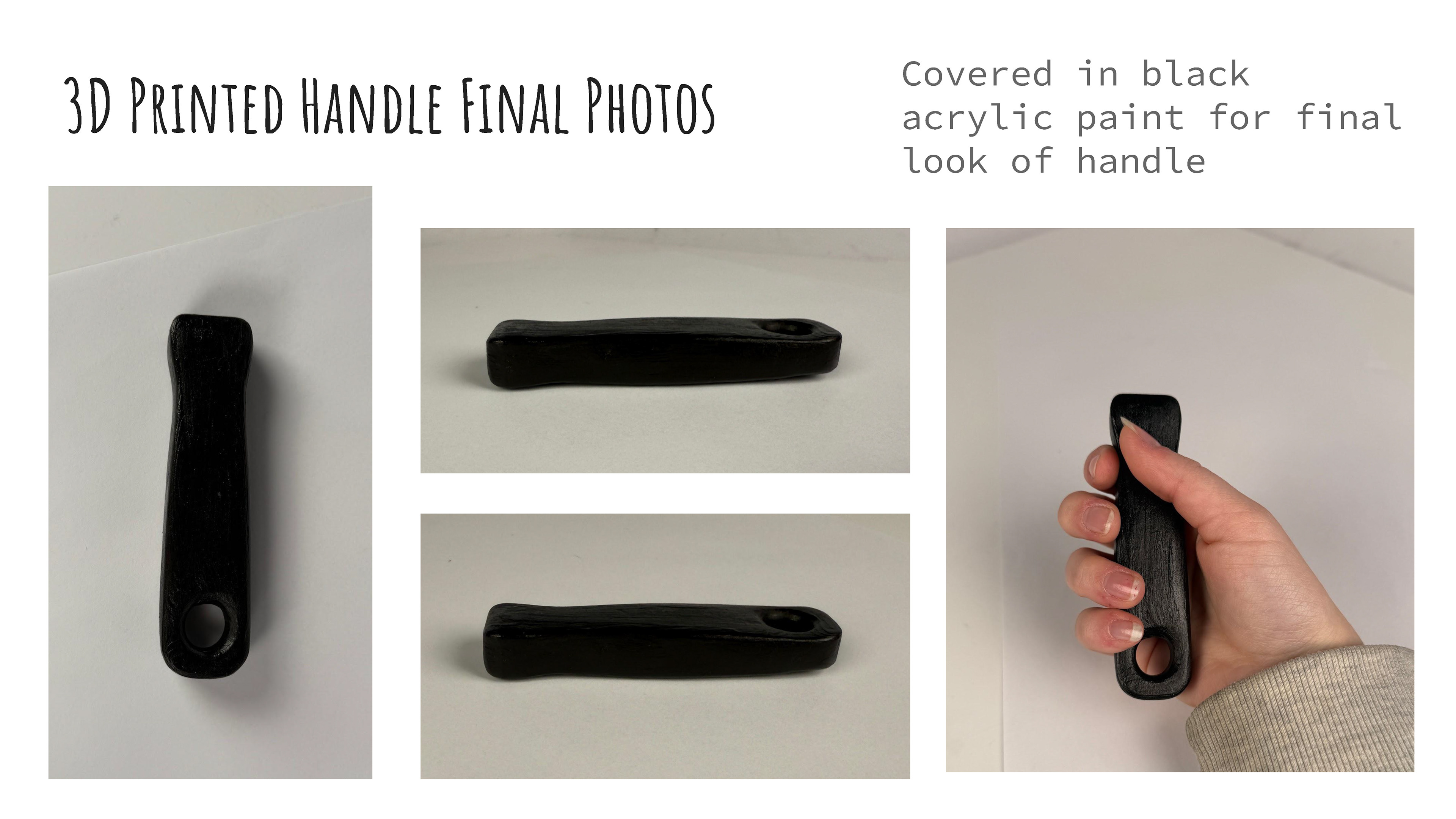

This exercize is just to help them understand the object better, so that when they get into 3D Modelling on the computer they are able to model seamlessly. This 3D model then gets printed and is presented next to the original and foam handle to test the replication process.

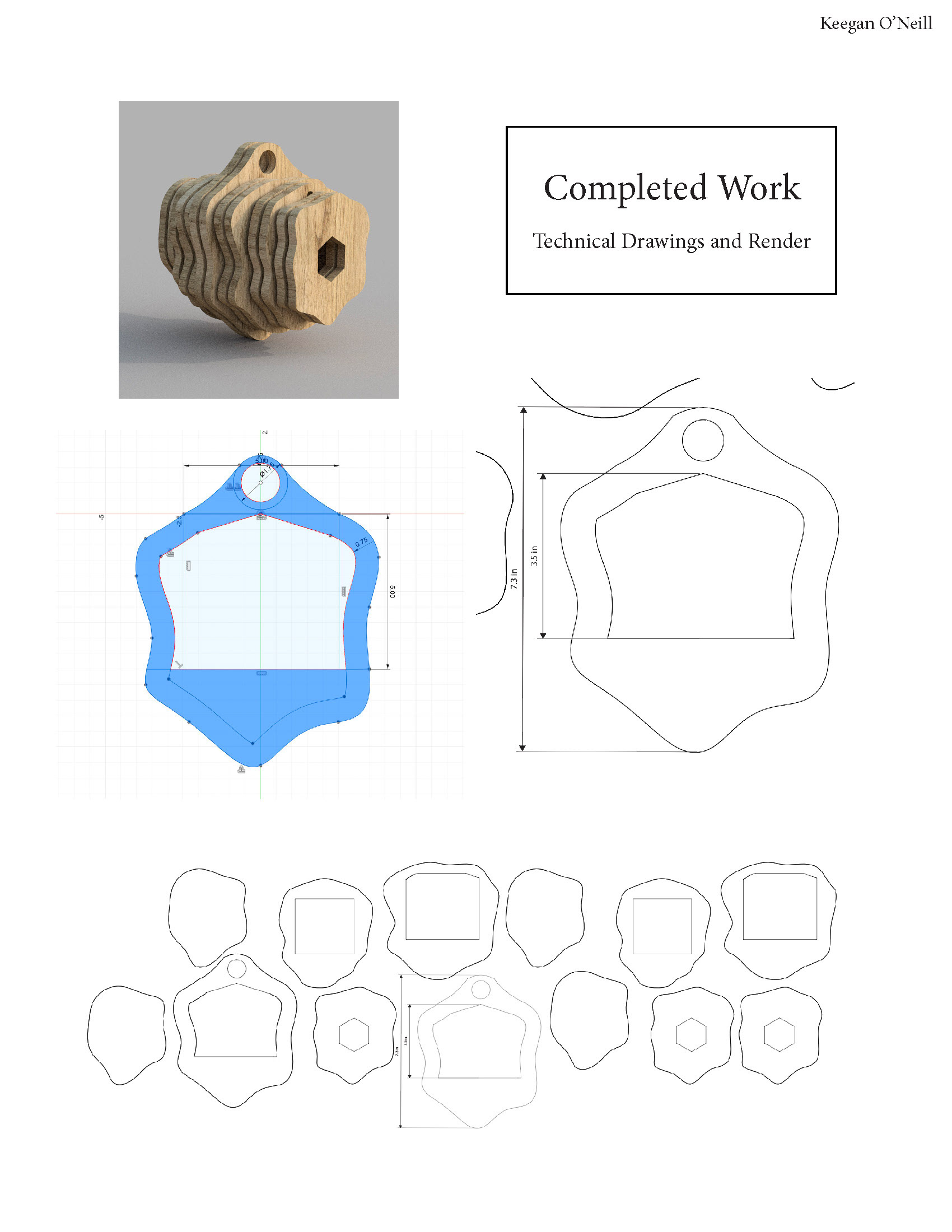

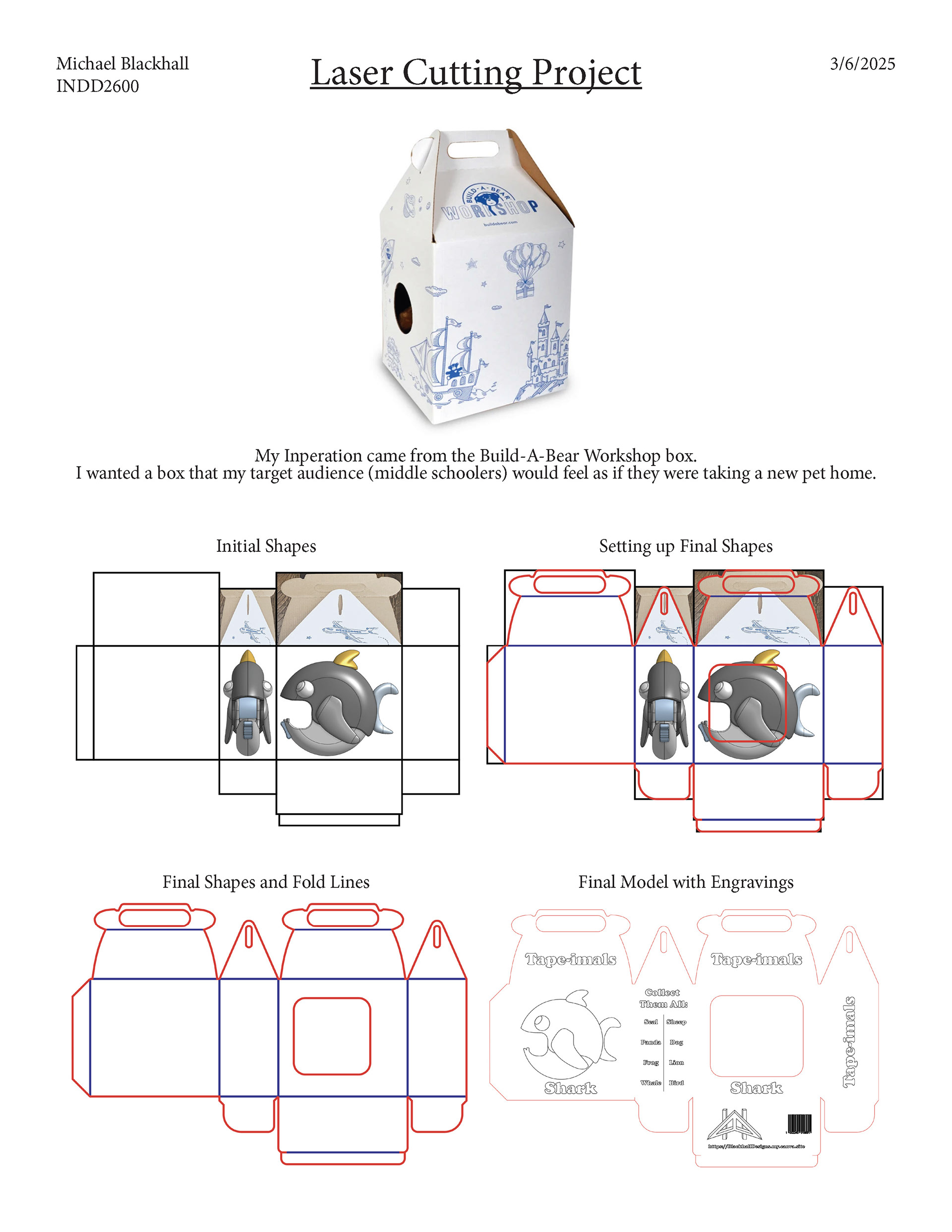

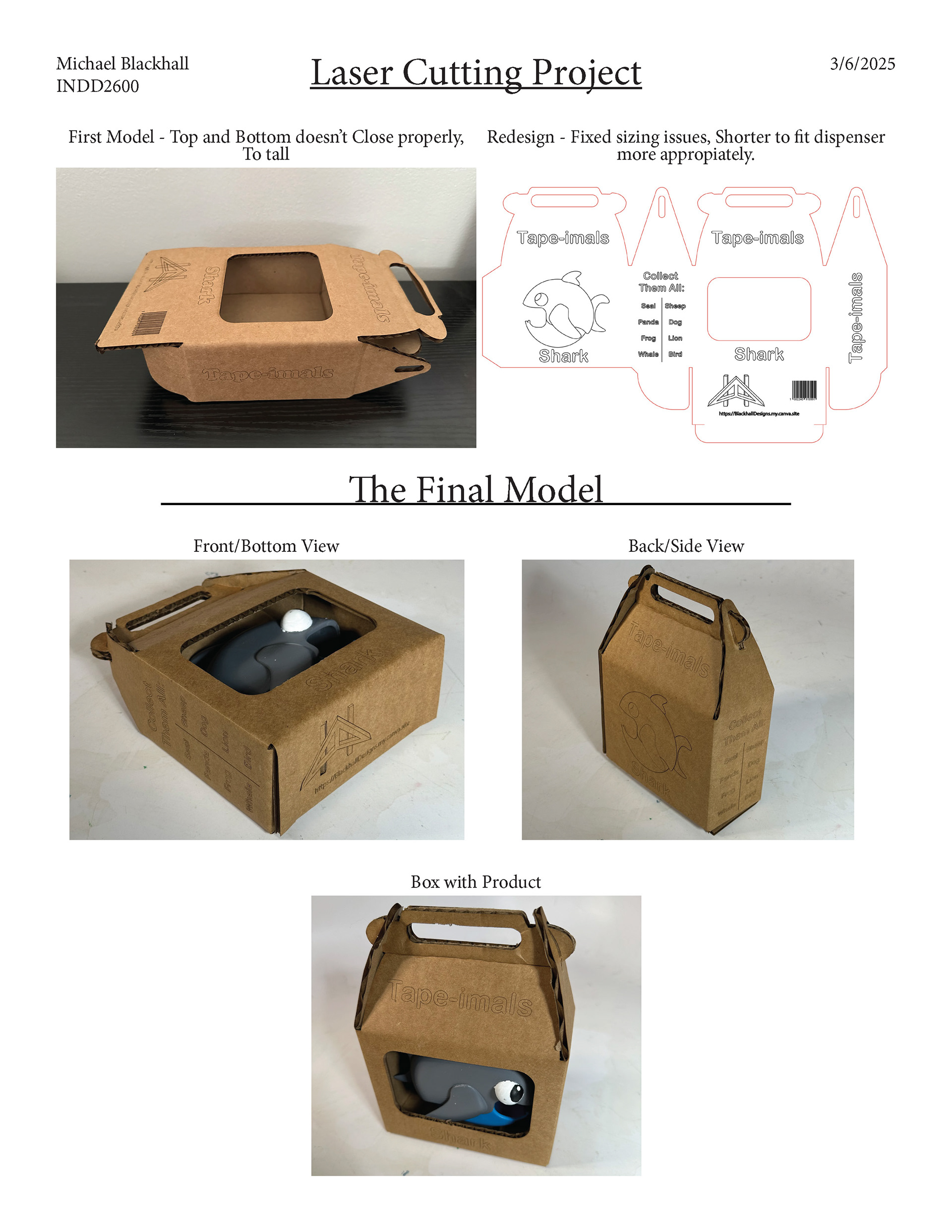

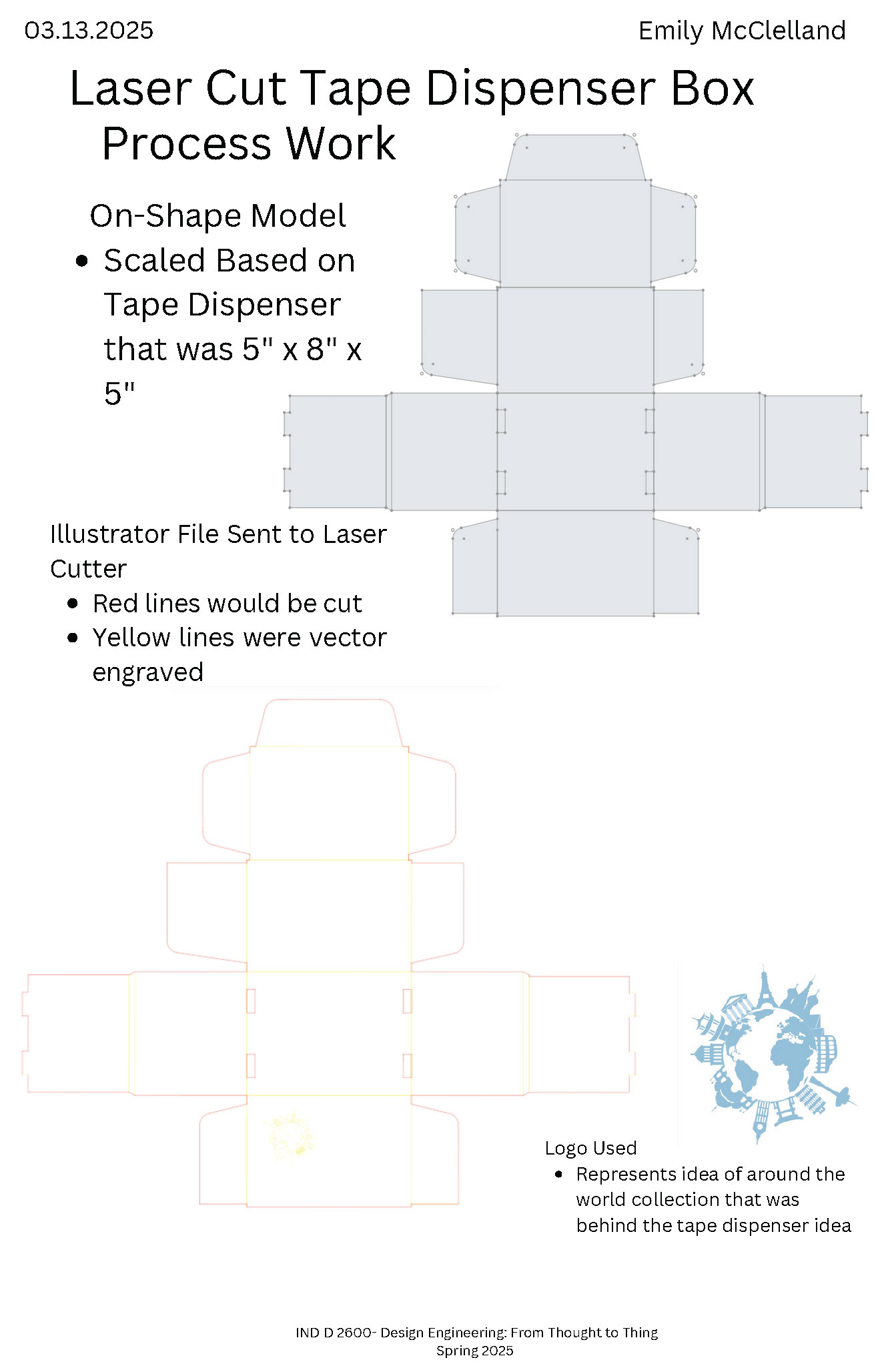

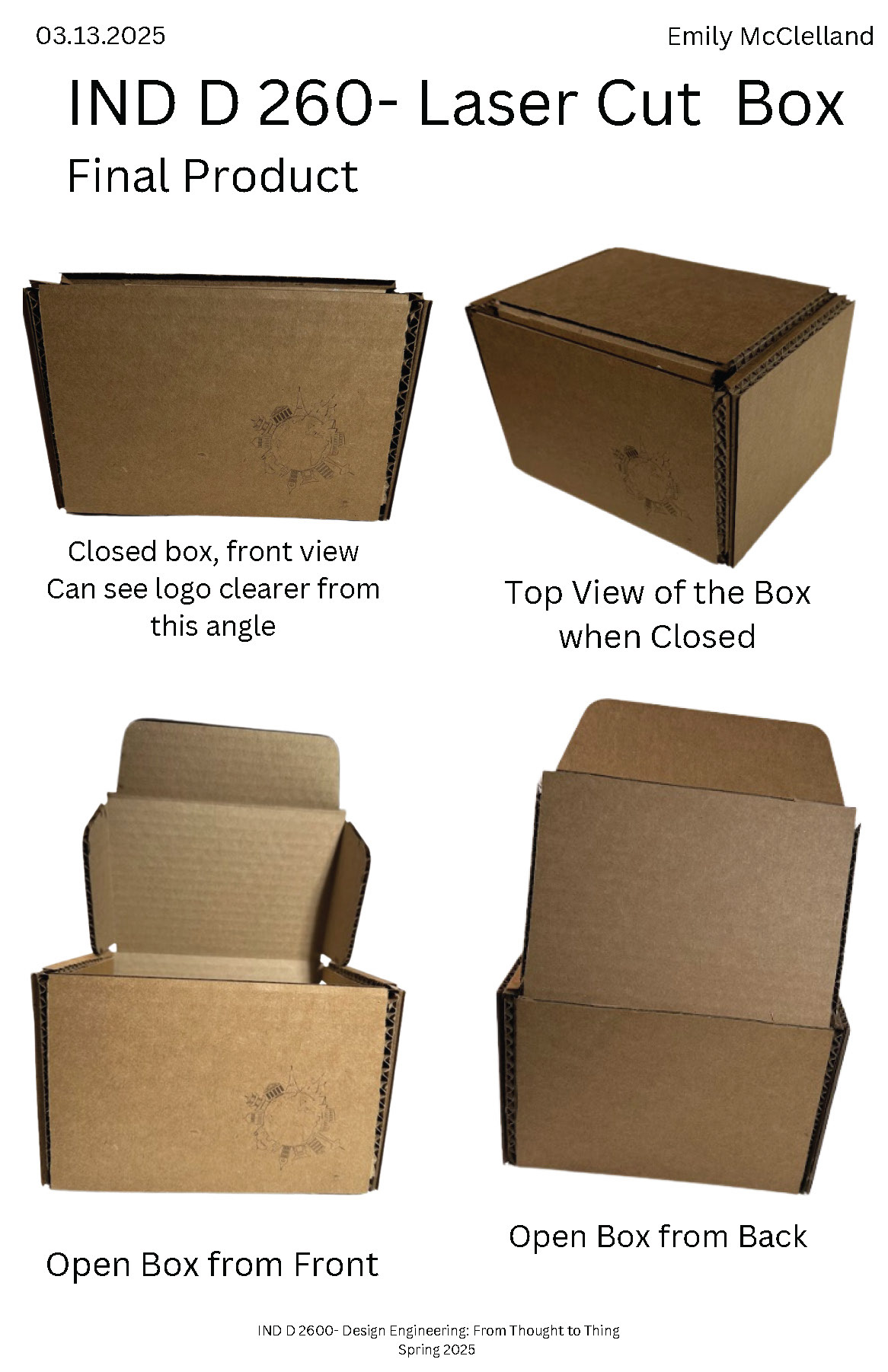

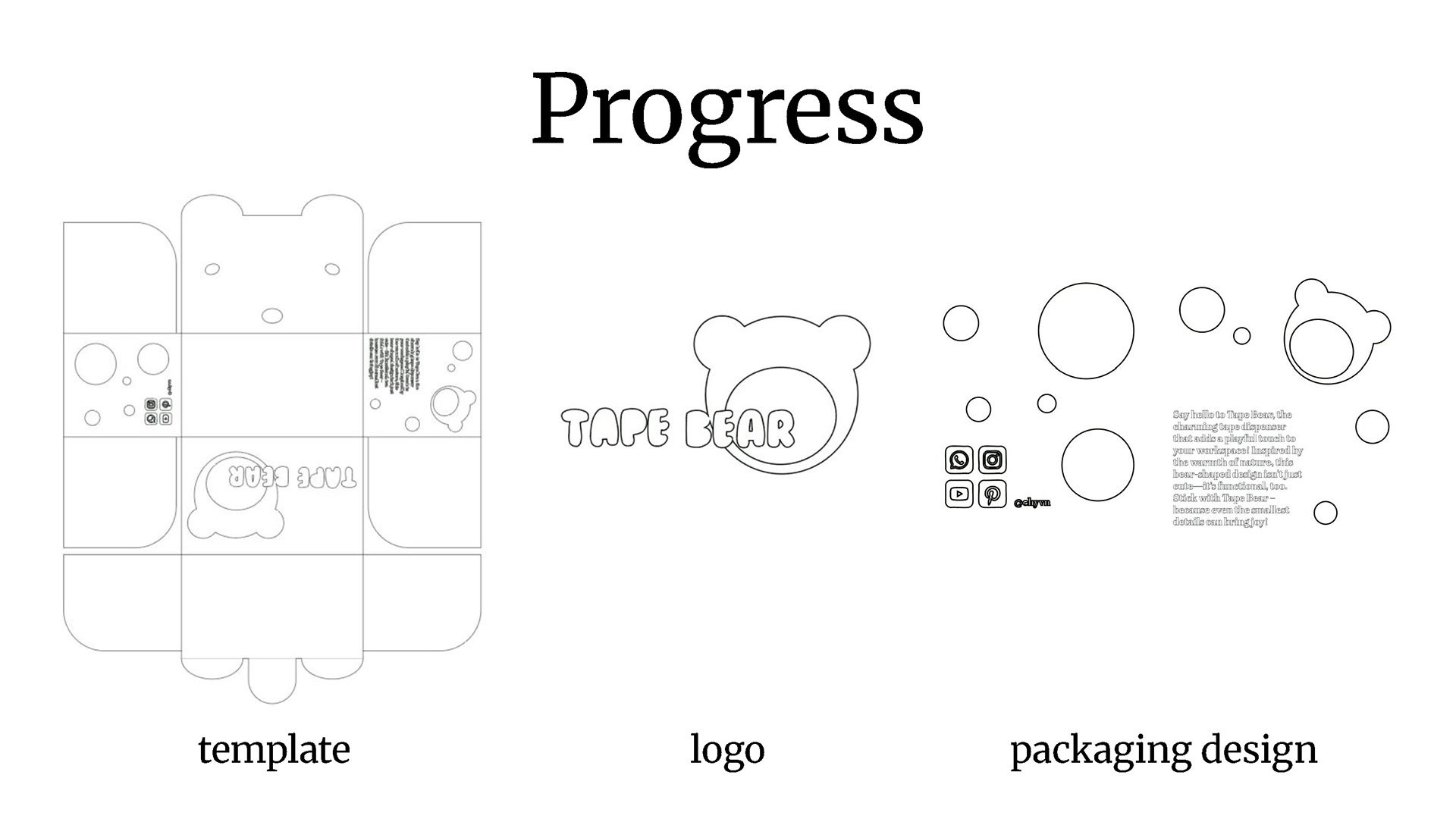

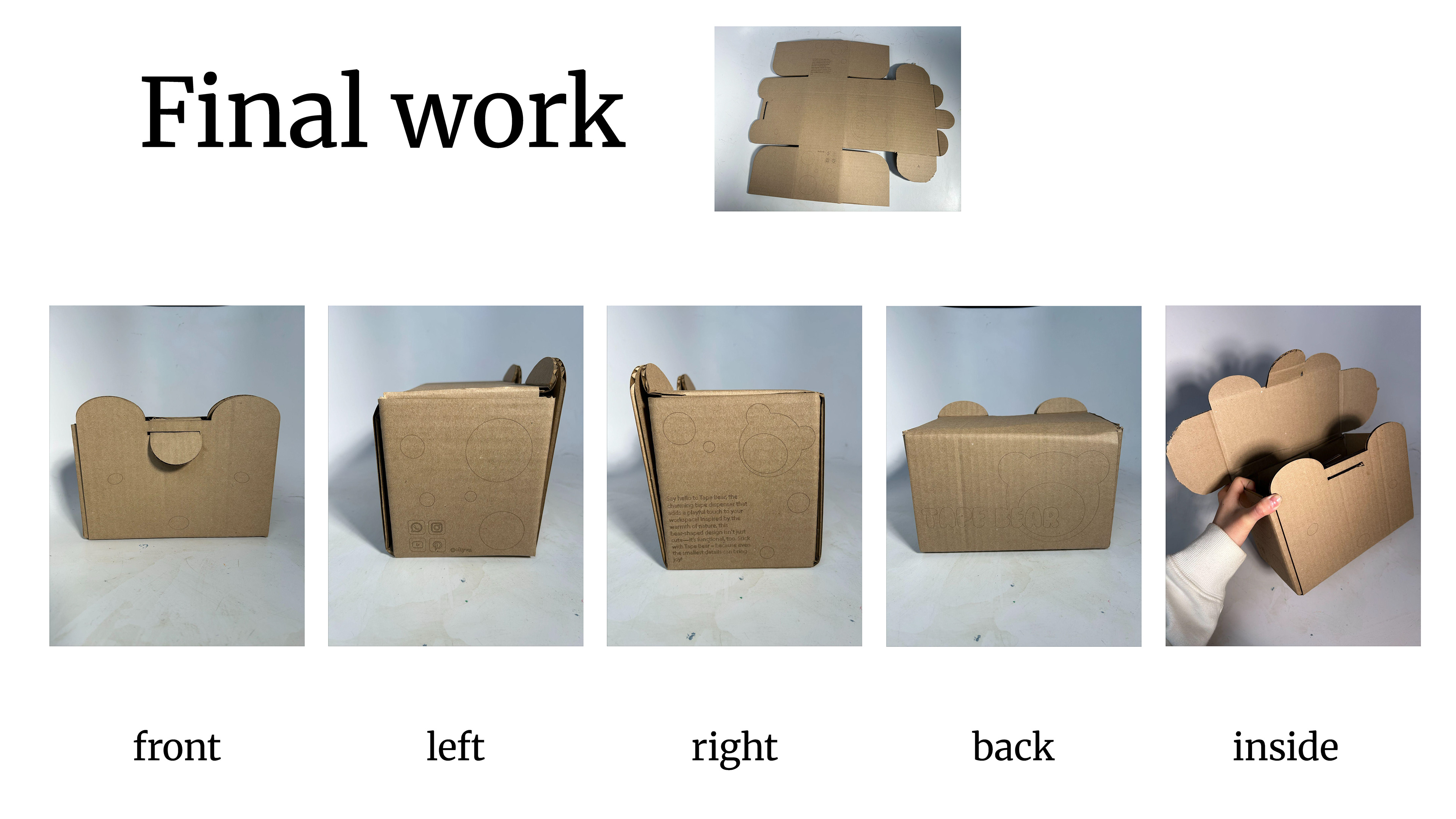

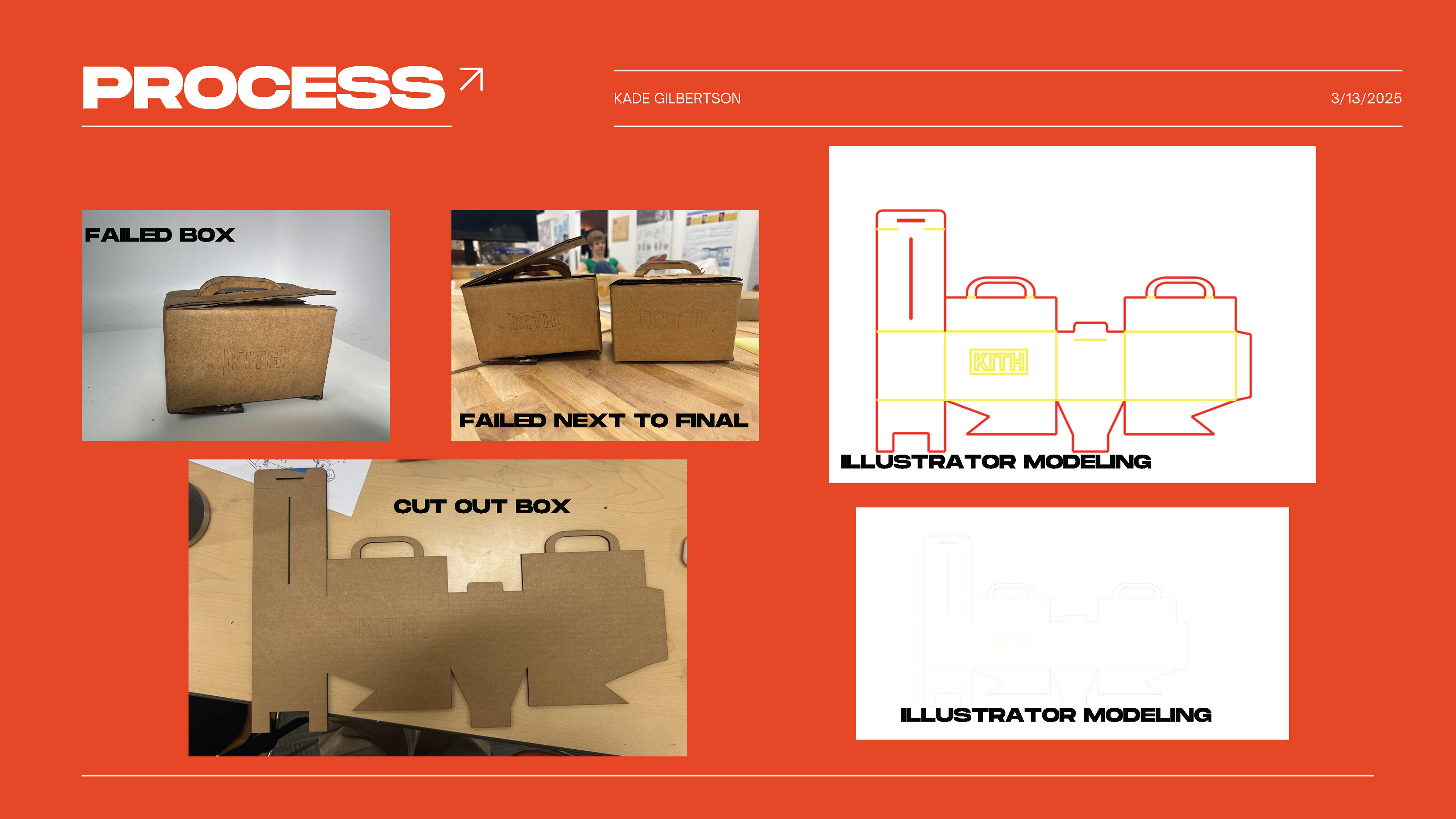

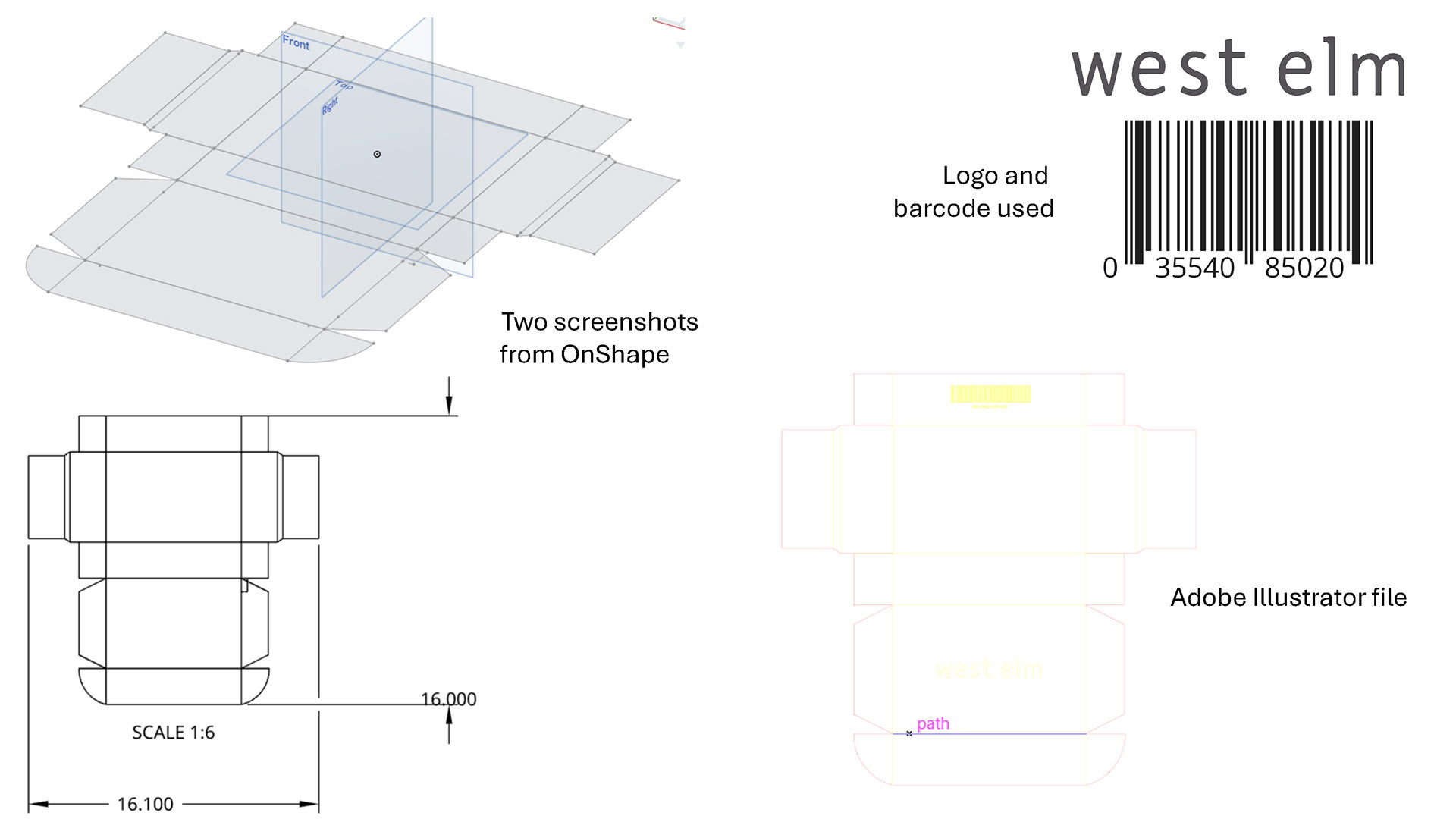

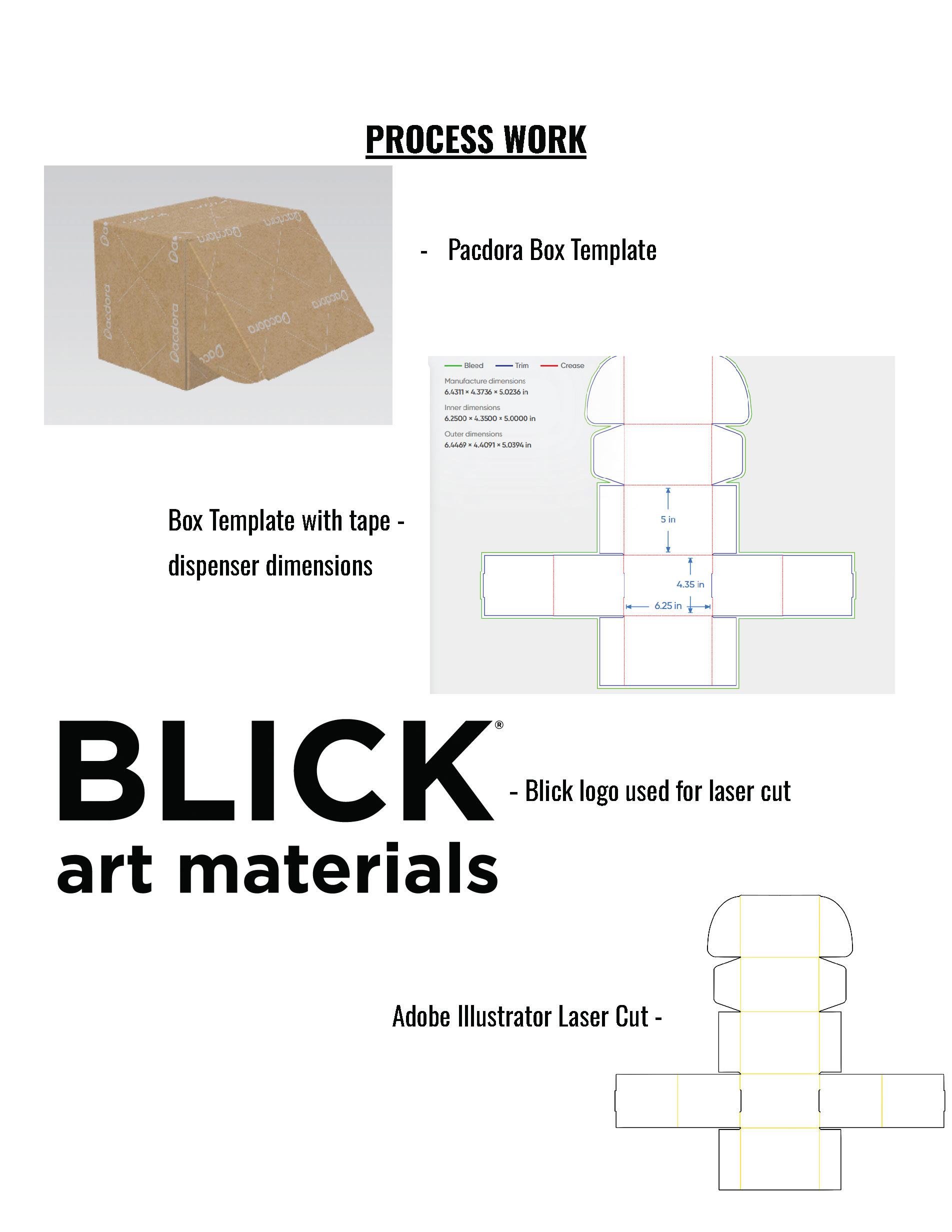

Laser Cutting is another big fabrication system that students need to learn and understand to be able to manipulate sheets of materials.

Here students are taught to laser cut through packaging design, therefore covering 2 topics, packaging in industrial design and the manufacturing system of laser cutting.

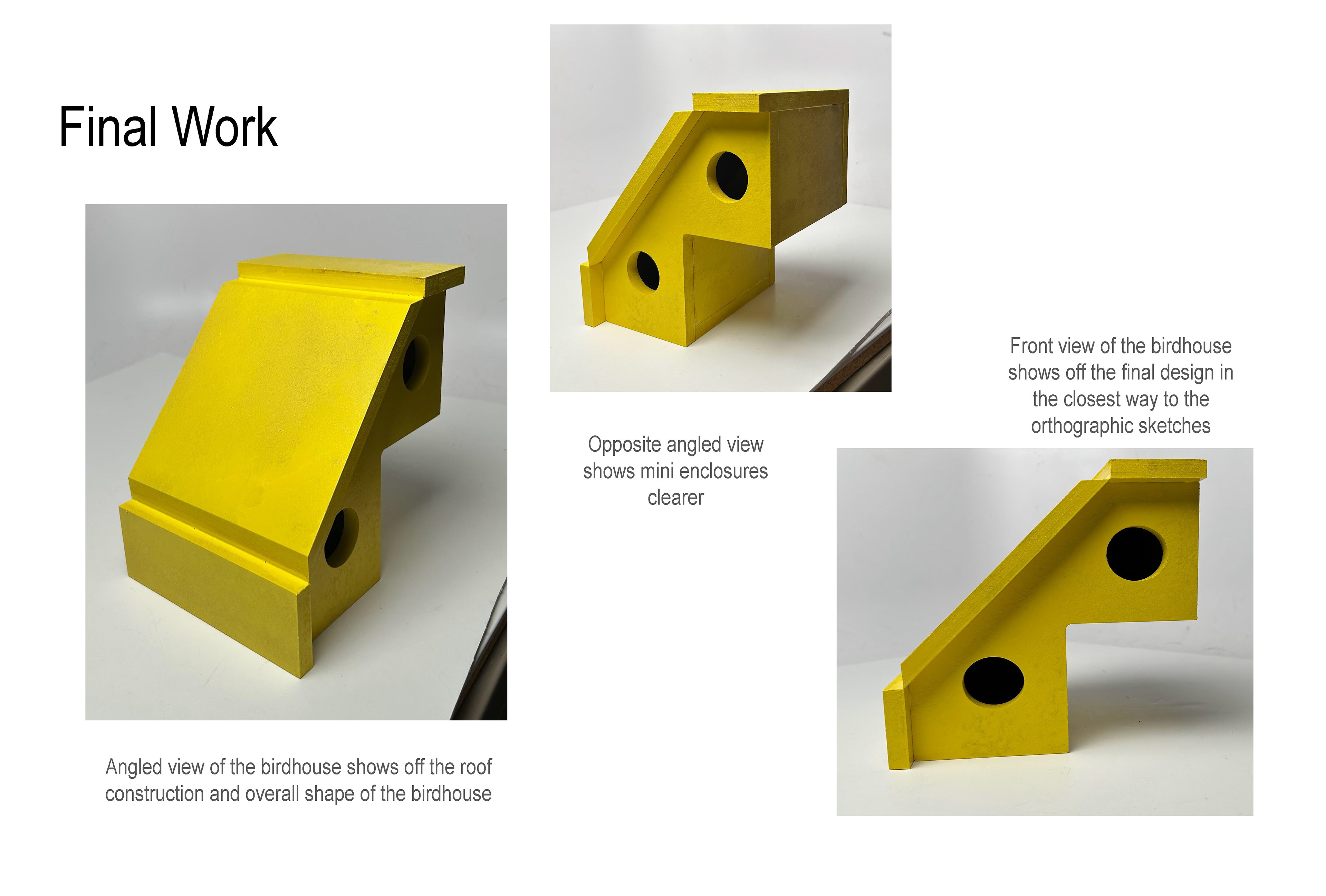

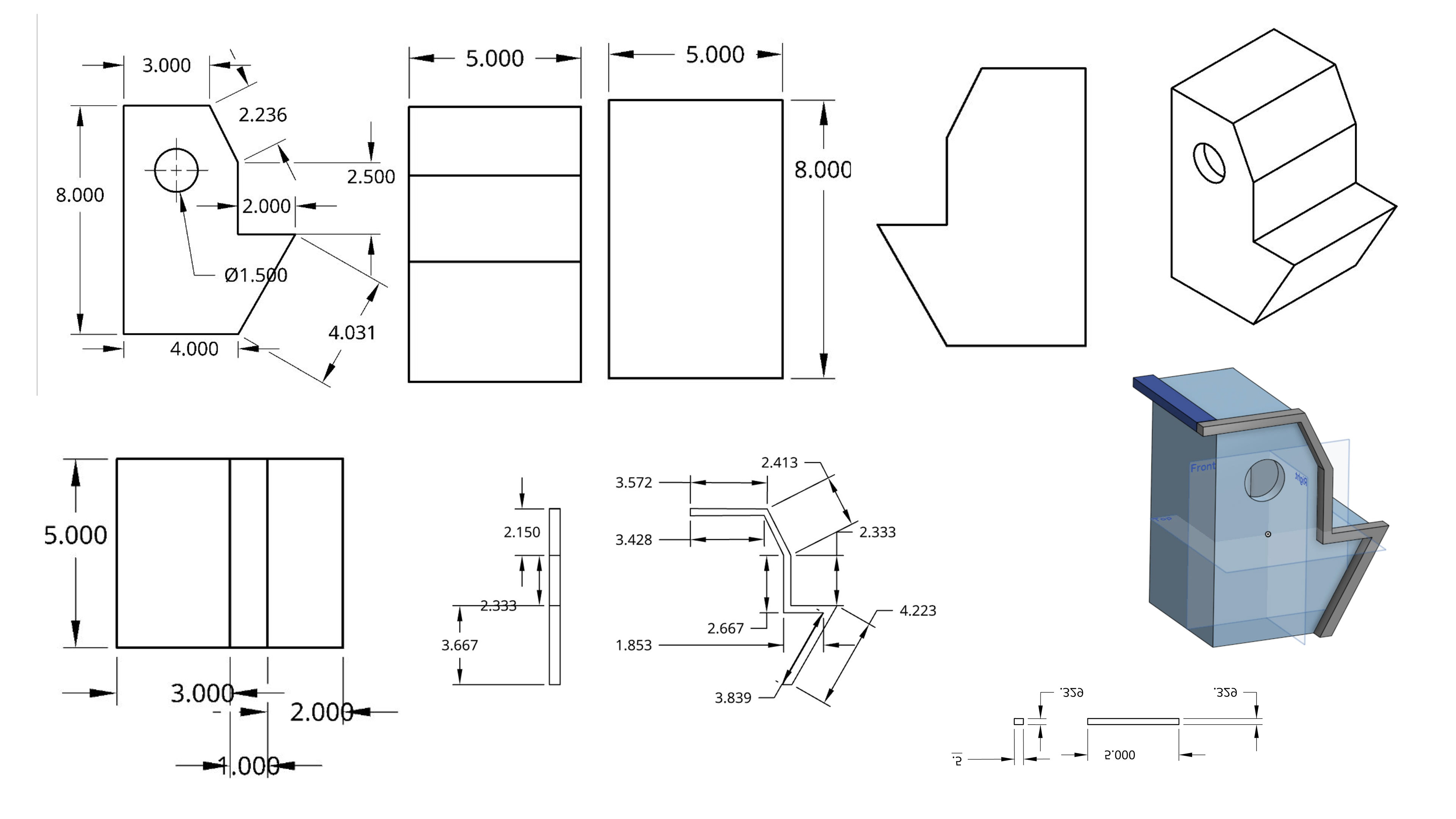

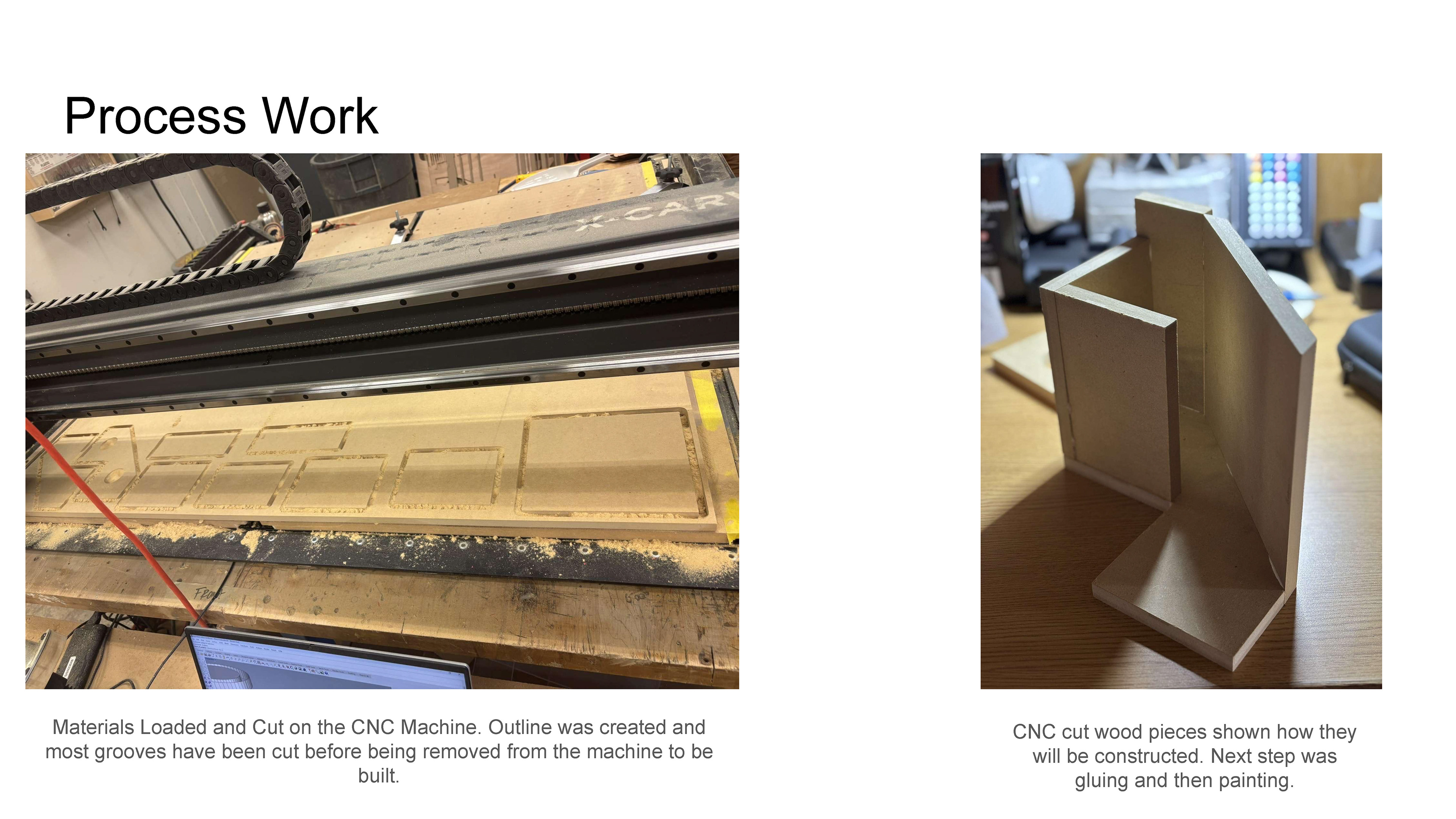

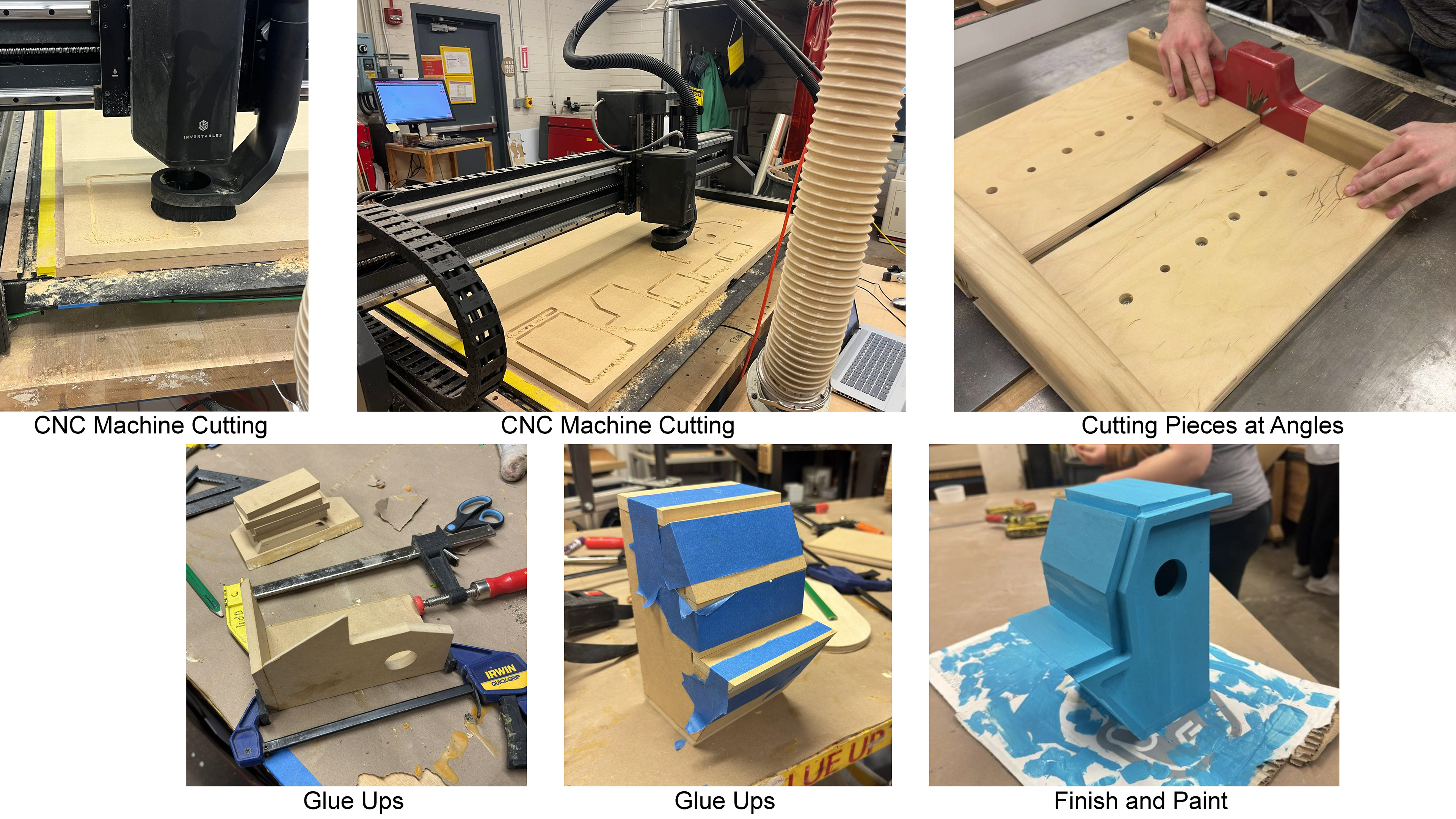

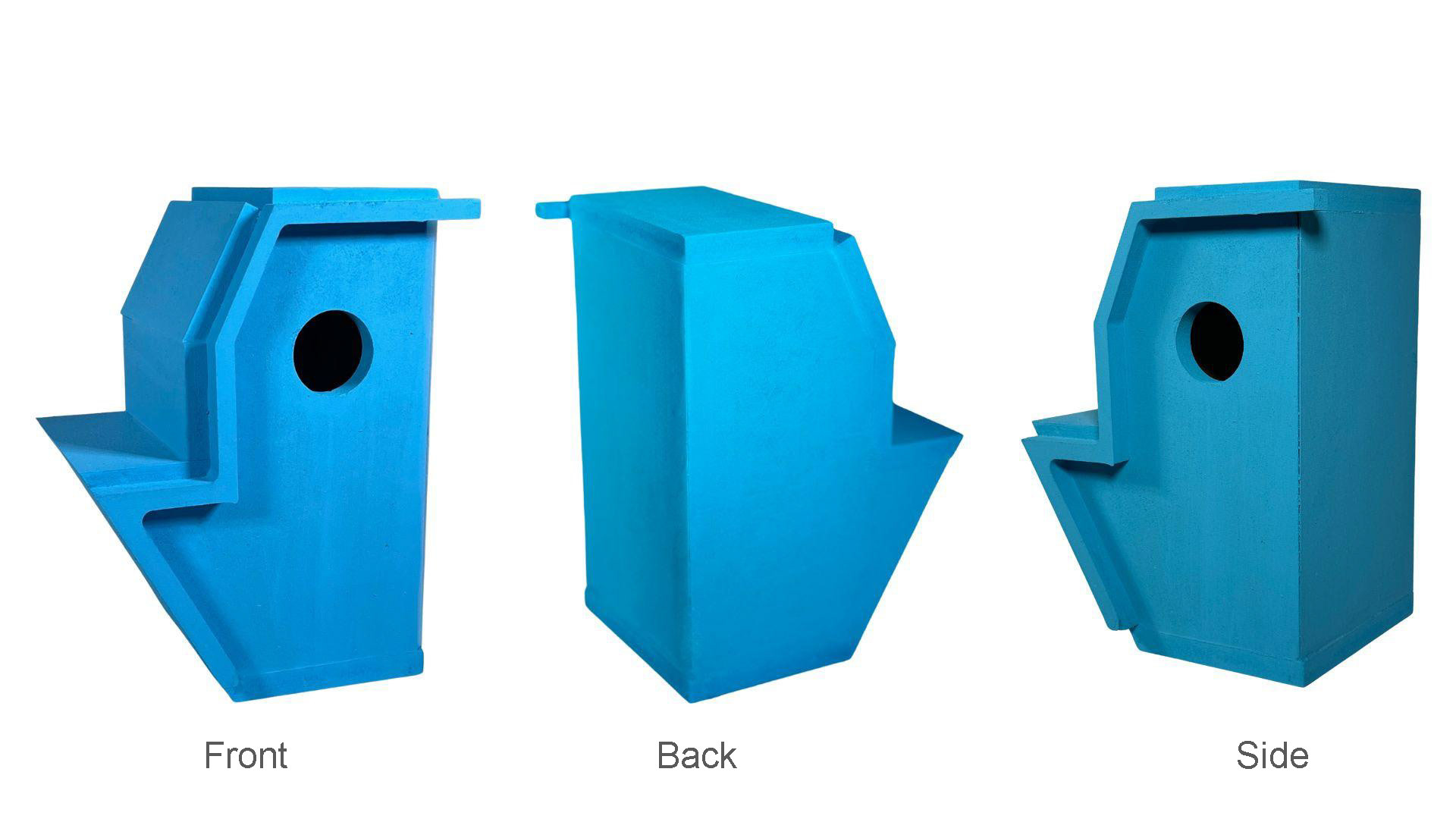

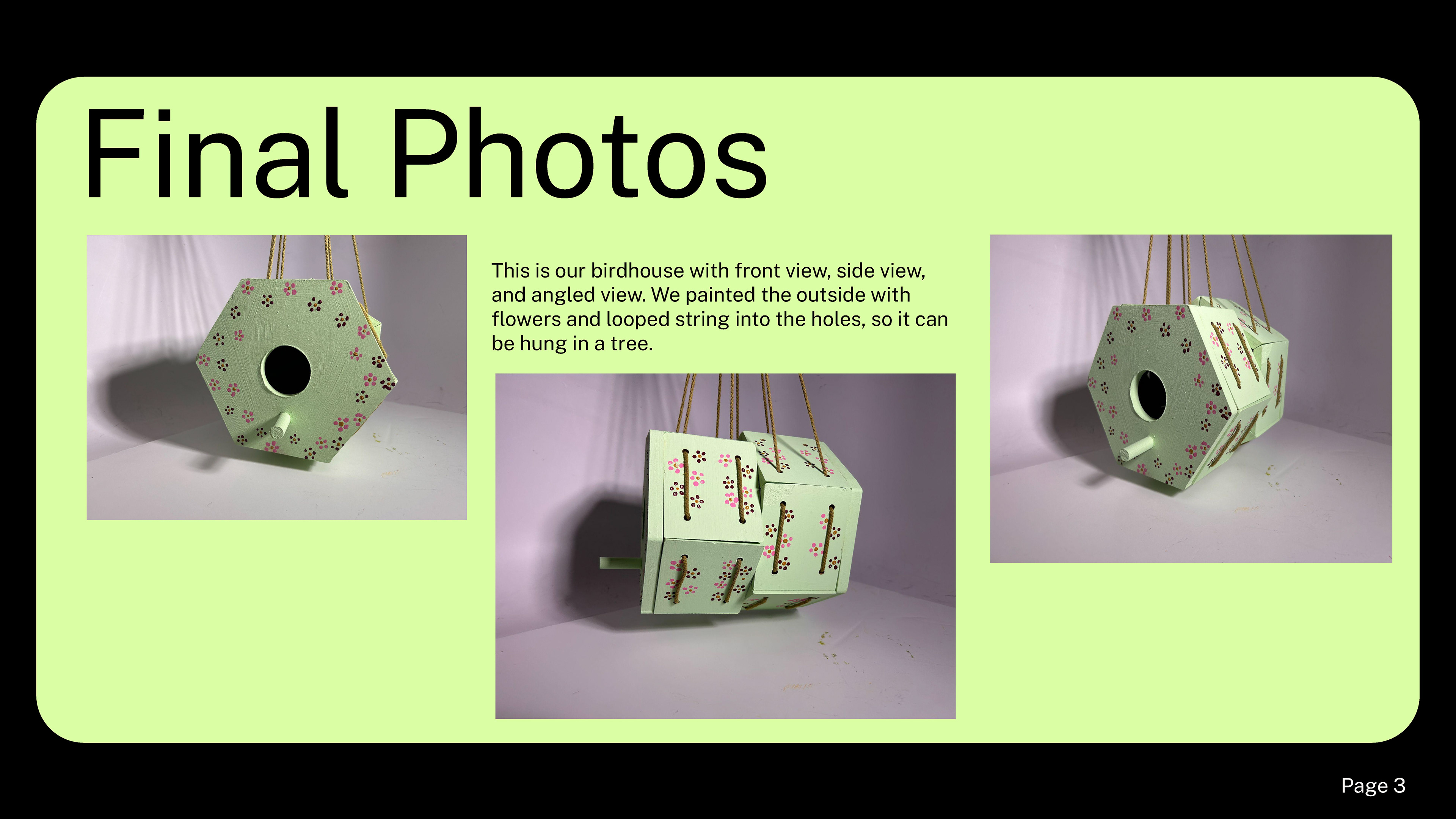

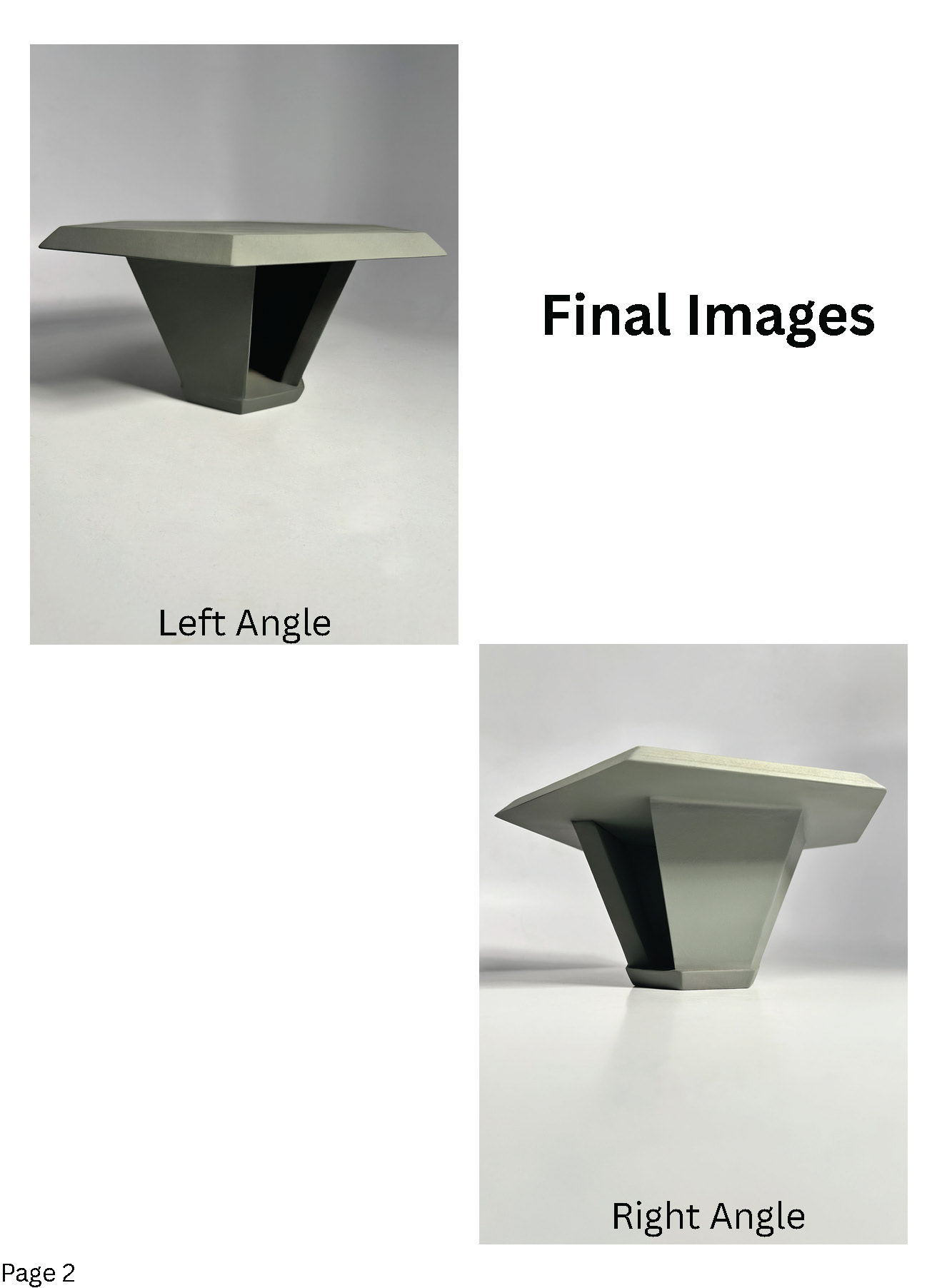

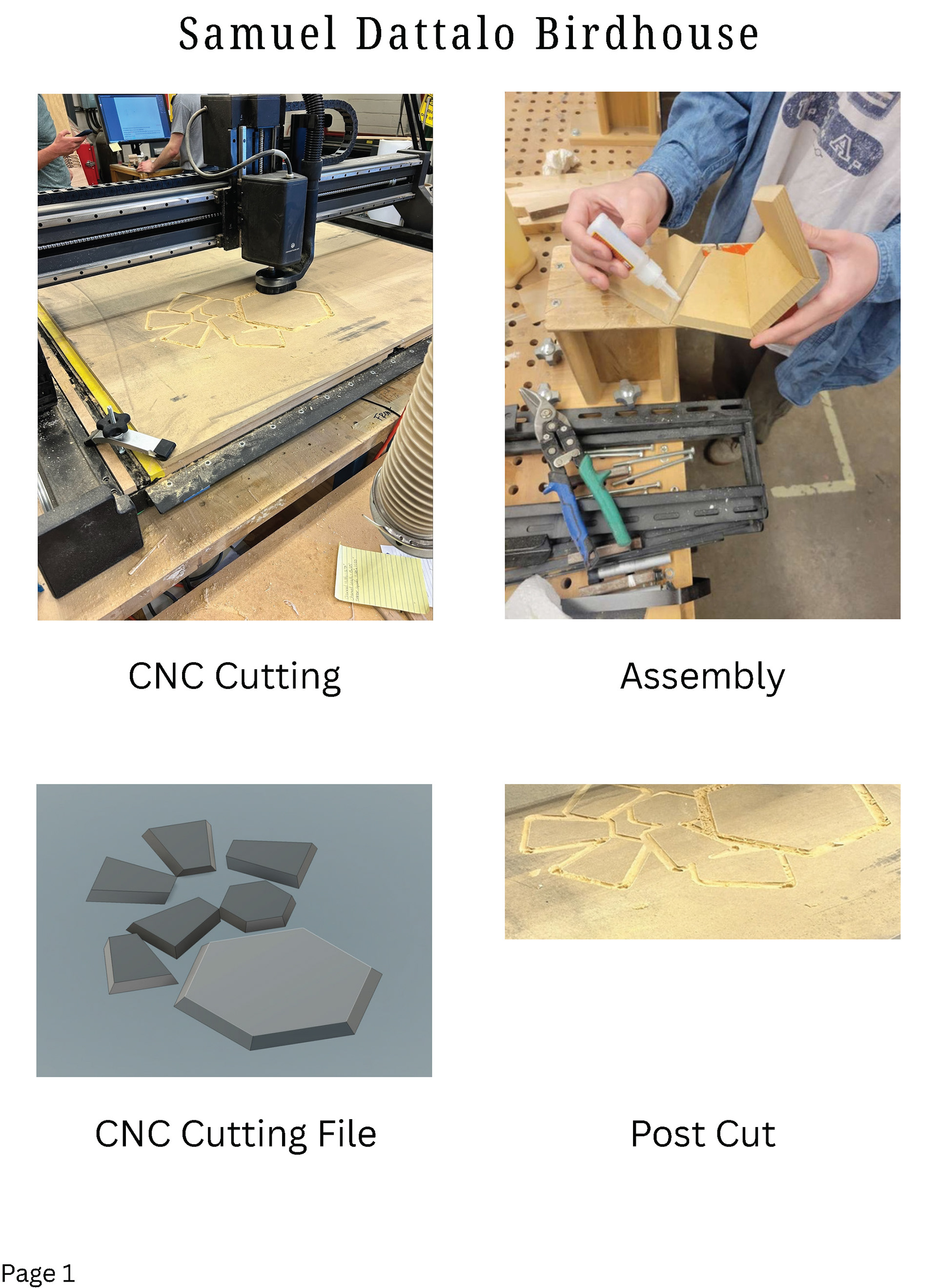

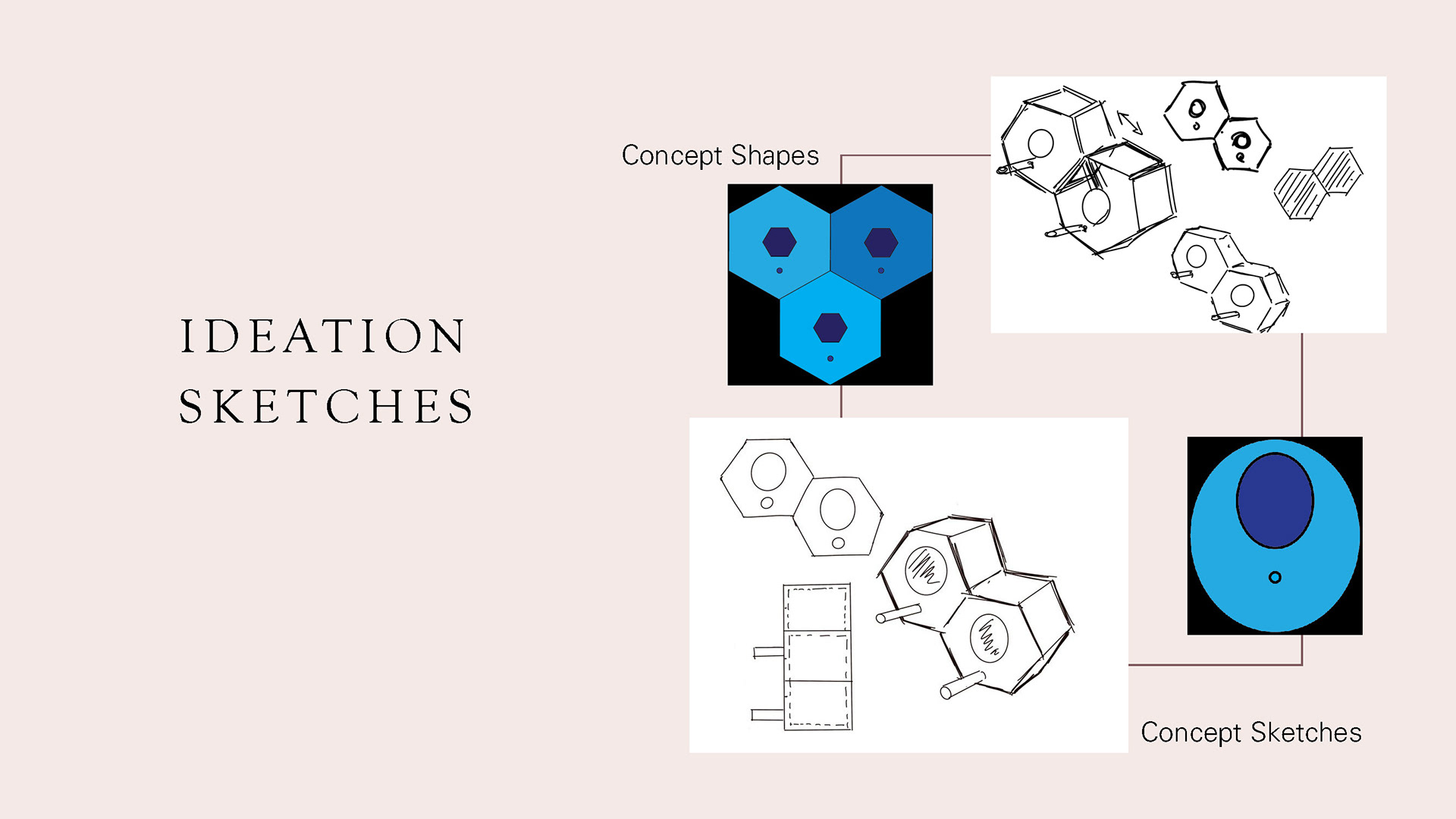

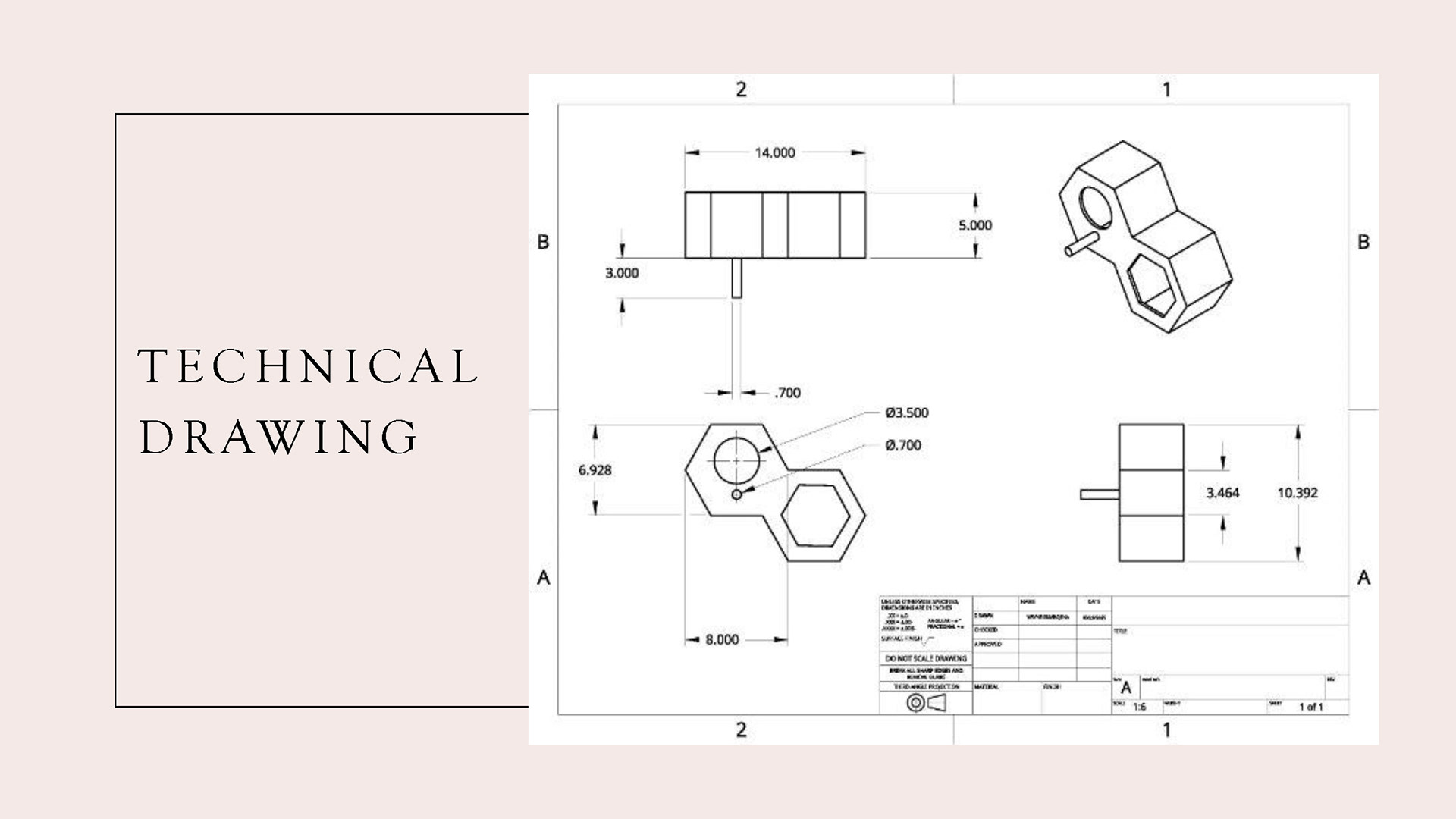

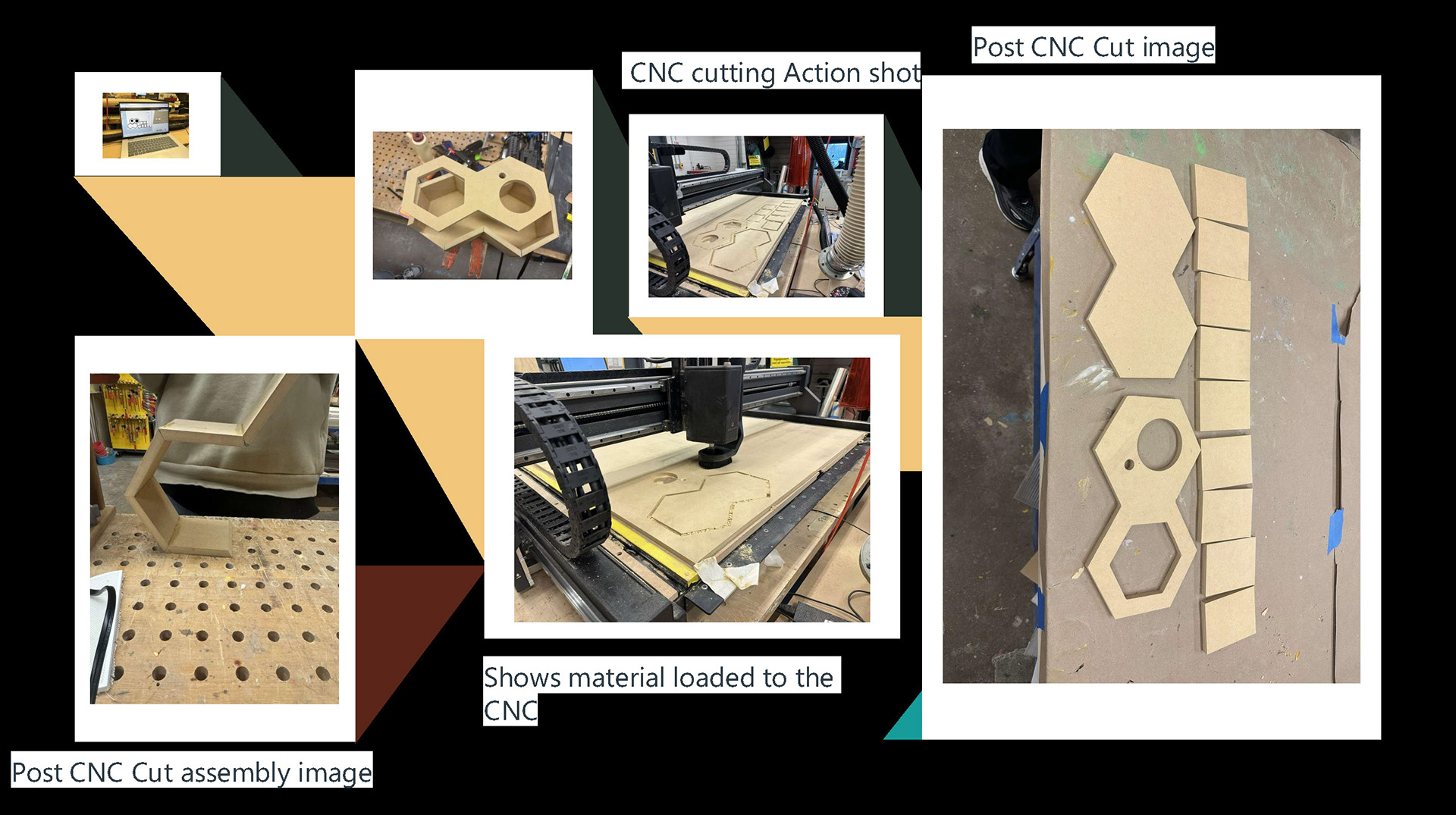

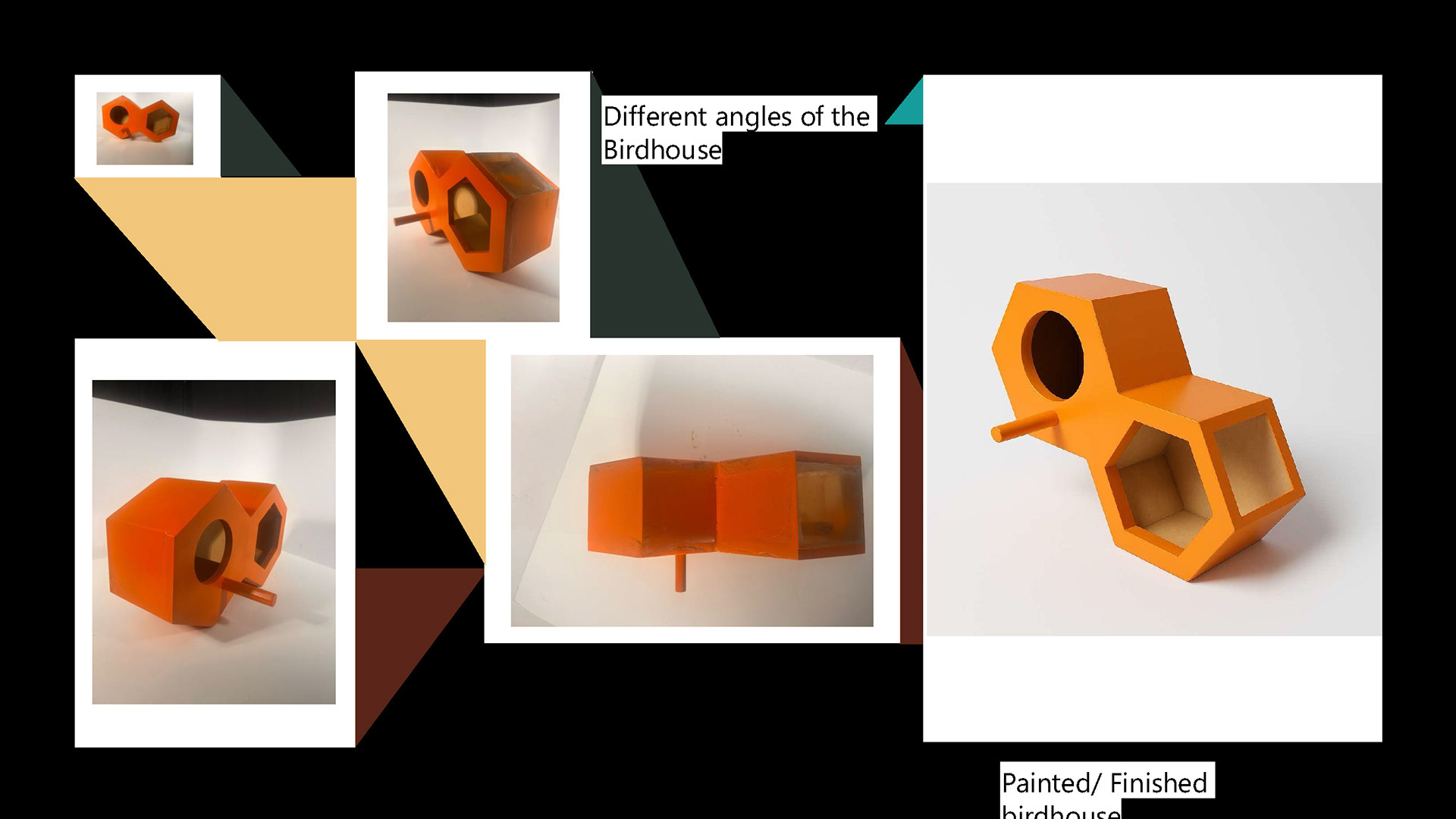

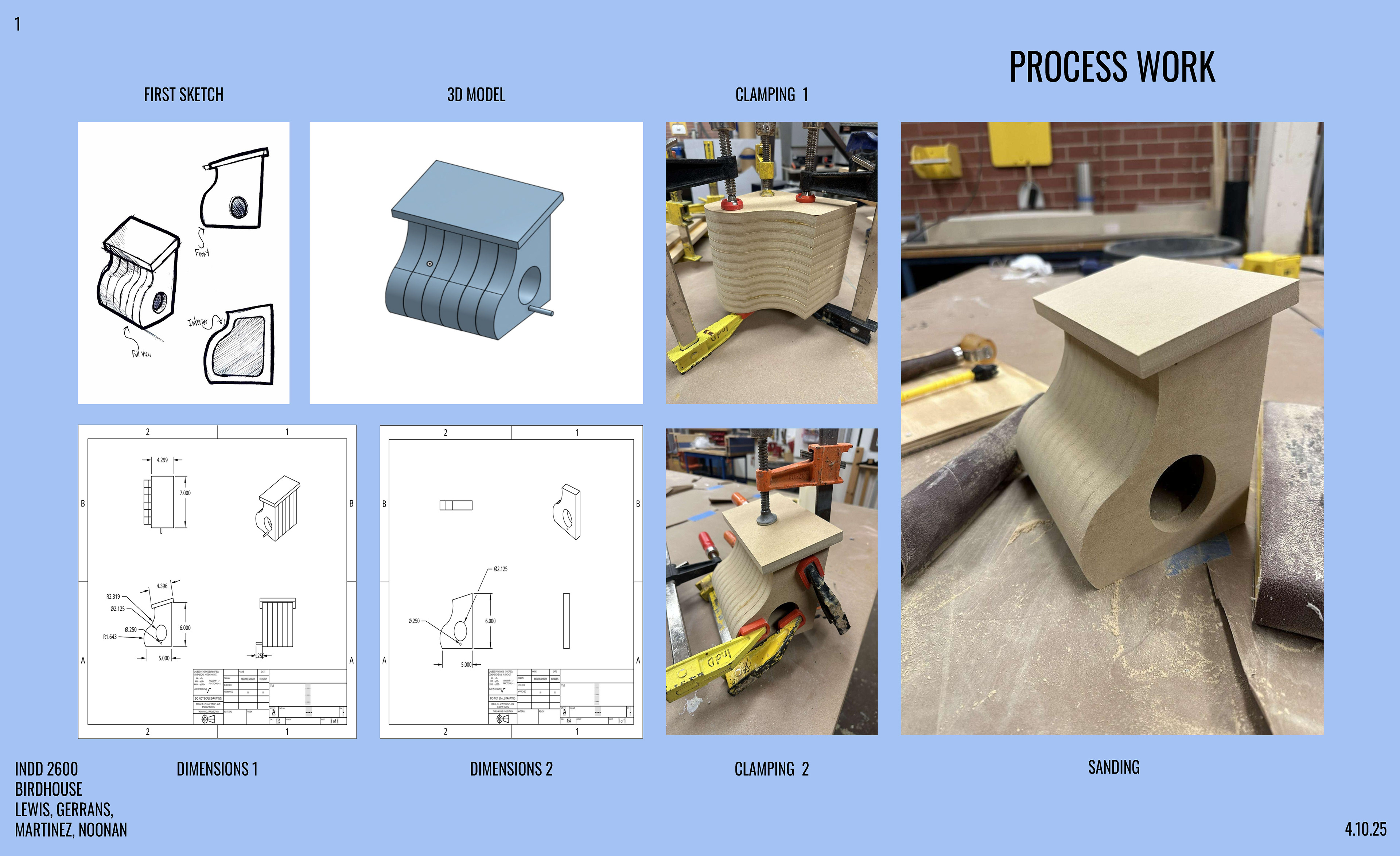

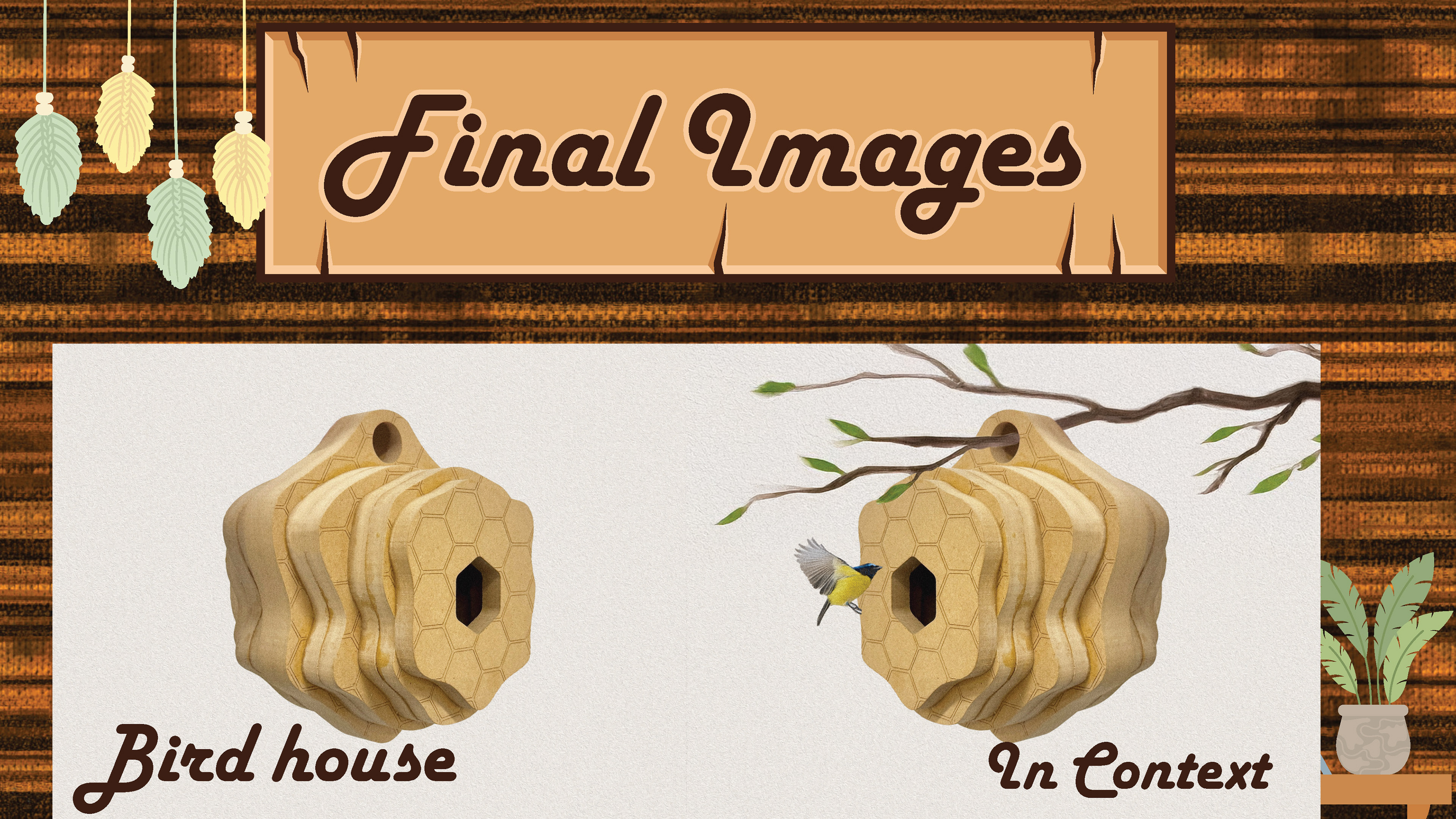

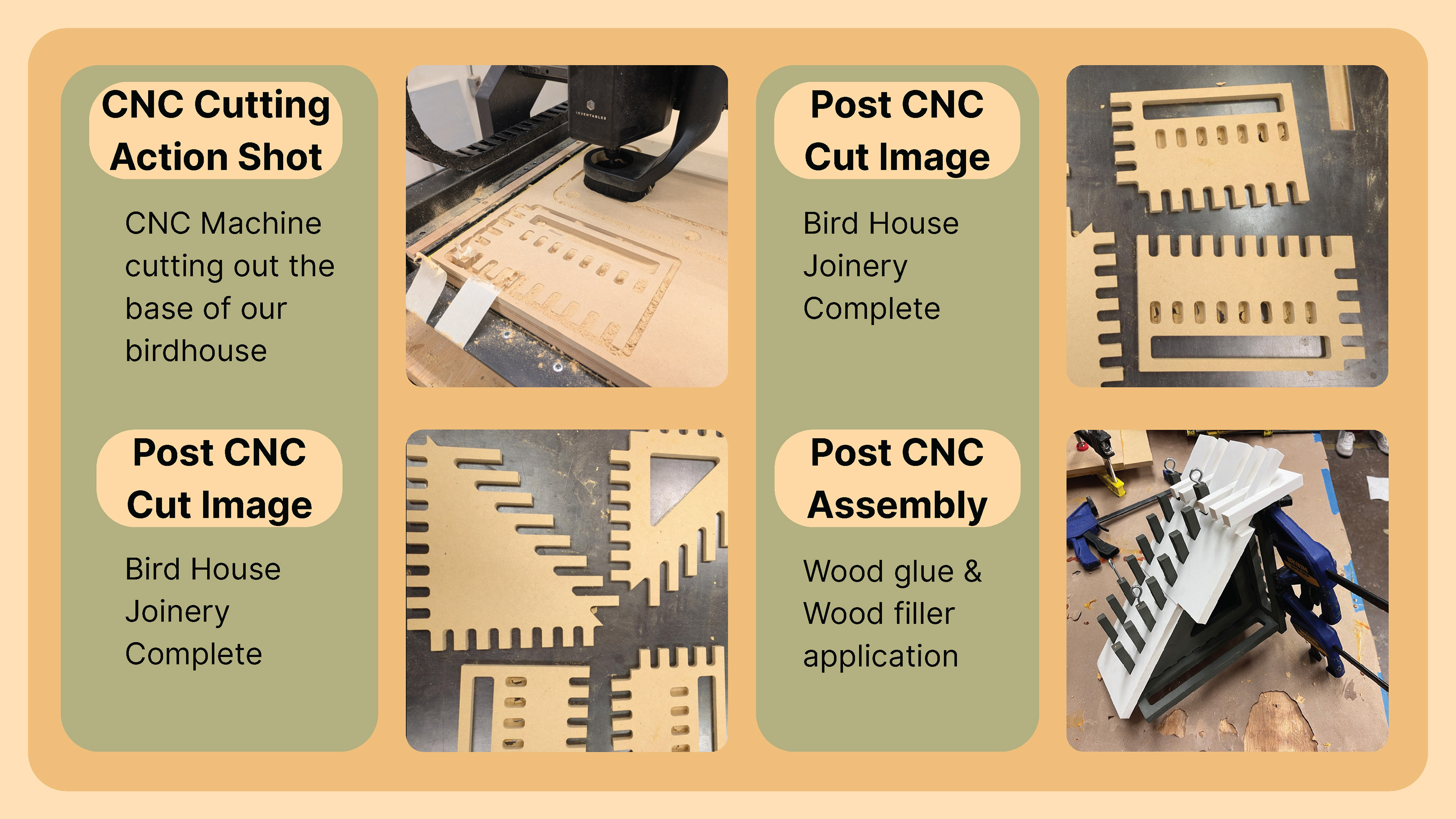

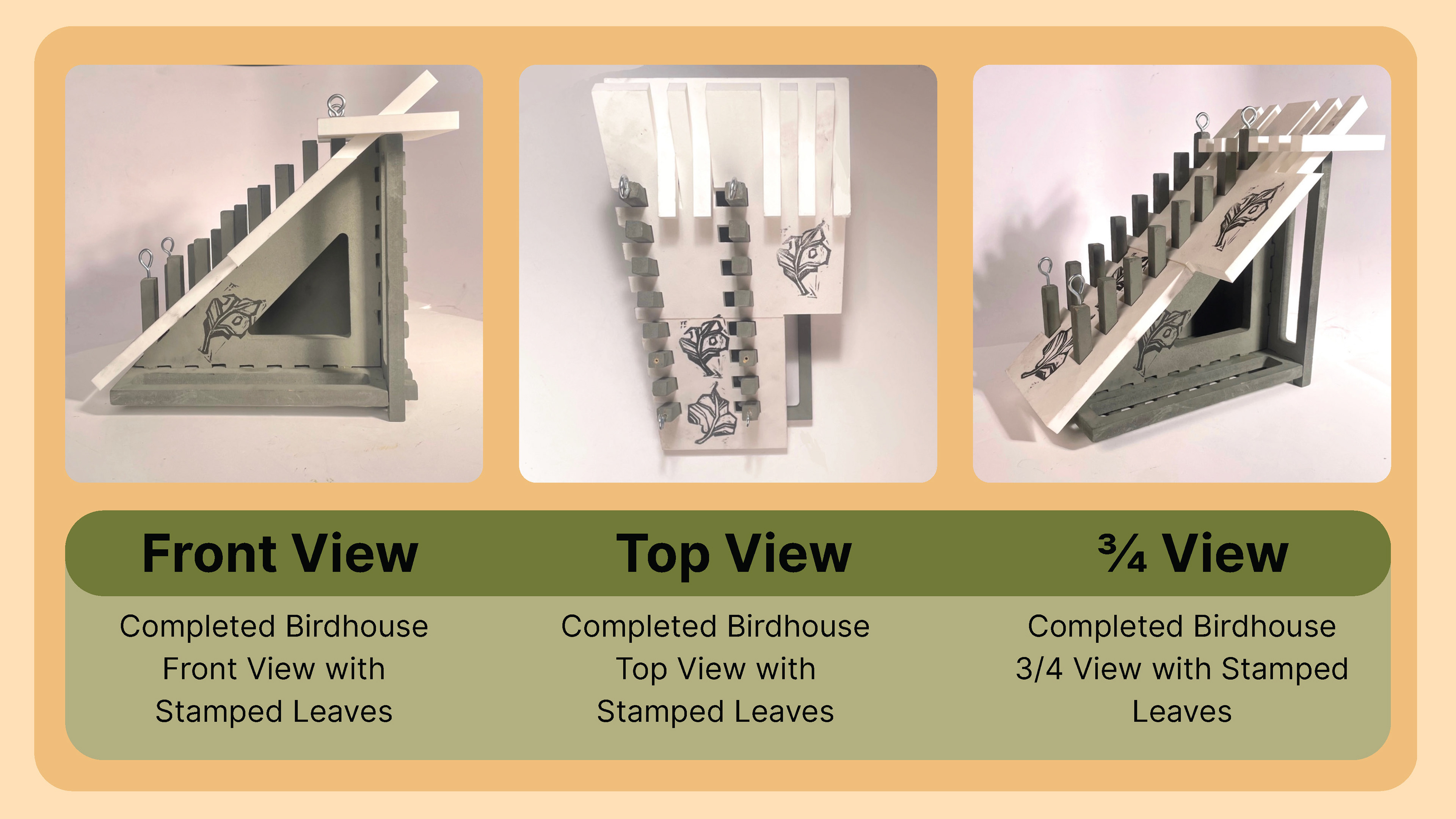

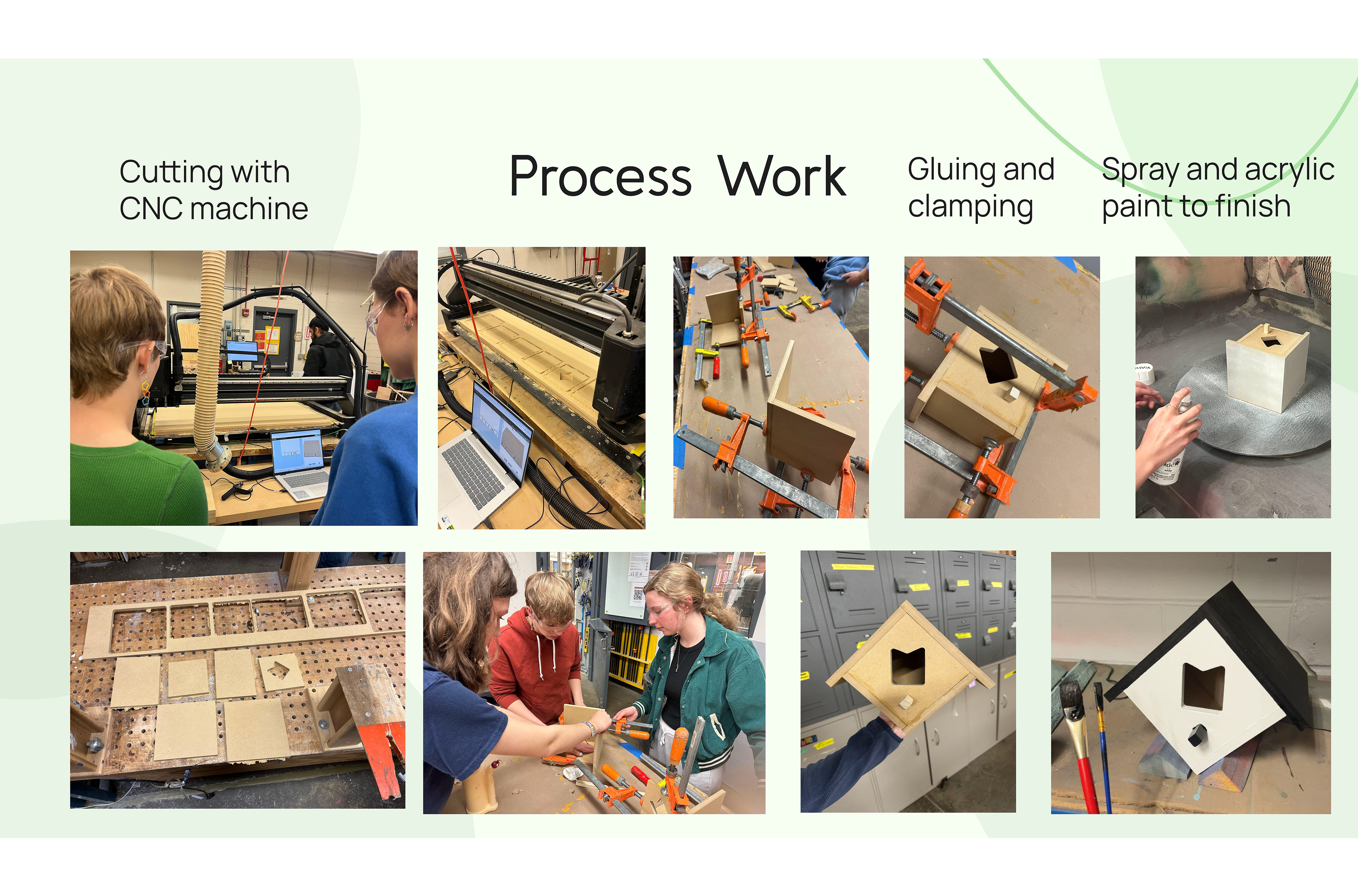

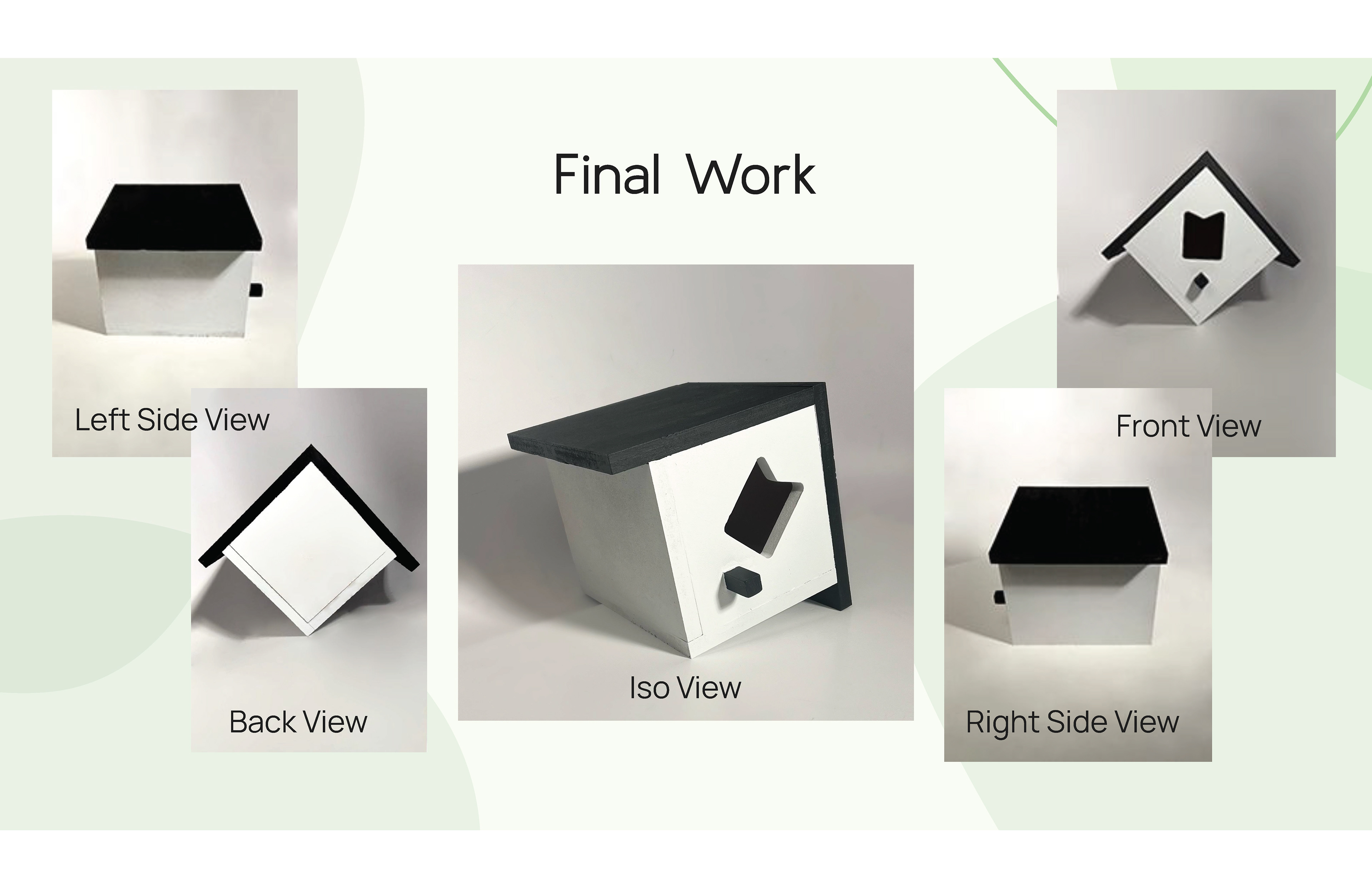

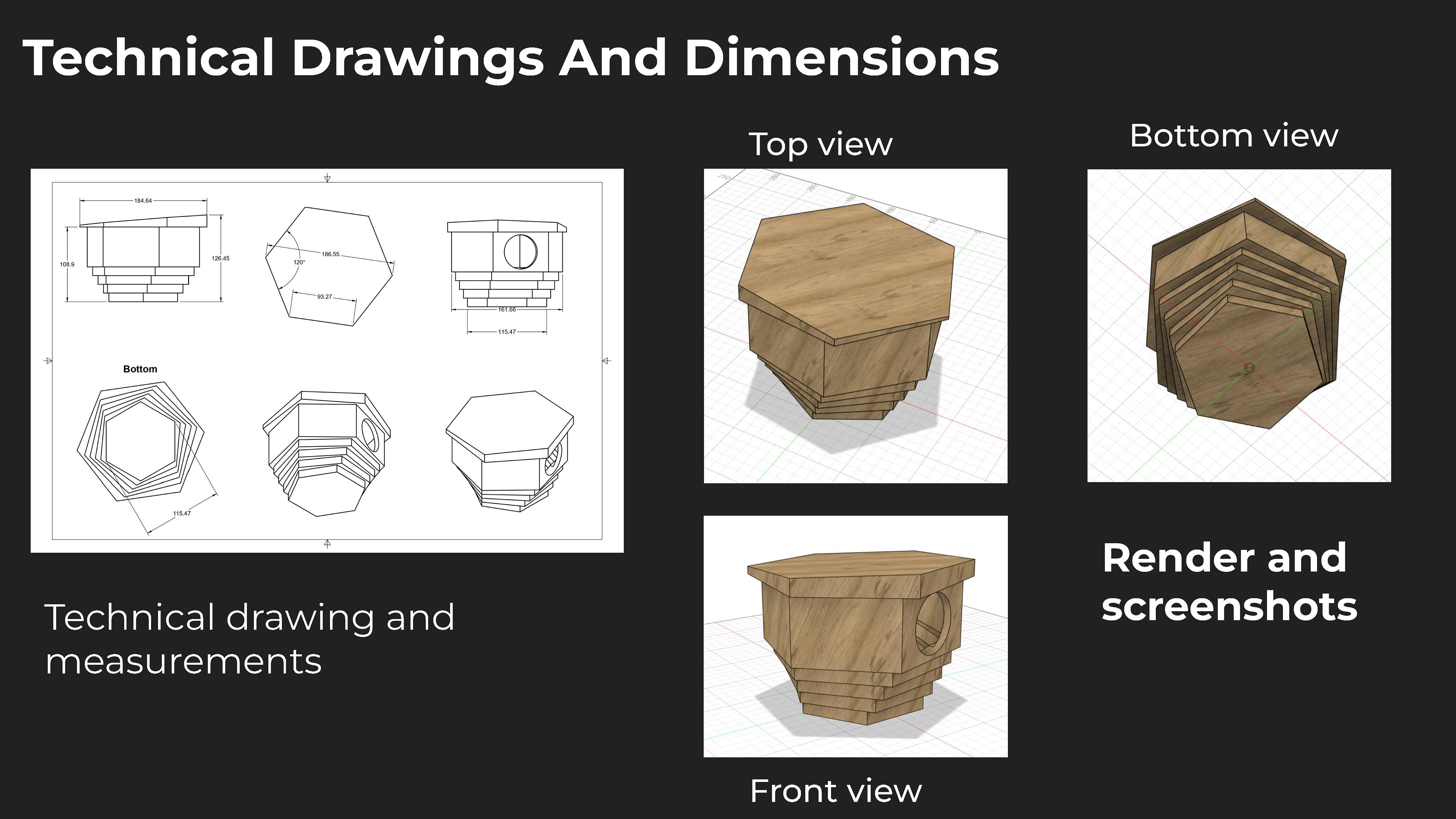

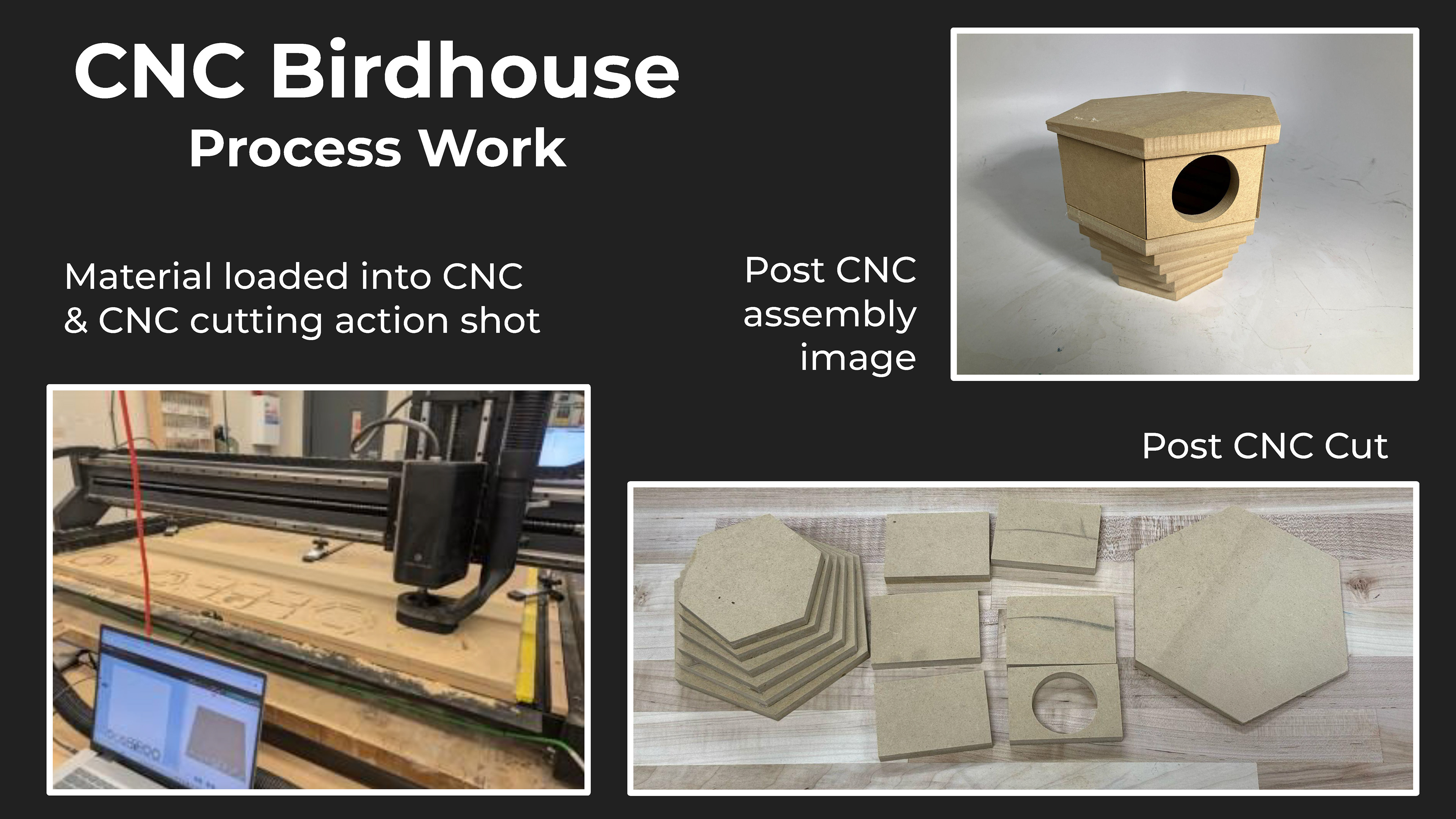

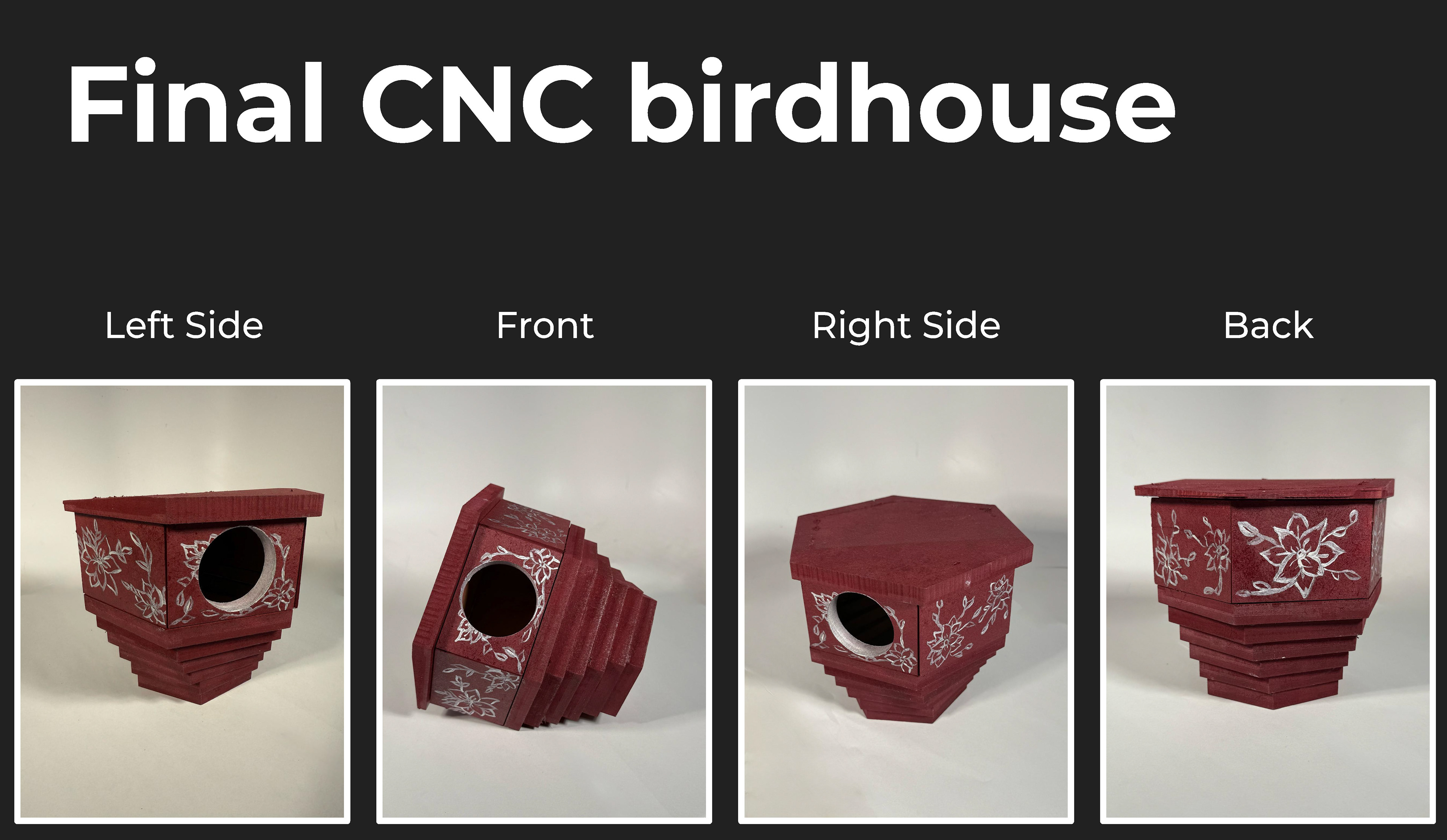

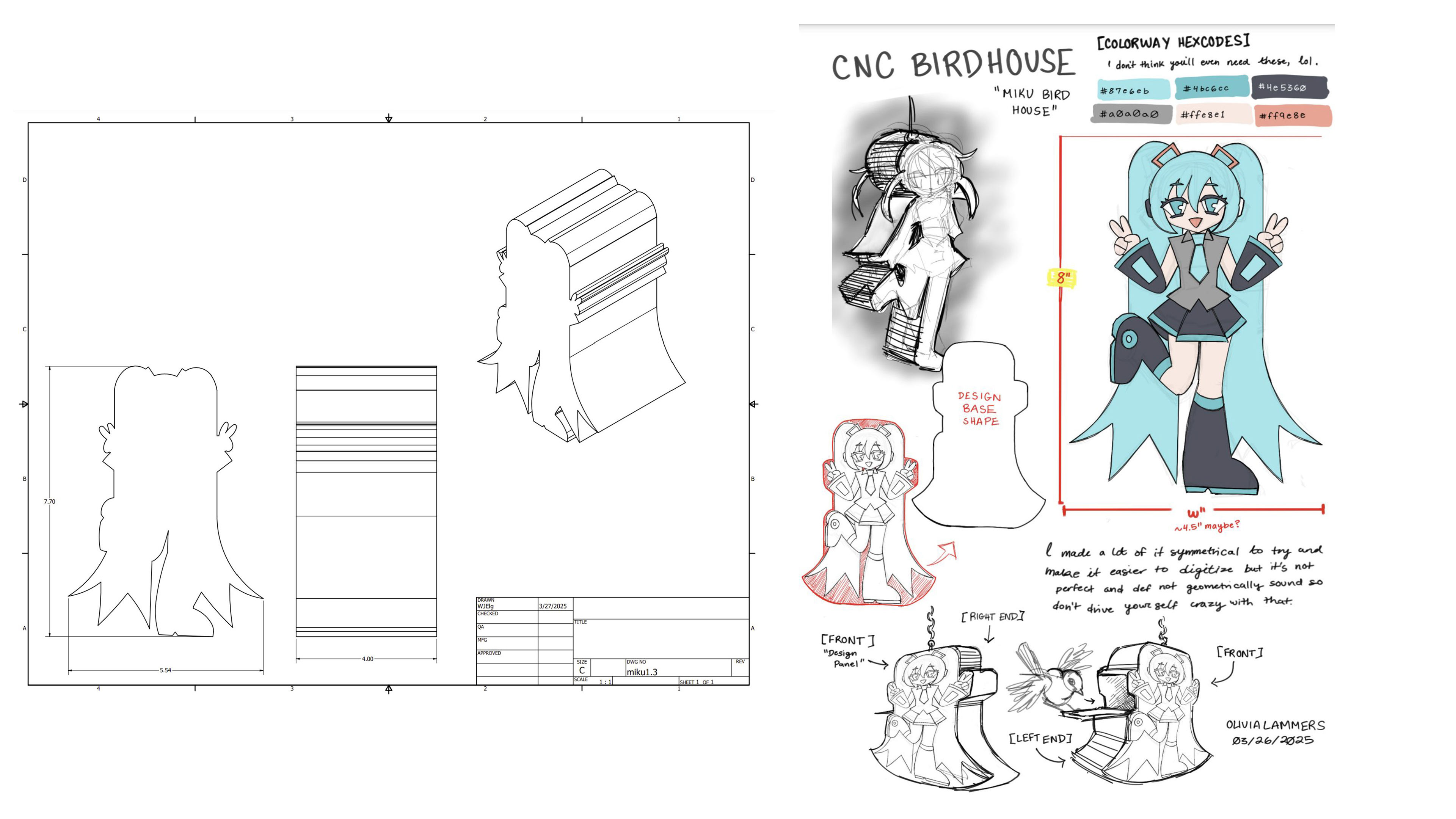

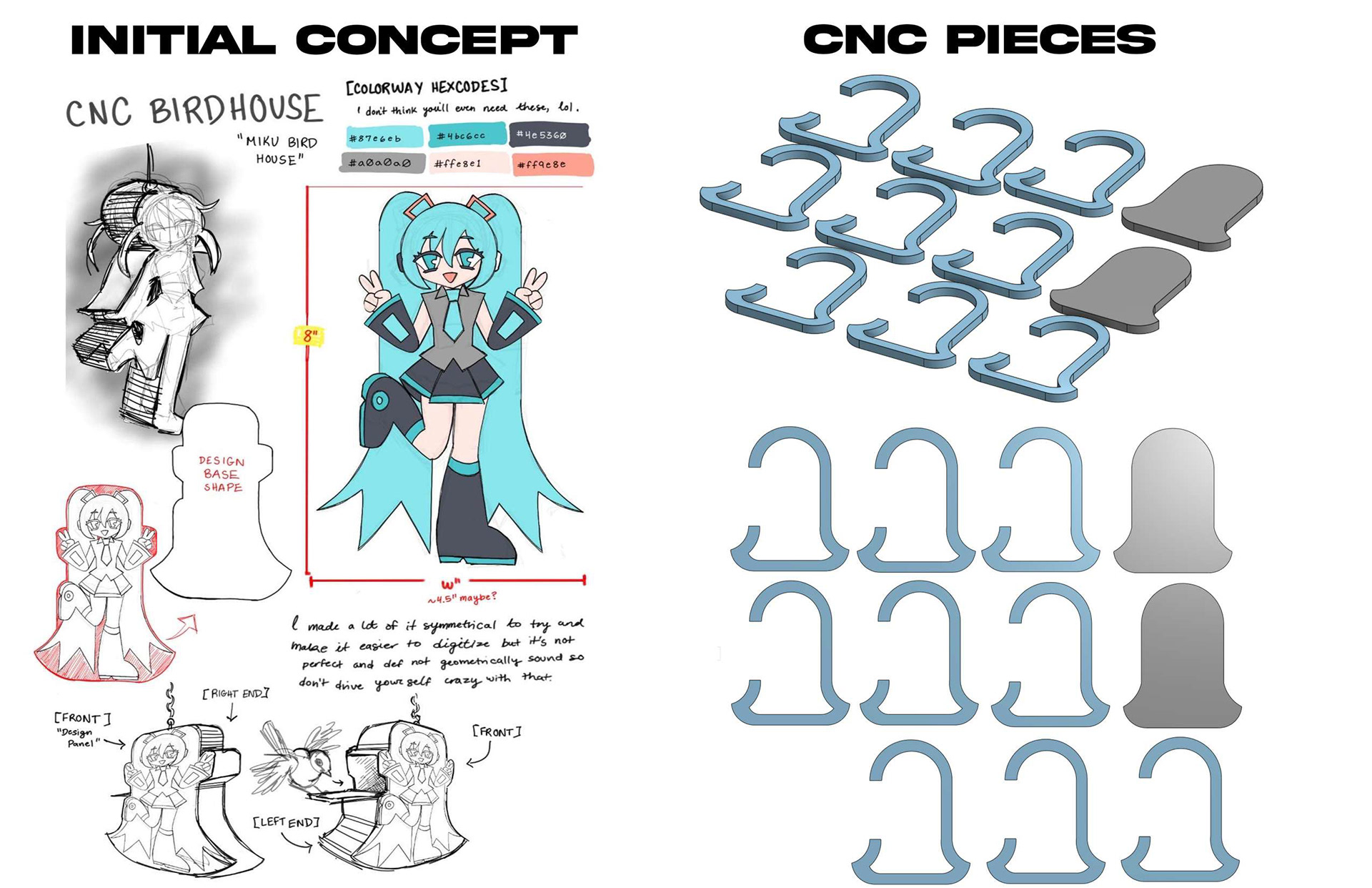

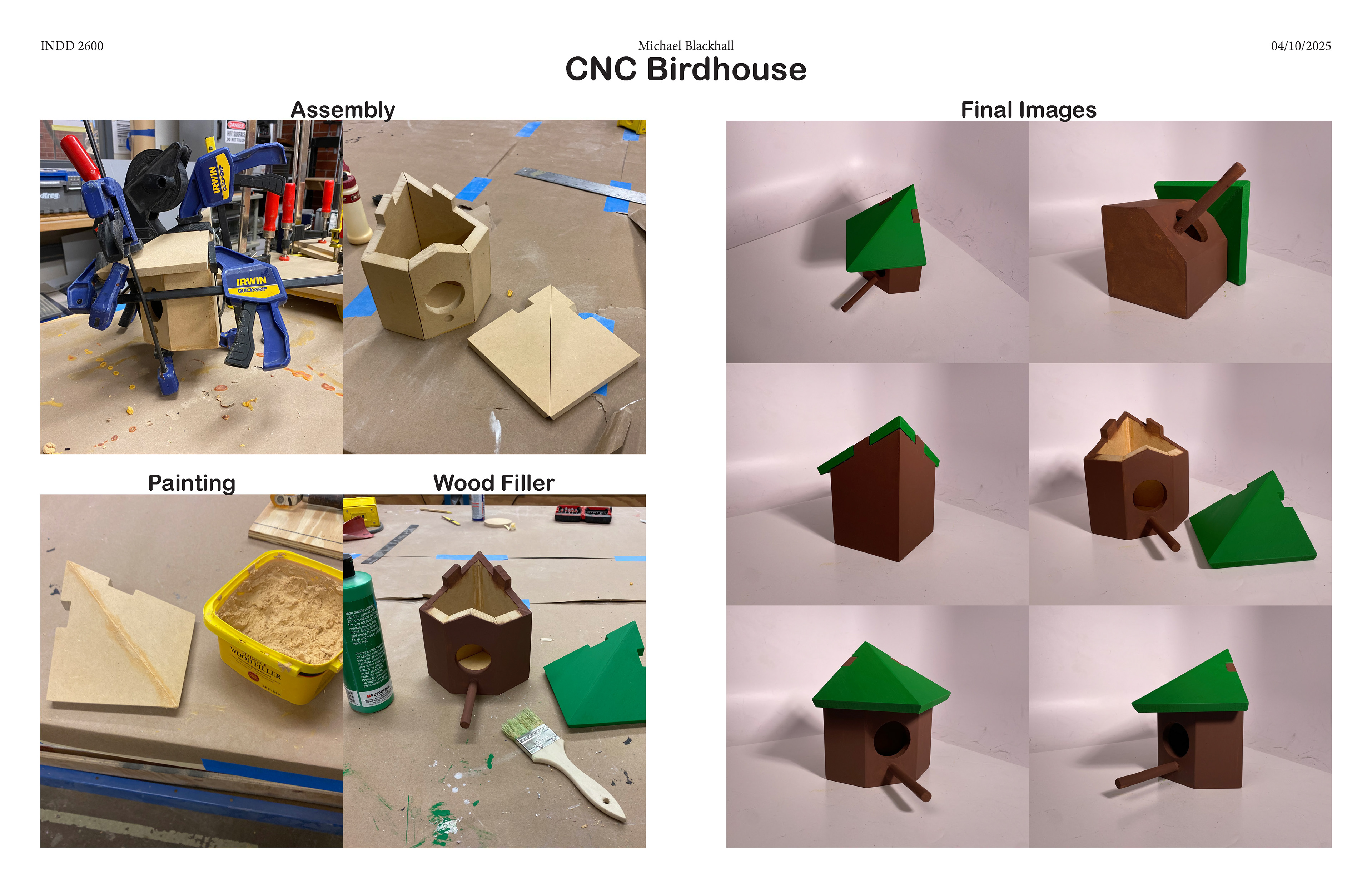

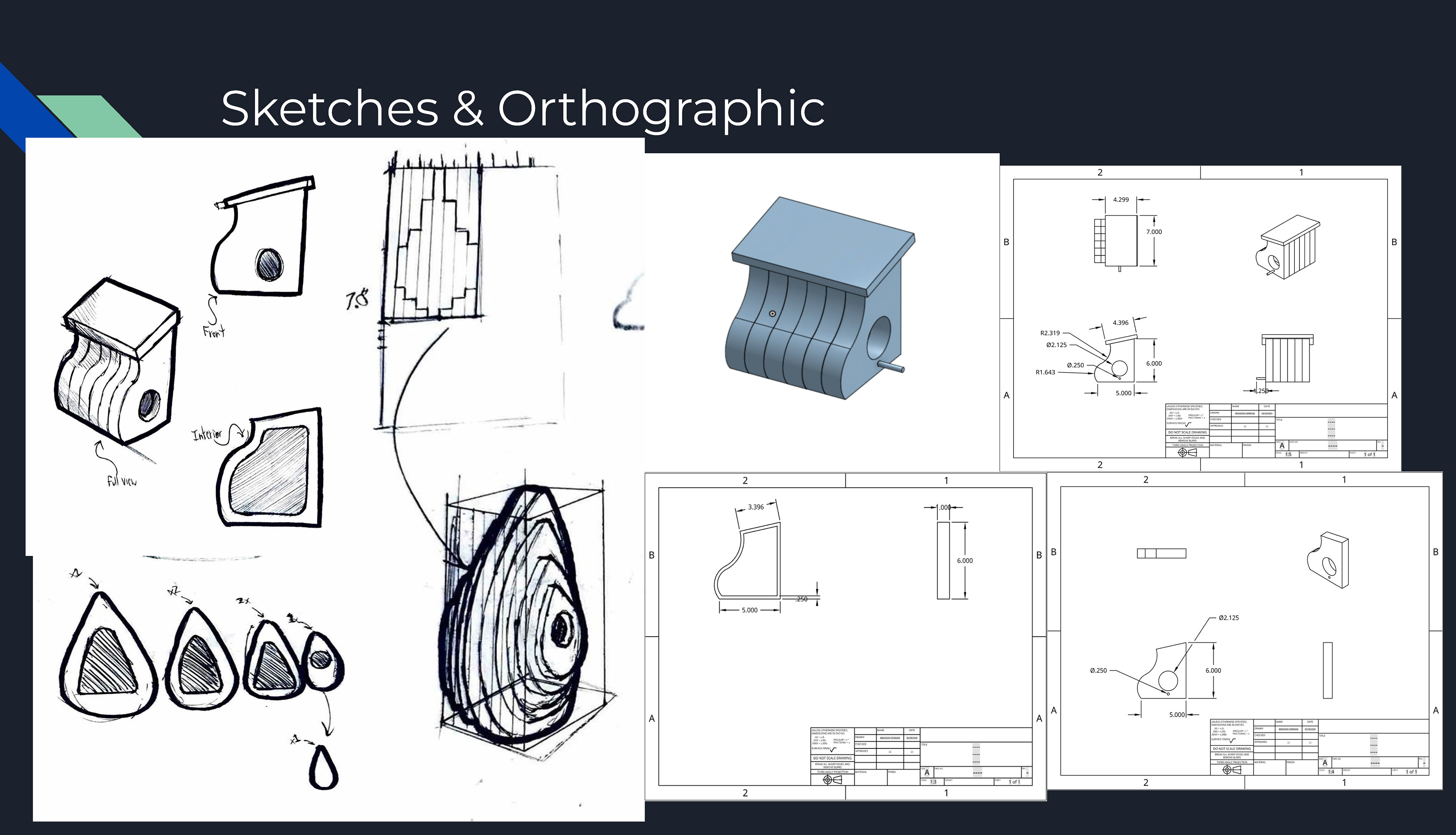

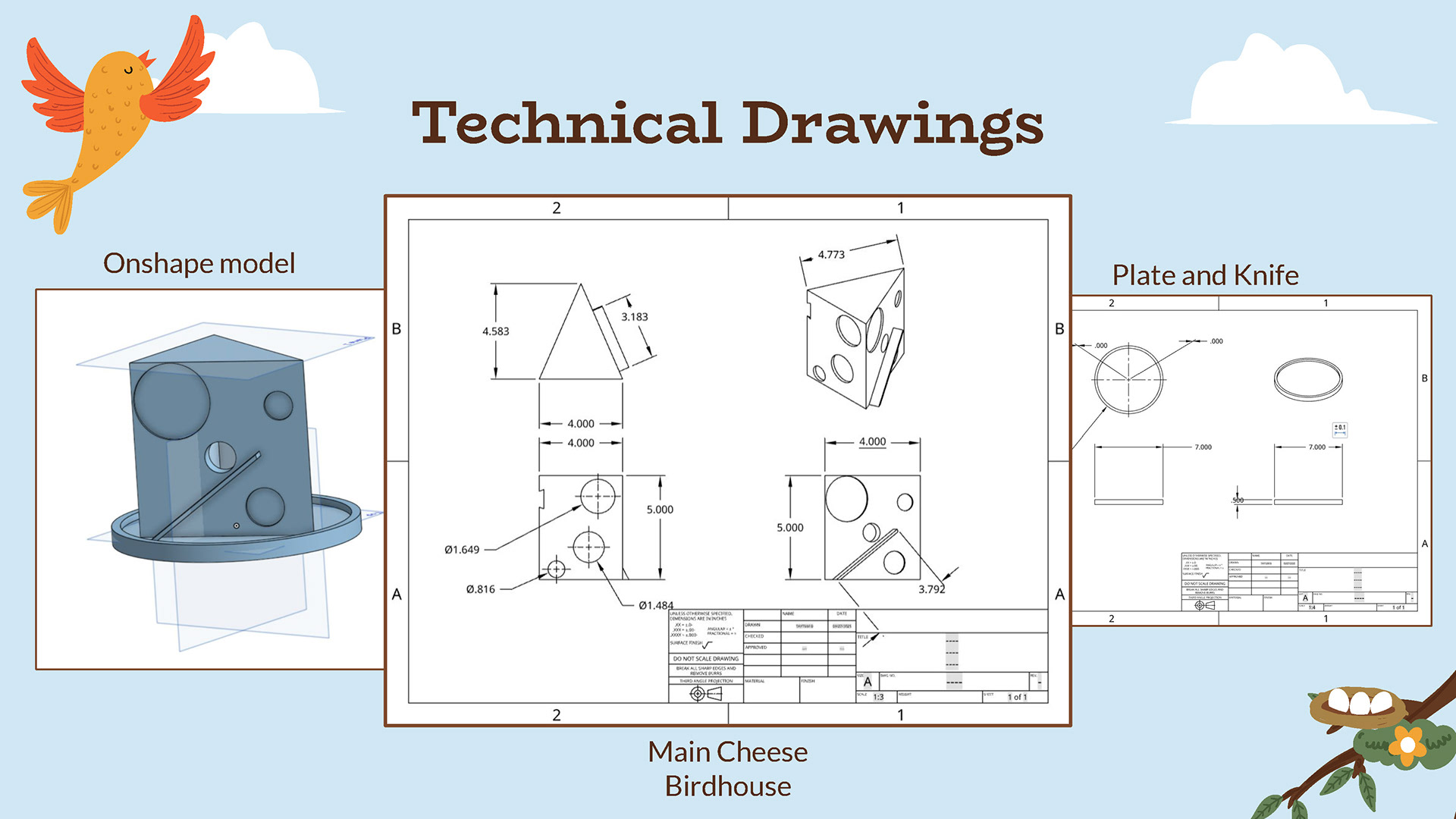

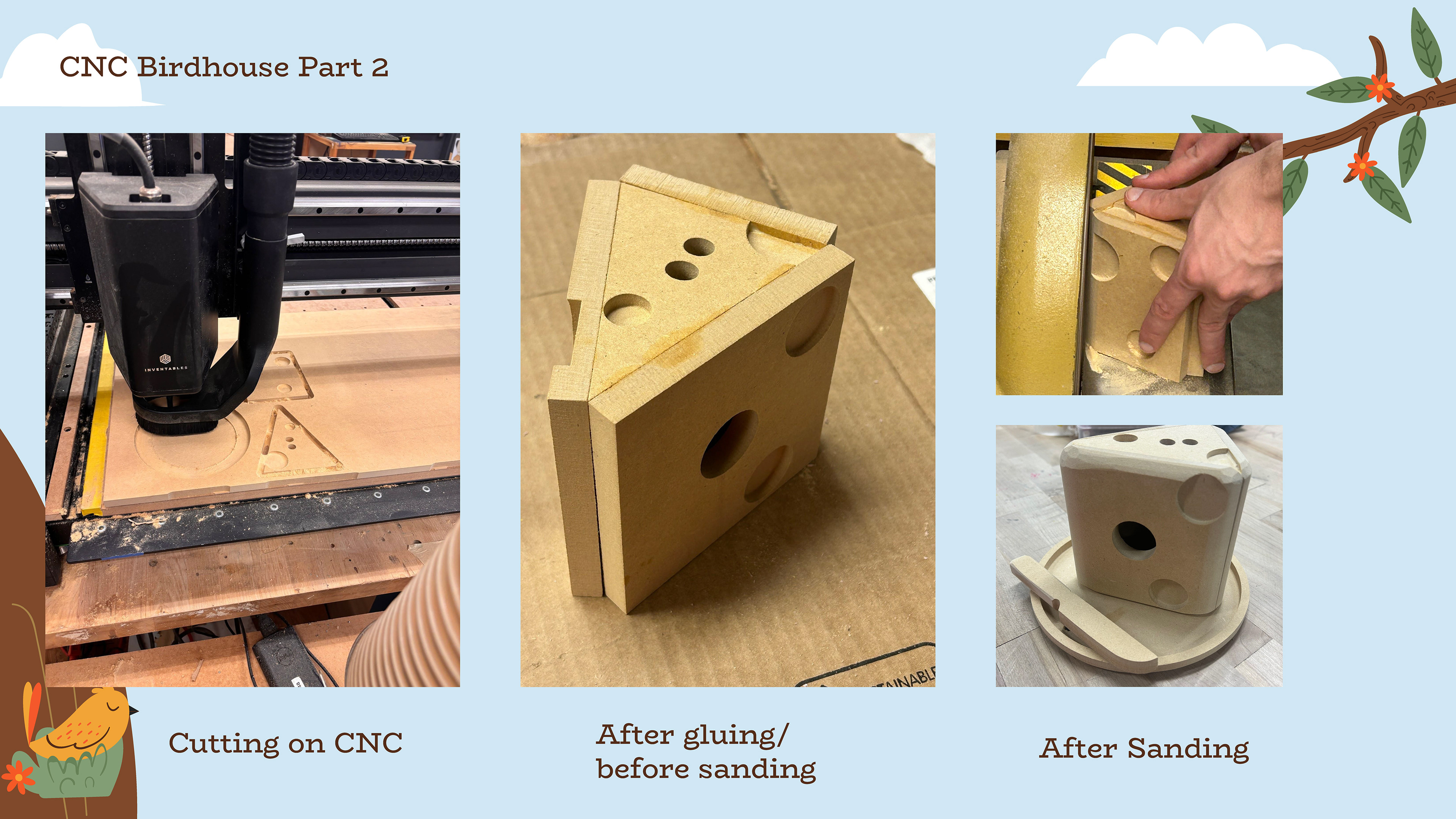

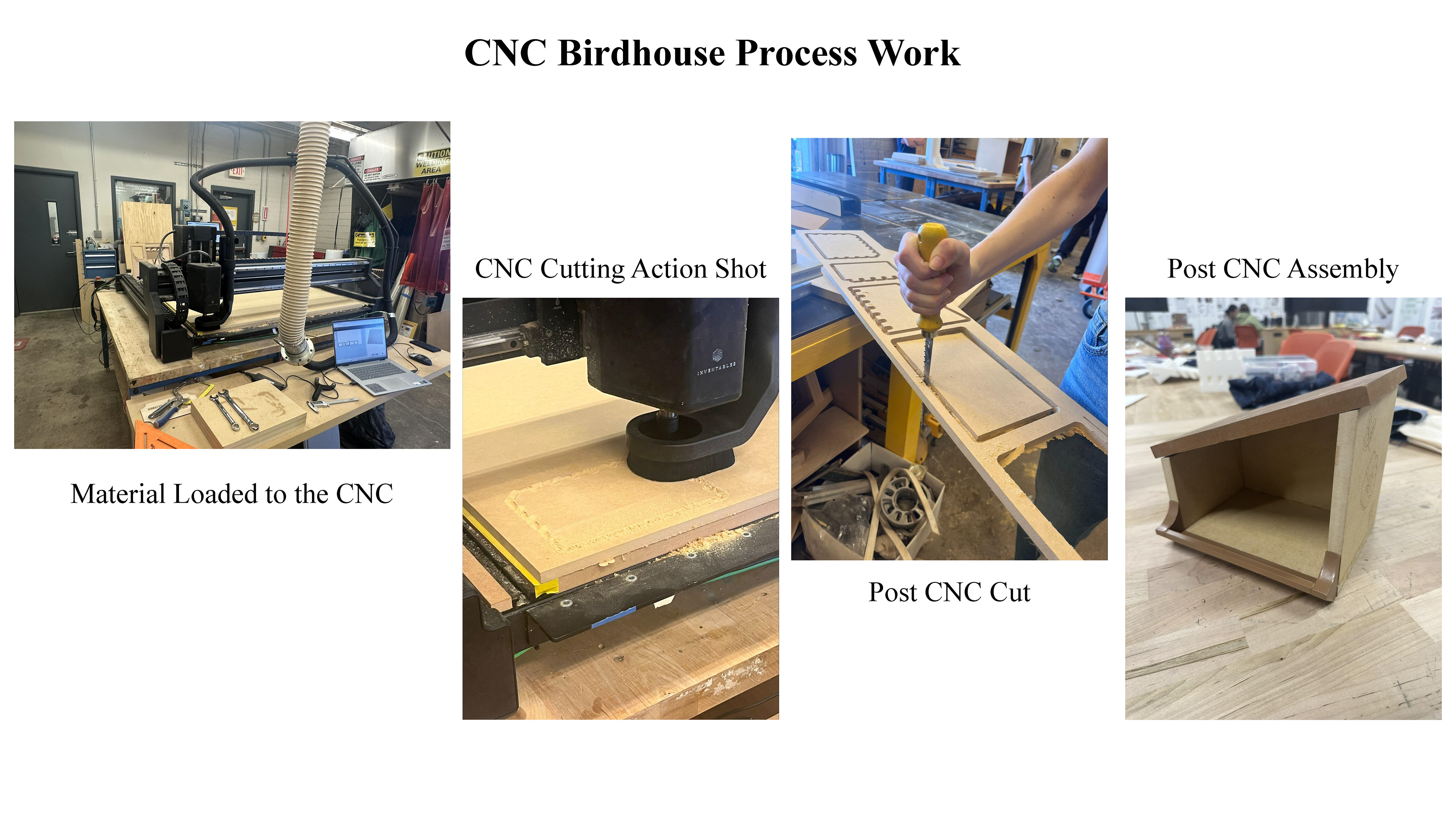

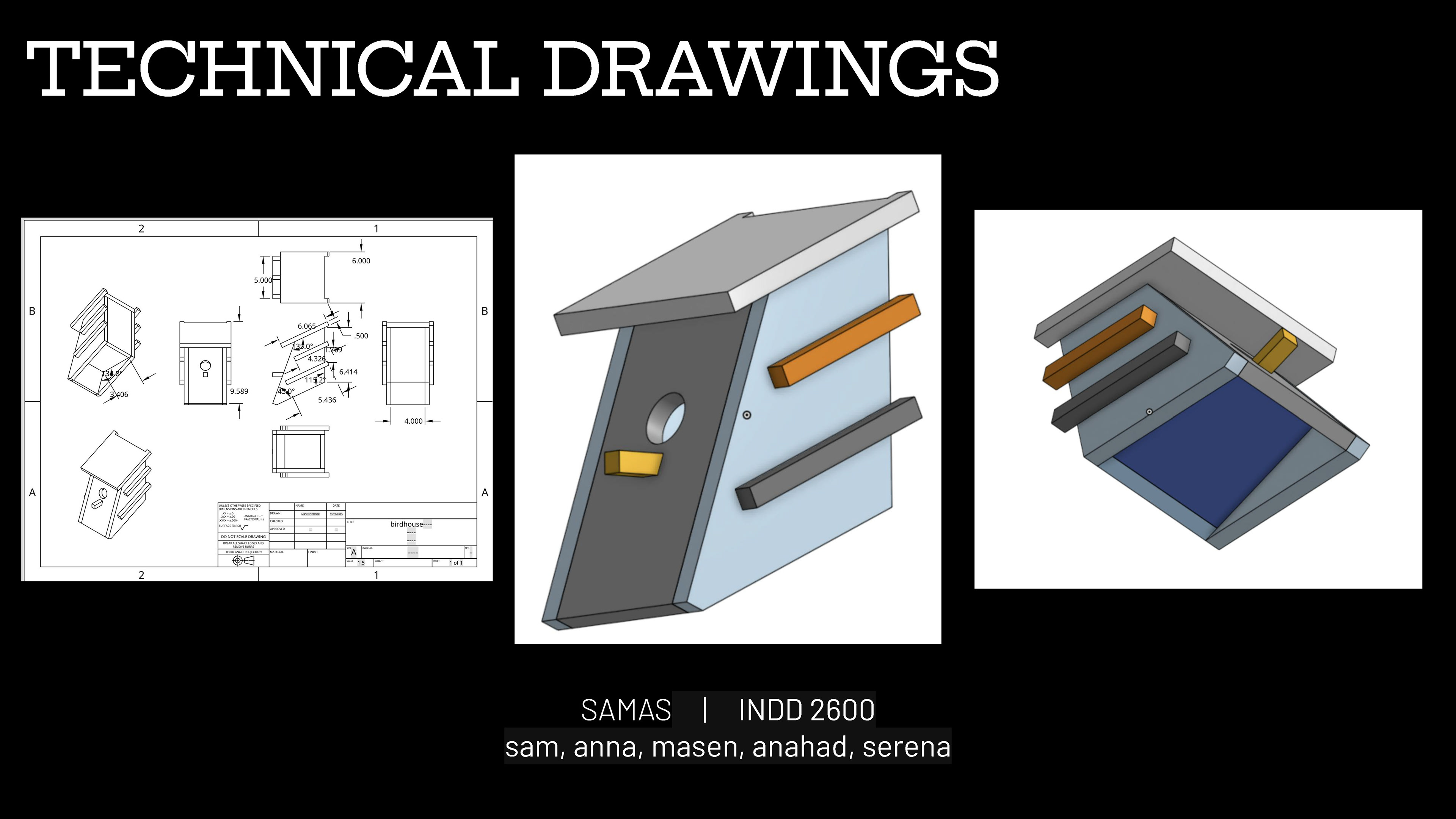

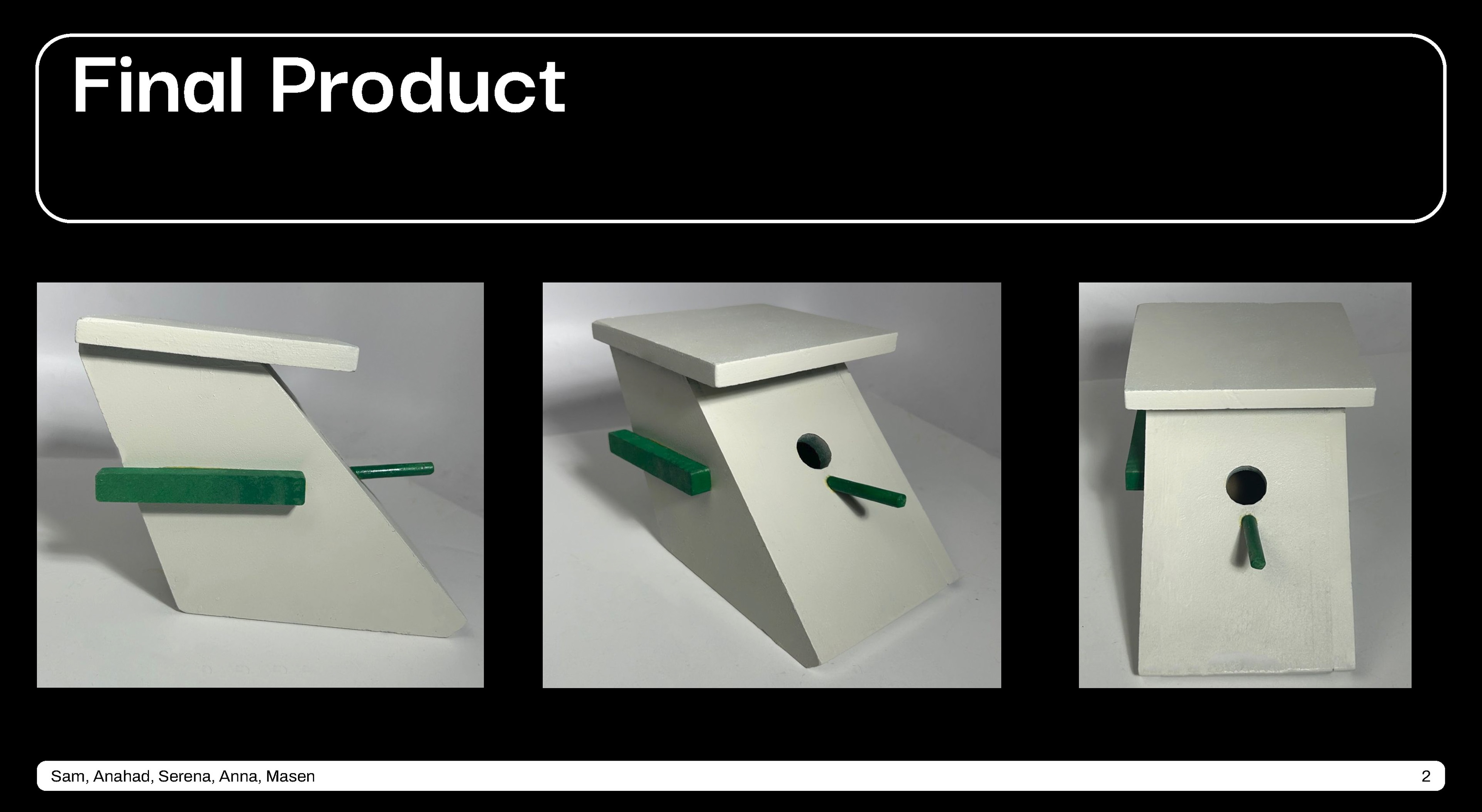

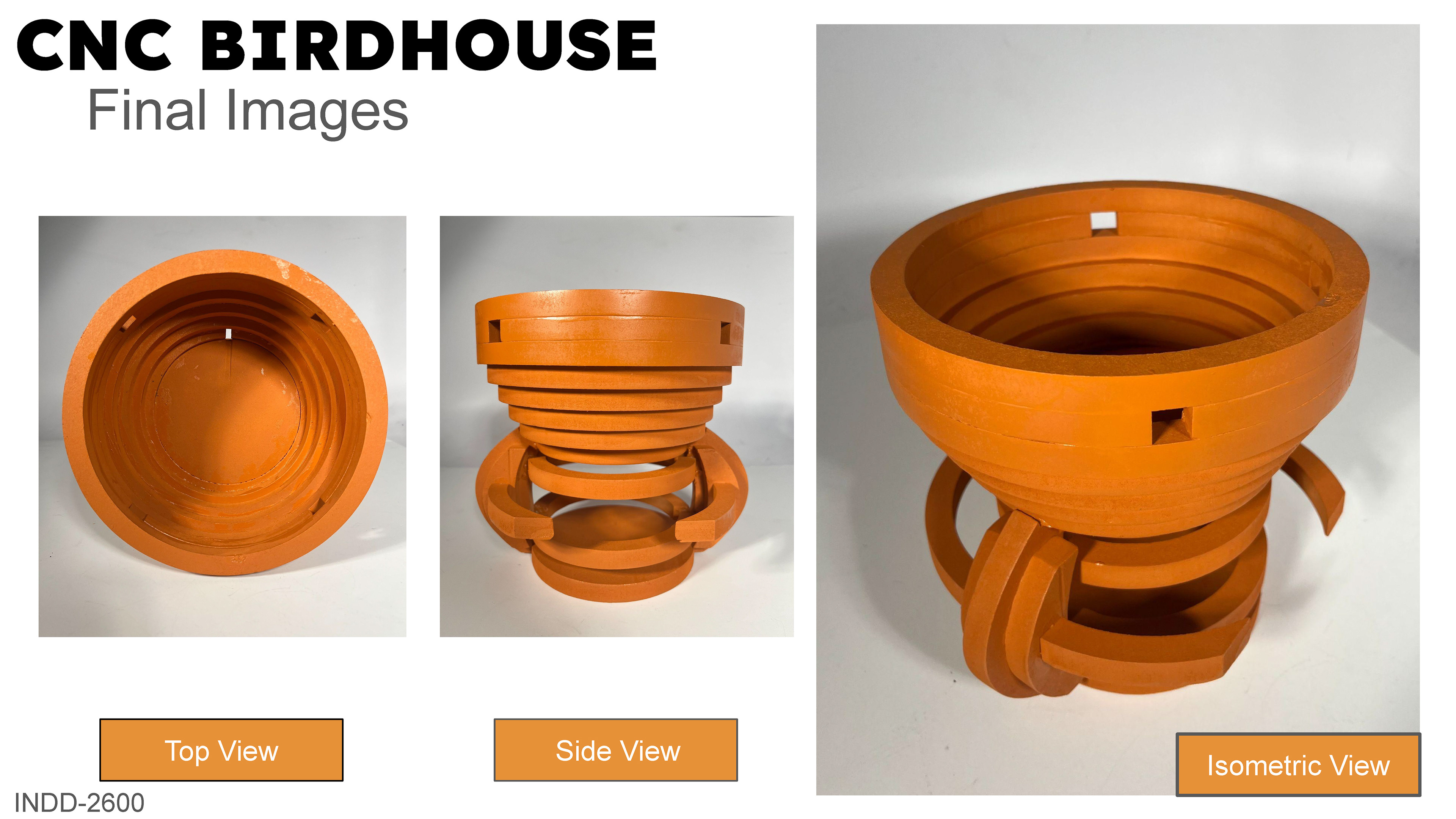

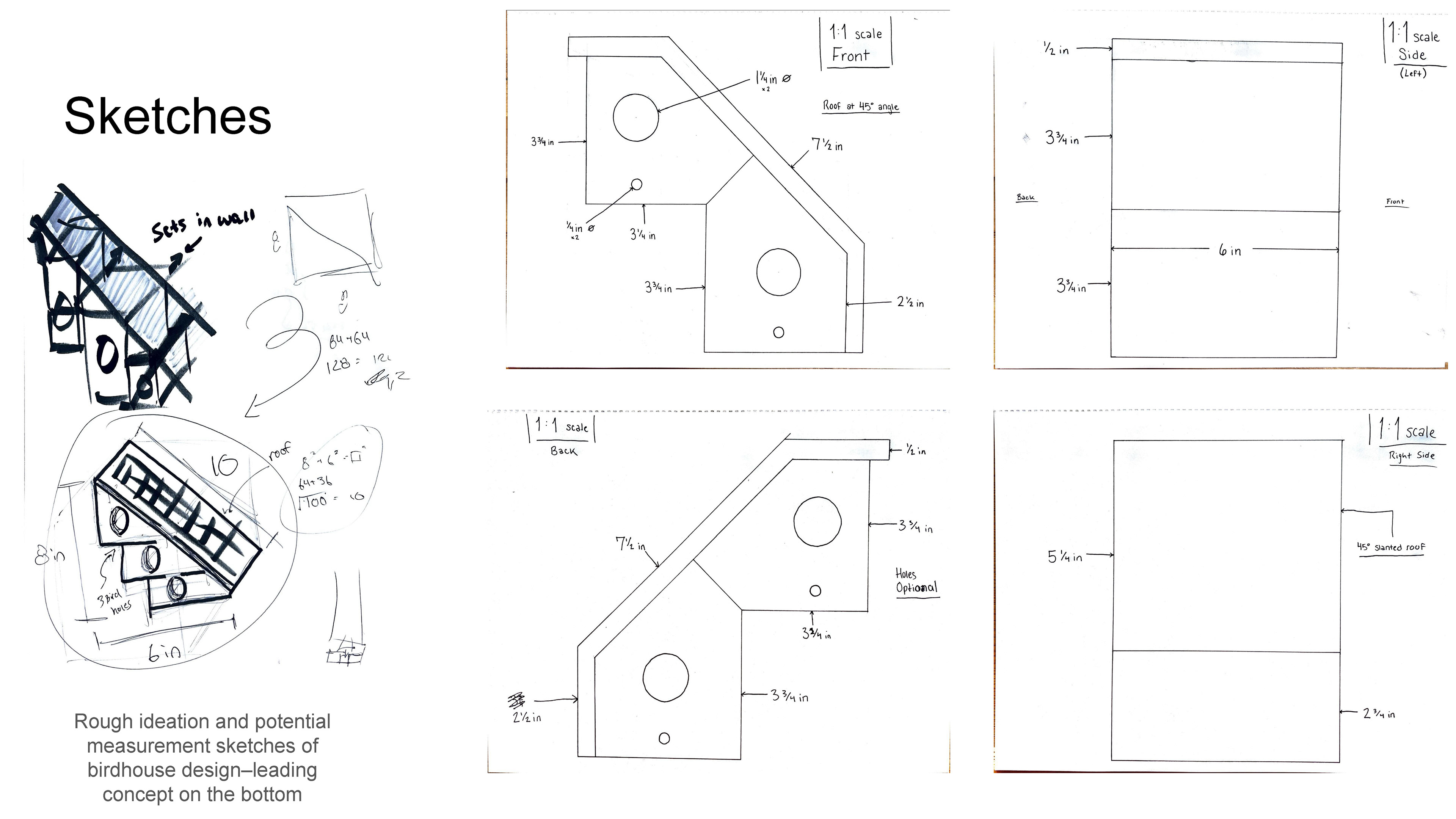

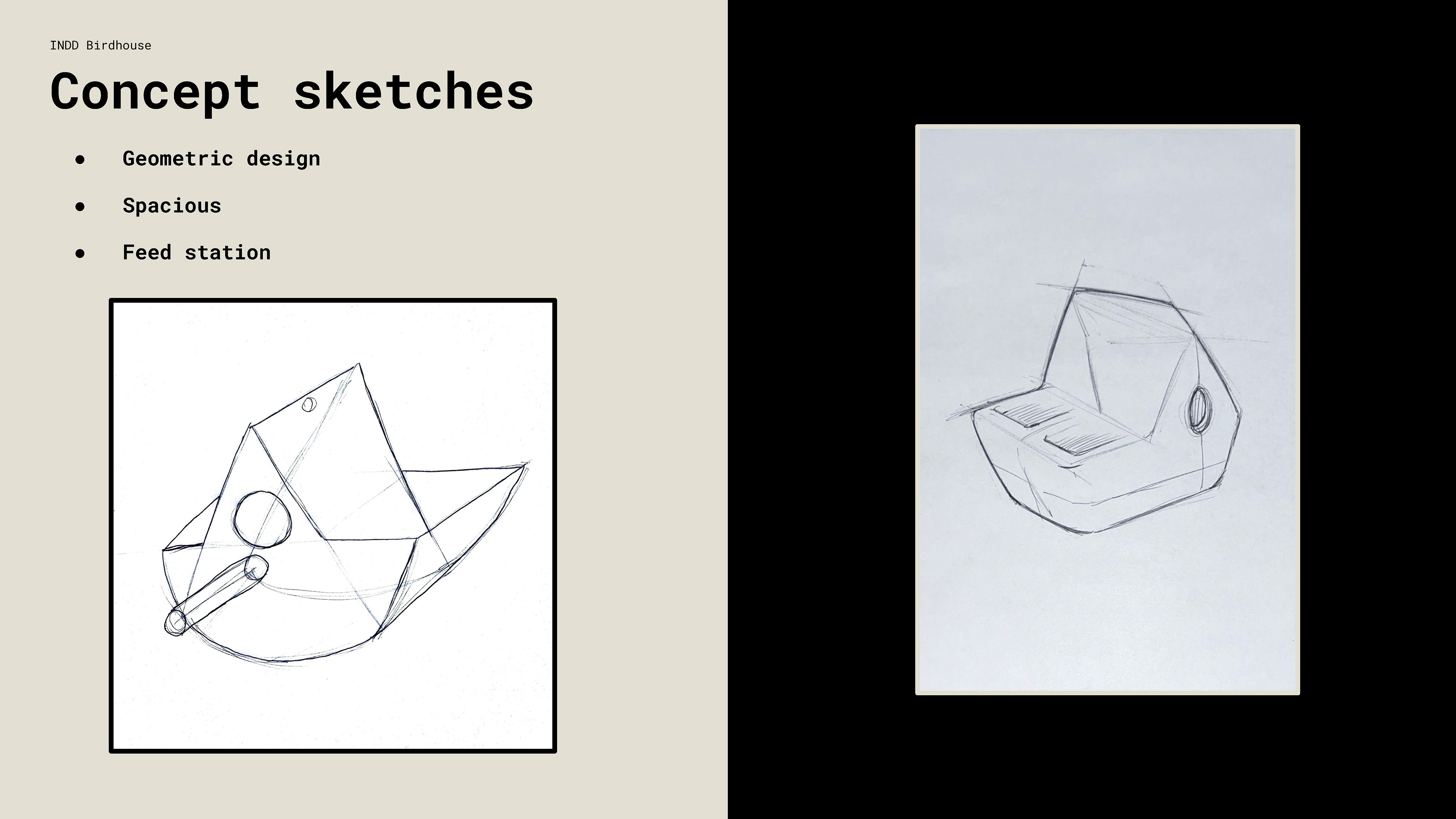

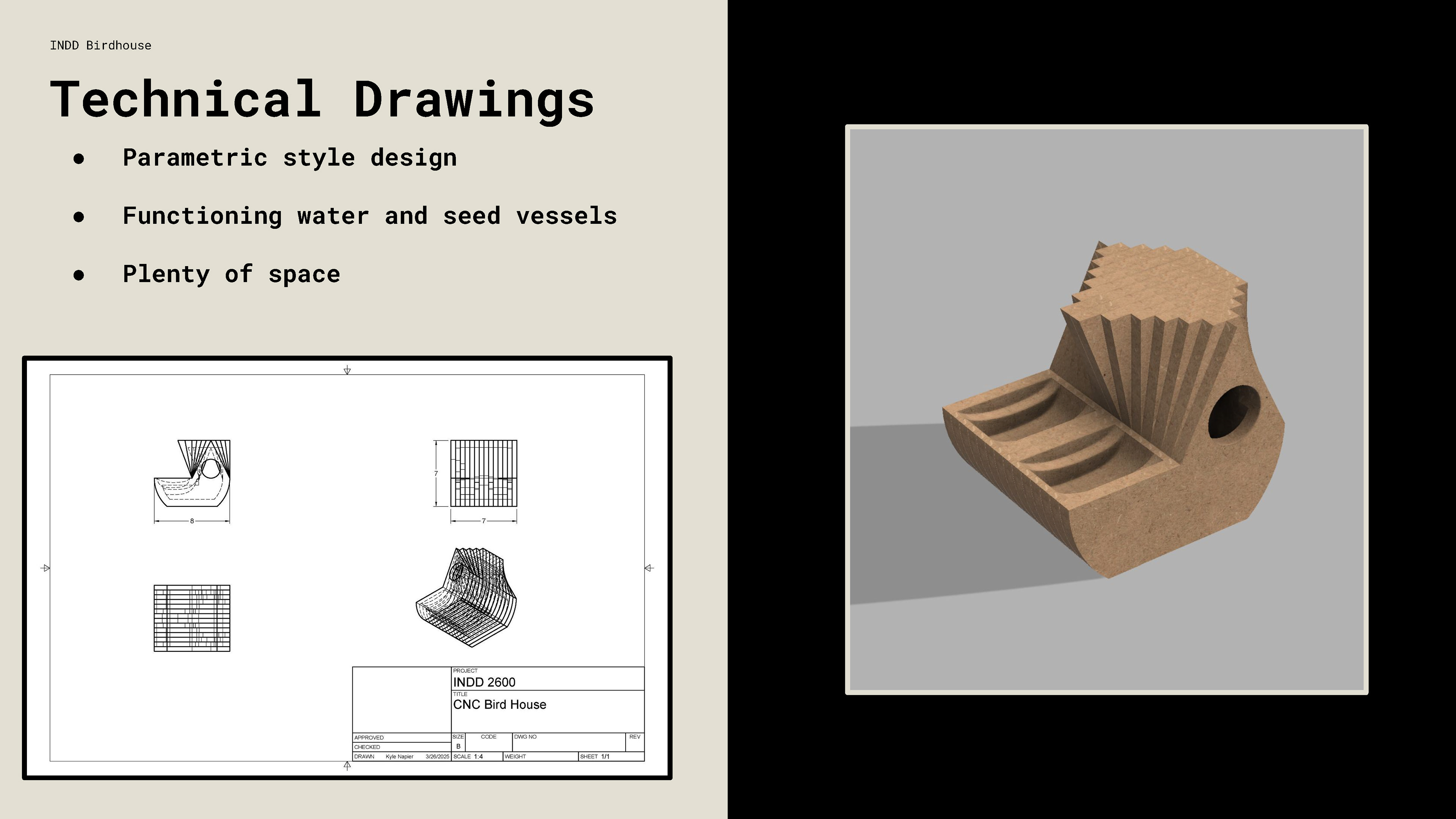

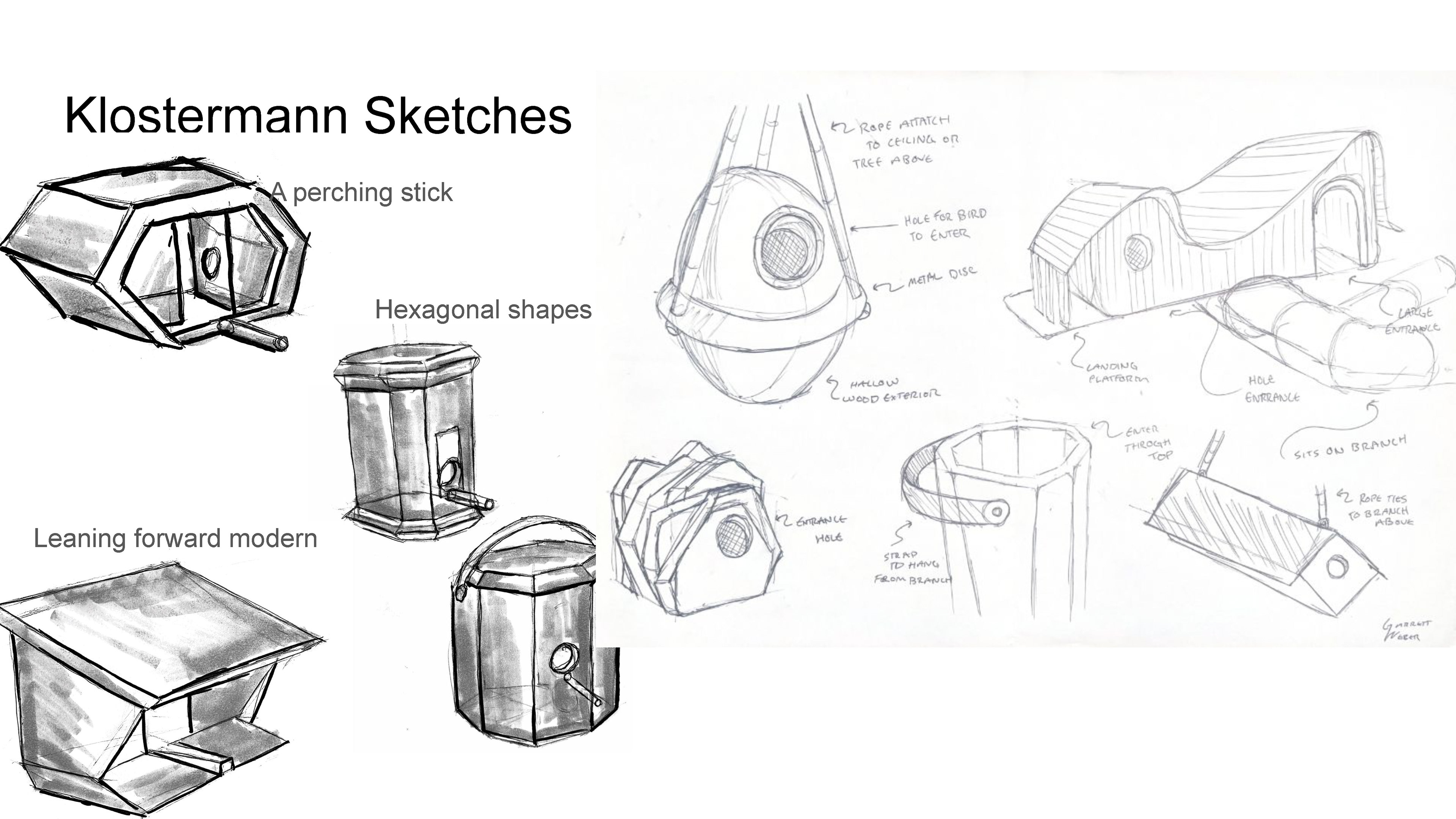

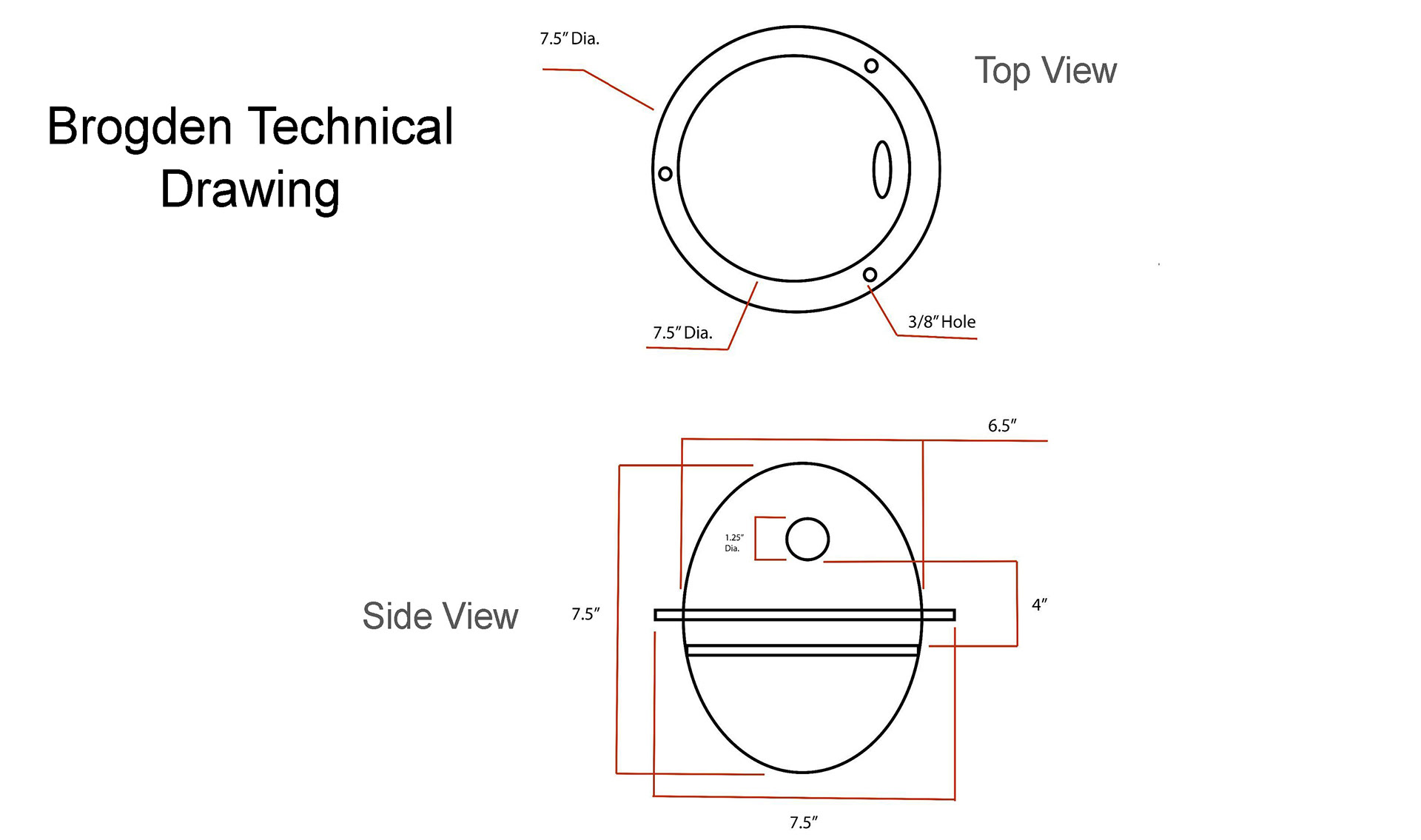

Working with CNC Machines is similar to a laser cutter and 3D printer, the students learn early on the concept of additive and subtractive manufacturing and this exercise of using the CNC and its software helps them understand the process of subtractive manufacturing.

Here the Students have been given a bird house design prompt and they have to use a CNC machine to create parts of the birdhouse and then assemble it.

This assignment takes a page out of the book of Ikea assembly.